Can I Cut Mirror Glass Cutter

Glass products have always been very popular: frescoes, stained glass, dishes and many other things created from scraps of this material have always amazed people with their grace and smoothness of lines. Looking at this magnificence, it seems that to create it you need to be a real professional with extensive experience working with glass and a lot of necessary tools, and a simple “mortal” can never master this complex science. In fact, not everything is as sad as it seems at first glance, and anyone can get knowledge on how to cut glass at home.

Preparing glass for cutting

A lot depends on this stage, and the preparation process itself depends on which glass you decide to use for cutting. A new glass, bought specifically for the intended purpose, is enough to simply wipe, and it’s best to use the old newspaper for this (this will avoid stains and settling of small fibers). With the same used material will have to work, spending much more effort. Firstly, it must be thoroughly rinsed using a special glass cleaner. Secondly, degrease with a cloth dampened, for example, in kerosene and, finally, dry it indoors to prevent dust from entering the surface.

In addition, the preparation of glass implies its cutting. As you know, it is unlikely that you will be able to achieve completely waste-free production when working with glass, especially if you are planning to get a product of an irregular geometric shape. However, accurate calculation will reduce possible waste to a minimum. At this stage, a more rational solution would be to combine the longer side of the glass with the long side of the workpiece. Note that the resulting trim should not be thrown away, they can be used in the future to create new products.

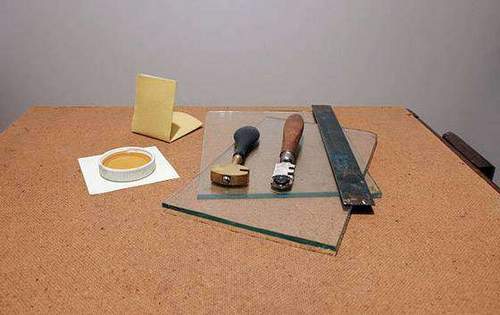

What tools to use?

Many of us are accustomed to believing that it is possible to cut glass correctly and accurately only with a glass cutter. But what if you cut off a piece of glass urgently, but this tool was not at hand? There is another unusual, but no less effective way, which helped our great-grandfathers to get out of this situation. Such a tool is the usual scissors that are available from any owner. Consider each method in detail.

Option 1: glass cutter

The technology for cutting glass with a glass cutter is quite simple. To do this, you must comply with certain conditions and choose the right glass cutter. Today, the choice of this tool is wide enough, which allows you to turn the work into a pleasure.

On how to choose a good glass cutter, see the:

So, having figured out the glass cutter, place the glass on a flat surface. Mark the glass and get to work. To facilitate the task, you can use the ruler. It is worth considering the moment that the line needs to be carried out the first time, otherwise a second attempt will lead to cracking of the surface. Cut glass with a glass cutter by applying equal efforts along the entire length of the line.

Option 2: ordinary scissors

Cutting glass with scissors like paper is not a fairy tale, but a completely ordinary reality. For this purpose, you need the scissors themselves (sewing is best for this) and a water tank (preferably hot). It is necessary to mark the glass in advance, and then elementary physics is included in the work: the scissors create a microcrack, and the capillary effect completes the process. Of course, the result obtained will differ from that achieved by the glass cutter, but if necessary, this method can significantly help.

Types of glasses and features of work

Cutting ordinary glass does not cause almost any difficulties. Not only glass cutters, but also ordinary tailor scissors do an excellent job of this task. But what to do for those who set themselves the task of obtaining a glass product with a more complex configuration. To do this, you should familiarize yourself with the properties of some glasses.

In any case, it is worth remembering that work with any glass should be accompanied by certain precautions. The presence of tight gloves and goggles are the main conditions for the implementation of their own safety. It will not be superfluous to take care of arranging the workplace. Since working with glass implies the presence of fragments, cover the work surface with any material that will not get rid of AL-KO. Feeling your own safety will allow you to achieve the best results.

