Battery voltage of an electric screwdriver, what is the difference

How to choose a drill

The drill is one of the most popular construction tools. Without it, it is difficult to imagine not only repairs, but also ordinary everyday situations when you need to hang a shelf or curtain. However, the huge variety of models on the market will easily baffle even a professional repairman, let alone a layman. Therefore, we will try to present the most complete range of drills offered by modern manufacturers, and figure out how to choose the right one from this sea of models.

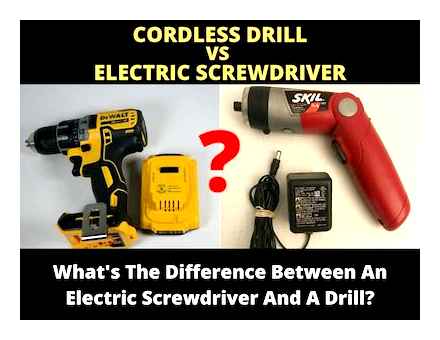

Differences between a drill-electric screwdriver and a conventional drill

The main difference between this tool and a conventional drill is the mandatory presence of the function of screwing in and out of fasteners. Such a tool is very convenient, as it allows you to solve several problems at once.

Most often, screwdrivers are presented on the market in a cordless version. They are convenient, as they allow you to work independently of the electrical network and not get tangled in the wires. There are also electrical models that operate from the mains. Therefore, if you need to work for a long time and not think about when the battery charge runs out, you can choose the mains drill-electric screwdriver.

How to choose an electric drill

An electric drill is an indispensable thing for both a repairman and an ordinary user who from time to time has to drill holes to hang a picture, or assemble an elementary piece of furniture: a shelf or a simple cabinet. Let’s try to figure out what kind of drills there are and how to make the right choice.

How to choose a wrench

An impact wrench is a hand tool for working with threaded fasteners of various diameters. It will not be difficult to choose the right model if you know the main characteristics of the tool and its capabilities.

Characteristics affecting the choice of a drill-electric screwdriver

Battery voltage, capacity and type (for cordless drill-electric screwdriver) The power of the tool depends on the voltage that the battery provides to power the tool.

The battery capacity determines the operating time of the tool: the higher the capacity, the longer the operating time.

Battery type for device operation: Ni-Cd, Ni-MH, Li-Ion, Li-power and Li-HD.

Nickel-cadmium (Ni-Cd) has a low cost, can work in cold weather. Cons: relatively small number of charge / discharge cycles, self-discharge up to 20% per month, memory effect. Ni-Cd battery must be fully charged / discharged to avoid shortening the operating time of the tool on a single charge.

Nickel-metal hydride (Ni-MH) with the same dimensions as Ni-Cd, has a high capacity and self-discharge from 3 to 7%, reduced memory effect, designed to work in cold weather.

The lithium-ion (Li-Ion) battery does not have a memory effect, self-discharge is about 1% per month, but when working in cold weather, the battery is quickly discharged.

The new generation Li-power and Li-HD batteries can operate at temperatures up to 18 and 30 ° C, respectively, without fast discharge.

When choosing a specific type of battery, we advise you to be guided by whether you already have a cordless tool. In this case, you can choose a drill without batteries and a charger in the kit and save money, and use suitable tools from an existing tool as a power supply.

The higher the torque, the greater the working range of the tool.

| Torque value | Recommended tooling size, mm | Maximum allowable tooling size, mm |

| Up to 20 Nm | 3,5×50 | 3,5×50 |

| Up to 30 Nm | 4×50 | 5×150 |

| Up to 35 Nm | 4.5×60 | 6×200 |

| Up to 40 Nm | 5×100 | 6×280 |

| Up to 48 Nm | 5×120 | 6×300 |

| Up to 60 Nm | 6×200 | 8×240 |

| 90-110 Nm | 8×350 | 10×600 |

Drill drivers with high torque. from 110 Nm and more. can be used for drilling holes in ice.

Number of speeds The higher the speeds, the more efficient the tool. High speed is usually used for drilling holes, low speed for screwing / unscrewing self-tapping screws.

Number of revolutions The maximum number of engine revolutions per unit of time. Even at low power, the high number of revolutions provides the tool with high productivity.

Number of torque steps Affects the ability to control the tightening torque. The greater the number of torque steps, the higher the likelihood that all screws and screws will be screwed to the required depth.

