Adjusting The Oleo-Mac Sparta Carburetor 38

How to adjust the carburetor on a chainsaw and properly adjust the idle speed with your own hands

For self-tuning the carburetor, you need to familiarize yourself with its device and remember the order of work that is carried out to adjust the parts that are responsible for the correct functioning of the constituent elements of the device and nearby parts. It is necessary to carefully handle objects for adjusting the chainsaw system, and also to determine the correspondence of the set parameters to the maximum permissible values.

Final check at idle

Before this procedure, it is necessary to perform a full adjustment of the components of the carburetor when operating at maximum speed. Next, you should check the functioning of the device in idle cold mode. When the correct parameters are achieved during the adjustment, you will notice that the carburetor design exactly matches the following criteria:

- When the idle cold mode is connected, the chain does not move.

If violations are noticed in the above parameters or the device was not completely adjusted, you need to perform the main setup step again. Sometimes actions are performed incorrectly. In this case, the device may fail due to the loss of the correct node settings. In this case, you will have to contact a specialist.

First stage

The adjusting screws for the highest and lowest speed should be moved clockwise until the highest resistance is encountered. When the screws reach the stop, you need to move them in the opposite direction and leave them after 1.5 turns.

What you need to have to set up and adjust a chainsaw with your own hands

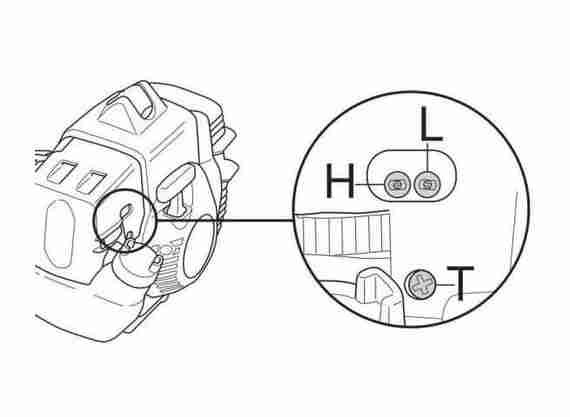

Every carburetor owner should have the necessary tools to adjust this system. There are three adjusting screws that are located on the body of the device. They have their own markings:

- L. screw for low speed correction.

- H. screw for high speed adjustment.

- T. regulates the idle speed, in most cases it is used for experiments.

Before adjusting the carburetor, you need to prepare the device:

- The engine warms up, that is, it starts about 10 minutes before the repair, and turns off when you start work (see how to start the chainsaw).

- The air filter is checked and washed.

- Stop the chain by turning screw T as far as it will go (see chain oil).

To carry out a safe repair, you need to prepare a flat surface where you can carefully position the device, and turn the chain in the opposite direction. We need a tachometer. It determines the presence of a violation in the operation of the carburetor. When the screws are turning, the sound should be perfect and absolutely smooth. If squealing notes are noticed, then the mixture is oversaturated.

The main stage

The engine turns on at medium speed and warms up for about 10 minutes. The screw responsible for adjusting the idle speed must move clockwise. It is released only when the engine comes into stable operation. It is necessary to check that the chain does not move during this process.

Oleo-Mac Sparta 38 Part 1

In idle mode, the engine may stall (the reason is here). In this case, immediately turn the adjusting screw clockwise until it stops. Sometimes the chain starts to move. In this case, turn the adjusting screw in the opposite direction.

About the carburetor device

The carburetor is used to mix the combustible mixture with air in compliance with the predetermined proportions. If the exact dosages are not followed, the correct operation of the engine is jeopardized. When a large amount of air enters during the mixing of the components, and there is not enough fuel, then such a mixture is considered “lean”.

Over-saturation should also not be allowed, since with a large amount of fuel compared to air, malfunctions or engine wear are also possible. Carburetor adjustment is necessary not only before initial use, but also when any abnormalities in its operation are detected. Before starting work with the chainsaw, do not forget to run it in.

The carburetor design contains a standard set of elements, but may vary slightly depending on the manufacturer. Components:

- The foundation. It is a special tube that visually resembles an aerodynamic structure. Air passes through it. In the transverse direction in the middle of the pipe there is a damper. Its position can be changed. The more it is pushed into the passage, the less air enters the engine.

