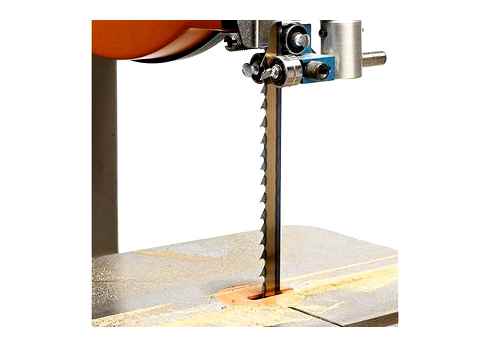

4 Best Bandsaw Blades in 2023. Wood bandsaw blade

Best Bandsaw Blades in 2023

Bandsaw blades are an essential component of any woodworking shop, and choosing the right one can greatly impact the quality and efficiency of your work. In this 2023 buying guide, we’ll discuss the different types of bandsaw blades, how to determine the right size, and the best TPI (teeth per inch) for cutting wood. Let’s dive in!

These are the top recommendations based on suggestions from our community of metallurgists and the latest customer sentiment data:

What kind of blade do you use for a bandsaw?

The type of blade you choose for your bandsaw depends on the material you’re cutting and the desired outcome. A blade with a medium tooth count (around 4-6 TPI) and a versatile tooth geometry (e.g., hook or skip tooth) is ideal for general-purpose woodworking. You’ll need a blade with a higher TPI and a different tooth geometry for metal cutting, such as a bi-metal or carbide-tipped blade.

Three types of bandsaw blades

Regular tooth blades: These blades have evenly spaced teeth and are suitable for general-purpose cutting, such as crosscutting and ripping softwoods and hardwoods. They work best at slower speeds and provide a smooth finish.

Hook tooth blades: Featuring a deeper gullet and a positive rake angle, hook tooth blades are designed for aggressive cutting in thicker materials. They’re ideal for resawing and cutting green (unseasoned) wood.

Best Band Saws For Resawing In 2023 �� Top 5 Items Tested & Reviewed

Skip tooth blades: With widely spaced teeth and a shallow gullet, skip tooth blades are perfect for cutting softer materials and providing a smooth finish. They’re also great for cutting non-ferrous metals like brass and aluminum.

Top 10 Bandsaw Blades in 2023 (Top Picks)

How to determine the right size bandsaw blade

You’ll need to consider the blade’s length, width, and thickness to find the correct size bandsaw blade for your saw. First, consult your bandsaw’s user manual or the manufacturer’s specifications to find the recommended blade length.

For blade width, consider the type of work you’ll be doing. Wider blades (3/4″ to 1″) are great for resawing and cutting straight lines, while narrower blades (1/8″ to 1/2″) are perfect for cutting curves and intricate shapes.

Finally, consider blade thickness. Thicker blades are sturdier and less prone to bending or breaking, but they may not be suitable for cutting tight curves. Thinner blades are more flexible and can navigate tight curves but may wear out more quickly.

What is a good bandsaw blade for wood?

A good bandsaw blade for wood should have a versatile tooth geometry, such as hook or skip tooth, and a medium TPI (4-6 TPI). This ensures a smooth cut with minimal tear-out. Popular brands for woodworking include Timber Wolf, Laguna Tools, and POWERTEC.

What TPI is best for cutting wood?

The best TPI for cutting wood depends on the type of cut and the material’s thickness. A TPI of 4-6 is ideal for general-purpose woodworking, as it balances cutting speed and finish quality well. For finer cuts or cutting thin materials, a higher TPI (8-14) is recommended. Conversely, a lower TPI (2-3) may be more suitable for cutting thicker materials or resawing.

Top 4 Bandsaw Blades in 2023

Best Overall: DeWALT Portable Band Saw Blade

The DeWALT DW3984C Portable Band Saw Blade is our top pick for the best overall bandsaw blade in 2023. This blade offers a perfect balance of quality, performance, and value, making it suitable for hobbyists and professionals.

Key features of the DeWALT DW3984C include its Matrix II high-speed steel edge, designed for heat and wear resistance, and its 8% cobalt content, which adds durability and wear resistance. With an Rc 65-67 tooth hardness, this blade can withstand increased wear and maintain its sharpness longer. The alloy steel backer provides fatigue resistance, ensuring a long-lasting and reliable blade.

Customers have praised the DeWALT DW3984C for its excellent cutting performance on various materials, including metal. Its 24 TPI configuration allows for smooth and precise cuts, and the 3-pack offers great value for the price.

Material: Matrix II high-speed steel edge, 8% cobalt content, alloy steel backer

- Heat and wear resistance, thanks to the Matrix II high-speed steel edge

- Added durability and wear resistance due to the 8% cobalt content

- Alloy steel backer ensures fatigue resistance

The DeWALT DW3984C Portable Band Saw Blade is a top choice for anyone seeking a high-quality, versatile bandsaw blade with exceptional performance and durability.

