Baumaster the punch does not fix the drill in the cartridge. Replacing brushes

Do.it.yourself repair cartridge repair

Sometimes the master needs to disassemble the cartridge for various reasons: whether it is repair, cleaning the tool, lubrication or replacement of certain parts. For competent disassembly of the infantry cartridge, first of all, you need to know the manufacturer’s company, since the analysis process depends on this point.

Among modern manufacturers of electric peorators, the most popular are Bosh, Makita and Interskol. These brands managed to prove themselves in the construction market as a manufacturer of quality products.

In principle, there is no particular difference between the installation of peorators of different companies, but there are small nuances that are quickly solved as the cartridge is disassembled.

Consider how to disassemble the cartridge from Bosh electric drills, since this brand is the most popular and purchased.

First you should push the plastic part and remove the rubber seal. With the help of a screwdriver, you must very carefully remove the ring that fixes the structure and the washer. Under this part there is another fixing ring that needs to be turned, and then under the tool and remove.

Next is the SDS clamp, which includes three details: washer, ball and spring. SDS must be disassembled strictly according to the rules: first of all, there is a ball, then a washer, and the last is the spring

It is important to observe this sequence so as not to damage the internal device

Extension of the service life

The extension of the operational period of the cartridge directly depends on the proper use of the peorator itself. Several useful tips:

- Do not press the tool too much.

- The long.term idle operation of the peorator leads to the premature wear of the cartridge mechanism.

- Working with soft surfaces, it will be correct to use an unstressed mode of operation.

- For drilling especially hard materials, it is recommended to use special lubricants or emulsions.

- It is more practical to work with brown of smaller length.

- The shanks of the drills need to be lubricated after each hundred holes, first cleaning them.

- With long.term work, the tool must be given a break, during which you can cool the drill in oil and examine the peorator.

- The device requires care both before work and after it.

To prevent dust from entering, you can use special devices. Even a trimmed plastic bottle, worn on a drill, will help to achieve this goal.

If you fulfill these minimum requirements, then the tool will work for many years and will not let the master at the right time.

Material and types of Sovers and Burov

The main material for the production of drilling nozzles is steel of different types:

To work with the most durable surfaces. metals, solid stone. the drill tip is additionally equipped with attacks with diamond crumbs. By type of design, the brown is divided into:

Her color will also tell a lot about the drilling nozzle:

- The black. The drill was previously processed overheated by steam. Contrary to the well.known statement that the black drills are stronger than everyone else, this is not so. Here the color does not affect the strength.

- Brown. Such a drill pre.released to remove internal stresses.

- Golden, bright golden. The tip of the drilling equipment of such colors has nitride titanium coating. It adds strength to the drill, but the cost also.

Checking serviceability

Before inserting and fixing the drill in the ashorator, you need to make sure its performance. For this, the tool is included in the network, put in the drilling mode without impact, and then press the start button. If there are no extraneous sounds, uncharacteristic smells, then the unit is ready to work, and you can take up the installation of a storm nozzle.

Important! For the Bosch model, the drill is installed only with a fork turned off from the network.

How to extract a nozzle from a penetrator

Most tools for attaching the working nozzle use fast-and-packed cartridges such as SDS-Plus or SDS, in professional ones, SDS-MAX are often found. Differ in the number of longitudinal grooves and the distance of the drift of the drills. The curtain from the cartridge of any pedorator is pulled out: Bosch, Makita, Zenit the same.

Important ! Before extracting, the cartridge is necessarily lubricated, for example, with a common Synthetic lubricant WD-40, after which it waits at least 10 minutes so that the substance penetrates the nozzle.

- The fork of the electric tool is necessarily extracted from the outlet or extension cord. the device is disconnected from the mains.

- The lower part of the cartridge or the back clutch is diverted along the fastening axis towards the penetrator.

- The second hand is removed from the Gluck without applying significant physical efforts.

- The back clutch is released.

She will return to her former place on her own.

When the cartridge is withdrawn back, the fixing or stopping balls jump out of the closed grooves or grooves, and the nozzle is released from closed grooves.

If the nozzle does not remove, then the drill jammed. Most likely, his shank is mechanically damaged: twisted, curved, flared up.

How to pull out a stuck or broken drill from a penetrator

Ways to get a drill from a penetrator, including a broken one, which is not removed in the usual way, a lot.

