At What Angle To Cut Skirting Board

Preparatory process

Before gluing the skirting boards to the ceiling in the corners, you need to prepare the tools that will be needed when gluing the ceiling skirting board:

- To calculate the required amount of materials, you need a tape measure.

- It is recommended to fix the ceiling skirting boards with quick-drying glue or putty.

- You can knead the adhesive in a pre-prepared container, it is best to apply the putty with a spatula.

- Remove excess glue or putty with a dry, clean cloth.

- For cutting skirting boards at a certain angle, it is best to use a miter box.

- Direct cutting of products is performed with a sharp construction knife or file.

It is recommended to glue the ceiling plinth on a pre-filled and leveled wall. As for the wallpaper, they are glued after the fillets are installed. In this case, the fastening of the elements will be more durable. In addition, when gluing new wallpaper, there is no need to change the ceiling plinth, since wallpaper strips are glued along the lower edge of the fillet. Fixing over wallpaper reduces the fixing strength of the skirting board and requires its dismantling when changing the finishing material for the walls.

The task of how to properly glue the ceiling plinth in the corners is recommended to be solved with the help of acrylic or silicone glue, characterized by fast drying, or on a construction putty. With the help of a putty, the skirting board is glued directly to the wall, the frieze is glued to the wallpaper using quick-drying glue. When using these materials for fixing products, there is no need to hold the elements for a long time to set the adhesive backing. In addition, with putty, you can simultaneously repair wall defects in the form of irregularities and cracks.

Using a thread or construction cord, it is necessary to draw a control line in accordance with the width of the frieze. In this case, you can count on a more even gluing of the ceiling plinth, and the process itself will not cause much trouble.

Selection of material and calculation of the number of skirting boards

Ceiling plinths are very popular, for the manufacture of which polystyrene, polyurethane and expanded polystyrene were used. The main advantages of such products are lightness, resistance to moisture and temperature extremes. Thanks to the various widths and a large selection of patterns and reliefs, it becomes possible to choose a skirting board to create any decorative effect. Additional coloring of ceiling skirting boards makes it possible to create a variety of artistic decor.

The problem of how to stick polystyrene and expanded polystyrene skirting boards on the ceiling should be solved with extreme caution, since they are easily deformed and damaged by mechanical stress. As for polyurethane fillets, such design elements are characterized by increased strength and the ability to maintain a clear relief shape.

Polyvinyl chloride ceiling plinth is widely used in cases where the budget for renovation and decoration of the premises is limited. However, when using it, it should be remembered that such products are not recommended to be painted. In addition, PVC skirting boards are afraid of temperature extremes, under their influence, product deformation may occur.

When choosing plaster, wood or aluminum skirting boards for ceiling decoration, you should remember a few very important points. First, such products cannot be bent due to the low ductility of the base material. Secondly, the skirting boards are quite heavy. The presence of these qualities makes the solution to the question of how to glue fillets on the ceiling special.

Before you go shopping for skirting boards, you need to make a few calculations. In particular, it is required to determine how much material is required to finish the ceiling in a room of a certain area. First, measure the perimeter of the room, this value will correspond to the total length of the ceiling plinth. To calculate the number of fillets, it is necessary to divide the perimeter of the room by the standard length of the products, which corresponds to 1.2 meters, 1.4 meters and 2 meters. Experienced craftsmen performing finishing work recommend purchasing skirting boards of greater length, in this case, fewer connections are obtained.

The width of the plinth is determined according to the height of the ceilings in the room. In rooms with low ceilings, it is better to use narrow products; for high rooms, it is recommended to install a wide ceiling plinth. This visually reduces the height of the room.

How to glue skirting boards to the ceiling in the corners. step by step guide

When performing repair and finishing work, each stage should be treated responsibly. The final stage, when additional and decorative elements are mounted, requires special care. Most often they are in plain sight, so any mistake can spoil the appearance of the entire interior. Therefore, it is necessary to strive for the perfect execution of the final stages of repair and decoration.

The completion of any work on finishing the ceiling is the installation of ceiling skirting boards, which are called friezes or fillets. Thanks to this element, the transition between the ceiling and the wall becomes smooth, and the renovation takes on a complete look.

The main purpose of the ceiling plinth is to decorate the room, so you need to choose a fillet in accordance with the overall interior. In addition, this element allows you to mask minor defects at the junction of the ceiling and walls. Therefore, it is important to know how to glue fillets correctly.

Main steps

Installation of a ceiling plinth cannot be called a complicated and time-consuming process; even a novice master can do it. However, for a high-quality work, you need to know all the intricacies of installing ceiling plinths. When solving this issue, you should be especially careful about the design of the corners. Errors and shortcomings at this stage cause the formation of cracks and mismatches, which to a greater extent spoil the appearance of the entire ceiling. Therefore, the problem of how to glue the ceiling plinth in the corners can be called actual.