Best Premium: LENOX Tools Portable Band Saw Blades

The LENOX Tools Portable Band Saw Blades are our choice for the best premium bandsaw blades in 2023. These blades offer superior cutting performance, durability, and longevity, making them ideal for professionals and serious woodworking enthusiasts.

Key features of the LENOX Tools Portable Band Saw Blades include high-speed steel teeth that provide a strong, long-lasting cutting edge. The bi-metal construction of the blade ensures it’s shatter-resistant, allowing it to bend and resist breaking, extending its life. Additionally, the Tuff Tooth design reinforces the tooth for even longer blade life.

Tooth Hardness: High-speed steel teeth

Material: Bi-metal blade with Tuff Tooth design

High-speed steel teeth provide a strong, long-lasting cutting edge

Shatter-resistant bi-metal blades bend and resist breaking, extending blade life

Tuff Tooth design reinforces the tooth for longer blade life

Higher price point compared to other options on the market

The LENOX Tools Portable Band Saw Blades offer exceptional cutting performance and durability, making them an excellent choice for those seeking a premium bandsaw blade.

Best Budget: Bosch BS6412-24M Metal Bandsaw Blade

The Bosch BS6412-24M Metal Bandsaw Blade is our top pick for the best budget bandsaw blade in 2023. This affordable blade offers excellent performance and durability for those seeking a cost-effective option without compromising on quality.

Key features of the Bosch BS6412-24M include its construction from premium grade steel, which resists heat build-up for a longer life. The blade also features optimized tooth geometry for the best cutting performance on various materials, including wood and metal.

Tooth Hardness: Alloy steel teeth

Material: Premium-grade steel

Made from premium grade steel for durability

Resists heat build-up for a longer life

Optimized tooth geometry for the best cutting performance

Some users may find the blade’s longevity to be shorter compared to higher-priced options

The Bosch BS6412-24M Metal Bandsaw Blade offers great value for money, making it an excellent choice for those seeking a budget-friendly bandsaw blade without sacrificing performance and durability.

Best Compact: Milwaukee Sub-Compact Band Saw Blade

The Milwaukee 48-39-0572 Sub-Compact Portable Band Saw Blade is our top pick for the best compact bandsaw blade in 2023. This blade is perfect for those who need a compact and portable option for precise cutting tasks in tight spaces or on-the-go projects.

Key features of the Milwaukee 48-39-0572 include its Matrix II high-speed steel teeth, which deliver maximum durability and cutting performance. The alloy backing steel design ensures extended blade life, and the precision-formed teeth enable fast, clean cuts on various materials such as iron, metal, and copper.

Tooth Hardness: Matrix II high-speed steel teeth

Material: Alloy steel backing

Matrix II high-speed steel teeth deliver maximum durability

Alloy backing steel design provides extended blade life

Precision-formed teeth enable fast, clean cuts

Some users may find the blade less suitable for heavy-duty cutting tasks

The Milwaukee 48-39-0572 Sub-Compact Portable Band Saw Blade is an excellent choice for those seeking a compact, portable bandsaw blade focusing on precision cutting and durability in various materials.

Key Takeaways

Our top picks for the best bandsaw blades in 2023 include the DeWALT DW3984C for the best overall, LENOX Tools 8010738PW145 for the best premium option, Bosch BS6412-24M for the best budget choice and Milwaukee 48-39-0572 for the best compact blade. Each blade offers unique features and benefits to cater to different requirements, budgets, and preferences.

When deciding, consider factors such as the number of teeth, tooth hardness, material, and the specific cutting tasks you’ll be performing. With the right bandsaw blade, you can confidently and precisely tackle your woodworking and metal-cutting projects.

Blade Construction

Carbon Blades

Hard Back type:A one-piece blade made of carbon steel with a hardened back and tooth edge.

Flex Back type: A one-piece blade made of carbon steel with a hardened tooth edge and soft back.

Bi-metal Blades

A high speed steel edge material is electron beam welded to fatigue resistant spring steel backing. Such a construction provides the best combination of cutting performance and fatigue life.

Carbide Ground Tooth Blades

Teeth are formed in a high strength spring steel alloy backing material.

Carbide is bonded to the tooth using a proprietary welding operation. Tips are then side, face and top ground to form the shape of the tooth.

Set Style Carbide Tooth

Teeth are placed in a high strength spring alloy backing material. Carbide is bonded to the tooth and ground to form the shape of the tooth. The teeth are then set, providing for side clearance.