Chuck type Drills usually use chucks:

Reverse This function reverses the direction of rotation of the tool from CW to CW. Used for turning out the rig.

Pulse mode Only present in Metabo. The essence of the pulse mode is that the spindle rotates with jerks, while a temporary increase in torque occurs. Pulse operation increases tool efficiency.

Illumination Used for spot illumination of the working area.

Operating modes Manufacturers offer impact drills and hammerless drills.

The hammering function makes it easier and faster to drill holes in hard materials, especially in concrete, by means of a rotational-translational motion. But such a tool still loses to a punch in performance. So consider whether you need a hammer drill, or better get a cheaper no hammer drill and hammer drill specifically for concrete work.

Maximum drilling diameter Characteristic shows the maximum possible drilling diameter in wood, in metal.

If, after familiarizing yourself with the characteristics, you still have doubts about choosing a model, be sure to evaluate the ergonomics of the tool: its weight, thickness and shape of the handle, etc. This will help you finally make your choice and purchase a convenient and reliable tool that will last a long time.

Electric drill for home: how to choose

A home drill should be able to do everything, while being comfortable, durable and preferably inexpensive. At home, you often need to screw a shelf to the wall, assemble new furniture or fix old ones, and just make repairs. all this cannot be done without a drill. Let’s look at the main characteristics and features of the tool that will help you make the right choice.

Summarizing

Summing up the article, it is worth noting that the power of the battery of an electric screwdriver, although it is an important parameter when choosing a suitable model, is much more important than the voltage and capacity indicators. And it is often worth paying attention to the torque only if it will be used not only for screwing in, but also for drilling. You should also know that the maximum power of a cordless electric screwdriver of all commercially available models has a device with a voltage of 36 V, a torque of 60 Nm and a capacity of 3000 mAh. Such equipment is rather difficult and not very convenient to use without professional experience. And, therefore, you should opt for less productive options produced by well-known and reliable brands such as Bosch, Hitachi, Makita, AEG, DeWALT and Metabo.

In this article, we would like to touch on the topic of choosing an electric screwdriver, take a closer look at their types and, of course, technical characteristics that you should pay attention to when buying this type of tool in order to fully answer a question that has recently arisen more and more often, namely. how to choose an electric screwdriver for home, summer cottage or work.

Using a car battery

The principle of such alteration does not differ from the method using charging from a laptop. Thanks to today’s trends for small-sized impulse chargers, non-automated linear analog devices are bought in the car market at a very attractive cost.

If the voltage on the battery changes smoothly, then it will completely fit any screwdriver, and the alteration of such a tool is done as follows:

- To connect a screwdriver to a car battery, you should use cheap wires with a small cross section, auto wires for lighting are suitable.

- Cut off the so-called “crocodiles” on all sides of each of the wires, strip the wire from insulation by 2-3 cm at the free end.

What is the duty of a screwdriver. Power

Do you think that the simpler it is in size and not just W, the better? It turns out differently. I took it on pila.prom.ua.

Chucks and reducers

Screwdrivers come with either a quick-release three-jaw chuck (clamping range of the tooling from 0.5 to 13 mm), and with a hexagonal tool seat with a 1/4 inch shank. Keyless chuck is more practical and allows you to use any tool of suitable diameter. Of course, the larger the chuck diameter, the more versatile the electric screwdriver.

The hexagonal chuck is convenient for frequent tool changes and when working in hard-to-reach places. To drill with such an electric screwdriver, you must use drills with a hex shank. Possibility to install a conventional chuck with a hex shank.

Rotation from the engine to the chuck is transmitted by means of a gearbox. The gears inside the gearbox can be made of metal or plastic. Metal gears are most common in powerful professional screwdriver models.

If the battery is faulty: how to make an adapter for a screwdriver?

There are two methods to make an adapter: use an old battery pack, it already has a connector that fits a screwdriver, in other words, connect the wires directly to the handle.

Connecting an old battery pack

Connecting an old block is done in this way:

-

The first step is to disassemble the battery pack, for this purpose unscrew the screws as shown in the figure.

Applications of the electric screwdriver

- tightening / unscrewing screws, screws, bolts and other fasteners

- drilling holes in wood, metal and brick

- stirring of building mixtures and paints

- drilling holes for winter ice fishing

Which type of electric screwdriver to choose: corded or cordless?

