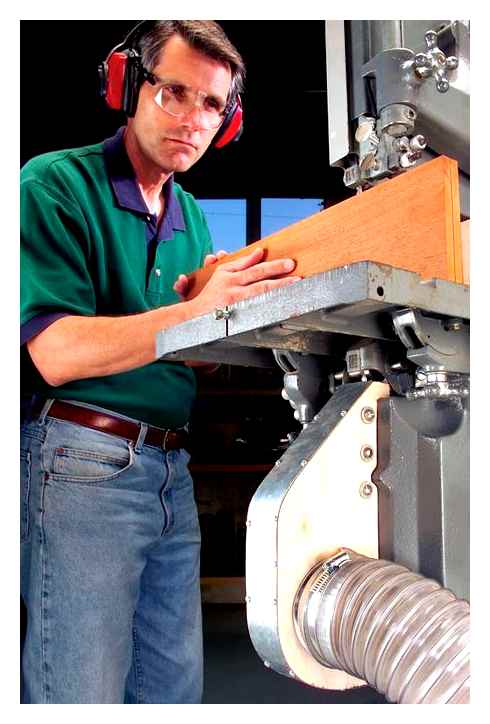

Best Dust Collector for Woodworking. Bandsaw dust collector

Dust Collection

Item #386. 2-1/2″ Router Table Dust PortDust Ports are the most popular fittings used in creating an airway on your router table, bandsaw or any other machine that does not come with a dust port. This Right Angle Dust port allows easy connections from your router table, bandsaw or other machines to your dust collection system using a 4″ to 2-1/2″ reducer (SOLD SEPARATELY)

- Will fit just about any router table fence system.

- The small end of a 4″ to 2-1/2″ reducer fits inside the right angle port.(Reducer Sold Separately)

- Attach a 4″ hose to the larger end of reducer with a hose clamp (Hose Clamp Sold Separately)

Item #441. 4″ to 2-1/2″ ReducerCan be used in combination with the 4″ Router Table Dust Port. The small end on the 4” to 2-1/2” reducer fits perfectly inside the right angle port so you can then attach a 4” hose to the larger end of the reducer with a hose clamp.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

2-1/2″ Extended Router Table Dust Port

2-1/2″ Extended Dust port directly accepts a standard 2-1/4″ Shop-Vac hose end in the dust port opening. No hose clamp is required for this type of connection. You can easily attach a standard 2-1/2” dust collection hose around the outside of the extended dust port opening with a single hose clamp.

- Directly accepts a standard 2-1/4″ Shop-Vac hose end in the dust port opening

- Easily attach a standard 2-1/2” dust collection hose around the outside of the extended dust port opening with a single hose clamp

- The fitting itself attaches to the back of most router fences

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

2-1/2″ Low Profile Dust Port

2-1/2 Low Profile Dust port directly accepts a standard 2-1/4″ Shop-Vac hose end in the dust port opening. You can also attach a standard 2-1/2” dust collection hose around the outside of the dust port opening with a single hose clamp. The fitting itself attaches to the back of most router fences with two standard wood screws. See more product details

2-1/2″ Low Profile Dust Port

2-1/2 Low Profile Dust port directly accepts a standard 2-1/4″ Shop-Vac hose end in the dust port opening. You can also attach a standard 2-1/2” dust collection hose around the outside of the dust port opening with a single hose clamp. The fitting itself attaches to the back of most router fences with two standard wood screws. The low profile makes this fitting an excellent add-on to any drill press fence system.

Features

- The 2-1/2″ Extended Dust port directly accepts a standard 2-1/4″ Shop Vacuum hose end.

- The fitting attaches to the back of most router fences with 2 standard wood screws.

- Attach a standard 2-1/2″ dust collection hose around the outside of the extended dust port opening.

- Outside connection requires a hose clamp for proper connections

- The 2-1/2″ Extended Dust port directly accepts a standard 2-1/4″ Shop Vacuum hose end.

- The fitting attaches to the back of most router fences with 2 standard wood screws.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

2-1/2″ Router Table / Bandsaw Dust Port

2-1/2″ Router / Bandsaw Dust Port is one of the most popular fittings used in creating an airway on you router table, bandsaw or any other machine that does not come with a dust port. Attaches with 4 screws (not included) on each corner. The dust port will accept a 2-1/2” hose. A hose clamp is required for this type of connection. This fitting will also accept a standard 2-1/4″ Shop-Vac hose end, no hose clamp is required for this type of connection.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

4″ Dust Port

4” Dust port can be used on machines with 4” openings, such as bandsaws and joiners. Attaches with 2 screws (not included) at the top and bottom. The dust port accepts 4” hose. A hose clamp is required for proper connection

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

2-1/2″ Round Dust Port Flange

Round dust ports are the perfect way to add a dust port to any machine without one. Attach it directly to your machine with screws (not included). Hose clamps are required for proper connection

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

4″ Round Dust Port Flange

Round dust ports are the perfect way to add a dust port to any machine without one. Attach it directly to your machine with screws (not included). Hose clamps are required for proper connection

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

4″ Bell Dust Port

4″ Bell Dust Port sets up similar to a flange. It is generally used on larger machines, such as the table saw or joiner. The long neck allows for a 4″ hose to be secured in place.

- Generally used on larger machines such as the table saw or joiner.

- The long neck allows for a 4″ hose to be secured in place

- A hose clamp is required for proper connection.

- Measures 9-1/2″ long by 4-1/2″ wide.

Note: A 4″ hose clamp is required for proper connection.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

4″ Elbow Dust Port

4” Flat End Elbow Dust Port Is a great fitting that is fastened directly to your machine when space is limited around the machine. There is no need for all the extra little connector pieces with this one! A hose clamp is required on one end for proper connection.

Note: A hose clamp is required on one end for proper connection. Hose clamps sold separately.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

Mini Gulp Dust Hood

Just like it’s big brother the Big Gulp, the Mini Gulp can be used anywhere in the shop where size constraints are an issue. The hood is 13-1/3” x 7-1/4” and accepts a standard 4” dust hose with a hose clamp

- The Mini Gulp is 13-1/2″ x 7-1/4″ and accepts standard 4″ dust hose with a hose clamp.