BANDSAW BLADE MATERIAL TYPES

Cutting Wood using a Wood Bandsaw:

- Flex-Back.Carbon Steel Blade. General Wood cutting operations

- Neo-Type. Carbon Steel Blade (Hardback) tooth size 8 to 24 tpi for thin wood and plastics (originally for cutting metal but at 75 to 300 BFPM)

- #32 Wood.Specialized Woodworking Applications

- Diemaster 2. Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Classic. Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Woodmaster B. Bi-Metal blade specifically for use on Portable Band Mills also Horizontal and Vertical Re-Saws

- Woodmaster CT. Carbide Tipped for use on Portable Band Mills also Horizontal and Vertical Re-Saws

- Tri-Master. Carbide Tipped Precision triple chip grind results in smooth cuts and excellent finish.

Cutting Metal on a Wood Bandsaw:

- Diemaster 2. Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Matrix. Bi-Metal blade.020 thick, provides 6x the life of Carbon Steel blade stock

- Classic. Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Classic Pro. Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

NOTE: When using a WOOD Cutting Band saw for cutting metal (saw running about 3000 BFPM) hardened metal will not be able to be cut. Bandsaw blade speeds between 75 and 300 BFPM are required to cut hardened materials and receive favorable blade life. If your wood saw has two speeds, use the slow speed for cutting soft metal.

Selecting the Proper TPI (teeth per inch):

When cutting wood, the Rule of Thumb is 3 to 12 teeth in the work, with the most general purpose count being 6 TPI. The fewer teeth per inch provide a faster, but rougher cut; and more teeth per inch provide a smoother, but slower cut. When resawing use the widest blade suitable for your saw with the fewest number of teeth per inch. Make sure that you select a blade of proper thickness. The continual flexing of the blade causes metal fatigue and failure of the blade. Fatigue is the tendency of a metal to break under continued flexing. The thickness of the blade required depends upon the diameter of the wheels and the work to be done. Thick blades will withstand more strain from cutting than thin blades, but will break more easily from the bending action, especially when run on small wheels. Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and break quickly. Thinner blades are recommended when the work is light.

Bandsaw Blade Speed BFPM is Band Feet Per Minute

The types of Lenox Band Saw Blade stock listed below are for general metal cutting to high performance metal cutting operations

LENOX Bi-Metal Band Saw Blades

- Diemaster 2. Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Matrix. Bi-Metal blade.020 thick, provides 6x the life of Carbon Steel blade stock

- Classic. The Ultimate Multi-Purpose

- Classic Pro.The Ultimate Multi-Purpose Blade for Production Cutting

- QXP. Long Blade Life at High Cutting Rates

- RX. Engineered to Cut Structurals, Tubing and Bundles

- Armor RX. Engineered for Long Life

- Contestor GT. High Performance Sawing

LENOX Carbide Band Saw Blades

High performance backing steel and optimized carbide grades give premium Band sawing performance. These Band saws will cut faster and last longer than any other Band saw blade in a wide variety of sawing applications.

- ARMOR CT BLACK.For Extreme Cutting Rates

- TNT GT. Extreme Performance on Super Alloys

- CAST MASTER.Superior Performance When Sawing Castings

- TRI-TECH CT.Set Style Carbide Blade for Difficult to Cut Metals

- TRI-MASTER.Versatile Carbide Tipped Blade

- ALUMINUM MASTER CT.Triple Chip Tooth Design

- HRc.Carbide Tipped Blade for Case and Through-Hardened Materials

- MASTER GRIT.Carbide Grit Edge Blade for Cutting Abrasive and Hardened Materials

Understanding Product Tag

H A = Hook Tooth, Alternate SetH L = Hook Tooth, Lenox SetH R = Hook Tooth, Raker SetS L = Standard Tooth, Lenox SetS R = Standard Tooth, Raker SetS W = Standard Tooth, Wavy SetV W = Vari-Tooth, Wavy SetV P = Vari-Tooth, Positive VP TR = Vari-Position, Triple ChipSTP R = Triple ChipSTP TR = Triple ChipVP TR = Varied Position, Triple ChipVP TR 051 = Varied Position, Triple Chip.051 kerfVP TR 065 = Varied Position, Triple Chip.065 kerfVP TR 072 = Varied Position, Triple Chip.072 kerfVP TR 085 = Varied Position, Triple Chip.085 kerfVP VR = Varied Position, Varied RakerVP VR EHS = Varied Position, Varied Raker, Extra Heavy Set

Bandsaw Blade Terms

A clear understanding of blade terminology can help avoid confusion when discussing cutting problems.