There are 2 large groups of electric screwdrivers: corded models, which tend to be more powerful, and cordless models that run on a battery.

An important parameter to consider is the weight of the electric screwdriver. With the same power, corded screwdrivers are lighter than cordless screwdrivers. Their weight directly depends on the weight of the battery.

- screwdrivers with wire

- cordless screwdrivers

Comparing Milwaukee 12 & 18 Volt Drills

Which model of electric screwdriver to choose?

You have a choice between the types of screwdrivers:

- Straight screwdrivers, the body of which corresponds to the screw-in axis. These screwdrivers are well suited for workplaces where they can be suspended from a drum system with a top-down screwing direction. Some straight screwdrivers are designed to work with numerical control on workstations.

- Pistol-shaped screwdrivers with curved body for better grip.

- Angle screwdrivers that allow you to reach the screws located in hard-to-reach places.

- straight screwdrivers

- gun-shaped screwdrivers

- angle screwdrivers

How to choose an electric electric screwdriver ?

The choice of an electric electric screwdriver depends on how you intend to use it. For example, will you often use it in construction? For construction or renovation? In a machine shop? For furniture? For assembly?

The second point that needs to be determined is the frequency of use of the electric screwdriver. If it will be used all day, it is better to use the model with a wire. However, if it will only be used for 2-3 hours a day, a rechargeable model is ideal, perhaps with an extra battery and charger nearby. Do not forget to carefully study the ergonomics of the electric screwdriver, especially if it will be used intensively.

Torque is another important criterion to consider. The increased torque corresponds to a high tightening force. The higher the torque, the easier screwing is, even in hard materials.

Torque is directly related to the power of an electric screwdriver. For corded screwdrivers with mains supply, the power is directly related to the motor power. It ranges from 450 to 705 W (watts). If the screwdriver is powered by an external transformer, the higher the supply voltage, the higher the power of the electric screwdriver. The power of cordless screwdrivers depends on the voltage of the battery. It can range from 3.6V to 18V (volts) for the most powerful screwdrivers. In the case of cordless screwdrivers, the high voltage provides longer autonomy and eliminates the need to charge the batteries too often. Some screwdrivers are called impact drivers: they are used for intensive screwing / loosening.

Rotational speed is a key characteristic, especially if you need to use an electric screwdriver regularly: Corded screwdrivers tend to have a higher rotational speed than cordless screwdrivers. Typically, screwdrivers have one single rotation speed. For corded screwdrivers, it is between 3000 and 6000 rpm, and for cordless screwdrivers, between 180 and 450 rpm. For impact screwdrivers, the speed is indicated in beats per minute: it ranges from 3,000 to 50,000 beats per minute.

- screw configuration

- frequency of use

- torque

- energy source

- rotational speed

How to choose the right electric electric screwdriver

An electric electric screwdriver is a portable electrical device that allows for easy screwing and unscrewing. The head of the electric screwdriver is equipped with a holder that can be magnetic or have a quick release system. The holder allows you to quickly attach the bit that matches the impression on the screw head.

This manual only applies to screwdrivers, portable power tools that only have screwdriving and unscrewing functions. They should not be confused with screwdrivers.

What are the benefits of choosing a cordless electric screwdriver?

Cordless screwdrivers can be used in any work environment. Cordless electric screwdrivers are convenient and can be used indoors without a power source. They are limited by the autonomy and power of the battery.

Cordless screwdrivers are especially suitable for assembling furniture as they allow you to move around with ease. They are also widely used for fixing drywall and for dismantling or assembling car body parts. On the other hand, the battery charge must be sufficient to guarantee the torque required for screwing. It is recommended to provide at least one spare battery to avoid battery drain problems.

For portable screwdrivers, it is important to keep in mind the weight of the device with the battery, which can be about 2 kg for high power screwdrivers.

As a rule, cordless screwdrivers are equipped with lithium-ion batteries. These batteries have the best performance to date: they are lighter than other battery types and have better charging capacity. The higher the intensity of the battery, the higher its autonomy. Screwdriver batteries are generally of three types: batteries less than 1.5 Ah (Ah), batteries 1.5 to 2 Ah, and batteries greater than 2 Ah.