Knuckling the drill from the cartridge

The simplest way to solve the problem that does not require disassembly of the cone and special tools. A broken shank is pushed deep into the cartridge to stops using a screwdriver or other similar object. If you do not succeed in doing this with the efforts of the hand, you need to use the core and hammer.

Carbon brushes for power tools

- Kern is inserted into the cartridge to contact with a broken nozzle. With light blows of the hammer drives deep into the cone.

- The lock of the cartridge is squeezed to open.

- The peorator turns on at maximum speeds for a split second.

Due to the blows of the box on the nozzle, it flies out. It is important here that the broken shank does not harm people and objects, including after a ricochet.

Through the extension, the shank clogs inside.

Sometimes the procedure will have to repeat several times.

Using a vise

The stuck nozzle is pulled out using a vice. To do this, through soft gaskets, such as rubber or wood, the drill is clamped between the viges. After the back the coupling is diverted “on itself”, the peorator is pulled back with an effort and slightly staggered in different directions.

As an option, the peorator itself is clamped or otherwise, and the jammed nozzle is extracted using pliers. Captured and pulled out with staggering in different directions.

A way to extract a broken shank using a welding machine

Welders are known that the electric current is not enough for welding metals and maintaining a stable arc. Due to a prolonged touch, it sticks to the welded surface. the so.called phenomenon of sticking the electrode arises.

When deciding to remove the drill from the peorator, the described method should be careful. Due to the inaccurate handling of the welding machine, you can cause micro.officers on the moving parts of the tool. The second feature. with a breakdown of an arc, it is likely to grab a bearing or a rotor shaft to it.

- A vinyl or other tube is inserted into the cartridge with an outer diameter of up to 10 mm and the internal more thickness of the electrode to protect against contact.

- A current is set below welding.

- The mass “throws” at the case of the penetrator.

- The electrode is inserted into the tube and tapping is in contact with the broken shank.

- After the sparks appear. the ignition of the arc. the electrode is held for about a second in a state of contact with a broken drill.

- The network is opened. the welding is turned off, the electrode is extracted from the holder or the clip is removed.

- The cartridge is diverted in the direction of the penetrator.

- The electrode with a sticky part of the drill is extracted.

If it doesn’t work out the first time, you have to try more, but with interruptions in a couple of minutes. They are necessary to cool the cartridge.

On a note! It is advisable to take an electrode with a diameter of 2 mm. It is important not to overexpose it adhered, which is fraught with overloading the electric network, overheating of the broken part of the drill and the champion elements in contact with it.

Removing a drill from a pencil case with a micro.grinder

A welding inverter or semi.automatic does not have every person. You can do without it. A miniature hook is bent from a thin steel wire with a hammer, pliers, a suite.

- The finished hook is inserted into an open or long groove of the nozzle.

- The cartridge is drawn to extracting.

- The broken drill is hooked and extracted.

If it doesn’t work, you should try a couple of hooks-one for each groove of the SDS-Plus cartridge.

When using cheap consumables, the shanks are often riveted up by a boy. The flat surface in the end of the shank becomes similar to the “rose”. Extracting such a drill from a cartridge without disassembling it becomes impossible.

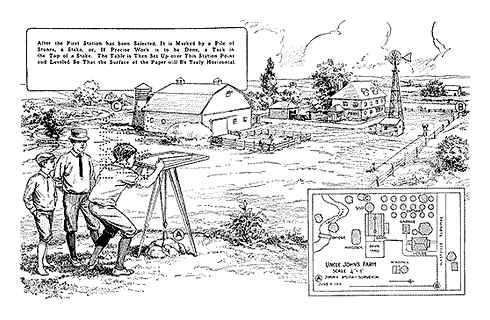

The further process is described by the example of the DWT BH-09 peorator. When disassembling other models, there may be differences in details.

The second situation is the shank of an inexpensive drill. It will not work to extract it described above. After getting a raster sleeve from the case of the penetrator, you need to remove the shock bolt.

If the nozzle is flared up from the end. a cheap consumable was used, it will have to be drilled with a quality drill with diamond or cobalt spraying.

The rivet shank is drilled strictly in the center. Inexperienced masters should take a cobalt drill with a diameter slightly less than the thickness of the stuck equipment.