-

1. Blade Back. The body of the blade not including tooth portion. 2. Gauge. The thickness of the blade. 3. Width. The nominal dimension of a saw blade as measured from the tip of the tooth to the back of the Band. 4. Set. The bending of teeth to right or left to allow clearance of the back of the blade through the cut. 5. Tooth. The cutting portion of a saw blade. 6. Tooth Pitch. The distance from the tip of one tooth to the tip of the next tooth. 7. TPI. The number of teeth per inch as measured from gullet to gullet. 8. Gullet. The curved area at the base of the tooth. The tooth tip to the bottom of the gullet is the gullet depth. 9. Gullet Depth. The distance from the tooth tip to the bottom of the gullet. 10. Tooth Face. The surface of the tooth on which the chip is formed. 11. Tooth Back. The surface of the tooth opposite the tooth face. 12. Tooth Back Clearance Angle. The angle of the tooth back measured in relation to the cutting direction of the saw. 13. Tooth Rake Angle. The angle of the tooth face measured with respect to a line perpendicular to the cutting direction of the saw. 14. Tooth Tip. The cutting edge of the saw tooth. 15. Kerf. Amount of material removed by the cut of the blade.

Band SPEEDThe rate at which the Band saw blade moves across the work to be cut. The rate is usually measured in feet per minute (fpm) or meters per minute (mpm).

BASE Band SPEEDList of recommended speeds for cutting various metals, based on a 4″ wide piece of that stock.

BI-METALA high speed steel edge material electron beam welded to a spring steel back. Such a construction provides the best combination of cutting performance and fatigue life.

BLADE WIDTHThe dimension of the Band saw blade from tooth tip to blade back.

CARBIDE TIPPED BLADECarbide tips welded to a high-strength alloy back, resulting in a longer lasting, smoother cutting blade.

CARBON FLEX BACKA solid one-piece blade of carbon steel with a soft back and a hardened tooth, providing longer blade life and generally lower cost per cut.

CARBON HARD BACKA one-piece blade of carbon steel with a hardened back and tooth edge that can take heavier feed pressures, resulting in faster cutting rates and longer life.

CUTTING RATEThe amount of material being removed over a period of time. Measured in square inches per minute.

DEPTH OF PENETRATIONThe distance into the material the tooth tip penetrates for each cut.

Tooth Form and Construction

As with a bi-metal blade design, there are advantages to differing tooth constructions. The carbide tipped tooth has carbide tips welded to a high strength alloy back. This results in a longer lasting, smoother cutting blade.

Tooth Form

The shape of the tooth’s cutting edge affects how efficiently the blade can cut through a piece of material while considering such factors as blade life, noise level, smoothness of cut and chip carrying capacity.

Variable Positive. Variable tooth spacing and gullet capacity of this design reduces noise and vibration, while allowing faster cutting rates, long blade life and smooth cuts.

Variable. A design with benefits similar to the variable positive form for use at slower cutting rates.

Standard. A good general purpose blade design for a wide range of applications.

Skip. The wide gullet design makes this blade suited for non-metallic applications such as wood, cork, plastics and composition materials.

Hook. Similar in design to the Skip form, this high raker blade can be used for materials which produce a discontinuous chip (such as cast iron), as well as for non-metallic materials.

Tooth Set

The number of teeth and the angle at which they are offset is referred to as “tooth set.” Tooth set affects cutting efficiency and chip carrying ability.

Raker:3 tooth sequence with a uniform set angle (Left, Right, Straight).

Modified Raker: 5 or 7 tooth sequence with a uniform set angle for greater cutting efficiency and smoother surface finish (Left, Right, Left, Right, Straight). The order of set teeth can vary by product.

Vari-Raker:The tooth sequence is dependent on the tooth pitch and product family. Typically Vari-Raker set provides quiet, efficient cutting and a smooth finish with less burr.

Alternate:Every tooth is set in an alternating sequence. Used for quick removal of material when finish is not critical.

Wavy:Groups of teeth set to each side within the overall set pattern. The teeth have varying amounts of set in a controlled pattern. Wavy set is typically used with fine pitch products to reduce noise, vibration and burr when cutting thin, interrupted applications.

Vari-Set:The tooth height / set pattern varies with product family and pitch. The teeth have varying set magnitudes and set angles, providing for quieter operation with reduced vibration. Vari-Set is efficient for difficult-tocut materials and larger cross sections.

Single Level Set:The blade geometry has a single tooth height dimension. Setting this geometry requires bending each tooth at the same position with the same amount of bend on each tooth.

Dual Level Set:This blade geometry has variable tooth height dimensions. Setting this product requires bending each tooth to variable heights and set magnitudes in order to achieve multiple cutting planes.

Selecting Bandsaw Blade Width, Thickness and TPI

Choosing the Correct Bandsaw Blade Width

Blade width is measured from the tips to the teeth to the back edge of the blade body. The instructions for the particular bandsaw being used should be followed when selecting blade width. If no such instructions exist, the blade width should be determined with the following guidelines:

Cut-Off Sawing (Re-sawing) The blade selected should be as wide as the machine will allow, keeping in mind the blade thickness and wheel diameter. The wider the bandsaw blade is, the straighter the cut will be.