Battery specifications for cordless screwdrivers:

- their power is expressed in volt-amperes (VA). The more powerful the battery, the more autonomy the electric screwdriver will have and the higher the torque.

- their voltage affects the torque: the higher the voltage, the higher the torque will be.

- their intensity affects autonomy: the higher the intensity, the longer the battery life will be.

What are the Benefits of Choosing an Electric Screwdriver with Wire?

The corded electric screwdriver is designed for intensive use. It is characterized by high torque. Another advantage is its low weight due to the absence of a battery. You can choose the corded model if the power source is close to where you use the electric screwdriver.

The corded electric screwdriver is suitable for use in industrial assembly stations, mechanical workshops, that is, in confined areas. Its advantage is heavy use. However, the wire connecting it to the power supply may be a limitation due to its length (restricting access to all parts for screwing or unscrewing) or even a risk of malfunction if it is routed through the passage.

Portable corded electric screwdrivers are usually designed to operate on a single-phase mains supply. Cradle screwdrivers typically require 32 or 40 volts DC power from the control box.

What options are available?

Some screwdrivers are equipped with a torque control system. They can disengage when the set torque is reached, either because the screw is fully tightened or because the screw is seized to avoid transmitting torque to the operator. This system can be mechanical or electronic.

The most modern screwdrivers include electronic settings for connecting to external systems, allowing very precise settings. The cheapest screwdrivers provide only mechanical adjustment of torque and speed. Some inexpensive screwdrivers have no adjustments at all.

There are also screwdrivers that are equipped with an LED that allows the user to correctly position the tip on the screw head in poorly lit work areas.

- power pair regulation

- lighting

How to properly charge the battery for an electric screwdriver?

The cordless tool is convenient in nature, in places where there is no stable permanent access to power supply. The absence of a cable allows you to avoid inconvenience with extension cords, fear of overloading the network, entanglement with wires, inability to crawl to hard-to-reach areas.

The operation of the cordless tool has its own characteristics. How to properly charge the battery without damaging it? What are they made of, how do they differ? Answers. in the article.

Features and rules for charging the battery of screwdrivers

The batteries are made from different materials. This affects the size, weight, the ability to drill at subzero temperatures, voltage, capacity, susceptibility to the memory effect. The latter especially affects the principle of charging an electric screwdriver.

The memory effect is the loss of capacity achieved by incomplete discharge of a battery. If you stop using the tool before it is completely discharged, the device will “remember” this and will not use the resource in full. Failure to properly handle the battery will reduce capacity.

Checking the battery condition with a multimeter

It will be helpful to determine the reason why the battery is not charging. The procedure will reveal the health of the batteries. Here are some easy-to-implement methods that you can use at home. Prepare the equipment: in addition to the multimeter, you will need tools for disassembling the battery (pliers, soldering iron, screwdriver, knife.

- Check the battery on charging by taking readings at 30 minute intervals. The voltage should rise steadily until fully charged.

- A quick method to check the condition of the battery. We measure U with no load. We compare the result with the real voltage and the number of elements. The indicators differ. the battery has non-working parts that need to be replaced.

Charging methods without using a charger (non-standard methods)

NEED TO KNOW! We do not recommend using the information from this paragraph in practice. We provide for informational purposes.

There are non-standard methods on how to charge the battery of an electric screwdriver without a charger:

- car charging,

- universal charger,

- external energy source.

The effectiveness of such actions can be justified if there is no proprietary charging. Safety questionable. recharge possible. We do not recommend using these methods. they can lead to failure, damage to the battery and are dangerous for the user. Purchase a branded battery of a brand similar to the screwdriver or suitable in terms of characteristics.

What types of batteries are there?

What types of batteries are used by screwdrivers?

- Nickel cadmium (NiCd). The first type of devices, holds a charge for a long time, is equipped with sufficient capacity. There is a memory effect that prohibits charging when the battery is not fully discharged. Therefore, frequent recharging is unacceptable, this leads to a reduction in the battery capacity. Before using for the first time, first fully charge the unit, then start using the tool. Nickel-cadmium are used with budget-class screwdrivers. They are cheap. Suitable for infrequent use.

- Nickel metal hydride (NiMH). They replaced nickel-cadmium. environmentally friendly and weigh less. Worse keep charging when idle, which can quickly deplete battery capacity. It is advisable to recharge before each use, always take the charger with you.

