Assembling The Makita Rotary Hammer 24 50

General characteristics

“Makita 2450” is known among builders and repairers as a fairly functional professional tool. It is simple and reliable to operate, lightweight and well balanced. Thanks to this “Makita 2450” will serve for a long time. It has a good dust protection system, which makes the operation of the equipment durable.

Its popularity is explained by the possibility of repairing the Makita 2450 hammer drill at home. You don’t need to spend a lot of money on its maintenance. However, before assembling the Makita 2450 perforator, you should familiarize yourself with the technology of its disassembly and repair.

Specifications

The hammer drill “Makita 2450” possesses a certain set of qualities. The characteristics presented by the manufacturer in the instructions are as follows.

The tool weighs only 2.4 kg. The drills are supported by the SDS system. The hammer drill is designed for crushing, drilling and hammer drilling. It has three modes of operation. The idle speed is 1100 per minute, and the maximum number of strokes. 4500 per minute. The force of translational movement at the maximum is 2.7 J. Maximum drilling diameter:

- for a tree. 32 mm;

- for metal. 13 mm;

- for concrete. 24 mm;

- for a hollow crown. 54 mm.

There are also additional functions for the Makita 2450 hammer drill. The characteristics highlight the presence of a safety clutch, reverse, lock of the power button, as well as electronic speed control.

The power supply power is 780 W. The cable length is 4m.

Repairs

“Makita 2450” is repaired with its own hands with certain knowledge and skills. Inspection and replacement of HR 2450 parts is fairly straightforward. It involves disassembling the tool, after which all old grease, dust, dirt are removed. Damaged assemblies are replaced with new ones. Then all the details of the punch are put together. It is necessary to familiarize yourself with each item of such work. They can be produced in the area of the chuck, mode switch, punch body.

For repairs, first remove the cartridge, then the speed switch. After that, repairs are carried out inside the case. The grease and worn rubber elements are being replaced.

Faults in the gearbox housing

The case of the HR 2450 model is characterized by high strength; breakages in this unit are quite rare. But it happens that certain troubles occur here as well. If the housing comes with the needle bearing, then its seat is badly worn out. When this part is very loose, the case should be replaced.

Sometimes the intermediate shaft seat is broken. Repairs are supposed to be similar to the first case.

The gear housing washer has an oil scraper ring. If it is damaged by construction dust (which happens extremely rarely) or careless actions of the repairman, it is changed along with the body.

The same procedure is carried out in the event of failure of the mode switch holes. The listed types of breakdowns are typical for fake copies.

Switch malfunctions

In the process of getting acquainted with the question of how to assemble “Makita 2450”, you should find out the frequent malfunctions of the switch. They can be caused by wear on the metal pins. In this case, any of the modes will not be activated. The switch will need to be replaced. This should also be done in the event of a breakage of the landing lugs.

If the rubber ring is worn out, there will be a slight leakage of grease. We’ll have to replace it.

It happens that the beak of the retainer breaks, with which it is attached to the depressions of the gearbox. The tabs may be damaged. To avoid all of the above damage, you need to handle the tool carefully.

Reducer housing

To remove the housing from the gearbox, lift the tool barrel up. The punch should be pressed against the workbench while pulling the shell upwards. In this position, all parts remain in place.

After their revision, check and replacement, the gearbox housing is installed in place. All its elements must be located in their original form. Required elements need to be lubricated.

During assembly, the gearbox housing must be cleaned with kerosene or gasoline. Next, the shell is put on its original place. The mode switch should not be in it.

Now grease all parts of the mechanical block with the recommended grease. Here is an example of how to properly lubricate rotating surfaces and here is another example of generous lubrication of a mechanical block.

You can’t spoil porridge with butter

So it is also allowed to apply lubricant. You can‘t spoil porridge with butter!

The lubricated mechanical block must be closed with a plastic housing pos. 14 black.

Place the body on top of the assembly and press the body down until the assembly is fully seated in it.

Backwardness, insert four bolts (pos. 10) into the body and tighten. Now it is the turn of the connection to the mechanical part of the electric motor rotor.

Installing the rotor

The helical gear of the rotor is tightly inserted into the housing of the mechanical block and pressed.

It remains to insert four self-tapping screws m4 × 60 pos. 57. and screw them into the body of the electrical unit.

Assembling the striking mechanism

And how to assemble the hammer mechanism of the Makita rotary hammer?