How to Choose the Correct Number of Teeth Per Inch (TPI)

The number of teeth per inch (TPI) is important in obtaining the finish desired and the proper feed rate. A coarse tooth blade (2, 3 TPI) should be used for re-sawing wood and cutting thicker stock up to 8″ thick. A fine toothed blade (18 to 32 TPI) should be used for thinner metals and plastics under 1/4″. For general cutting of 3/4″ plywood 6 TPI will provide a fast cut and 14 TPI will cut much slower but leave a smooth finish on the cut.

- TPI gives a smoother but slower cut.

- Fewer TPI allows for a faster cut with a slightly rougher cut surface.

- Should have at least 3 teeth and less than 12 teeth in the work piece.

The thickness of a bandsaw blade is determined by the thickness of the blade body. Bandsaw blades vary in thickness.014″.018″.020″.022″.025″.032″.035″.042″.050″.063″.Make sure that you select a blade of proper thickness. The continual flexing of the blade causes metal fatigue and failure of the blade. Fatigue is the tendency of a metal to break under continued flexing.The thickness of the blade required depends upon the diameter of the wheels and the work to be done. Thick blades will withstand more strain from cutting than thin blades, but will brake more easily from the bending action, especially when run on small wheels. Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and brake quickly. Thinner blades are recommended when the work is light.

This chart offers Guidelines for selecting Blade Thickness for wheel diameters.

It is not always possible to adhere to the above recommendations due to the cutting operation you intend to perform and the particular Band saw you are using. To maintain extended fatigue life of the blade, select the thinnest blade possible that will offer you the appropriate number to TPI to perform you cutting operation.

Choosing The Right Bandsaw Blade

New bandsaw owner? The blade supplied on your machine will not last forever, so eventually you will need to take the plunge and purchase a new bandsaw blade. To save you time and money, take a look through this guide and make the right choice first time.

Watch Axminster Expert Craig Steel talk through the production and manufacture of Axcaliber bandsaw blades. Manufactured in Axminster, using advanced CNC machining and specialised heat treatment, Axcaliber offers a wide range of high-quality bandsaw blades designed to meet all requirements.

Length

The most obvious piece of information you need to know is “how long is my blade?” This should be on the spec label on your machine, or in the instruction book. If you have neither, please call us for advice.

Find by model or blade length. the easy bandsaw blade selector

Width

Secondly, you need to choose the width of blade. Always use the widest blade possible – it is stronger and will withstand greater feed pressures without flexing. Consult your machine manual for the maximum and minimum blade widths that it will accept.

If you are a woodturner, cutting bowl blanks with a bandsaw is both safe and effective. However, you will need to choose a blade that will cut the radius you need.

The minimum radius of curve for each blade width is as follows:

| 13mm (1/2″) | 63mm (2 1/2″) |

| 10mm (3/8″) | 27mm (1 1/16″) |

| 6mm (1/4″) | 19mm (3/4″) |

| 5mm (3/16″) | 13mm (1/2″) |

| 3mm (1/8″) | 10mm (3/8″) |

And, don’t forget. A blade used for a batch of cutting bowl blanks will not be much use for straight cutting. Cutting curves will disturb the set of the teeth on the blade, consequently making it impossible to cut in a straight line. So we advise you to keep your bowl blank cutting blades separate from other blades. We also have a specialist curve cutting blade, the Back Tooth blade, for details see below.

Tooth form pitch

The third area to consider is tooth form and pitch. This will depend on the type of work you intend to do, i.e. rip cutting (with the grain) or cross cutting (across the grain). Generally, a skip tooth blade is used for rip cutting, whereas a regular or triangular tooth blade is for cross cutting.

The skip tooth is provided on coarse tooth blades, those with 3, 4 and 6 teeth per inch; it has a wide shallow gullet with plenty of space for waste to collect. Please note that the quality of the cut can be adversely affected by sawdust packing between the teeth.

3 tpi (skip form)

Used for deep cutting especially rip cuts. This blade will leave a rough sawn finish although slow feed rate and high tension will improve the finish of the cut.

4 tpi (skip form)

Good for general-purpose use with a degree of cutting across the grain and with the grain. A reasonable finish can be achieved with slower feed rates and good tension.

6 tpi (skip form)

The ideal general purpose blade suitable for cross cutting up to 150mm and ripping in sections up to 50mm thick, although thicker sections can be cut using slow feed.

The regular, or triangular, tooth form is provided on blades with 10 or more teeth per inch where, because of the reduced material removal, there is less need for waste storage.

10 tpi (regular)

Good for cutting plywood and MDF as well as non-ferrous metals and plastics. The finish is good when cutting natural timbers, but the feed rate should be slow and maximum depth of cut should not exceed 50mm. When cutting metals, reduce the speed as much as possible especially when cutting ferrous metals or cast iron.