- Can be used on your chop saw, lathe, drill press and other machines.

- Place it behind, underneath or where ever is convenient on you machine.

- Great catch all device for dust, chips and debris.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

Quick Dis-Connect Ball Joint Fittings

#477. 4″ Quick Dis-connect x 2-1/2″ Hose end Ball Joint Fitting

The Ball joint fitting is designed to be pressed on to any 4″ tapered diameter opening for a quick and easy fit. The Ball Joint prevents kinking of hose at the connection point which allows for great mobility. The opposite end accepts a 2-1/2″ hose. A 2-1/2″ hose clamp is required on one end for proper connection.

#478. 4″ Quick Dis-connect Ball Joint Fitting

The 4″ Ball joint fitting is designed the same has 477, but the opposite end accepts a 4” hose. A 4″ hose clamp is required on one end for proper connection.

- Ball joint fitting is designed to be pressed on to any 4″ tapered opening

- Stops kinking of the hose at connection point.

- Ball swivels for easy placement.

- Stops kinking of the hose at connection point.

- Ball swivels for easy placement.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

Big Gulp Dust Hood

The Big Gulp works most anywhere. It’s a great catch all for dust, chips and debris. The Big Gulp Dust Hood is 12-1/2” x 16” and accepts a standard 4” dust hose with a hose clamp (not included).

- The Big Gulp is 12-1/2″ x 16″ and accepts standard 4″ dust hose with a hose clamp.

- Can be used on your chop saw, lathe, drill press and other machines.

- Place it behind, underneath or where ever is convenient on you machine.

- Great catch all device for dust, chips and debris.

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

Dust Port Clamp Bracket

This universal bracket allows you to clamp dust collection on your workbench, lathe, chop saw, sanding area or any work station in your shop. The head assembly swivels, letting you direct suction right where you need it. Heavy duty steel bracket clamps from 1/4″ to 2-1/4″ and comes with a 4″ steel hose clamp.

- Universal Bracket. clamps dust collection to any work station in your shop

- Head assembly swivels, giving you direct suction where needed

- Heavy duty steel bracket clamps from 1/4″ to 2-1/4″

- 4″ steel hose clamp included

California Residents: WARNING: Cancer and Reproductive Harm. www.P65Warnings.ca.gov.

A Lung Cancer Scare Motivated Me to Find the Best Dust Collection System for My Woodworking Shop

By Joshua Farnsworth | Aug 25, 2022

A Lung Cancer Scare Motivated Me to Find the Best Dust Collection System for My Woodworking Shop

By Joshua Farnsworth | Aug 25, 2022

Table of Contents (Skip to a Section)

In this video and article I talk about my experience in finding what I consider to be the best dust collector on the market.

I’ll also share my recent health scare that motivated me to stop ignoring the importance of having an effective dust collection system.

My Recent Lung Cancer Scare

Recently I had a surgery that required a CT scan on my chest. After my surgery, the radiologist notified me that the CT scan showed unusual nodules on one of my lungs, which may be a sign of lung cancer.

As you can imagine, that’s not great news to get right after a surgery. They told me that I would need another CT scan after a few months to see if the nodules were growing or not.

So during those nerve-racking months, I had time to think about what could have caused this issue. I figured that if I did have lung cancer, it wasn’t from smoking, because I’ve never done that…but it would have been caused by exposure to so much wood dust.

My Failed Attempt at a Cheap DIY Cyclone Dust Collector

I had always used dust collection in my workshops over the years, but always did it as cheaply as possible. Sound familiar?

When you’re fairly young, you think more about your budget than you do about health risks. For years I had been using cheap single-stage dust collectors, because I figured that they would be better than no dust collection.

Which is true, but it doesn’t make it safe enough to prevent lung diseases caused by sawdust. So a few years ago I attempted to improve the air quality in my workshop by modifying my cheap single stage Grizzly dust collector into a DIY cyclone system, using a special lid and trash can.

Cyclone technology basically means that you’re using a two-stage dust collection system where the bulk of the wood chips and sawdust are first dropped into a can, and then the finest particles are carried away for filtration. This keeps your dust collector from having to filter all the big stuff.

My DIY dust collection system seemed like it would work great in theory, but in reality, this system turned out to not work very well. No matter how much I modified the plastic lid, I couldn’t get it to do a good job at collecting most of the big wood chips and sawdust, so most of it was thrown at the air filter.

Also, my dust collector didn’t have enough CFM to keep up with my machines. CFM is just a measure of airflow. So both of these problems led to fine dust escaping through the air. And anyone who has used a cheap bag-style dust collector knows how much fine dust gets blown into the air when the collector starts up. That’s the fine dust. So the purpose of having a dust collector is kind of missed.

Dust Collection 101

As a woodworker, keeping dust out of your lungs is one of the best things you can do for your health, along with always wearing eye, ear, and respiratory protection in the shop, and making sure you have the same number of fingers at the end of the day as at the beginning. And unlike the treadmill in your basement, collecting dust is something best done intentionally and proactively. In this article, we’ll go through the various options for dust collection, explain what you need to know about pressure and flow rate, explore best practices, and try to keep sarcastic wisecracking to an appropriate minimum. WEN has an extensive lineup of air filtration systems, dust collectors, vacuums, accessories, hoses, and more to meet all your dust collection needs.

Dust collection categories

Broadly speaking, you can break dust collection methods down into 3 categories:

- Point-source: as the name implies, this is collecting dust at its source. Think of a wet-dry vacuum or dust collector hooked up to a tool directly, such as a circular saw or hand sander. This is the method most often used with small and/or handheld tools.

- Central: this method makes use of a central dust collector and a series of ducts or tubing, connectors, and/or blast gates combined in a network. This network hooks up to multiple (usually stationary) shop tools such as sanders, Band saws, table saws, and more.