Cutting skirting boards at an angle

The process of deciding how to glue a wide ceiling plinth always starts in one of the corners. Many manufacturers, in the process of manufacturing products, cut skirting boards at a certain slope for easier decoration of external and internal corners. The problem of fitting fillets with a complex pattern or pattern is especially urgent. When using a cornerless ceiling plinth, you can correctly and beautifully arrange the corner using a miter box or a file.

In order not to spoil the appearance of the baguette, it is necessary to properly cut off its corners. To form a normal right angle, the skirting boards should be cut at a 45 degree angle towards each other.

Determination of the slope and cutting of the skirting board is performed as follows:

- The product is applied to the ceiling in order to understand the direction of the cut for proper installation.

- You need to cut baguettes in a mirror image.

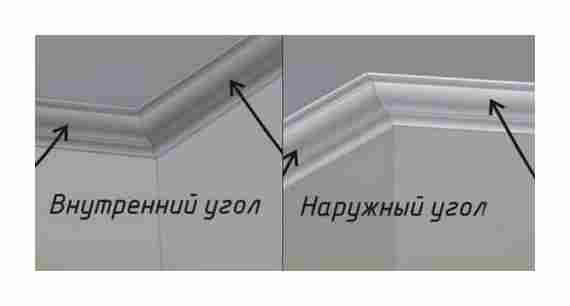

- To decorate the inner corner, the top edge is made shorter than the bottom edge.

- Correct outer corner occurs when the top edge is longer than the bottom.

- On the ceiling plinth, which will be located on the right side, make a cut on the left side.

- The product on the left side should have a cut on the right side.

- When cutting the plinth, you must carefully advance the knife in one direction. In this case, the formation of chips and roughness can be avoided.

The appearance of the ceiling depends on the correct solution to the question of how to glue and cut ceiling plinths.

To make a miter box yourself, you must perform the following steps:

- Take any solid foundation and draw a line on it.

- Then they retreat about 10 cm and draw a line parallel to it.

- Draw a line through the parallels at right angles to them.

- Measure 5 cm from this line on each mowing line and connect opposite points.

- The resulting mowing lines form an angle of 45 degrees with the parallels.

To cut the skirting board using a homemade miter box, the product is laid along the parallels and cut along the marks, taking into account the direction of the corner.

However, it should be understood that for angles other than 90 degrees, it is necessary to cut the plinth at a different slope. In this case, the product is applied to the wall and its boundaries are outlined. Then the place of intersection of the skirting boards is determined and the corresponding marks are put. The baguette cut is performed according to these marks.

Gluing the ceiling plinth

For high-quality gluing of the baguette, you must do the following:

- Take a baguette and put glue on its back.

- The place of fixation of the product can be moistened with a primer or plain water to increase the adhesion of surfaces.

- The plinth is firmly pressed against the wall and ceiling and held for a while.

- Excess glue or putty is removed immediately.

- The resulting cracks and gaps are covered with putty.

If necessary, the skirting boards are painted in the desired color.

Other corner trimming methods

When the contacting planes of the walls of the room form a right angle, the best solution would be to use a miter box. In other cases, you can use other methods, such as sawing the ceiling plinth at an angle, for example, by marking this product on the ceiling. This technology allows you to take into account all deviations regarding the size of the angle, as well as the unevenness of the walls.

In this case, the work is performed as follows:

- First of all, two workpieces are cut according to a straight vertical mowing line.

- Next, one of the planks is applied to the surface, resting it with its butt against the perpendicular wall. Do the same with the second part of the skirting board.

- Their contours are outlined on the ceiling plane with a pencil. The intersection point is the mark relative to which the fillet is cut, forming an angle in it.

- Then reapply each of the planks and mark the cut line on them, which will connect its two edges.

- The plinth is cut in accordance with the intended lines, after which both parts of it are connected and applied to the installation site.

If of all the ways how to cut the corners of the ceiling plinth, this one is chosen, it is important to take into account several nuances:

- it is best used for interior corners;

- you should not proceed to fastening the fillets one at a time, without making a preliminary docking of the two parts and without checking their relative position. The gaps remaining between the slats must be putty.

Using a template

There is a way how you can cut the corners of the skirting board without a miter box. using a template. It is made of wood, cardboard or paper.

The markings are applied to the material in the following order:

- first draw two clear parallel straight mowing lines;

- between them determine the central point and outline it;

- using a protractor, apply the desired angles, which can exceed 90 degrees.

Before using the template, take into account the angles between touching walls and between the ceiling and the walls. Cutting technology using a template is almost the same as using a carpentry tool.

Self-made miter box

To make this device with your own hands, you can use one of the following methods:

- A U-shaped box is assembled from three slats or planks, on the walls of which grooves are marked and cut out under certain slopes.