How to pull a drill out of a fast.packed or two.lump cartridge

In the case of jamming of a conventional drill in the fist cartridge installed in the peorator:

How to pull a stuck drill out of a penetrator?

The performance of repair work most often requires the use of such an instrument as a peorator. They drill holes and dismantle the surfaces. Any power tool during operation is subject to load, and this gradually leads to faults. Often, after the work performed, the problem arises with the removal of the drill from the tool cartridge. To pull out a stuck drill, you need to work a little.

This kind of problem occurs in two cases:

- The drill in the ceremony cartridge, which is used to nozzle of a conventional drill, jammed

- The part was stuck in the clamping lips of the penetrator

The first problem happens due to the need to use a conventional drill in the operation of a drill, which requires a special cartridge-adapter cartridge for manipulations using a peorator. It is inserted into the clip.

After the end of the work, it often cannot be pulled out by the drill, because the clamping element of the penetrator harshly holds it. To remove the drill, in this case it is enough to use a special composition, for example, WD-40. He will relax the clamp within a few minutes. If there is no such remedy, and the store is far away, you can use ordinary kerosene. After 5-10 minutes, you need to try to remove the drill, tapping the cartridge and at the same time shaking the nozzle. This should help, and it will safely free itself, and the clamp must be cleaned and greased.

The second reason for the jamming of the nozzle may consist in the clamp of the penetrator. This type of interference in work occurs under other circumstances. The nozzle in the drill spin around the axis, sometimes performs weak movements of the reciprocal nature. This happens in connection with the transfer of power to the power tool through the lips of the clamping element and the bottom of the cartridge.

The mechanism of the pea transfers energy differently, therefore the drill in the clamp moves differently. The tool contains rotational-attendant and simply shock working functions. The energy to the device is transmitted by a special boy, which hits the tail of the installed nozzle.

There are special grooves on the nozzle, which are firmly fixed in the clamping element, ensuring the transmission of the moment of rotation. Poor nozzles are made of soft alloy, which is not amenable to heat treatment, as a result, the tails do not withstand the load and become unusual.

What to do if the drill is stuck in the penetrator?

Когда в процессе выполнения большого объема работы сверло с противоположной стороны расклёпывается, вытащить его из пеоратора свободно не получается.

To get a drill from the power tool, two ways are used:

- The stuck drill must be taken in a vice, while the tool, holding in the hands, shake to the sides and pull to yourself.

- In a large vice, using rubber lining, so as not to crush the housing, the peorator is clamped. Then the drill is clamped with a small vice and a small hammer is easily inflicted on it to the side aimed at the exit of the equipment from the clamping cartridge.

In both cases, you can use penetrating solutions.

If it is not possible to pull out the drill directly from the cartridge during turning, then you need to remove the details of the cartridge or try to crank the drill back 90 degrees. Its rotation usually leads to a complete replacement of the components of the clamping element.

So that there are no problems with jamming the drill, it is better to use high.quality nozzles of well.known brands. In the process of working to different surface materials, you need to select the appropriate drill.

If attempts to pull the drill out of the device are unsuccessful, then so that the peorator does not break out, it is better to seek help from the master.

Replacement of the cartridge

If you do not have a drawing, photograph the process of disassembling the phone. This will save you from the error when assembling. The following tools will be needed for work: flat screwdriver, plots with long lips, hammer and an open key.

- Remove the rubber tip from the end.

- Picking up with a screwdriver, remove the first locking ring.

- Pull the plastic casing of the coupling down (as for a change of drill).

- Dismantle the second stop ring in the same way as the first.

- Remove the casing of the couplings.

- Remove the spring, stop plates and balls.

- If you can do without replacing the entire node, then add steel details in a suitable container and pour kerosene.

The cartridge is fastened to the spindle usually using a thread. Squeeze it using a vise or gas key. And rotate the spindle with an ore key behind. If there are no faces, then disassemble the case of the oerator, fix the spindle and rotate the cartridge.

Carefully. Do not put the tip in kerosene. Since its rubber is not oil.resistant, it will not withstand a long contact with it.

Installation and assembly of the node is in the reverse order.

The drill is not fixed

The reasons that the cartridge does not hold the shank of the drill, there may be several. Below we list the most likely.

- Wear of the case, locking plates or balls.

- Lowing or breakdown of the lock spring.

- Drying or thickening of lubrication from dirt that prevents the movement of balls-fixers.