- Ambient: best used as a supplement to either point-source or central dust collection, this method uses a device such as an air-filtration system to scrub any dust from the air that was missed at the initial collection point, and is important for keeping air quality high and particulate concentration low.

A diagram showing the different types of dust collection.

Before we dive into a bit more detail, it’s important to note that even if you have a great dust-collection system set up, it’s always a good idea to wear proper NIOSH-appoved respiratory protection as an added layer of defense when dealing with wood dust.

Point-source dust collection

Collecting dust at its source is one of the keys to effective dust management. The point-source method offers maximum versatility and portability. Usually, this method will involve one dust collector (or wet/dry vacuum) attached to one other tool at a time. When you move to the next tool, you disconnect the collector from the first tool and connect it to the second. Simple, right?

This method is often the least expensive and most modular, especially for those just beginning their woodworking journeys, or for anyone whose shop space is limited. However, it does involve a little more hassle than central dust collection. disconnecting the collector from each tool and reconnecting it can be a bit of a pain if your project requires many different types of tools to bring it to life.

Central dust collection

The central collection method is best used by those who have large shops, or advanced / professional woodworkers. It requires more resources and time initially to set up a duct network, and obviously, the more machines it will connect to, the more time, effort, and money it will take to set up.

- A central dust collector. It’s often physically positioned centrally in the shop (or as close to centrally as possible) to minimize the distance between the collector and the furthest machines. This minimizes pressure loss (more on that later). This dust collector is almost always a dedicated dust collector, not a wet/dry vacuum, for reasons we’ll discuss later.

- The machines in your shop (duh).

- A ducting network. This network, in turn, consists of:

- Rigid or flexible ducts that connect to each machine and the dust collector. Most permanent setups use 4-inch to 6-inch diameter rigid tubing, which is more efficient than flexible hoses.

- Blast gates to direct air flow within the network. Generally, they should be positioned as close to the collector as possible to maximize efficiency.

- Connectors, cuffs, and fittings to connect the various parts of the network together. They come in all sorts of shapes and sizes.

If you have a small or medium-sized shop, and only need to connect to one or two machines, you probably don’t need a large network of rigid tubing. You can likely get by just fine with a couple of blast gates, flexible hoses, and connectors.

The WEN DC3401 (left) and DC3474 (right) dust collectors are great for use as mobile point-source dust collectors, or can be mounted on the wall for use as central dust collectors in small to medium shops.

Keep in mind that central dust collection may require a large dust collector. Large dust collectors require large motors. Large motors require large electrical circuits. Some 120-volt dust collectors require a 20-amp or 25-amp circuit to run properly. Some dust collectors may require a 240-volt circuit, so make sure that your shop is properly wired to supply the dust collector (as well as the other machines in your shop, which will be running simultaneously). If it’s not, bring in a professional electrician to help get your shop shipshape.

The WEN DC1300 1300-CFM dust collector has two 4-inch inlets for easy connection to larger networks.

Once the initial setup is done, there’s very little adjustment required. Simply turn on the dust collector, adjust the blast gate network to direct airflow from the tool(s) you plan to use, and get to work.

Ambient dust collection

Whether using a point-source method or central method, ambient dust collection is a great complementary option. It will not replace either of those methods, and is intended to help circulate and clear the air in your shop, not to collect dust from a tool or get it off your workbench. Most ambient dust collection is done using an air filtration system, often one suspended from the ceiling for maximum airflow. The system draws air into the housing through its filters, which capture any airborne dust, then exhausts the clean air into the shop. Look for a system capable of cycling the air in your shop several times per hour.

The WEN 3410 remote-controlled air filtration system is a great entry-level option for small to medium shops, garages, and more.

Pressure and flow rate

Let’s shift gears and discuss a bit about the differences and relationships between pressure and flow rate. This is an essential concept to understand when selecting a dust-collection tool, so travel back to high-school physics class with us for a moment.

Pressure is force distributed over an area. In terms of dust collection, it’s the “muscle” behind air movement. It’s often expressed in pounds per square inch (PSI), kilopascals (kPa), or inches of water column (inWC or WC). If you prefer an electrical analogy, it’s like the voltage in a circuit. When there is a pressure difference between two points in space, air flows from the area of higher pressure to the area of lower pressure. Higher pressure means more muscle, if you will.

Speaking of air flowing, the flow rate is the amount (volume) of air that moves through a given area in a certain period of time. It’s often expressed in cubic feet per minute (CFM) or cubic meters per minute (CMM or m3/min). Dust collectors are often rated by CFM. Going back to the electrical analogy, it’s like the current flow in a circuit. Higher CFM ratings mean more flow.

Band Saw Dust Collection

What does this mean, practically? Good question. Two things:

Pressure loss in a network

If you’re setting up a central dust collection network, you will lose some pressure due to resistance in the system. As rules of thumb, a longer network will suffer more losses than a shorter one, and a more-complex network will suffer more losses than a simpler one. The goal is, of course, to minimize losses. To do so:

- Use rigid tubing if setting up a large, permanent network. For semi-permanent connections to a couple of tools, flexible hoses will suffice. Flexible hoses cause approximately 5 times the pressure loss per linear foot as rigid tubing, depending on the diameter, flow rate, and construction. If using flexible hoses, stretch them as much as possible to minimize losses.

- Keep connections as short as you can. Long lengths of tube cause more losses than shorter lengths, even in rigid tubing.

- Avoid 90-degree turns if possible. Every 90-degree elbow causes a pressure loss equivalent to 5 to 10 feet of rigid tubing, again depending on the diameter, flow rate, etc. 45-degree turns or wyes cause about half that loss.

- Make sure your connections are tight. Loose connections invite leakage. Use hose clamps at each connection point. If you’re using flexible tubing, make sure there are no punctures or tears.

The exact numbers and calculations are a topic for another time. Keep in mind that larger-diameter ducting generally suffers less loss than smaller-diameter ducting, but is bulkier, heavier, and more expensive. If you lose too much pressure in the system, you will not collect any dust, or will collect very little.