- They take two boards and knock them down strictly perpendicularly. A piece of paper depicts a template with angled lines for cutting at an angle of 45 degrees. The product is applied to the corner and pressed by hand, as when using a miter box, and a paper template is placed on the opposite side. Fillets are cut in accordance with the lines applied to the paper sheet. When cutting ceiling plinths, you can use anything that forms an angle of 90 degrees.

Cutting corners

At what angle the ceiling fillet should be cut directly depends on its location, or rather on whether the slope will be internal or external.

The cutting of the inner corner using a miter box is performed in a strictly defined sequence:

- The required length of the plinth is measured on the ceiling.

- The workpiece bar is placed in the fixture as it will be on the ceiling surface. To do the job correctly, the fillet must be placed face up.

- The workpiece is pressed against the far wall of the device and held with the left hand.

- Next, the file is placed at an inclination of 45 degrees so that its handle is as close as possible to the left hand. To saw down the ceiling plinth. the cutting is performed without too much pressure on the hacksaw.

- Then you need to prepare a striker, for which the workpiece is moved to the far wall and held with the right hand.

- The hacksaw is turned at a 45-degree tilt. In this case, the handle is directed to the right and part of the plinth is cut off.

- After cutting the inner corner of the decorative fillet, the correctness of the work performed is controlled by joining the strips.

Acting in accordance with the above algorithm, it is possible, with an accuracy of one millimeter, to cut the corners of the ceiling plinth without much effort.

Experts advise to start cutting the outer corner after the problem with the inner corner has been solved, since the length of the product is not always enough.

To make the correct cut of the outer corner, you must proceed as follows:

- First, as in the situation with the inner corner, markings are made on the ceiling by marking with a pencil.

- Further, the fillet blank is placed close to the near wall of the carpentry device.

- Holding the bar with your left hand, turn the hacksaw handle to the left by 45 degrees and cut off.

- To saw off the mating element, it must be brought closer to the front wall of the miter box, holding it with your right hand. The fillet is cut with an inclination of 45 degrees, turning the handle to the right.

- At the end, the cut parts are joined and, if necessary, the surfaces are trimmed, creating a neat outer corner.

Used tools

Before you install the moldings, you need to have certain tools at your disposal. Some of them are always at hand from a home craftsman, while others will have to be purchased or made personally. When installing these decorative products, there will certainly be a problem with how to make a cut on the ceiling plinth, observing the required slope.

To solve this problem, they use tools that allow you to do the job correctly and as quickly as possible, including:

- pencil;

- roulette;

- hacksaw;

- an ordinary, but better stationery knife;

- miter box.

The last in the above list is the miter box. this is an easy-to-use and popular carpentry device that allows you to cut the corners of the ceiling plinth at a certain angle. Different materials are used to make this tool. wood, metal or plastic.

There are always vertical slots on the side walls of the miter box, necessary in order to cut fillet corners at an inclination of 90, 60 or 45 degrees.

Professional samples of this carpentry tool have a swivel mechanism that allows you to fix the file relative to the baseboards at almost any angle. As a result, solving the problem of how to cut fillets for the ceiling at the desired slope is greatly simplified.

How to properly cut the corner of the ceiling plinth. rules and methods

In order to hide the joints between the walls and the ceiling surface and to give the ceiling a finished look, fillets should be installed. In the process of performing this type of work, difficulties often arise, but they are mainly due to the fact that there is not enough knowledge of how to properly cut off the corner of the ceiling plinth.

How to fit beading without a mitre

Types of decorative ceiling skirting boards

Before proceeding with the installation of fillets, they need to be purchased, and for this you should have information regarding the range of these products.

Skirting boards are made from various materials, namely:

- polyvinyl chloride;

- polyurethane;

- wood;

- polystyrene (foam).

To have an idea of each type of decorative ceiling elements and choose the right product, you must own at least their brief characteristics:

- Skirting boards made of polyvinyl chloride have a favorable cost, but this material has the ability to accumulate static electricity.

- Polyurethane stucco molding is distinguished by high quality, strength, moisture resistance and elasticity. Its main disadvantage is insufficient resistance to sudden temperature changes and for this reason, polyurethane products should not be installed in rooms with high humidity.

- Wooden fillets are subject to high temperatures, moisture and are heavy.

- Polystyrene skirting boards are characterized by moisture resistance, good quality and attractive appearance, but they break under mechanical stress.

In addition, fillets differ in other parameters. width, length, relief and shape. Their use in rooms of different sizes depends on these characteristics.

For example, wide products look harmonious in tall rooms. There are nuances in how to cut wide skirting boards. The fact is that these profiles are joined at an angle of 90 degrees. For an accurate cut, use a miter box. But when the corners of the room deviate from the standards, the work is done manually.