- Diffuser. This is the tapered part of the tube. With its help, the air flow rate increases exactly in the segment from which the fuel comes out.

- Fuel supply channels. The fuel mixture is contained in the float chamber, then passes into the nozzle, from which it flows into the sprayer.

- Float chamber. It is a separate structural element, reminiscent of the shape of a tank. Designed to constantly maintain an optimal level of fuel fluid in front of the entrance to the channel where the air comes from.

Not sure which chainsaw to choose? Read our article.

Looking for models that are cheaper, but reliable and time-tested? Pay attention to Russian-made chainsaws.

Alternatively, research foreign chainsaw manufacturers such as Stihl.

Dismantling the carburetor if it is necessary to check or repair components

The device of different models of carburetors is almost the same, so when working with them, you can use the standard scheme. All elements must be removed carefully, and then laid out in the order below so that you can successfully place the items in place at the end of the repair work.

- The top cover is removed. To do this, unscrew the 3 bolts holding it in a circle.

- The foam rubber can also be removed, since it is the upper part of the filter that conducts air.

- The fuel hose is removed.

- The drive thrust is output directly to it.

- The cable end is detached.

- The petrol hose can be completely removed by systematically pulling it off the fitting.

To finally prepare the carburetor for overhaul or replacement of the smallest parts, you need to carefully disconnect it from the main system. Sometimes further disassembly is required. Unscrew the components carefully and fold the fasteners in groups, as these small parts are easily lost.

Is it worth doing DIY repair

Self-repair of the Oleo Mak chainsaw carburetor is advisable in the following cases:

- the breakdown is simple, obvious, the necessary parts are available;

- have experience in performing such work, qualifications;

- the manufacturer’s warranty is not lost;

- there is no way to contact the service center or it is financially unprofitable.

It should be clearly understood that self-repair cannot guarantee a positive outcome of events. Therefore, it is worth taking on it only if you have knowledge of the design and principle of operation of the carburetor.

Carburetor adjustment

When buying a chainsaw, the carburetor has factory settings and is adjusted to optimal operating modes. However, during operation, the engine (ICE), the fuel pump, and the carburetor wear out, as a result of which their repair, maintenance and adjustment are required. In this case, the role of the carburetor is to limit the minimum and maximum engine speed.

The main criteria for determining the need for tuning the carburetor:

- the engine does not start, stalls, does not respond to pressing the accelerator;

- no idling;

- increased fuel consumption, the internal combustion engine does not develop power;

- wear of the piston group, carbon deposits on spark plugs, black exhaust gases, incomplete combustion of gasoline.

The reasons for the failure of the carburetor settings are as follows:

- failure to fix the screws that regulate the minimum and maximum engine speed due to strong vibrations or mechanical stress;

- with wear of the internal combustion engine piston system;

- clogged air or fuel filters, nozzles, fuel line, intake valve breakage.

To set up a carburetor, it is important to understand what parts and assemblies it consists of and how it works. This will allow you to determine the causes of the failure, which tools to prepare for adjustment and the type of repair kit if repair is necessary.

Carburetor repair kit

To repair the carburetor, you will need a repair kit, the composition of which is as follows:

- rubberized seals;

- diaphragms: for the pump and control;

- needle valve assembly.

Oleo-Mac chainsaw carburetor. adjustment, repair

The stability and reliability of the engine of the Oleo-Mac chainsaw depends on the quality of the preparation of the air-gasoline mixture in the carburetor, it performs important functions. it allows you to smoothly change the engine speed, control idle speed. With long-term operation, it may be necessary to reconfigure it. how to do it correctly and avoid mistakes?

Advantages and disadvantages

The main advantages of Oleo Mak chainsaw carburetors:

- great resource;

- compact size;

- three adjustment screws that allow precise adjustment (a feature of all modern chainsaws with membrane carburetors);

- compact size and relatively low weight of the structure, in comparison with analogs;

- affordable cost of parts, carburetor assembly;

- unpretentiousness to the quality of gasoline.

A number of disadvantages are also worth noting:

- it can be difficult to find a repair kit on sale, in small towns;

- difficulties with settings, high requirements for the qualifications of tuners;

- the need for periodic adjustments during long-term operation.