Air power

Combining pressure and flow rate gives power. It’s important to understand that two different machines can offer the same amount of air-moving power, but do so in two different ways. Maybe one has high pressure and low flow rates, and the other has lower pressure but higher flow rates. One will be suitable for some tasks, one for other tasks. Many vacuums’ power levels are advertised as being a certain number of airwatts, which is a measure of power (both pressure and flow rate, related by a mathematical constant).

The WEN 20861 20V handheld vacuum has a maximum power of 94 airwatts, and is a powerful, portable part of the WEN 20V lithium-ion cordless power tool system.

Another practical example of the difference here can be seen when putting wet/dry vacuums and dust collectors head to head.

Wet/dry vacuums versus dust collectors

As a general rule of thumb, wet/dry vacuums offer higher pressure and lower flow rates. Dust collectors offer lower pressure but higher flow rates.

Wet/dry vacuums are often used to clean up general shop debris, wood chips, small pieces of concrete, and other miscellaneous construction detritus. Their higher pressure allows them to suck up heavier debris than dust collectors can, but they don’t have very high flow rates, and are usually connected to flexible hoses. They do their best work when used as point-source collectors.

The WEN VC4710 and VC9209 wet/dry shop vacuums are ideal for cleaning up all sorts of messes at home or on the job site, and work great as point-source dust collectors thanks to their included HEPA filters.

Dedicated dust collectors, on the other hand, tend to have much higher flow rates than shop vacuums, meaning they are not as good at picking up heavy debris, but are very good at moving lots of small debris (i.e. sawdust). As we mentioned earlier, this is why wet/dry vacuums are almost never used as central dust collectors.

For general point-source collection, it’s important to choose a tool that will work well for your needs. A dedicated dust collector may not perform as well as a shop vacuum when connected to woodworking machinery that produces large chips (planers, jointers, etc.), since those chips are heavier than fine sawdust. However, when used with machines that produce fine sawdust (sanders, Band saws, table saws, etc.), dust collectors excel.

Dust collection: best practices

If you just need the basics, here they are:

- Wear NIOSH-approved respiratory protection.

- Use point-source dust collection (whether a wet/dry vacuum or dedicated dust collector) whenever possible. If you have a central dust collection setup, use it as well.

- Ambient dust collection machines, like air filtration systems, are a helpful supplement to point-source and central dust collection.

- If you have a machine that produces large chips, a wet/dry vacuum may perform better than a dust collector. If your machine produces fine sawdust, a dust collector will excel.

Your lungs will thank you, and considering you’re not tracking dust all over the house, so will your family.

Conclusion

Thanks for reading! If you have any questions, or need help deciding which WEN dust-management machine is right for you, please give us a call at 1-847-429-9263 (M – F, 8 – 5 CST), or drop us a message here to talk to our friendly and knowledgeable technical support team.

Powertec Wall Mounted Dust Collector Review | DC5370

When you step up to larger tools as I did recently when buying a Jet 14-inch bandsaw, you find they have larger dust ports. My bandsaw has two 4-inch dust ports. Using a shop-vac for a dust collector will not begin to work on larger tools that need more CFM (Cubic Feet per Minute) of airflow of the larger dust ports. The solution? Buy something like the Powertec Dust Collector. In my case, the wall-mounted DC5370 worked best, taking up no floor space. In fact, I was able to hang it right at the ceiling.

Pros

- Does not take up floor space

- Clear viewing window to know when it is time to empty the filter

- Extremely well built

- Works well for one tool

Powertec Wall Mounted Dust Collector Performance

Let’s get real for a moment. If you think you can buy a dust collector this small, run 4-inch hoses all over your shop, and have a system that works you are going to be sorely disappointed. A must-watch video for anyone before they buy a dust collector is James Hamilton’s (AKA Stumpy Nubbs on YouTube) 11 Common Workshop Dust Collection Mistakes.

I bought this small dust collector knowing my bandsaw was going to be the only tool I would use with it. My other tools use shop-vacs because they have 2-inch dust ports. I am not qualified to explain the physics of it, but the air in a 4-inch air hose cannot be compressed enough to create adequate suction when reduced to a 2-inch dust port. You are much better off using a shop-vac on tools with 2-inch or smaller ports and a dust collector on 3-inch or larger ports. Watch James Hamilton’s videos to find out more on the subject. He is much more of an expert on dust collection than I am.

Knowing what mistakes not to make, I used PVC to hard pipe the duct all the way to the floor so I could keep my flexible hose as short as possible. Then I was ready to use the Powertec Dust Collector.

I was thrilled with the results. I am building a custom coffee table and needed to rip over 100 linear feet of red oak on my new bandsaw. Both the bandsaw and the dust collector worked great! There was a little dust on the table of course and a little ended up in one spot on the floor—but that was all. There was zero dust floating around in the air when I was done.

I have an industrial ceiling-mounted air filter that automatically senses when dust is in the air and turns itself on to clean it. It is so sensitive, if someone smokes a cigarette, it will turn on. Even after sawing over 100 feet of wood, the air filter never sensed any dust in the air thanks to the Powertec Dust Collector.

Noise

I only have one complaint about the Powertec Dust Collector—the noise level. This thing measures 85 dB(A) from 6-feet away. My Band saw only measures 75 dB(A) at 2-feet (not under load).

When I first turned on my bandsaw I thought “wow, a tool I don’t need hearing protection for!” Then I turned on the Band saw’s dust collector. Bummer.

Powertec Wall Mounted Dust Collector Design Notes

The first thing you will notice when you open the Powertec Dust Collector is how extremely well built it is. Actually, the first thing you will notice is how cheap the expanded polystyrene they used in shipping is. It is the old school type that gets everywhere, including inside the unit, all over my floor, and all over me. Make sure you put the bag on before you turn on the unit just to catch the flying polystyrene. Ask me how I know this is a good idea! I’m still findings the stuff in my house weeks later!

I have 10-foot ceilings, so I hung my dust collector 1-inch below the ceiling. I park my table saw below the dust collector when not in use. Even if you have 8-foot ceilings you could do the same thing. You could put this over a workbench, in a corner, or in other unused off-the-ground space. It hangs down a total of 46-inches counting the 1-inch of clearance you need to lift it on and off the included wall bracket.