How to cut outside corners

Sometimes there are corners projecting outward in the room, which is much more difficult to trim. There are also several ways to implement this procedure, how to cut skirting boards to the ceiling. The simplest is to use a miter box: in this case, the outer sections of the joints must be cut so that part of the ceiling is on the plane of the miter box, and the side from the wall is adjacent to the wall of the tool. In addition, you can apply in-place markings by running the line along the base of the ceiling. The procedure here is very similar to the preparation of the inner corners.

There is also an option with a wall marking, when the baguette is positioned parallel to the ceiling and the fishing line is drawn along the lower cut. In the presence of excessive roundness of the outer corner, a sharp painting knife enters the work. At the point of convergence, the line is drawn exactly along the cut of the future docking: it must connect the ceiling and wall mark. The resulting marking is a guide for sawing off or cutting off the butt end.

How to cut ceiling skirting boards. cutting tools and rules

Any kind of ceiling finish will look unfinished without a skirting board. With the help of these elements, you can reliably hide the unevenness of the joints between the wall and the ceiling.

Self-made miter box

Given the simplicity of the miter box design, it is often made by hand from wood and steel. The parameters of the product do not matter much, but as their width increases, the accuracy of the cuts increases. It should be borne in mind that if the width of the device exceeds the length of the hacksaw, the sawing procedure will face additional difficulties.

The first step is to outline the central axis of the workpiece, which requires a long steel ruler. Next, make an indent by 0.5 of the width of the workpiece from the points of intersection of the axis and the edges, for marking. These mowing lines must be connected crosswise. The existing base is used to mark the side walls of the tool. When drawing lines, they are guided by the existing marking, from which transverse straight lines depart.

Then you can proceed to the miter box assembly procedure. Self-tapping screws are used to fix wooden or chipboard walls to the base. If these elements are made of steel, bolted angles will be required. The fully assembled structure is equipped with saw guides and the attachment is ready for use. With its help, you can significantly speed up the procedure for repair and finishing work, without wasting time on manually cutting corners. It takes a little experience to cut the ceiling plinth with a miter box as it should.

Purpose of the miter box

The procedure for cutting the corners of the ceiling skirting boards is as follows:

- Attach the baguette to the area of the future fastening. This will make it possible to accurately mark the place of the cut.

- Place the plinth in the recess of the miter box so that the back side is firmly against the underside of the tool. The surface to be coated with glue must be oriented upwards.

- The ceiling plinth is cut along a 45-degree guide. You can use a knife or saw to clean up uneven cuts.

Trimming the oblique corners of the ceiling plinth

As practice shows, the corners in the room are far from always even. It depends on the quality of the preparation of the walls and the architectural features of the room. In such a situation, an ordinary miter box or marking sheet turns out to be powerless, since you have to deal with other parameters of the butt sections. blunt, or vice versa, sharp. Most often, this can be found in old-style houses, village buildings and summer cottages. There is only one way out in this situation. to make markup in place.

The order of work, how to cut the ceiling plinth at a non-standard angle:

- The baguette is positioned on any wall in such a way as to achieve abutment of the end against the adjacent wall.

- On the surface of the ceiling, a line is drawn along the cut of the plinth.

- The other wall is marked in the same way.

- At the point of intersection of two lines, a mark is made on the surface of the baguette.

- By connecting the mark and the corner part, cut off.

- A similar procedure, how to cut the corner of the ceiling plinth, is carried out on another workpiece, which will be on the adjoining side.

- When installing blanks, it is important to achieve a snug fit.

Recommendations for the selection of tools

The process of choosing a specific fixture for cutting the corners of the ceiling plinth primarily depends on the material for making the baguette:

- PVC. Plastic products are prone to damage from any careless pressing. Since their elasticity is weak, the dents are not restored back. This moment should be taken into account, and do not press too much on the product when trimming corners. As a tool, how to cut a ceiling plinth on a miter box, it is best to use a sharp construction knife or a hacksaw for metal.

- Styrofoam. A very popular option for the manufacture of ceiling plinths and other decorative elements (moldings, chandelier linings, etc.). Foam products are very lightweight, which makes installation much easier. Cut the corners of these friezes carefully due to their fragility.

- Wood. Wood baguettes are elite expensive products that are distinguished by their external beauty and style. A metal hacksaw is usually used to cut this type of skirting board. In the process of work, it is necessary to regularly clean the teeth, because they get clogged with chips rather quickly. It is recommended to choose a hacksaw blade with a close tooth pitch.

When there is no miter box

It so happens that the miter box is not at hand. In this case, you have to be smart. Before sawing the ceiling plinth, it is recommended to apply the cutting direction on paper, cardboard or wallpaper. It will act as a guide for applying blanks to it when cutting. To make the drawing correctly, I attach a piece of baguette to the paper and draw a couple of parallel lines. They will serve as the side boundaries of the workpiece.