14, 24 and 32 tpi (regular)

A very clean cutting blade for plywood, plastics and MDF, although too fine for natural timbers unless they are very thin sections (sub 25mm thick). The 14tpi and above blades are very good to use at slow speeds when cutting non-ferrous metals. A slow feed speed should be used at all times with a blade tooth pitch this fine.

Blades with variable pitch teeth (4-6tpi, 6-10tpi and 10-14tpi) are also available for wider ranging applications (see Premium Bandsaw Blades).

Types

Now you have made the three basic choices, we will guide you through the types of blades that we offer. Depending on the length of blade required, it can be an easy choice or a little more complex. For machines with a blade length up to 70 1/12”, we supply high carbon blades only. This is because small machines need a highly flexible blade to accommodate small diameter wheels and relatively low power motors. High carbon steel bandsaw blades are often known as “Standard Blades”. Standard blades are best described as general purpose and are fit for all those normal tasks in the workshop where a smooth, good quality, ‘no fuss’ performance is required, day in and day out.

Ground Tooth Bandsaw Blades

Our “Standard Blades” are the unique Ground Tooth (GT) design. This newly developed material is designed for the production user with high feed rates of cutting and is ideally suited to the rigours of running on two wheels. The diamond ground teeth are so unbelievably sharp (they stay sharper for at least 30% longer) that the blades work extremely well in all materials giving an exceptionally high quality finish and clean cut. The GT range is designed for general purpose board and cross grain cutting work.

Freshcut 37 GT

Its sister range for rip cutting is the Freshcut 37. The teeth are precisely diamond ground, before going through a hardening process, then annealed for flexibility and finally the stock straightened by a machine process. This produces a super sharp, hard tooth, with the benefits of a long cutting life and a smooth, quiet cut. The teeth have a light set which gives a narrow kerf and reduces the waste produced whilst the hook configuration provides maximum penetration. These blades are perfect for ripping all types of timber, producing veneers and boards, the ground teeth retaining their edge far longer than normal milled tooth blades. a unique bandsaw concept.

Premium Bandsaw Blades

If you hit the occasional nail with your bandsaw blade, it invariably happens just after installing a new one! No longer a problem with these Premium Bandsaw blades! They use M42 High Speed Steel with 8% cobalt which has been welded to a spring alloy steel backing. This results in a material that has a far greater resistance to heat and abrasion, therefore giving improved cutting performance in those materials that might have proved troublesome with a Standard blade. All types of material can be cut with ease, including abrasive timbers such as teak as well as man-made boards like MDF and chipboard, where the glue used has little, if any effect on the life of the blade. M42 blades are so resilient that reclaimed timber presents no difficulties, as the blade will slice easily through the odd nail buried under the surface.

Back Tooth Bandsaw Blades

For woodturners, we have a unique blade concept, the Back Tooth bandsaw blade. Woodturners often prepare their own blanks, which is where the back tooth blade becomes particularly useful, as it has been specifically developed for curvature cutting. The teeth on the rear of the blade are not sharp to handle but have the effect of clearing the back of the cut by widening the kerf, enabling a much tighter curve to be cut making them an ideal choice for preparing timber for the lathe. Available only in 8mm 4 tpi configuration which is suitable for almost all machines.

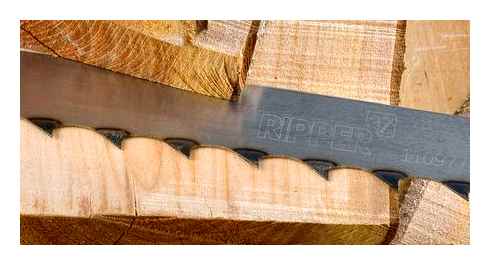

For deep rip cutting work we offer the Ripper 37 blade. Specifically intended for wood processing and deep ripping tasks, fitting only a few larger machines where motors of sufficient capacity are able to handle the 32mm wide blade. The teeth are precision ground using CNC machinery and then induction hardened. Furthermore, to ensure a very long working life, each blade can be re-sharpened up to twenty times, offering the best possible cutting performance.

Where are Axcaliber bandsaw blades made?

The answer is, right here in Axminster. All Axcaliber blades are made from UK sourced stock, sized, welded, finished and packed in our own engineering production facility in Axminster. Carefully chosen production techniques and constant quality control checks ensure each blade will exceed your expectations. And if the weld breaks under normal use, we will replace the blade, no quibbles.