Speaking of the wall bracket, It is too narrow to span across multiple studs. The Powertec Dust Collector weighs a hefty 45 lbs. I spent 19 years installing 40,000 works of art on the walls of a museum. Many of them were huge and heavy. In my opinion, 45 lbs is too heavy to install on a single stud when it is cantilevered out 16-inches. And this weight does not include the sawdust. I have no idea how heavy the bag is going to be when it is full. I would like to see Powertec make their wall cleat wider. In the meantime, the simple solution is to mount the unit on a board that spans two studs.

The only control on the Powertec Dust Collector is a simple on/off switch with a removable safely lock-out key. Since I am unable to reach the switch without a ladder, I bought a remote control rated for 15 amps. I mounted this to my bandsaw near the on/off switch with double-sided tape so I would not lose it. It works great.

Powertec Wall Mounted Dust Collector Price

The Powertec dust collector retails for 249. I bought mine at Amazon for 218. Powertec is known for its dust collector fittings, hoses, blast gates, adapters, and all the parts you need to get a dust collection system working.

The Bottom Line

If you only have a single tool that needs a dust collector, this is a good option. If you have more than one tool with large diameter dust ports, I would suggest you look at a larger floor model. The only downside is the noise level. If you normally wear hearing protection anyway, this is not a big deal.

Powertec Wall Mounted Dust Collector Specifications

- Model DC5370

- 2.5 micro filter bag

- 1 HP motor, 120/240 V

- 7 amp at 120V, 3.5 amp at 240V

- 537 CFM air flow

- 4-inch duct inlet

Setting Up the Best Woodworking Dust Collection System

Setting up an efficient and easy-to-use dust collection system is important in every woodworking shop. A workshop with excessive piles of wood chips and surfaces coated in sawdust can affect how well you work and how much you enjoy being in your shop. importantly, wood dust can directly impact your personal health and safety.

The best woodworking dust collection systems contain and collect dust at the source, minimize any mess that is left after your project is complete, make it easy to clean up the mess that is left behind, and makes your shop a healthier place to work. In this article you’ll learn how to select and set up the best dust collector and dust collection accessories for your shop.

This article will answer the following questions related to Dust Collection.

Why Do I Need a Woodshop Dust Collection System?

Woodworking projects tend to have three parts: Plan it. Build it. Clean up after it.

It’s that third part. clean up. that can take the joy out of a favorite activity. Every method of working wood – sawing, routing, planing, jointing, drilling, sanding, even whittling – creates waste in the form of dust of some consistency. Heavier chips and saw swarf pile up or go flying, while extremely fine dust becomes airborne and travels wherever the air currents take it.

And no matter how well you clean up your workspace afterward, wood dust – especially very fine dust – can go everywhere. If your shop is anywhere in your house, even separated in a basement or garage, fine dust can still find a way to travel to all parts of it. Even a freestanding workshop or garage can quickly turn into an uncomfortable dust-coated environment.

Is Wood Dust Dangerous?

The short answer: Absolutely. The nature of that danger depends on the type of dust being produced.

Physical Danger

At first glance, you’d consider that planers, jointers and routers create chips, not dust, and you’d be partially correct. These tools use a knife edge to scrape shavings or chips off wood. This heavier wood waste can fly a few feet or more, but quickly succumbs to gravity.

Without a means of collection in place, expect woodworking dust and chips to go everywhere. A vacuum hose or even a simple collection bag would easily contain this mess.

No problem, right? That’s why they invented brooms. But until you start sweeping, those chips and dust are everywhere you’re moving, creating a walking hazard. If your shop floor is extremely smooth, those chips can be slippery.

You also have to consider that flying chips don’t always fly where you want them to. At best, those chips will only go down your shirt, but can also fly right into your face and eyes. Even with eye protection, flying chips in your face are a dangerous distraction.

Saws create finer waste – the literal “sawdust” we talk so much about. Although it’s more on the granular side than chips or flakes, it can still fly, can still get into your face and eyes, and can still create a walking hazard.

Health Danger

Both of the above types of woodworking also create fine dust. You see the chips or sawdust, but there’s also a fine dust so light it’s difficult to see. Plus, it almost immediately becomes suspended in shop air.

It’s hard to even use the word “dust” to describe what sanders put out. It’s more an extremely fine powder than anything else, and possibly the most dangerous woodshop dust.

Then there’s even finer dust, the type generated by sanders that’s more powder than dust. This stuff is the most dangerous. Suspended in the air, you take in whole lungfuls every time you breathe. Short, minimal exposure is a respirational irritant. Longer exposure can worsen existing conditions like asthma or impaired breathing. In a worst case scenario, continued long-term exposure to extremely fine dust can lead to serious conditions such as pneumonitis, chronic bronchitis, emphysema and even various cancers.

Aside from respiratory issues, airborne fine dust is a constant irritant to skin and eyes. And if you have an allergy to any wood species – cocobolo, some cedars and many nut-based woods are commonly cited – your susceptibility is increased when the air is filled with fine dust.

Fire Danger

Your woodshop is an environment already filled with flammable material: wood. But properly stored, it’s not a particular danger in itself. But converting it to wood dust that goes everywhere can create fire hazards, a danger that only increases with the amount of dust produced.

Sure, you can vacuum up most of this fine dust off the floor and other surfaces, but it can also collect on top of hot light fixtures, inside machinery housings, atop (and under) water heaters and furnaces, etc. The more that accumulates, the greater the risk.

Even if wood dust doesn’t spontaneously combust or cause an actual fire, should a fire start from other causes the dust can act as an accelerant or even, in extreme cases, an explosive fuel.

Annoyance

Aside from outright danger, dust is also a general annoyance that can impact how – and how well – you work.

Larger chips and sawdust can build up in critical areas that prevent components from being worked accurately. Chip buildup might slightly tilt a workpiece against the face of a miter gauge, for example, or prevent a component from accurately resting against a stop. Chips underneath workpieces tend to lift the wood off a table even if only slightly, resulting in an inaccurate measurement or cut.