Next, using a school protractor, measure 45 degrees and plot the direction of the cut. In work, a similar drawing is used in the same way as a miter box: you need to put a workpiece and cut off all protruding parts along the mowing line. The disadvantage of this method is that the cutting tool has to be held in weight above the drawn line. There are no special saw guides here.

Ready-made corners

For convenience, some ceiling frieze manufacturers supply ready-to-use products for sale. This makes it possible not to waste time on manually cutting corners. It is enough just to cut the product to size at right angles, which makes joining much easier. The main disadvantage of such friezes is the large dimensions of the corner elements in comparison with the skirting boards. As a result, the corners start to stand out noticeably, and the perimeter is uneven. In some situations, this really affects the overall beauty of the finish. In addition, if the corners of the room are not ideal, laying the docking part will be difficult.

The procedure for trimming the corners of ceiling plinths is a very demanding task. Any mistake made can ruin the appearance of the finish. Most often, a miter box is used as a device for high-quality design of corner sections. This simple tool allows you to get an accurate cut at 45 or 90 degrees. In cases where the walls in the room do not form a right angle, the procedure for how to cut the ceiling plinth is usually carried out manually. When choosing a tool for pruning, the material for making baguettes is taken into account.

How to cut skirting boards using decorative corners

With the help of them you can easily and quickly obtain the desired angles in polystyrene or polyurethane skirting boards. Install them on the ceiling, and then glue the strips to them. Cutting them is easy using a clerical knife.

Making corners using a miter box

If the walls and corners of the room are even, you can use a miter box for work. In order to properly cut the corner, a part should be laid inside the miter box, in which the person will make a gash, then insert the saw into the guides. This holds the part in place and can be cut at the desired angle. For high-quality cutting of the skirting board, it must simultaneously adhere to both surfaces, so it should be pressed against the wall of the miter box. The ceiling plinth is pressed with the side that is closer to you.

With a miter box, you will need to cut a 45 degree angle. First you need to decide how to position the plinth in the miter box. To avoid confusion and cut correctly, place the right plank on the right and the left plank on the left.

Follow the instructions below:

- Press the part of the miter box that will be on the ceiling to the bottom of the miter box. The other side will be lifted up and closer to you. It can be resting on the wall of the tool, and then it will not stagger when cutting.

- Determine the cutting direction as shown in this illustration, and then cut the corner.

- Fold the cut pieces together. you have an inside or outside corner.

Place it on the ceiling and check the geometry. If it is not even enough, it can be slightly corrected with a knife, and in the case of minor defects and wide gaps, you can use a putty.

Using fillets

You can not make fillets yourself, but immediately purchase those that were initially prepared for docking. This is how they produce expanded polystyrene fillets, which do not need to be adjusted to each other.

The baguette that will be fixed to the left must have a right cut, and the right baguette must have a left cut. When creating the inner corner, make the bottom section rise above the top, for the outer corner everything should be the other way around.

Attach the baguettes to each other, if necessary, make undercuts at the joints of the base. If everything is in order, the skirting boards can be fixed with glue or screwed to the walls with further sealing of the seams.

How to cut a ceiling plinth in the corners: instructions and recommendations

A high-quality renovation requires an attentive and accurate attitude to detail. Finishing the work with the ceiling, you need to arrange it well. for this, ceiling skirting boards are used. As a rule, the installation of slats does not cause any particular difficulties; you will have to tinker with the corners. Let’s take a closer look at how to cut the ceiling plinth in the corners, talk about different methods, and give useful recommendations.

Ceiling skirting boards from any material can be cut using one of the methods described below. They are suitable for everyone except for plastic ones: they are made out using ready-made corners.

What tools will be needed?

For ceiling plinths, the following tools may come in handy, depending on the chosen method of work:

- Saw on wood. Suitable for working with wooden ceiling plinths.

- Metal sheet. Suitable for other types of skirting boards (foam, plastic, etc.).

- Miter box. The tool is a chute, which has the shape of an inverted P, where mowing lines are outlined at angles of 45 ° and 90 ° for cutting.

- Electric miter saw. Can be used instead of a miter box, helps to achieve high cutting accuracy.

- Electric jigsaw. Easy to operate, with the help of it you can efficiently and correctly cut a corner without burrs.

- Stationery or construction knife. Suitable for Styrofoam skirting boards, it is important that it has an excellent cutting blade, and therefore must be well sharpened.

How to join skirting boards in the corners

When a certain part of the skirting board is glued and a small distance remains to the corner, so as not to be mistaken with the length, it is necessary to leave a margin. To begin with, you can cut off a piece that will be 10-15 cm longer. Then cut the corner in a convenient way, try it on a dry surface, attach the plank to the ceiling and highlight the place to which it needs to be shortened. Cutting is performed at an angle of 90 °.