17 Комментарии и мнения владельцев

hello, i have purchased a bandsaw from yourselves, and i am have real problems cutting anything, i have purchased the AWHBS250N, i think that i need a better blade, i would like to cut bowl blanks and hardwood pen blanks, any idea why the blade wont cut and the saw slows to a stop if i try and cut anything thicker than a couple of mm, regards Steve

Hello Steve and many thanks for your enquiry. A new blade will certainly go a very long way to improving the performance of your saw and I would recommend the appropriate Diamond Ground blade for your machine. That said, there are things that can be done to ensure the saw is set up correctly, for instance it’s worth checking that the blade is at the correct tension on the wheels (it should make a ‘pinging’ sound when plucked with a fingernail) and that it’s not binding anywhere (you’ll hear it if it is) Also check the alignment of the blade guides and that the saw blade is tracking correctly. The excellent User Manual is available as a download and it’s worth going though it step by step to ensure that everything is as it should be, but if the problem still persists, please don’t hesitate to call our Customer Support on 0800 371822.

I suppose this is a stupid answer, but are the teeth acually running the right way, I once remember a customer complaining that (all) his teeth were welded on the wrong way round !

Steve, I have a Record 250( same machine) and find a 3tpi hook tooth blade with a high set to work very well for bowl blanks, you also should round off the back of the blade so it doesn’t bite as you turn the blank. with this machine you have to make extra sure that the drive belt is tight enough.

An alternative is to use one of our Back Tooth Blades (i.e.505169) which are specifically intended for cutting circular bowl blanks.

Hi. a few years ago I purchased an Axminster Hobby Band Saw. I tend to use it for the occasional projects, such as making new garden gates, trimming down wood (usually soft wood) and general DIY stuff. I am very much an amateur!! I need to order a new blade and would like to check my details with you. The length of blade is 2240mm and blade wisth is given as 6. 16mm. I am thinking of buying a Ground Tooth Skip tooth blade, 6tpi, and 13mm in width. Would you agree this would be a good choice? Many thanks.

Hello Caroline, I would have to agree that you are making a very good choice with this blade. The GT blades are known for their cutting performance and a 1/2′ 6tpi one is the perfect choice for general DIY tasks. Before you purchase one of these though, are you able to confirm which model of Axminster Hobby bandsaw you have? This is just so I can confirm that you need a 2,240mm blade for that one. Thanks, Mark

Hello. I’ve owned an Axminster Hobby Series HBS200N bandsaw for the last several months, and generally use it for shaping out curved templates in softwoods and plywood. I’ve been mainly using the original blade provided with the machine for the curved cutting, which is a 6mm, 6 TPI blade. So far, so good! Earlier today, while cutting a fairly gentle curve in a 30mm thick piece of pine, the blade snapped (not at the weld). Do you have any suggestions as to whether a different blade would be more appropriate for this type of work? The blade which broke hasn’t had a vast amount of use, although it may have been getting a little dull. Also, can you offer any tips for setting the appropriate tension in the blade on this particular bandsaw? Thanks for any advice! Richard Quirke.

Hi Richard, Over time the stresses on a blade, especially doing curved work will start to cause metal fatigue and can lead to the blade snapping.The best way to minimise this is by ensuring maximum support, with the blade guides as close to the blade as possible and down as near to the work as close as you can get them. Using a dull blade will also increase the stress on it which can lead to breakages. We would say that four months of usage from a ‘stock’ blade is quite good and you could expect to see them last around this time. If you are doing mainly curved pieces, we do sell a high carbon back tooth blade, specially made for this type of work, which you can find more information about here. http://www.axminster.co.uk/axcaliber-high-carbon-back-tooth-bandsaw-blades-ax927088. Although we don’t sell 1,400mm size in this type, if you give our Business Services Team a call on 0800 371822, they can place a specialist order for you, for that size, which can be dispatched in 2-3 days. A tip for tensioning this bandsaw is to open the top wheel door, where the blade runs parallel to the spine of the saw, use your thumb to push against the blade towards the spine. If with moderate force you can easily touch the blade to the spine then it is under tensioned. Turn the tensioning handwheel clockwise with your free hand and continue to push on the blade with moderate force until you can’t touch the spine and you should be there or thereabouts. The good news with this bandsaw is that you will struggle to over tension the blade, with the handwheel being quite small. I hope this helps with your enquiry, Thanks, Mark

Dear Mark, Thank you kindly for all of that excellent advice! I hadn’t realised that I could have a custom made 1,400 mm carbon back-toothed blade, so I’ll place an order for one of them to try it out. Meanwhile I’ve ordered a few replacement blades of various widths / tooth-counts. In general, I’m extremely satisfied with this bandsaw and would highly recommend it to anyone searching for a bench-mounted model. Best wishes, Richard.