Fine airborne dust will absolutely settle on any freshly applied finish. Dust can also play havoc once it gets into the innards of machinery. Gears and belts, already attractive to dust because of lubricants, can quickly be caked with accumulated oily dust.

Any electronics in your shop? Fine dust will seep into laptops or other computer equipment, radios and other entertainment devices, even cell phones, causing excess heat and performance issues. In the case of any video screen – TV, laptop, phone, even small LCD screens on machinery – dust can creep in and coat the underside of the clear screen where it can’t be removed, affecting appearance and visibility.

This computer screen shows how fine dust has actually crept inside the left edge of the monitor. There is no practical way to get this dust out.

As noted before, this fine dust will travel anywhere in your house that air moves, so expect furnace filters to clog more quickly, leading to a fine film of dust on every surface or your home.

Methods of Dust Collection

There are numerous ways to manage woodshop dust collection, and figuring out what is best for you depends on factors like the way you work, your particular workspace, and how much time and money you want to invest. Let’s take a look at the different ways to grab and contain dust.

On-Board Dust Collection

While it wasn’t always true, most of today’s hand-operated tools come with some means of collecting dust, typically a tool-mounted canister or bag. Although their effectiveness varies, you should always use these when possible.

Among the most basic means of controlling dust, a properly attached canister, such as this FlexiPort Dust Canister (left), or tool specific dust bag (right), will grab some of the dust produced by handheld power tools.

Virtually all miter saws and circular saws these days include a dust port and bag. These typically accomplish sawdust collection by means of centrifugal force – the spinning blade shoots the lion’s share of sawdust directly out the port and into the bag. Of course, that blade goes through a full 360-degree rotation, part of it on the other side of the workpiece, so a lot of sawdust gets flung elsewhere.

Handheld planers and biscuit joiners also use ports and bags, but are somewhat more efficient since the cut is “closed,” that is, the blades don’t penetrate the other side of the wood, so chips have only one direction to go – toward the bag. But you’re still relying on centrifugal force, so not everything is captured.

Sanders have seen the greatest improvement in dust collection, with bags and canisters that excel at grabbing fine dust. An impeller arrangement inside the sander actually creates a suction that, combined with perforations in sanding discs, draws dust through the tool and into the bag or canister. Again, though, some dust escapes. (Especially if you don’t empty the bag frequently.)

Some larger tools, like thickness planers. also use impellers that forcefully eject chips and shavings to a dust port and collection bag.

Hose-Assisted Dust Collection

Replacing canisters or bags with a hose connected to any vacuum source greatly increases the efficiency of these tools’ dust handling capabilities. Further, other tools that don’t typically come with collection receptacles, such as routers and drills, can be outfitted with dust shrouds that also connect to a hose.

Router dust collection can be difficult, but many newer machines incorporate a dust shroud into the tool base. Connected to a shop vacuum or dust collection system helps maintain a clean shop.

These methods work by combining the tools’ innate means of dust handling (centrifugal force or internal impeller) to guide dust away from the tool, and then using a vacuum source to forcefully draw it out of the tool and to a collection point. The means of providing a vacuum source – and attaching it – can vary.

What Size Vacuum or Dust Collector is Right for my Shop?

For single small tools – typically anything that uses a canister or small collection bag – a standard shop vacuum or dust extractor outfitted with a hose adapter like the Dust Right FlexiPort Connectors will do the trick in most cases. Ditto for many small benchtop tools. Of course, that takes into consideration that the vacuum will be rolled to where you’re working, and that it’ll be handling only the small volumes of dust those tools create.

For larger tools, stationary equipment, multiple connections, or collection running through a system of longer ducts, you’ll do better to consider collectors with more power.

I’m using “power” here as a catch-all phrase. Dust collector “power” is really a combination of a few factors: the horsepower of the collector system, air velocity (expressed in linear feet-per-minute or FPM), static pressure and, most importantly, the volume of air being moved (expressed in cubic-feet-per minute, or CFM). These figures intertwine and the topic can get technical fast, so the main rating you want to consider is when shopping for a dust collector is CFM. Learn more about how dust collection systems work and CFM demands for each tool.

What CFM Rating Does My Dust Collector Need?

Standard shop vacuums typically pull 100-200 CFM. Dust collectors generally start in the 450-650 CFM range, and go up from there depending on motor size.

Clearly, then, a shop vacuum is the most basic collection you can use, and although it isn’t the best it is far better than none at all. Plus, for tools that have internal impellers, combined with the centrifugal force of a spinning blade directing dust to the dust port they can be more efficient than simple CFM ratings would indicate.

Most small-shop stationary machinery, meanwhile, requires 300-600 CFM. Larger machines, of course, have higher CFM requirements. For stationary machines, then, a regular dust collector is the better choice.

CFM Requirements for Each Tool

| CFM Requirements | |

Types of Dust Collection Machines

Shop Vacuums and Dust Extractors

The easiest, least expensive and most readily available means is any standard shop vacuum. Hooked up to a tool, shop vacuums provide plenty of suction for handheld tool use, and even for some larger tools. Plus, shop vacuums easily roll to wherever you’re working. Their main downside is excessive noise and lack of power to handle the amounts of dust and large chips produced by larger stationary tools, but for smaller tools shop vacuums provide an excellent way to begin wrangling dust.

Shop vacuums are the workshop general-purpose means of dust collection, and as such are designed as all-round suck-’em-up machines. Sawdust, dirt, spilled pet food, even water can be picked up and sent to the shop vac’s tank. With few exceptions, they don’t discriminate – everything that comes through the hose ends up at the same place. That’s because most shop vacuums are single-stage machines that do not separate what they pick up, and generally incorporate only one type of filter medium.

Shop vacuum filters are usually pretty basic, and allow a lot of small particles – the kind that go airborne – to pass right through. Higher-end units offer better filtration, but they remain compromised by the lack of dust/debris separation and can clog quickly.