Next, you need to correctly join the corners. The made ceiling moldings are attached at an angle of 38-45 °, so the classic 45 ° is not always suitable at the joints. In various cases, the cut edges do not join and leave gaps. For this reason, after the initial trimming of the corners, it is necessary to carry out a “dry” and the most accurate joining of the baguettes directly to the ceiling. Especially you have to tinker with wood and plastic materials.

Having completed the rough joining of the skirting boards, glue or screw the fillets to the walls and ceiling, then, if necessary, use a putty and seal the seams at the end.

Important points on how to cut ceiling plinth in corners

Let’s consider how to correctly cut the corners of the ceiling plinth and get an excellent result the first time. Follow a few helpful tips:

- Before fastening, both parts must be matched to each other. Place both halves together. The surface of the wall must be dry. Finding defects, you can easily level them with a knife.

- Several trims may be required. Don’t be discouraged if it takes a long time and has to make a few trims, especially if this is your first time doing the job.

- Determine the correct length of the planks in the corners. For the inner corner, the length of the plank must be adjusted exactly from corner to corner; on the outer corner, the measurement is taken from the inner point in the direction of the room.

- If the corners generally match perfectly, but there are small gaps in the middle, they can be repaired with a putty.

How to make an even corner: ways

The most difficult thing is to cut the corner so as to get a perfectly flat one: the surface of the materials used is not easy to cut, in addition, you need to observe good joining, preferably without huge gaps. How to make a corner on a skirting board? You can use several methods: with a miter box, without a miter box, using decorative corners, as well as an alternative way.

Using a miter box

If the corners and walls in the room are even, you can use a special carpentry tool. a miter box. This is an inverted U-shaped chute in which the mowing line is marked for cutting at 90 ° and 45 °. The part in which you need to make a gash is laid inside, a saw is inserted into the guides. The part is held in place, cut at the desired angle.

This is what the miter box looks like. Can be plastic, wood or metal

In the case of skirting boards, not everything is so simple: they must simultaneously adhere to two surfaces, therefore they must be pressed against one or the other wall of the miter box. When working with ceilings, they are pressed in the side closest to you.

The sequence of actions when finishing the outer corner, you need to make a gash at an angle of 45 degrees. Place the miter box in front of you. Trying on how the plinth will be located, determining which part of it will be attached to the ceiling. In order not to get confused and cut off the ceiling plinth correctly, put the strip that will be located on the right on the right, the one on the left on the left.

How to cut a corner on a ceiling plinth: install it correctly in a miter box

Press the part that is on the ceiling to the bottom of the miter box. The other side is closer to you and raised. Lean it on the wall of the device so that it does not stagger when cutting. That is, the front of the skirting board turns out to be turned away from you. Do the cutting direction as shown in the photo below. By folding the two cut pieces together, you get a protruding outer or outer corner.

How to make the outer corner of a skirting board using a chair

First put the cut-off parts in place “dry”, without applying glue. If the geometry of the corner is not so perfect, you can tweak it a little with a knife. It is easier to cover small errors with a special putty.

The situation is very similar with the inner corner of the skirting board. First you try on which side will be on the ceiling, press this part to the bottom of the miter box, lean the second part on the wall closest to you and make cuts as shown in the photo below.

How to make an inner corner of a ceiling plinth using a miter box

And again, first try on without applying glue, if necessary, slightly adjust. Then apply a thin bead of glue to both surfaces that will adhere to the wall or ceiling.

Your own version of how to use the miter box correctly is shown in the video.

How to get the correct angle

Most of the problems when working with skirting boards arise in the design of corners. Since the surface of the products is complex, it will not be possible to simply cut off at the desired angle: it is also necessary to cut it so that they dock and, preferably, without large gaps. In reality, there are several ways to make the corner of a ceiling plinth perfect (or almost).

What is it made of and what is it called

The very first skirting boards on the ceiling were made of plaster. They were cast in special molds and then installed on the ceiling with mortar. Such figured ornaments were called fillets. Today you can rarely see them: they are expensive, and outwardly they are almost indistinguishable from the cheaper options. And the name is almost lost.

The most popular ceiling skirting boards are made of polyurethane or polystyrene. They are inexpensive, look great, easy to install, have a wide range of profiles and patterns. The width can be from 5 mm to 250 mm. They are used in almost any room, decorated in any style. An exception is wooden houses with a corresponding interior. Wooden products are most often used here. the style dictates its conditions.

There is also a similar plastic finish. It is mainly installed in bathrooms. But even in damp rooms, you can safely mount polyurethane strips. they are not afraid of damp.

You need to cut the ceiling plinth in the corners of any material in one of the ways described below. The only exception is plastic skirting boards: you can arrange such a corner only using ready-made corners.