Types of glass cutters

First of all, you need to remember that glass is different: ordinary window, tempered, plexiglass, acrylic, corrugated and ten more options. Also, even ordinary, can be quite thick or, conversely, thin and very fragile. Depending on the type, the tool is selected, the cutting method. But the use of glass cutter is the most common option.

The construction market offers several options for glass cutters:

Before cutting glass with a glass cutter, it must be prepared:

Important! It is necessary to prepare the surface on which the cutting will be carried out. It is chosen smooth, clean, without changes in height.

Safety regulations

The approaches to how to properly cut glass with a roller or diamond glass cutter are the same. The main thing is to follow certain rules and remember about safety:

Expert advice! An even cut line can be obtained by using a ruler. So that the ruler does not slip, it is glued with double-sided thin tape. This will ease the break.

There is a relationship between the width of the glass and the width of the strip, which breaks loose:

Masters have their own style in working with glass surfaces, but you should follow some general recommendations on how to cut glass correctly:

How to replace the glass cutter

Not only professional tools will help when cutting glass, but also not quite ordinary ones, for example, such as scissors or an angle grinder. They can easily do this job under certain conditions.

In the air, scissors do not cut glass, but you can cut glass with scissors in water. In a liquid, gravity is less and scissors make not an incision, but a microcrack. This crack plays the role of a capillary into which water will fall. Capillary water has a wedging effect on weak crystallization points and the glass breaks off in pieces.

Interesting! If it is necessary to cut curly details, the glass is placed in cold water, and then boiled for several hours. After cooling, the tension inside is removed and the material becomes soft.

There are several ways and options on how to cut thick glass. The easiest. Use oil glass cutter, if the thickness is not more than 20 mm. But as an option, you can use an angle grinder. Tool dimensions should be small and comfortable. The diameter of the circle is the smallest, then it will be easier to work with it.

Plexiglass: glass or plastic

Not all types of glass are cut with glass cutters. On the construction market there are materials that either cannot be cut at home at all, or for cutting them you need to familiarize yourself with some rules, and some are very easy to cut.

One of the most malleable materials for cutting is plexiglass. It is a transparent plastic with thermoplastic properties. The material is very easy to process, but there is one feature: low thermal conductivity, due to which the edges of the cut immediately heat up. Therefore, before cutting acrylic glass, it is necessary to consider the method of cooling it.

The main tools for cutting plexiglass:

The choice of tool depends on the thickness of the glass: thin. With a knife, the thickest circular or on the machine. Saw blades are used special for plexiglass, but are suitable for copper, aluminum.

Work with a hacksaw or clerical knife must be quick. Unlike window glass, a cut line can be drawn several times. During cutting, the blades are cooled so as not to melt the edges of the cut. The resulting slice will have roughnesses that are removed during sanding.

The low melting point makes it possible to cut plexiglass with a jigsaw and get a wide variety of curly products. In a jigsaw, the file is replaced by nichrome wire. Which is connected to a transformer with an operating voltage of up to 4 V. The heated wire easily and gently passes through plexiglass along any path. The cut is smooth and even, not requiring additional processing.

Rules for cutting tempered, corrugated and refractory glass

Very rarely, but it may be necessary to cut refractory glass, for example, to replace in the oven or fireplace door. At home and without special skills, this procedure should not be carried out, since heat-resistant glass is a split system of several tempered and non-tempered glasses. But some craftsmen use an angle grinder with a very small diameter diamond blade. To avoid crushing while cutting the refractory glass angle grinder, the cut line is watered with oil.

Another view, loved by designers and often used in everyday life for decorative purposes, is corrugated glass. It differs from the usual one in that it has a non-smooth surface on one side. It is necessary to cut corrugated glass from an even side with any glass cutter, but oil is preferable. To make it convenient to work, the table is covered with a soft cloth, on which a glass sheet is laid.

I read a couple of pages and it became disgusting to read further. Well, by golly why write “smart” things if you don’t understand the issue at all?

Firstly, there is a lot of literature.

Good luck in your endeavors and do not forget that safety is written in blood.

If you have any questions, write to the e-mail.