Important. During the assembly, do not lubricate the details with technical petroleum jelly. It is used only in conservation. From consistent lubricants are best suited.

Repair of the infantry cartridge

A couple of details of the clamping device can be replaced with similar ones: a worn ball, rubber gasket and lost initial properties, for example, flexibility, spring. Иногда, например, при заклинивании или застревании насадки, усик пружины выскакивает из посадочного места.

With the wear of the remaining components, the repair of the infantry cartridge is practically not carried out, it must be changed to a new. A ball with a spring will have to look not in stores with tools and construction markets, but in service centers where the devices are serviced and repaired. As an option. to order a spare part on the Chinese trading platform. often it is easier to replace the cartridge with a new one than to repair it. It is a little more expensive, but more reliable and faster.

Replacement of the cartridge of the penetrator

Sometimes the old spare parts due to a fair amount of wear or careless operation have to be changed to new. Replacing the cartridge on the oorator begins with the removal of the old clamping device. After it is dismantled, a new equipment is set to the place in the reverse disassembly order.

It is necessary to change the damaged cartridge on the ashrater if its components are worn out: backlash appeared, nozzles fall out or the device sees. The most commonly suffer from locking plates, fixing balls, the case itself. Less commonly, the fixer spring weakens. Sometimes to correct the problem on the construction site, a thin washer is placed under it.

Types of cartridges for the penetrator

The peniterators can use different types of cartridges. Everyone has their own differences.

Tozhcato-Vennian

It is also called a key cartridge. This variety allows you to install a nozzle in which the shape of the shank is cylindrical. The mount is carried out using a special slot key. They are shifted by fists that reliably clamp the working organ. The plus of a gear-cage cartridge is a reliable fixation of devices with a cylindrical and hexagonal tail. But in order to fix or remove the drill in these cartridges, you need to spend a lot of time.

Quickly joke

Quickly and fast.and.packed are mainly used in the design of screwdrivers. There are one.flair and two.lump. Are fixed in the same way as key, only without using the key, everything is done manually. A more reliable mount is provided by two.luminous cartridges. But since the clamp is performed with hands. in reliability, fixation is inferior to the press with the key.

The disadvantage of the fast.fastenced fastener is that with long operation, it unreliably fixes the drill of large diameter. As a result, during the drilling, the instrument turns, which negatively affects the quality and speed of work.

Such a variety is considered the best option for peorators, although it appeared not so long ago. Many people call SDS-patrons quickly. They are suitable for drilling concrete, drilling wood and metal. But their clamping equipment can be of different types, therefore you need to know their features.

Equipped with several types of clamping devices:

- Plus. The tail of the cartridge of the tool designed for use at home.

- Top and Quick. Very rarely used. Buy nozzles for installation on such types of cartridges is not easy. Few firms are engaged in their production. Therefore, when buying, you should look at the modification of the latch.

- Max. These details are used only in specialized pedarators models.

The cartridge for the penetrator reliably fasten the drill. Fixation is carried out using 2 guide wedges and 2 stop balls. The advantages of SDS cartridges are that working with a clamping device is simple and safe. It perfectly combines torque and shock force. 90% of all manufactured peorators are equipped with these simple devices.

Reliable fixing the shank is a guarantee of effective and high.quality work.

How to remove a cartridge from a peorator

Before removing the Bosch 2-26 cartridge from the Bosch Peone, it is necessary to determine what type is installed in it. If the drill flows during operation, the clamping element should be replaced. The method of its fastening depends on the type. If the device is mounted on a screw rod or spindle, you just need to turn it. If the part is fixed strongly, you will have to use additional tools. They beat the screw on the screw head, as a result, strong fixation weakens. With the help of a screwdriver, twist a screw rod. In order to pull out the element mounted on the spindle, it is clamped by the key and the spindle is scrollful.

The disassembly of the cartridge must be carried out regularly for verification and maintenance. To find out what happened to the detail, it may have to fix it, replace it, you need to be able to disassemble it. The cartridge can be removed with a hammer. Fists are diluted to the required position so that they hide inside. A vertical cartridge is put up on the diluted locksmiths so that the case can fit between the lips, and the sleeve (adjusting the coupling, shirt) rests on them. The sleeve quickly heats the sleeve with a hairdryer. A shock absorber is placed on the cartridge on top. It can be a copper or aluminum plate. They hit the case with a hammer, knocking it out of the adjusting coupling (sleeves, shirts). The details are necessarily cleaned, lubricated and collected.