How to make a corner of a skirting board without a miter box

Few people in apartments or houses have angles exactly 90 °. Small deviations are easily corrected after fitting. But not always. Then you have to mark everything “in place”. under the ceiling.

You will need a finely contoured pencil (hard. it is not so visible on the ceiling, but leaves quite clear marks near), a small piece of plinth, a ruler and a good stationery knife if you work with polyurethane (polystyrene) baguettes or a metal saw for working with other materials.

Apply the plinth to the corner, draw along the outer edge with a pencil. Apply to the other side of the corner, also mark. You have a cross on the ceiling, the center of which marks the place where the plinths of the ceiling plinth should converge (look at the photo). Having installed a piece of plinth in the corner, which will be glued there and resting it with its end on the wall, transfer the mark to it.

How to make corners on skirting boards without using special tools

Now take a ruler and connect the edge of the skirting board with the marked mark. If you just put the plinth on the table and cut along the mowing line, the two parts in the corner will still not fold: the inner part will interfere. It can be trimmed later by trying on the ceiling. The second way is to place the piece to be cut on the table with the piece that will be on the ceiling. And cut along the mowing line, but holding the knife at an angle of about 45 °. It will still be necessary to correct, but much less (and less chance of error).

Repeat the same operation with the second bar. Put it to the desired wall, rest the butt against the adjacent wall, mark the place where the cross is drawn, draw the line and then cut it off. Correction Carried out “dry” without applying glue.

You repeat exactly the same steps for the outer (protruding) corner. Now you know another way to make a corner of a ceiling plinth, and without a scissor or other special devices.

How to cut ceiling plinth in corners

The quality of the ceiling finish greatly affects the appearance of the room. Therefore, they try to do everything perfectly, or very close to it. The finishing touch to the design is the ceiling plinth. They give the finish a complete and holistic look. The strips themselves are mounted on flat surfaces simply: on special white glue, but problems arise with the design of the corners. Without knowing how to make the corner of the skirting board correctly, a lot of material deteriorates. How and what to cut it in the corners and tell you.

With decorative corners

There is one more, the easiest way. For skirting boards made of polyurethane or polystyrene, use ready-made, factory decorative corners. They are installed in a corner, strips are glued to them closely. Cutting them if necessary is very simple: a few millimeters with an ordinary clerical knife.

Examples of finished fillet corners

What and how to cut

Working with skirting boards made from different materials means using different cutting tools. When working with a wooden ceiling plinth, it is more convenient to work with a saw on wood. All others, including plastic ones, made of foam and other polymers, are better cut with a blade for metal. The result is a smoother cut, less burr. Saws are usually used when working with a miter box.

Corner design looks attractive

When working with polystyrene skirting boards, they cut them with a good office knife without special devices. Its blade is quite thin and even, the cut is smooth, not wrinkled. If you use a saw with polyurethane or polystyrene, do not press hard: you can wrinkle.

In general, in order to get used to the tool and material a little, take a piece and practice on it: cut, saw, trim. So there will be fewer problems when working.

How to dock in corners

If the installation of the first corner is completed, we can assume that you have already learned almost everything. “Almost”, because you still need to learn how to join the corners and cut the planks to length. When some part is already glued and there is a small distance to the corner, how not to be mistaken with the length? The answer is simple: leave stock.

At first, you can cut a piece 10-15 cm longer: it will be possible to redo it several times if something does not work out right away. Then you make a corner in the way described above, try it on dry, adjust everything so that the result suits you. Only then can you attach the already cut strip to the corner and mark the place to which it can be shortened. You need to trim at exactly 90 °. It is not necessary to use a miter box. Just try to put the knife (hacksaw) perpendicular to the surface.

How to cut a plastic skirting board: tools and fixtures

At the final stage of arranging the floor, the places where the topcoat adheres to the walls of the room are usually covered with baseboards. Recently, the most popular are plastic products. They are not only aesthetic and varied, but also very functional. The question of how to cut a plastic skirting board arises from any home craftsman who has encountered this procedure for the first time. The tools and devices for carrying out such work are quite simple and quite affordable.

Varieties

There are several types of plastic skirting boards for the floor, depending on the material of the topcoat:

- Special T-shaped profile for framing carpeted floors. To decorate such products, strips are used, cut from the flooring itself, which are fixed with double-sided tape.

- L-shaped products specially designed to fix linoleum to walls.

- Versatile, suitable for floors of a wide variety of materials (from tiles to laminate or parquet boards).

In terms of functional features, such products are:

- with a cable channel equipped inside the fillet (one or more) for laying wires for various purposes (telephone, antenna, computer or electrical).

- with pressed-in rubber strips around the edges for a snug fit against rough and uneven walls.

In terms of geometric dimensions, the choice is also wide enough. The width of the fillet, which is usually chosen, is commensurate with the height of the ceiling of the room, and can be from 40 to 150 mm. The standard length is 2 or 2.5 m. The thickness of the profile in the lower part, depending on the design, is in the range of 10 ÷ 38 mm.