Still, shop vacuums come in a variety of sizes (including handheld models), are generally inexpensive, have high velocity that’s great for cleaning out small cracks and crevices, and they’ve rightly earned their spot in modern workshops.

A dust extractor is a step up from a shop vacuum. Generally larger and heavier than simple vacuums, extractors are designed specifically for handling dust. Nearly all extractors are two-stage machines that separate larger woodworking debris from fine dust, collecting each in separate areas of the machine. Their filters excel at grabbing extremely fine dust.

Whereas shop vacuums are low-volume/high-velocity machines, extractors are just the opposite and move a larger volume of air a bit more slowly. This increases efficiency for handling fine dust, much in the way larger standalone dust collectors do. Lower air velocity (along with better insulation and tighter seals) also makes them quieter machines than typical shop vacuums.

Nearly all dust extractors incorporate adjustable power control and an electrical outlet that pairs the machine with specific tools (top left photo). Plug a sander, say, into the extractor’s outlet and triggering the sander also starts up the extractor for automatic dust collection. Turning off the sander also turns off the extractor. Many dust extractors also feature HEPA filters and removable bags (bottom left photo). Brands such as Festool also manufacture a variety of accessories, such as this Festool WCR 1000 Work Center (right photo). Dust extractors are more expensive than simple shop vacuums, but their higher efficiency and considerably better dust handling – especially for extremely fine dust – makes them an attractive option.

Best Upgrades for Your Shop Vacuum or Dust Extractor

The benefits of a two-stage collector can also be applied to shop vacuums. If you regularly use a shop vacuum in your shop, you can add two-stage functionality by attaching it to a Dust Right Dust Separator. When used with most power tools and shop vacuums, the Dust Right Separator captures sawdust, wood chips, and other debris before it enters your vacuum, preventing the loss of suction power caused by a clogged vacuum filter.

Dust Collectors

The next step up from a shop vacuum is a true dust collector. powerful and able to move a higher volume of air (measured in CFM or Cubic Feet Per Minute), dust collectors extend dust handling to even the largest – and sometimes multiple – stationary tools.

The Dust Right 750 CFM Mobile Dust Collector uses gravity to collect heavier dust and chips in the lower bag, while a top-mounted canister wrangles the fine dust.

Among dust collectors, there are two types. A single-stage collector sucks up dust, chips and shavings and then blows everything through the machine and into a collection bag. A two-stage collector adds a conical section before the bag that spins the dust as it enters, causing heavier chips to fall through to the bag, while lighter dust continues on to a filter.

Single-Stage Dust Collectors

Single stage dust collectors, like this Dust Right 1250CFM Dust Collector draw filthy air through the machine, and collect everything – fine and coarse – in a filter bag.

Two-Stage Dust Collectors

Two-stage collectors like this JET 1-1/2HP Cyclone Dust Collector include a cone-shaped section that separates heavy chips and dust to a lower collection can, then send finer particles to filter and separate bag.

What is the Best Woodworking Dust Collection Hose Size?

As noted above, air-volume CFM ratings are important. However, a lot can affect that rating. Most dust collector specs given by the manufacturer are typically measured using a 4″ duct or hose. Decrease that diameter and CFM drops; increase it and the CFM goes up. Think of drinking a thick milkshake – you don’t get much with a thin straw, but you get more with a fat one.

Dust Collection For Your Band Saw

The two most common sizes of dust-collection hose or ducting used in small shops are typically 4″ and 2-1/2″. Use a 4″ hose/duct, and you’ll get the rated CFM, but a 2-1/2″ hose/duct cuts the CFM about in half. This doesn’t mean that 2-1/2″ hoses aren’t any good – they are! They’re just less efficient. For that reason, use 4″ hose/ducts whenever possible.

Rockler’s Dust Right Expandable 2-1/2″-dia. Hose retracts to allows the author’s planer to store out of the way against a wall when not in use. When needed, it stretches up to 12′ to give plenty of working room.

Learn : Choosing the Right 4″-dia. Dust Collection Hose

While 4″ dust ports are common for most stationary woodshop machines, many, usually benchtop tools, use smaller 2-1/2″ ports. For these, get your 4″ hose or duct as close to the machine as possible and then use an adapter to connect the hose. This keeps most of the dust collection “run” at the wider diameter, delivering higher CFM from there to the collector.

This section of a dust collection system features a 4”-to-2-1/2” Y-Connector between two 4″ PVC pipes. Two Schedule 40 PVC to 4″ Hose Adapters were used to splice in the Y-Fitting, The Y-Fitting diverts and reduces from a 4″-dia. to 2-1/2″-dia. hose that connects to one of the tools in the shop.

Hose/duct diameter aside, friction also affects CFM efficiency by increasing static pressure. Ribbed and flexible hoses create more friction than smooth hoses or tubes. Sharp turns in hoses and ducts are the biggest culprits, so try to keep duct/hose runs as straight as possible. For that matter, the length of the run also causes more friction, so shorter is always better. Mismatched connectors can create slowdowns, as can overuse of spiral hose.

Of course, all these things are often necessary components of connecting and running dust collection from the tool to the collector, so some decrease in efficiency is always to be expected. No system is perfect, but strive to keep things that affect CFM to a minimum.

What Fittings do I Need to Connect my Dust Collector to the Hoses and Tools?

Sometimes you’re lucky enough to be able to connect a tool directly to a collector, but when using a collector for multiple tools – especially in a duct-based system – you’ll quickly discover that one component of the system may not match or easily connect to another. For that, there’s a host of fittings available.

Today, some standardization is appearing, but there are also accessories geared specifically for dust collection that are readily available that make connections a lot easier. Rockler’s Dust Right FlexiPort connectors, utilize rubber fittings in different sizes that mold to fit tool dust outlets of almost any shape. The new Dust Right FlexiPort Click-Connect Upgrade Kit turns your FlexiPort hose kit into a quick connecting system.

A hose splice, like this Dust Right Ready-Mount 4” Hose Splice clamps in place to create hoses of any length.