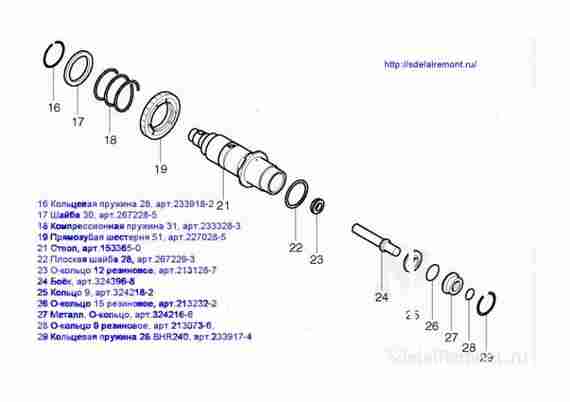

The percussion mechanism is assembled from two units: a barrel shaft with a spur gear and an intermediate shaft with a rolling bearing. A). A spur gear, pos. 19, is put on the barrel, pos. 21, and pressed by a compression spring, pos. 18.

To fix the spring, it is pressed with a washer 30 pos. 17 and secured with a retaining ring 28 pos.16.B). To assemble the striker, you need to put the ring 9, pos. 25 on the shaft of the striker, pull the rubber ring, pos. 26, press down with the metal ring, pos. 27.

Now we go to the opposite side of the barrel, pos. 21. On the other hand, the inner surface of the barrel must be lubricated with grease and inserted inside the assembled drummer, pos. 24.

Assembling the intermediate shaft and piston

Assembling the reducer assembly

The assembly of the reducer block is carried out on the inner casing pos. 49.

Inner body

By the way, there are cases when the axles pop out of the inner aluminum housing. Both axles are pressed into the housing.

The assembled intermediate shaft is inserted into the housing of pos. 49, the rolling bearing lever of which should fall into the hole of the cylinder hinge. In this case, the rolling bearing lever pos. 41 of the intermediate shaft must fall into the cylinder hinge, pos. 32, and the lower intermediate shaft bearing into the housing in the housing. This procedure is usually performed by rocking the structure until the parts are completely in the indicated places.

Assembling the intermediate shaft assembly

To assemble the intermediate shaft, it is necessary to put the rolling bearing (pos. 41) on the shaft (pos. 40) with its teeth to the splines of the shaft, and put the coupling (pos. 39) on the splines of the shaft.

Transmission of translational motion

On the opposite side of the shaft, a helical gear 26 pos. 42 is put on, a flat washer 8 pos. 45, a bearing 608zz pos. 46 and a circlip 8 pos. 47.

The intermediate shaft is assembled.

Setting the mode selector lever

The mode switch is designed to transfer the clutch, pos. 39, to various positions and transfer the translational motion to the percussion shaft through the rolling bearing, pos. 41, to the cylinder, pos. 32.

Makita 2450 Punch Mode Switch Lever Assembly

On the axis of the inner case it is necessary to put the mode switch lever pos.82, from above the pressure spring pos.88, crush it with a flat washer pos.87. Install the circlip, pos. 86. and fix.

The retaining ring must be carefully fixed. Turning the intermediate shaft, it is necessary to carefully check the correct operation and free movement of the cylinder in the housing. This must be done now so that it does not become clear at the end of the assembly that the assembly is assembled incorrectly.

Assembling the hammer shaft

First, you need to lubricate the inside of the cylinder (pos. 32) and insert the striker (pos. 30) into it.

It remains in the inner body of pos. 49 to put the lubricated barrel assembly in position 21 in place, putting it on the lubricated cylinder of pos. 32.

It is recommended to use a special grease developed for Makita rotary hammers as lubricants.

There are several types of lubricants: Makita P-08361 and Makita 183477-5 SDS-PLUS.

Makita Grease 183477-5 SDS-PLUS is recommended for the gearbox. Makita grease 196804-7 is used for drill shanks.

Lubricants vary in color, but have exactly the same characteristics.

And what other lubricants are used in the Makita 2450 and 2470 hammer drill?

And here we have an assembled mechanical block.

The order of assembling the punch Makita 2450

Makita Rotary Hammer Assembly Procedure

The assembly of any mechanism should be started after careful preparation. It is necessary to prepare not only the parts, but also the tools, place, lubricant.

Of the tools, you can not do without pliers, screwdrivers, a hammer, a brush for applying lubricant.

And what is the assembly diagram of the Makita 2450 and 2470 rotary hammer?

Do-it-yourself assembly of a Makita rotary hammer can only be performed if the attached instructions are followed.

The task of the assembly process is to replace faulty parts with usable ones and ensure the interchangeability and operability of the tool.

Dismantling the electrical part of the Makita 2450, 2470 rotary hammer

The electric part of the Makita 2450.2470 rotary hammer includes:

-

circuit breaker TG813TLB-1 pos. 68;

-

carbon brushes SV-419 pos. 65;

-

brush holder pos. 63.66.

To remove the stator, just knock on the end of the green plastic casing from the stator side with a wooden mallet or a block.

But first you need to unscrew the two self-tapping screws 4 × 60 mm pos. 57.

With frequent tapping on the body, the stator spontaneously protrudes beyond the edges of the body, and then is removed by hand.