Miter box: varieties and methods of use

A miter box for cutting plastic skirting boards is a special device designed to accurately cut at a certain angle. The simplest products are made from wood or plastic. In geometric shape, they represent a segment of an inverted U-shaped profile. The sidewalls have narrow cuts for the hacksaw blade. Until recently, the most common attachments were three-cut attachments that cut the end of the skirting board at 45 ° and 90 ° angles. However, the layout of modern apartments is very diverse and it is often necessary to equip different corners of the premises. Therefore, manufacturers produce products with a large number of slots designed for installing a hacksaw blade at various angles.

.

The application algorithm is quite simple:

- Using a marker and a ruler, we mark the cutting line of the cut.

- Press the profile tightly against the vertical wall of the device so that the markings clearly coincide with the installation site of the saw.

- Saw off carefully.

You can cut the plastic skirting board with a hacksaw for metal. This tool has its merits: small cutting teeth and a small spread. However, the low longitudinal stiffness of a narrow hacksaw blade can adversely affect the quality of the machined surface. It is better to use special butt saws for this (with a wider and stiffer blade). Hardened prongs handle plastic easily.

complex designs are a base with clamping clamps (for fixing the workpiece). The kit already includes a saw mounted on special guides. The cutting angle can be adjusted within wide limits. The base materials are metal or high-impact plastic. But such devices are already more expensive. So, popular rotary models from Gross or KWB with a double-sided saw (size and sharpening of teeth for various materials), depending on size, already cost 2,200-4700 rubles.

It is very simple to use such devices:

- set the required angle;

- we press the fillet to the frame with the help of clamps, so that the marking is strictly under the saw blade;

- making a cut.

And even if you decide to make repairs only in one room, then you should think about how to rent such a device and not think about how to cut the plastic baseboard. Ease of use, speed and quality of processing will pay off the money spent in full.

Advantages of plastic products

Compared to their counterparts made of wood or MDF, plastic skirting boards have a number of advantages. Their undoubted advantages include:

- Durability and strength.

- Moisture resistance. They are suitable for installation in rooms with high humidity (bathrooms, showers and toilets).

- They do not need to be painted or other protective coating applied.

- The construction market offers a huge selection of colors: from a variety of monochromatic to imitating the structure of expensive wood species. It is easy to choose fillets for any interior solution of the room.

- Easy handling and wall mounting.

- Convenience with subsequent care. The only limitation: it is unacceptable to use abrasive cleaning agents, which can scratch the upper decorative layer.

- Affordable price.

- Safety for human and animal health. All modern polymeric materials for this purpose are manufactured in strict accordance with sanitary standards and requirements.

Tools and fixtures

When arranging the finishing framing of the floor, any home craftsman reasonably has three main questions:

- How to cut a plastic skirting board?

- How to do it carefully and at the required angle?

- How and what to fix the cut pieces to the wall?

You can cut long products into separate parts of the required length using:

- angle grinder (fitted with a thin cutting disc);

- electric jigsaw;

- hand saw (for metal or with fine hardened teeth).

The final choice of what to cut a plastic skirting board depends on the tools already available, personal preferences and experience.

How to Scribe a Skirting board perfectly.

To securely fix the fillets to the walls of the room, you will need:

- a perforator (with a drill of the required diameter) or an electric drill (with an impact mode);

- a set of dowels and screws;

- screwdriver or screwdriver (to save time and effort).

For neat sawing off of pieces at the right angle, you will have to purchase a miter box (of course, if it is not on the farm). You can’t live without it.

How and what to fix

The simplest, least labor-intensive and rather reliable method of fastening is the use of universal quick-drying adhesives such as “liquid nails”. The disadvantages of this method include:

- When dismantled (if necessary), the product will most likely be damaged, therefore, initially it becomes a “disposable”.

- The inner surface of the fillet must have a sufficiently wide flat strip to be able to apply the required amount of adhesive.

If the delivery set of the plastic skirting board for the floor includes fasteners: metal (or polymer brackets) or special long profiles, then first they are fixed to the wall using dowels and self-tapping screws. Further installation is quite simple. The product is neatly snapped onto the already fixed fixtures. The advantages of this method include: the possibility of multiple dismantling (this is especially convenient when changing the wallpaper: the lower edge of the wall decoration can be brought behind the plinth).

The presence of a cable channel with a decorative outer strip allows you to simply screw such a fillet to the wall through pre-drilled holes.

Docking of individual segments

- for arranging internal and external corners;

- for horizontal joining of straight segments;

- for sealing ends.

These devices are either simply snapped onto the ends of the profile with the help of special tendrils; or in the places of their installation, brackets are attached to the wall, and then the docking elements are fixed to them.