What carburetors are used

Oleo Mak chainsaws are equipped with Walbro gasoline membrane carburetors for two-stroke engines. They are distinguished by their simplicity of design, maintainability, and unpretentious operation. Walbro is part of the Stihl group of companies, therefore it manufactures products that meet international quality standards.

Design and working principle

The principle of operation of the carburetor is based on mixing a fuel mixture of fuel and oil with air in a certain proportion for effective ignition and their complete combustion in the internal combustion engine. It is a one-piece body, inside of which the following structural elements are located:

- fuel chamber;

- air and fuel channels;

- nozzles: idle and main;

- fuel filter mesh

- inlet and outlet fuel valves;

- air and throttle valves;

- diffuser;

- fuel and control membranes;

- adjusting screws;

- gaskets.

Outside the body, there are screws to adjust the quality and composition of the mixture. In the upper and end parts there is a branch pipe for fuel supply and an impulse channel of the fuel pump.

The carburetor works according to the following algorithm:

- When the engine is started, the choke is opened. Air passes through the filter and bypassing the dampers (in the diagram number 1), enters the body.

- The fuel pump pumps gasoline into the chamber. Under pressure, an oil-gasoline mixture is sprayed through the nozzles (in the diagram above, position 2 is the main jet, 3,4 are idle jets), contacts with air, mixes, and then enters the combustion chamber. The engine starts to idle.

- When the accelerator is pressed, the second adjustable throttle is opened at a certain angle (this is the second damper in the photo), fuel is supplied through the main nozzle (position 2 in the diagram). Inside the carburetor, a larger amount of the combustible mixture is mixed, which, when fed into the combustion chamber, increases the engine speed.

- The amount of gasoline entering the chamber also depends on the settings of the adjusting screws that control the needle valves (in the diagram, these are spring-loaded screws on the left and right).

- The supply of fuel to the chamber is limited by membranes, the flow rate is determined by the change in pressure in the piston and is regulated through the feedback of the pump and the pulse valve. The operation of the fuel pump is synchronous with the engine: the higher the speed, the stronger the flow of the fuel-air mixture.

- To prevent fuel overflow, a special lever and a shut-off valve are provided in the chamber.

Carburetor fuel supply system. 1. regulating chamber; 2. membrane; 3. shut-off needle.

Step-by-step adjustment

We will analyze an example of carburetor adjustment using the example of the Oleo Mak 937 chainsaw. The principle of adjusting other saws is practically the same, therefore this algorithm is applicable for the following models: 941c, 936. With other, less popular models (for example, Oleo Mak 362 or Oleo Mak 35), the similarity is not checked, but most likely there are no serious differences.

Before adjusting the carburetor of the Oleo-Mac chainsaw, a number of conditions must be met:

- clean air and fuel filters;

- check the condition of the jets, make sure they are in good working order and clean;

- assess the integrity of the membranes: no damage, cracks;

- check that there is sufficient fuel in the chamber.

Disassembly is not required for standard carburetor adjustment. There are screws on the outside that allow you to make all the necessary adjustments:

- L. low rpm;

- H. high speed;

- S. idle.

Although the manufacturer recommends adjusting only the “S” screw, in practice this is not enough. Before adjustment, all three screws should be tightened to the stop, and then unscrewed by 1.5-2 turns.

The step-by-step adjustment is performed as follows:

- The engine starts, warms up for 3-5 minutes at medium speed.

- The tachometer is connected.

- The work at low speed is adjusted using the screw “L”. It is necessary to achieve 1-1.5 thousand rpm. engine without spinning the chain, and when you press the accelerator. there is no drop in revolutions. If a failure is found, the screw should be unscrewed until this effect is completely eliminated.

- High engine speed is adjusted with screw “H”. When the accelerator is pressed to the maximum, they monitor the increase in revolutions, it is important that they do not exceed the maximum permissible value. It is recommended to set it 5-10% lower than the maximum speed, so as not to provoke increased wear of the internal combustion engine.

- The carburetor is fine-tuned with the “S” screw. When the chain is moving at idle speed, the screw should be turned counterclockwise until it stops. If the internal combustion engine stalls, then the screw is unscrewed clockwise until stable operation is obtained.

- After the tuning procedures, the chainsaw is tested in real working conditions. Perform the setting again if necessary.