The remaining elements of the electrical part of the Makita 2450 or 2470 rotary hammer can be easily dismantled, since they are not attached to anything.

Disassembly of the punch is complete.

Hammer drill Makita 2450 disassembled

Instructions for disassembling the Makita 2450 rotary hammer

A hammer drill is a percussion drilling tool that simultaneously performs the function of percussion and drilling equipment when working with particularly durable materials.

The device uses two ideas at the same time: the tool rotates and moves in the longitudinal direction, transmitting the impact impulse to a hard surface.

Rock drills always work in an extreme environment with a high degree of dust.

The duration of trouble-free operation is influenced not only by the operating conditions, but also by the quality of the components included in the tool.

Hammers Makita 2450, 2470 are reliable high quality tools. But even the most reliable tool requires proper care and timely maintenance.

To perform maintenance on the Makita 2450, 2470 hammer drills, it is imperative that you familiarize yourself with the internal m of the tools included in the assemblies. To find out the weak points of the Makita rotary hammer, this instruction will help you.

To repair a hammer drill Makita 2450, 2470 with your own hands, a person who has locksmith skills and knowledge of electrical engineering is allowed.

Remember! When repairing a hammer drill, you must follow the safety rules when working with electrical appliances.

Hammer drills Makita 2450 and 2470 are assembled practically according to the same scheme and, practically, from the same, interchangeable parts. Repairing them is no different.

How to assemble Makita hr2450 rotary hammer drill armature, cylinder gears

General view of the Makita 2450 hammer drill

For ease of repair, below is an assembly diagram and parts catalog for Makita rotary hammers.

Makita 2450 hammer assembly diagram

The procedure for disassembling the shaft of the barrel of the percussion mechanism

To disassemble the shaft of the percussion mechanism, it is necessary to pull it out of the inner case.

From the shaft it is necessary to pull out the cylinder, pos. 32, inserted into the inner cavity of the shaft.

The cylinder is very easy to disassemble:

-

1. From it you need to get the drummer pos.30;

-

2. Knock out the hinge of the piston poz.34;

-

3. Two flat washers are removed poz.33,35.

To disassemble the shaft itself, pos. 21 of the percussion mechanism, it is necessary to remove from the side of the cartridge installation shaft:

- – ring spring 28 pos.16;

- – washer 30 pos. 17;

- – compression spring 31 pos. 18;

- – spur gear 51 pos. 19;

- – steel ball 7.0 item 20.

And from the side of the inner cavity of the shaft it is necessary to remove:

- – ring spring 28 pos. 29;

- – rubber ring pos. 28;

- – metal ring pos. 27;

- – rubber ring 15 pos. 26;

- – ring 9 pos. 25;

- – flat metal washer 28 pos. 22.

Barrel shaft disassembled

Setting the mode selector lever

The mode switch is designed to transfer the clutch, pos. 39, to various positions and transfer the translational motion to the percussion shaft through the rolling bearing, pos. 41, to the cylinder, pos. 32.

Makita 2450 Punch Mode Switch Lever Assembly

On the axis of the inner case it is necessary to put the mode switch lever pos.82, from above the pressure spring pos.88, crush it with a flat washer pos.87. Install the circlip, pos. 86. and secure. The circlip must be carefully secured. Turning the intermediate shaft, it is necessary to carefully check the correct operation and free movement of the cylinder in the housing. This must be done now so that it does not become clear at the end of the assembly that the assembly is assembled incorrectly.

Disassembling the Makita Rotary Hammer Chuck

Punch chuck repair begins with installing the punch vertically on the rear housing cover. The hrMakita perforator diagram will help you to correctly perform the disassembly work. Is it necessary to replace the chuck of the Makita 2470 hammer drill? The answer can be obtained only after complete disassembly of the cartridge with your own hands.

Using a screwdriver or a puller, the boot is removed, the cartridge is freed from the retaining ring, the coupling casing, the metal ring 20 pos. 4. Next, you need to carefully get out the ball, pos. 20, remove the guide washer, pos. 5, and the conical spring, pos. 6, that supports it. Cartridge disassembled.

The diagram below shows the device of the punch chuck.

The main malfunctions of the makita 2450 rotary hammer that cause defects in the chuck are:

- wear of the protective rubber boot pos. 1;

- relaxation of the retaining ring pos. 2 or its partial wear;

- ball wear, pos. 20;

- loss of elasticity of the conical spring pos. 6 or its extension.

Repairing a hammer drill chuck is not a complicated procedure and is usually easily done by anyone who can hold a screwdriver.

If replacing a rubber boot, retaining ring, conical spring is not difficult, then replacing a new ball requires attention. The new ball should be 7mm ± 1 µm in diameter. As a lubricant, it is recommended to use a special lubricant developed for the Makita rotary hammer.