In the process of extraction, experts advise to do the corresponding tags on the case and on the cams. This is necessary so that when assembling everything becomes in its place. Otherwise, the recorded drill will not be discounted.

It must be remembered when the cartridge is disassembled in this way, when knocking down the clips, individual parts often fly apart to the sides. Most often flies out a ring with cloves. which consists of 2 halves. If the user is not experienced, it will be difficult to assemble one whole components.

Before putting a disassembled cartridge in place, it should be cleaned, removed, rust and dust, be sure to lubricate the parts. The internal components of the cartridge are best lubricated with special compounds, lithol or solidol. When assembling a working nozzle in a cartridge, a small amount of grease is applied to the shank. You can not lubricate the details with technical petroleum jelly. It is used exclusively during conservation.

Unlike the key fast.packed cartridge, it is more complicated, so it will be more correct not to disassemble the knot completely. The screwdriver is spread out and praise the adjusting coupling. In order not to damage plastic, you need to act as accurately and careful as possible. The coupling should move, then it is removed with your hands. After that, you need to push the fists as much as possible, insert a metal rod into the cartridge (you can take a long bolt) and hit it with a hammer. With such actions it will be possible to knock out the case from the second half of the plastic coupling.

Disassembling the cartridge is needed not only during repair, but also maintenance

How to insert a drill into a peorator quickly and easy

The ability to work with a drill or drill is basic today. Below we will describe how to insert them correctly in a peorator.

To date, the tool uses the SDS cartridge. Its feature is that it does not require the presence of a key. Unlike a cam cartridge, the process of removing and installing the drill takes a couple of minutes. It is necessary to sequentially do the following:

How To. Replace Worn Power Drill Brushes

- Lower the cartridge down, holding the base

- Insert the lower end of the drill into the hole

- Release the cartridge, the spring will fix it on the starting place, the fixing balls will tightly fix the cutter

- Check the drill fixing in the cartridge, pulling it down. Any backlash should be absent. The maximum permissible distance to which the drill should not exceed one centimeter

- If a fist cartridge is installed, the drill is mounted by rotation of the cartridge, while the thread is delayed

- We are waiting for a complete stop of the rotation of the cartridge

- Pull it down

- We take out the drill itself

- Let go of the cartridge, the spring returns it to its place.

Attention! As a result of friction on the working surface, the metal metal is very hot, it is necessary to use gloves to prevent skin surface burns.

Some tips for using the tool

It would be useful to recall how to work with a peorator. This information will be useful for beginner builders.

- Use the protective equipment when working: bears, gloves, protective glasses.

- You can not make an effort on the penetrator during operation.

- The idle mode of operation of the apparatus is unacceptable.

- If the processed material has increased hardness, then it is necessary to apply grease. An alternative grease can serve as ordinary machine oil.

- In the case of using a long drill, drilling must be done by a shorter.

- To increase the life of the tool, it is necessary to periodically cool the drill in water or in oil, take breaks in work.

The pedorator has firmly entered the life of the builder and installer today. This instrument with proper attitude towards it will serve for a long time.

Dismantling of the intermediate shaft

To disassemble the intermediate shaft pos.57, you need to pull it out of the internal corps. From the shaft pos.58 Remove the leash of the post.55, spring pos.56.

On the other hand: Remove the supporting bushing bus.65, support of the spring pos.64, spring pos.63, gear.combined wheel wheel.62.

Interskol P-26/800er interim shaft

Installation of electric brushes

Remove the mud from the grooves of the brush holder and install the brushes to the area, fixing them with latches.

Now it’s time to check the performance of the penetrator. Connect the peorater fork to the outlet, turn on a short.term peorator while working in “Drilling” mode. After making sure the tools, turn it off. Put the mode switch to the “blow” position. Do not stick the tool. Check the operability of the peorator in this matter. At the same time, you checked the operation of the mode switch.

It remains to check the styling button of the speed of the speed of the speed, to make sure of the reliability of contact connections can be proceeded to installing the costly cover.

The cover is attached with 3 on-line screws M × 4 of different lengths.

Connect the Poorator to the 220β network and check in all modes. Makita 2450 Poorator in other words 2470 is assembled and works properly!