Carburetor for lawn mowers OLEO-MAC SPARTA 37-44, EFCO STARK (EMAK)

- Model: 2318735BR

- Manufacturer: EMAK

- Quality level:

- Availability: Delivery time 2-3 days

-

Payment:

- Cash upon receipt.

- To the current account. (VAT included)

- To Privat Bank card.

The carburetor is used in OLEO-MAC lawn mowers, models SPARTA 37, SPARTA 38, SPARTA 42, SPARTA 44

EFCO STARK 37, STARK 38, STARK 42, STARK 44

diagram.3 part number. 6.

Vikoristovuuu

Carburetor model WALBRO WT-870B

The manufacturer is the EMAK company. Italy.

Manufacturer: EMAK

Meet the Emak Group!

Tools Emak S.p.A. Your guarantee! A guarantee of quality, innovation and an integrated approach. After all, Emak is not in vain a leader in the development, production and sale of high-quality equipment, accessories and consumables for it. The company is always directed to the future and in its developments is ahead of future decisions and sets a new benchmark. Emak tools are distinguished not only by the advanced technologies used in their development and production. They are created with love and respect for nature and work in complete harmony with the environment.

That is why the Emak group and its trademarks Oleo-Mac, Efco, Bertolini and Nibbi are iconic names both for specialists who use these tools professionally, and for those for whom it is just a pleasant hobby.

The product range includes over 250 models of tools for private, farm and professional use. To each his own Emak!

Emak S.p.A Group.

Mission of the group. “Creation of innovative solutions that provide maximum benefits for the client”.

In the production and distribution of tools and components for landscape, agriculture and forestry, as well as industry, we intend to become one of the world’s leading players in offering such advanced technical solutions and services that would make our customers effective and comfortable, whether they are professionals or individual consumers.

To achieve these goals, the group lays in the basis of its work the following provisions, which are the key to our success:

High quality and innovative products

High level of service

competitiveness

Continuous strengthening of the distribution network

Development of human resources and customer relations

The group includes 28 divisions in 14 countries of the world

The group operates in the global market, directly distributing in Italy and in ten foreign countries. USA, France, Germany, Great Britain, Spain, Poland, Ukraine, China, South Africa, Chile and Brazil. through controlled companies, offering a wide range of products of well-known brands to various categories of customers.

4 brands, 4 manufacturing sites, 8 subsidiaries, 135 distributors, 85 countries of sale, 22 points of sale, 22 lines and 250 different tool models.

Every year Emak expands its product range and increases its presence on all five continents. Emak products enjoy great prestige all over the world, in particular, combustion engine tools are considered the benchmark for quality and reliability in the industry.

Certified care for nature and people

Product quality, attention to people, environmental protection. The Emak philosophy is based on these basic principles, they are the face of the company.

Carburetor with Ali. Express. Benzotrimmer EFCO STARK 38, OLEO. MAC SPARTA 38. Carburetor replacement.

We are responsible for the results of our company, confirming that our words do not creep with deeds!

The offered for the whole set of works are democratic. Using this fact, it is profitable for customers to contact our service center.

Remember!

A certain cost is calculated personally each time. Its surface is influenced, first of all, by the type of breakdown, which was identified by specialists. The level of difficulty of the repairs performed is also taken into account.

lawn mowers and trimmers are self-contained gardening tools for maintaining garden and local areas. These devices allow for highly efficient mowing of soft vegetation, dense grass, weeds, in other words, shrubs in open areas and in inaccessible places. The main modifications of lawn mowers and trimmers are equipped with two-stroke or four-stroke fuel (gasoline) engines and differ in power, dimensions, configuration, weight and equipment. For ease of use, depending on the terrain and the rigidity of the vegetation, the devices are equipped with removable cutting elements. attachments with strong fishing line, various special knives and discs.

To ensure high-quality work, increase the resource and prevent breakdowns, such as the lawn mower or trimmer does not start, it is recommended to carry out their maintenance after 1 season of operation. Initially, the firm’s maintenance staff will perform a comprehensive diagnosis of the devices. with the goal of determining the ability to repair the four-stroke trimmer. Diagnostics is carried out over a three-day period at the time the units arrive at our service center. Technical examination is carried out on high-precision equipment using advanced modern techniques and latest technologies. After identifying the problematic nodes of the tool, which have an impact, as it is also called, there are variations to affect its effective performance. repairs are performed. The repair time, when the lawn mower has broken down, can be 2-12 days. Its duration is directly dependent on the degree of breakdown, year of manufacture, brand of the device, also the presence of spare parts in the warehouse or the need to purchase them from the manufacturer, as the supplier is also called.