- Lithium-ion (Li-Ion). They are characterized by sufficient battery capacity. Free from memory effect, designed for intensive and regular use. They are quickly charged, cycles are up to 1000. They are distinguished by a relatively high cost. Discharges faster when operated at low temperatures, giving an unstable flow of energy. Store such batteries half-discharged, periodically replenishing capacity.

Electric screwdriver battery device

- The case on which the contacts are located (connected to a charger or a power tool).

- “Banks” (as a rule, there are several of them), united by a common chain.

- For safe operation, there is a temperature sensor to prevent overheating.

- Voltage (V) is an indicator that characterizes the capabilities of the tool. It affects how difficult tasks can be accomplished with it. The voltage can be described as the equivalent of the power of network devices. The indicator is not constant: it reaches its peak when the battery is fully charged, gradually decreases during the discharge process. That is why it makes sense to perform work that requires a high impact force, at first.

- Capacity characterizes how much energy the device stores. Affects the duration of work on a single charge. We must remember. one device with one battery will work for different times (depending on the complexity of the tasks).

- Weight and dimensions affect how comfortable they are to use with the tool. It will be inconvenient to hold a device with a heavy battery on the weight for a long time, which will affect productivity and quality of work performed.

- Additional functionality. The indicator reflects how much energy is left before a complete discharge. Useful to plan working hours. Some manufacturers produce batteries that are compatible with a wide variety of tools: trimmers, screwdrivers, power saws, jigsaws.

Storage rules for the battery of an electric screwdriver

Devoid of memory effect: can be recharged at any stage. Do not allow a complete discharge. it turns off the protective controllers that prevent overloads. As a result, the device may not withstand intensive use, fail.

Before storage, the battery is discharged almost completely (to the state of an inoperative tool). To put the device away for long-term storage (more than 6 months), perform 3 to 5 full charge-discharge courses.

BOSCH vs Black & Decker. Electric Screwdriver

than other types are subject to rapid self-discharge. After a long storage period, you need to put the battery on the charger for at least a day in order to replenish the energy reserves. There is a decrease in capacity after 300 charge-discharge cycles.

Which battery for an electric screwdriver is better to choose

The cordless electric screwdriver is a rather convenient and demanded tool. The independence of the power supply makes this device mobile and allows you to work in hard-to-reach places. But despite all the advantages, the rechargeable battery (AKB) is the weak link in an electric screwdriver. Therefore, when choosing a power tool, you first need to understand what types of batteries exist, what is their difference, the pros and cons of different types of batteries.

Replacing batteries with similar ones

On some units, you can see the mounting screws that need to be removed. But on most battery packs there are no self-tapping screws, since the body is glued together. To open such a block, you will need to carefully insert a screwdriver into the gluing place (shown by an arrow in the photo) and press lightly so that the walls of the case are detached. The same actions need to be done around the entire perimeter.

After opening the block, you will see the batteries in it.

- You need to solder quickly, not allowing the battery to heat up, as it may become unusable.

- For connections, you need to use the “native” plates, desoldering them from the old batteries (they have the desired cross-section and resistance).

- It is important to correctly connect the plus and minus of the battery. The elements must be connected in series: the minus of the previous battery must be connected to the plus of the new one, and the minus of the new battery to the plus contact of the next battery.

After connecting all the elements, it is necessary to equalize the potentials on all batteries, since they are different. Carry out one charge-discharge cycle: connect the charger to the battery overnight, then let it cool down for a day and measure the output voltage in turn on all the cells. If everything went well, then on all batteries the indicator will be the same. within 1.3 V.

Now the battery needs to be discharged by inserting it into an electric screwdriver and loading the latter to the maximum. The main thing is not to overheat the engine of the tool. Give him a little rest. Bring the battery to full discharge. Repeat this procedure 2 more times (full charge and full discharge).

Replacement with lithium batteries

Replacing NiCd cells with Li-Ion is also not difficult. It is known from the school course that if the batteries are connected in series, then their voltage ratings will be summed up. For example, your electric screwdriver runs on a battery with a voltage of 14.4 V, which means that it can be replaced with four 3.3 V finger batteries. This voltage will be enough, because the lithium batteries do not “sag” too much when starting the device.