Learn : Choosing the Best Dust Hose Fittings

For certain applications you need a longer hose or to divert the line in different directions, especially when setting up a whole-shop system. The Dust RIght Ready-Mount Fittings include a variety of fittings that allow you to smoothly change directions, split into multiple lines or transition between two different size hoses. The key when changing hose diameters is to keep smaller connectors and hoses closer to the tool, and enlarge as the line returns to the dust collector. This will help maintain higher CFM for most of the length of the hose/duct.

PVC sewer and drain piping is a favorite for setting up ducts for a whole-shop dust collection system, but they don’t directly connect to most dust fittings. Rockler’s 4″ fitting for PVC pipe easily makes the connection.

Dust RIght Ready-Mount Fittings, such as this Y-fitting create branches for dust collection hoses and ducts to connect two or more machines to the same system

In any system connected to multiple tools, you’ll want the airflow to go from only tool at a time to maintain peak CFM. Blast gates installed inline to each tool can open or close suction as needed.

Blast gates cut off the suction to tools that are not in use, focusing the dust collection suction on the tool that is being used.

Direct suction to only the machine you’re using with Stable Gate Blast Gates.

What is the Best Dust Collection System for Each Tool?

A direct connection between a hose and the tool is always the best method to collect dust at the source, but that’s not always possible with some tools. As with all things woodworking, there are no real standards between tool manufacturers for fitting item “A” to item “B.”

The trick, of course, is matching those ports to your system. Fortunately, most stationary and benchtop tools feature 2-1/2″- and 4″-dia. ports that can easily be connector directly to 2-1/2″ and 4″ hoses. However, handheld and benchtop power tools often have much smaller ports – usually 1-1/4″ and 1-1/2″ – so connecting a larger hose requires an adapter that mates to larger hoses. Some tools, like sanders, have ports as small as 3/4″, or even oddly shaped ports.

Rockler’s Dust Right FlexiPort connectors feature flexible mating sleeves to help match these.

Tool dust ports can come in weird shapes, but Rockler’s Dust Right FlexiPort connectors feature soft, rubbery connectors that shape themselves to match.

Routers

Routers, by their nature, need the spinning bit to be exposed. And because they’re spinning a full 360 degrees it’s impossible to fully enclose them and catch all the dust they produce. Handheld router dust collection can be improved by attaching a dust shroud that encloses the base or a shroud that partially encircles the bit. Centrifugal force directs chips to the shroud, while vacuum suction pulls in as much as possible. Some chips will always escape, however.

When it comes to dust collection for handheld router edge routing, the Dust Right Edge-Routing Dust Port attaches to any router that accepts a standard 1-1/4” diameter guide bushing, and partially surrounds the bit to capture dust when flush trimming or routing decorative edge profiles

When you need dust collection at a router table, the dust can be collected at two points. A fence-mounted port above the table grabs chips and dust as with handheld routers, but a shroud like housing underneath the table contains everything else. The dust collection hose is split between these two points – one to the tabletop, one to the under-table housing.

Router table dust collection works best when it grabs dust both above and below the table at the same time. The Dust Right Router Table Dust Bucket mounts below the table, but also allows a separate connection to a fence-mounted dust port.

The Rockler Fence Port Dust Brush does double-duty as both a cleanup brush and the hose to the dust port on your fence. Just pull it off the port to clean up stray dust and chips that collect on your router table or drill press.

Lathes

Lathes are more problematic, as chips and debris tend to fly everywhere. But a similar shroud enclosure can have a big impact on getting most of it. Lathe dust shrouds typically mount to the lathe bed or on a freestanding support, with the shroud adjusted as close as it can get behind and around the workpiece. You’ll still have chips that shoot to the side (and all over you), but a lathe shroud can make a huge difference.

Mounting a collection hood, such as this Dust-Right Lathe Dust Collection Hood behind the workpiece on a lathe helps tame the mess.

LEARN MORE: Setting Up a Lathe Dust Collection Hood

Lathe shrouds are more efficient when sanding on the lathe, one of the most intensive fine-dust producing activities you can do in the shop. Heavier chips aren’t shooting everywhere when sanding, nor do you need maneuvering room for using chisels. For sanding, shrouds can be adjusted closer to the spinning workpiece, creating a strong backdraft that pulls fine dust into the shroud and on to the dust collector.

Miter Saws

Miter saws are one of the most challenging tools in terms of dust collection. Most of the miter saw blade is exposed and chips fly back behind the tool. Some miter saws feature more effective dust shrouds behind the blade, but many saws do very little to contain the dust.

One option to help improve dust collection dust at your miter saw is to install a hood behind your miter saw.

Air Filtration Systems

We’ve talked entirely about collecting dust at the source, but no matter how efficient your dust collector system is, there will always be fine, powdery dust that escapes into the air. This will eventually settle, but until it does you’re breathing it and it’s spreading throughout your shop and home.

Shop vacuums and dust collectors, no matter how powerful or efficient, aren’t designed to filter shop air. For that, consider an air filtration system, sometimes called an ambient air cleaner. These units are usually metal boxlike structures with an internal fan that draws shop air in and through a pair of filters. The first separates and catches heavier airborne dust, while a second extremely efficient filter grabs the tiniest particles.

Air filtration machines are often ceiling-hung, usually centrally in a shop, and constantly recirculate and filter shop and filter shop air. Typical units vary from 450-1200 CFM, but larger cleaners are available. Better models have multiple speed selections and a remote control.

No shop vacuum or dust collection system can pull powder-like dust out of the air, but that’s where air filtration units shine. This JET 1000CFM Air Filtration System constantly filters and recirculates shop air while you work.

Any Dust Collection is Better Than No Dust Collection.

Setting up an efficient and easy-to-use dust collection system is important in every woodworking shop.Not implementing a dust solution because your dream collection system is beyond your means is no solution at all. It’s perfectly fine to start small, and improve dust handling as you’re able. understand a fundamental truth: Any dust collection is better than no dust collection. The best woodworking dust collection systems contain the mess that is created by tools, make it easy to clean up any mess that is left behind, and makes your shop a healthier and better place to work.