Adjusting the Carburetor Lawn Mowers Oleo-Mac Sparta 37

1st Special Service Center “Agrotechservice” offers for you professional repair of petrol trimmers in the capital. Our company employs experienced, certified and qualified mechanics who perfectly perform any work in the field of maintenance and repair of gardening equipment.

Before handing over the petrol trimmer for repair, we ask you to report in advance to the manager of the company: the name of the manufacturer; exact model of the vehicle (for example: lawn mower MTD 790).

We repair lawn mowers, also service non-brand brands (repair of Chinese trimmers) of the following brands: MTD, Husqvarna, Caiman, Efco, Champion, Bolens, Solo, Oleo-Mac, Stihl, ECHO, Honda, Partner, also repair of Chinese trimmers.

If you have not found your petrol trimmer, the repair that is needed, in the list of serviced brands, contact our specialists and check the possibility of repair.

If you have any questions about the repair of lawn mowers and trimmers, in other words, you need advice, ours will promptly respond to any of your requests and suggestions.

We pay great attention to the level of our service to meet the needs of all customers and offer you the service of transporting faulty equipment to ours. and additionally from the service center back to the designated time and place both in Moscow and the Capital Region.

- Exclusively in our car service, discounts up to 20% on spare parts and up to 30% on trimmer repairs are provided here!

- As a result of the repair, the service manager of the company will hand over a permanent client for you.

- With constant or repeated service, the Clients of our company are provided with a cumulative system of discounts.

- Large families, participants and invalids of the Second World War are provided with a system of special discounts. When repairing equipment, discounts are provided for spare parts!

- Special conditions and discounts for corporate clients!

You will like the price of the services we provide changed after the diagnostics of your equipment. The company works with all clients personally, which means the price is calculated according to the level of difficulty of a certain type of work.

Repair lawn mowers Oleo-Mac Sparta 42

Repair of lawn mowers oleo mak sparta 25 photos

Piston ITAL D40 for lawn mowers Oleo-Mac Sparta 37, 38, 42, 44, (127-10)

Piston piston ITAL Ø40, cylinder with piston complete for Oleo-Mac lawn mowers.

Used in Oleo-Mac lawn mowers: Sparta 37, Sparta 38, BC 380 T, BCF 420, Sparta 42, Sparta 42 BP, Sparta 42 S, Sparta 44, Sparta 44 FE, Sparta 44 S, Sparta 440 BP, Sparta 440 S. Sparta 440 T

Manufacturers

Spare parts for lawn mowers Oleo-Mac Sparta 38, 44

Carburetor for lawn mowers Oleo-Mac Sparta 37, 38, 42, 44, Efco Stark 44, (2318735CR)

Carburetor Walbro WT-870B for lawn mowers Oleo-Mac, Efco.

Used in Oleo-Mac lawn mowers: Sparta 37,370,38,380 (S, T); Sparta 42,44,440 (S, T, BP); BC380 (S, T)

Efco: Stark 44IC, Stark 3800T, DS3800T

Carburetor for lawn mowers Oleo-Mac Sparta 37, 38, 42, 44, Efco Stark 44, (PJOM4301)

Carburetor FARMERTEC for lawn mowers Oleo-Mac, Efco.

Used in Oleo-Mac lawn mowers: Sparta 37,370,38,380 (S, T); Sparta 42,44,440 (S, T, BP); BC380 (S, T)

Efco: Stark 44IC, Stark 3800T, DS3800T

Basket

Mob. (050) 733-00-41 (098) 049-05-74 (063) 833-67-71

HomeMart recommends

Subcategory

Chainsaw Saber SC-45ES

- Pumps

- Drainage pumps

- Fecal Pumps

- Garden pumps

- Surface pumps

- Borehole pumps

- Well pumps

- Pumping stations

- Fountain pumps

- Motor pumps

- Accessories and accessories