It is recommended to buy batteries from well-known manufacturers, for example, Sistem A123. The LiFePO4 battery of this company has a capacity of 2400 mAh, sufficient for the normal functioning of an electric screwdriver. If you buy batteries via the Internet, then they will cost you less. around 900 rubles for 3 pieces.

When buying batteries, pay attention to whether there are copper strips on their contacts. If they are, then the soldering process is much easier.

You will also need to purchase soldering acid instead of alcohol flux. In this case, overheating of the batteries will be minimized. The soldering iron must have a power within 65W.

You can learn more about how batteries are replaced with lithium batteries by watching this video.

Lithium-ion batteries

Li-Ion batteries significantly outperform other types of batteries. The advantages of lithium-ion batteries include the following:

- almost complete absence of the “memory effect”;

- You can recharge the lithium-ion battery at any stage of discharge, without fear of loss of capacity;

- no power loss at low battery charge;

- the effective service life is 5-8 years;

- low self-discharge;

- takes little time to charge;

- there are no toxic elements;

- high power with small dimensions.

- sensitivity to impacts (may explode with strong impacts);

- the battery does not tolerate full discharge and overcharge. this causes the battery to fail;

- discharges quickly at low temperatures;

- high price;

- service life is lower than that of nickel-cadmium batteries.

It is difficult to say unequivocally which battery is better. Basically, you must decide for what purpose you are going to purchase an electric screwdriver. If for home use, which implies infrequent switching on with long interruptions in work, then you need to choose a tool with a nickel-cadmium battery.

This can be explained by the fact that during long-term storage without recharging the NiCd battery does not lose its properties, provided that it has been completely discharged.

Lithium-ion batteries are the professional choice. They are designed for continuous, long-term and uninterrupted operation. The recharge time of the battery is also important for a professional tool. But it’s worth remembering one rule: a lithium battery cannot be brought to full discharge.

Varieties of batteries for an electric screwdriver

There are 3 types of rechargeable batteries on the power tool market:

- (NiCd) nickel-cadmium;

- (NiMH) nickel metal hydride;

- (Li-Ion) lithium-ion.

Nickel-cadmium batteries

This type of battery is the most common, although it is over 100 years old. NiCd batteries have good capacity and low cost.

Nickel-cadmium batteries have the following advantages.

- Durability. With proper operation, the battery can last 8-10 years.

- Ability to work at low temperatures. The battery power is practically not reduced, which allows using the tool in the winter outdoors.

- High degree of reliability and unpretentiousness to working conditions.

- The battery can withstand a thousand charge-discharge cycles.

- The battery can be stored for a long time in a discharged state.

Since NiCd batteries are not “afraid” of full discharge, you can work with the tool until it stops completely, that is, until the battery is deeply discharged. Only then can you put it on charge, without fear that the battery capacity will decrease.

However, nickel-cadmium batteries are not without their drawbacks. Toxicity of internal battery filling causes disposal problems.

In some European countries, the operation of nickel-cadmium batteries is prohibited in order to preserve the environment.

Batteries of this type are quite heavy when compared to other types of batteries. In addition, they have a “memory effect”. This phenomenon occurs in a nickel-cadmium battery when it is prevented from fully discharging. If you turn on such a battery for recharging, then it will “remember” this value and during further work it will be discharged exactly to this mark. This will lose a significant portion of the battery’s capacity. The figure below clearly demonstrates how the “memory effect” appears.

Nickel metal hydride batteries

NiMH batteries have been designed to overcome the disadvantages of nickel-cadmium batteries. The positive characteristics of NiMH batteries are as follows:

- have smaller dimensions and weight;

- have low toxicity;

- The “memory effect” is poorly expressed;

- have high capacitive characteristics;

- resistant to mechanical damage;

- increased number of charge-discharge cycles (up to 1500).

However, NiMH batteries have their drawbacks:

- it is forbidden to use them at negative ambient temperatures;

- The battery tends to discharge quickly;

- shorter battery life when compared to nickel-cadmium batteries;

- high price;

- takes a long time to charge;

- The battery does not “tolerate” deep discharge.

Thus, although NiMH batteries were designed to compete with nickel-cadmium batteries, they are significantly inferior in performance to the latter.

Battery voltage and capacity

Let’s briefly analyze the widespread opinion. “when two batteries (accumulators) are connected in series, their capacity does not change, it remains the same as that of one battery, so the battery life with such a connection will be less”.