The grease has the index Makita P-08361, Makita 183477-5 SDS-PLUS 30g for the gearbox. It is recommended to use Makita grease 196804-7 for drill shanks.

When assembling the chuck, install the conical spring with the narrow side to the hammer drill. Do not forget, repairing a punch chuck with your own hands requires care from the collector.

We disassemble the gearbox

To get to the mechanical part, you will need to remove the plastic case.

The procedure for disassembling the mechanical part of the Makita rotary hammer First, the protective black plastic case is removed. The case is removed after you unscrew the four screws securing the case from the end. By pressing on the end of the shaft, you will push the gearbox out of the housing.

After removing the housing, it is necessary to separate the rotor from the gearbox. A general mechanical part is called a reducer. It is easy to separate the rotor from the mechanical part (gearbox). Clamp the gearbox with your right hand, clamp the rotor with your left. Swinging, pull both sides in opposite directions. The rotor is held in the gearbox by friction of helical gears.

The main malfunctions of the Makita rotary hammer occur in the mechanical part of the tool.

The most typical malfunction for the mechanical part, failure of the percussion mechanism.

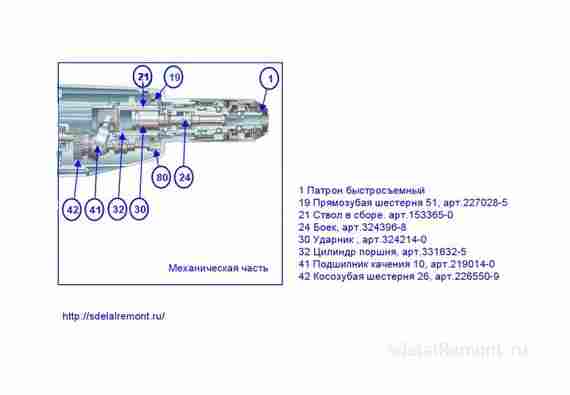

Disassembly of the percussion mechanism The percussion mechanism is assembled on the inner case and consists of a gearbox shaft and an intermediate shaft. The rotary motion is transmitted through helical gears to the intermediate shaft.

The gearbox shaft is a hollow barrel in which the cylinder moves freely.

A small spur gear mounted on the intermediate shaft transmits rotation to the large spur gear of the gearbox shaft, in which the percussion mechanism is mounted. And the translational movements on the shaft of the percussion gearbox are simultaneously transmitted due to the transmission from the rolling bearing of the intermediate shaft to the cylinder moving in the gearbox shaft.

We proceed to disassembling the intermediate shaft.

Dismantling the intermediate shaft

On the shaft poz.40 mounted helical gear poz.42, which is transmitted rotation from the rotor gear, rolling bearing 608zz poz.41, which transmits translational motion to the hinge poz.34 piston poz.32. On the other side of the shaft, a clutch clutch (pos. 39), a spur gear 10 (pos. 80), a compression spring (pos. 38), a circlip S-7 (pos. 37), a bearing 606zz (pos. 36), should be paid special attention to the condition of the rolling bearings. Imported bearings are installed in the hammer drill. Installation of domestic bearings is allowed.

Bearing 606zz can be changed to 80016, bearing 609zz can be changed to 80019.

Moving on to disassembling the shock mechanic’s shaft

Disassembling the hammer shaft Disassembling the barrel of the Makita 2470 hammer drill is a simple process if you use the diagram of the Makita hammer drill. The shaft is a barrel poz.21, in which the impact mechanism is assembled. A gear, pos. 19, is attached to the barrel, which is pressed down by a spring, pos. 18, through a washer, pos. 17, and is fixed with a retaining ring, pos. 16.

The cylinder, pos. 32, moves in the barrel, acting on the firing pin, pos. 24. On the reverse side of the striker, a metal ring pos. 27 is fixed, transmitting the blow to the drill.

And when you need to replace the drill barrel?

Most often, the metal ring fails. Striker

Cylinder with drummer

We figured out the disassembly. We change the parts for serviceable ones and get ready to assemble. Learn more about rock drill lubrication and assembly.

Read if there are problems with the electrical part of the hammer drill.

Now grease all parts of the mechanical block with the recommended grease. Here is an example of how to properly apply lubricant to rotating surfaces. And here is another example of generous lubrication of the mechanical block.

You can’t spoil porridge with butter

So it is also allowed to apply lubricant. You can’t spoil porridge with butter!

The lubricated mechanical block must be closed with a black plastic housing pos. 14. With the body on top of the assembly, press down on the body until the assembly is fully seated in it. Backwardness insert four bolts pos. 10 into the body and tighten.

Now it’s the turn to connect the electric motor to the mechanical part of the rotor. Installing the rotor

The helical gear of the rotor is tightly inserted into the housing of the mechanical block and pressed.

It remains to insert four self-tapping screws m4 × 60 pos. 57. and screw them into the body of the electrical unit.