Hi Richard, Your welcome, we always try to help out as best as possible. The HBS200N is proving to be a very popular bandsaw and a machine that we are very proud of ourselves, so I’m glad that you are happy with it. If you do get the back tooth blade, I would love to hear how you get on with it in your work. If you see a big difference in the ease of cutting as well as the finish on the piece. Happy sawing! Best wishes, Mark

Just bought my first ever bandsaw hobby series hbs310 so still a total novice. What blade would you recommend for making bandsaw boxes

The bandsaw blade is an essential tool for woodworking. Its primary advantages include accuracy, precision and versatility. However, the choice of the blade matters the most because if you select the wrong blade for the job, it will do more harm than good. No single blade can suffice all your requirements. Understand your requirements and decide the length, width and teethper inch (TPI) along with right tooth configuration to get the best outcome.

Hi, what would be the best blade for My startrite 351E for cutting logs of all shapes sizes, I make chopping boards etc, ?

Wood bandsaw blade

High quality steel strip from England Japan

LBSB is the pioneer in the region offering completely made up ready to use bandsaw blades. Our nickel alloy steel bandsaw blades are manufactured using latest Flash Butt welding machines

Automatic Stellite tipping machine is used for tipping high precision saw kerf to save on expensive Wood. We offer 80mm, 100mm, 4″, 4.1/2″, 5″, 6″, 7″ 8″ width bandsaw blades with thickness of 19G, 18G, 17G.

English Strip Steel

Our Steel adheres to strict tolerances for uniformity of thickness straightness, consistent hardness, and all EU quality standards. This steel delivers an easily swaged tooth that is both tough and resistant to wear.

Tooth Shapes

A variety of tooth shapes are offered to suit almost every resaw application and cam profile.

Butt Welds

Skarpaz butt welds are tempered to withstand rugged use and are finished to a high standard. Using our proprietary process we are able to weld some of the thinnest wide bands.

Band Styles

Bands can be supplied as single cut, double cut, or with a Sliver tooth back. Toothed coils can be supplied on request.

Benching

With a combined 100 years experience of wide Band tensioning and leveling on hand, you can be assured that bands track and run correctly every time out of the box.

Tolerances

Straightness: Max. deviation 0.25mm/1000mm (0.01″/39.4″) or Max. deviation 0.80mm/3000mm (0.03″/118″)

Stellite Tipping

Our stellite tipping process has been recognized as a superior value both in terms of cost effectiveness and finished tip quality and accuracy. Special thin kerf stellite bands and frame saw blades are available.

Other than timber cutting, LBSB offers full range of Narrow Bandsaw ( ¼” to 2″ width) thickness 0.45, 0.60, 0.70 0.80 mm, used for the following applications:

Hard tips flexback wood, metal, fish meat cutting bandsaws

Our Quality bandsaw steel is imported from leading English Japanese steel mills. Customers have a choice of variety in quality depending on usage and budget.

Bi. Metal Bandsaw M42, Carbide Tipped Bandsaw

BI METAL Bandsaw

Bi. Metal Bandsaw M42, Carbide Tipped Bandsaw

We are Exclusive Distributor for Bichamp,

Our Supplier of high quality bi-metal bandsaw made with sophisticated manufacturing facilities combined with highly skilled, experienced manufacturing team. Bichamp offers various combination of teeth hard material and backing material to perform simple cutting task to difficult, demanding cutting operation.

Bi. Metal Bandsaw Blade:

Wear resistant PMP tooth tips combine with reliable 4%Cr backing material make this general- purpose blade suitable for cutting various commonly used materials.

- Perfect for sawing small to medium profiles and solid materials.

- 4%Cr backing material for superior fatigue resistance

- High cutting efficiency with upgrade processing techniques

PM Tooth tips combined with reliable 4%Cr backing material make this general-purpose blade the all-round blade for cutting more commonly used materials

- Aluminium/ Copper

- Structural Steel

- Bearing Steel

- Carbon Steel

- Alloy Steel

- Mould Die Steel

- Stainless Steel

- Deep gullet tooth design for better chip removal.

- Wear resistant PM tooth tips.

- 4%Cr backing material for your good beam strength

Engineered for sawing medium to large work pieces with high precision clean cut surface. High-Low tooth design is engineered to reduce cutting force, resulting in smooth and efficient cutting.

- Wear resistant PM tooth tips.

- Quality backing material for long fatigue life and good beam strength

- Deep gullet tooth design for better chip removal.

Carbide Bandsaw Blade:

Carbide tipped bandsaw blade with a Multi-Chip geometry, that is designed for cutting difficult to cut materials providing excellent cutting performance, toughness and wear resistance.

- Titanium Alloys

- Stainless Steel

- Inconel

- High Nickel Chrome Alloy

- Aerospace Alloys

- Alloy Steel

- Abrasive Graphite

- Precision ground multi chamfer tooth profile.

- High cutting efficiency with reduced cutting forces.

- High rake angle set style bandsaw blade

- Wear resistant, extra fine grain carbide grade tooth tips