But what about the law of conservation of energy? Yes, when connecting batteries in series, formally, the capacity is considered as that of one battery, and the voltage doubles (or triples, quadruples, etc., depending on the number of batteries connected in series). With a parallel connection of the battery, the capacity doubles (triples, etc.), and the voltage remains the same.

Battery connection options

There is no contradiction here. When people talk about a battery (usually a car battery), they report its capacity, but do not specify the voltage. It’s just that everyone is used to the fact that batteries have a voltage of 12V, and it is implied that it is stupid to mention this. But in general, the capacity without indicating the voltage has no physical meaning. There are batteries of very different capacities and for different voltages. 2V, and 6V, and 12V, and, rarely, 24V. In addition, any identical batteries can be connected in series, in parallel, or in series-parallel at the same time.

But one has only to indicate after the value of the capacity its voltage, how everything falls into place. After all, the energy intensity in any case, no matter how we connect the batteries, will remain the same.

So, if, for example, two 200Ah 12V batteries (for example, Delta GEL 12-200 Battery) are connected in series, you get an energy capacity of 200Ah 24V. And if the same two batteries are connected in parallel, then it will turn out. 400Ah 12V. Let’s check: 200Ah 24V = 480Ah V = 400Ah 12V

But for calculating currents (usually, the nominal charge current is considered to be a current of 0.1C, where C is a value equal to the capacity of the battery), C is taken exactly by the number on the left, i.e. in our example, with a serial connection, C = 200, and with a parallel connection, C = 400. It is easy to see that the power of the charger in both cases will be the same.

For the first case, the charging current will be 0.1200 = 20A, but at a voltage of 24V. Those. charging power, P = 20A 24V = 480W

For the second case, the charging current will be 0.1400 = 40A, but at a voltage of 12V. Those. charging power, P = 40A 12V = 480W

If we consider single batteries, then, for example, one 600Ah 2V battery (see the FAAM Batteries section) corresponds in its energy capacity to one 100Ah 12V battery (for example, DELTA GEL 12-100 Battery).

To get a large storage battery from these batteries (600Ah 2V), for example, 24V, you need to connect 12 pieces of such batteries in series using jumpers (Jumper for 250 mm batteries). The total final capacity will be 600Ah 24V. This energy capacity, if we compare it with 12-volt batteries of 200 Ah each (and these are used in trucks), corresponds to 6 pieces (three battery chains connected in parallel, where each chain consists of two batteries connected in series):

(600Ah2V) 12 = 600Ah24V = (200Ah24V) (200Ah 24V) (200Ah 24V)

Pay attention. in all the figures it is specially shown that if the minus of the inverter is connected to the conditionally first battery, then the plus is to the last one. So it should be connected in order to compensate for the resistance of even thick copper wires connecting the batteries. Otherwise, because of their resistance, at huge currents, the battery “farthest” from the inverter terminals will not be “recharged” or “re-discharged”.

So, the capacity (read “energy capacity”) of the battery (combined group of batteries) is the amount of electricity (ie power equal to the current multiplied by VOLTAGE) that the battery gives off when discharging to the lowest allowable voltage.

In order for the battery to serve for a long time, it must not be discharged more than 80%. For a 12-volt battery, this corresponds to a voltage at its terminals of approximately 11.5V. But here it is important with what current relative to the capacity of the battery we discharge it.

The higher the discharge current, the lower the voltage to which the battery can be discharged. This is because during a rapid discharge with large currents of a relatively small battery capacity, the electrolyte does not have time to mix, and the discharged layer accumulates around the plates. The battery voltage drops and the load is removed. However, after a few tens of minutes, the electrolyte is mixed and the capacity (and, accordingly, the battery voltage) rises.

If you discharge with a small current relative to the capacity, then you can draw out all the energy, which is bad for the longevity of the battery. Always leave at least 20% of the capacity. on this further.

How To. Electric screwdriver repair

Note that during charging, the charger gradually increases the voltage on the battery, and then, after removing the charge, the voltage decreases, returning to a quiet state (for example, on a 12-volt battery, depending on the type of battery, it usually rises to 14. 1. 14.5 V, and after removing the charge, even without load, within half an hour it returns to 12.5. 12.8 V).