Which glass cutter to use for tiles

Smooth cutting of tiles can be performed not only with a professional tool, but also with devices aimed at working with other materials. One such device is the good old glass cutter. Please note that when it comes to purchasing a special tool for working with tiles, it is best to take a tile cutter. If we are looking for a replacement, and in our building arsenal there are several types of glass cutters, then you can use one of them to complete this task. Let’s find out which glass cutter for the tile to choose if there is no tile cutter at hand.

The most common glass cutters used in everyday life are roller and diamond. The principle of operation of these tools is reflected in their names, and consists in cutting glass with a diamond or carbide roller. Glass cutters with a diamond tip are excellent for working with thick glass, but they are practically unsuitable for a more porous structure of tile. Roller types of devices, on the contrary, easily bite into the tile material, leaving neat cut lines.

If you want to use a glass cutter for tiles, we recommend choosing a roller type, preferably with an oil supply. This device will be able to cut tiles with a glossy surface to the second level of wear resistance on the PEI scale (this indicator is indicated on the package). For a denser tile, a roller glass cutter will not work.

How to cut a tile with a glass cutter

When tile laying forces you to resort to cutting, and there is no special tool at hand, you can resort to using other devices. Let’s see if it is possible to cut tiles with a glass cutter and how to do it exactly.There are many types of tiles with different coatings and levels of wear resistance. In order for the work of the glass cutter to give positive results, the surface of the processed tile must be glazed, and the wear resistance should not be more than the 2nd level. The wear resistance of the tile is measured on a scale of 1 to 5 and can be indicated on the packaging by the abbreviation P.E.I. If your material meets the specified requirements, you can start marking.

We lay the processed tile on a flat surface, without obvious bulges or indentations. Next, take a felt-tip pen, mark the cut points from two edges and draw a fishing line between them. When the marking is applied, we draw a glass cutter along it with a pressing force above the average. Keep the glass cutter perpendicular to the surface of the tile. It is advisable to drive on the stop (ruler or level rail) and low speed. After the cut, there should be a clear, even fishing line, a little less than a millimeter wide. If in some places the fishing line disappears, you can draw it again.

When the cut line is successfully applied, it remains only to break the tile in a flat line. You can do this in several ways: break on the straight edge of the table or stools or put cloves under the cutting line and press from 2 sides. Experienced craftsmen can break the inflow even even on the knee. We hope that the above process will help you successfully complete this task. If textual information was not enough, we recommend watching a of cutting tiles with a glass cutter, and using a clear example to understand the principle of this operation.

Other tile cutting methods

Although a glass cutter can do for cutting tiles, this is not the only tool that can cope with this task. Below, we will look at a few more ways how to cut a piece of ceramic tile using other devices, without using a tile cutter. So, what other tools can you cut tiles:

Angle Grinder

Quite effective, but not the best quality way to cut tiles. Fishing line is obtained with chips and requires further processing with sandpaper. A diamond blade (not segmented) and, of course, an angle grinder are required for operation.

The principle of action is extremely simple. We lay the tile on a flat surface, outline the fishing line and make a cut, slightly leaning the disk against the surface of the tile. Cutting the tile completely is not necessary, it is enough to get an even hollow and make a break on it. To reduce dust, moisten the tile with a wet cloth before use.

Drill

A very convenient way to cut round holes by using special nozzles on a drill or screwdriver. There are 3 types of special nozzles: diamond-coated crowns, ballerina drills and conventional drills for glass and tile. The most ideal cut and the highest price is for crowns. Next in terms of quality and cost is a ballerina. Special drills are the cheapest and with the help of them you can get a cut of any shape, but you will have to clean the edges with sandpaper.

If everything is extremely clear with diamond crowns and a ballerina, then sometimes there are several questions regarding the tile drill. The principle of operation is as follows:

- We outline on the tile a circle, square or other figure that needs to be cut.

- We drill a lot of holes along the planned line with a minimum distance from each other.

- Carefully break out an unnecessary piece and clean the edges with sandpaper.

Hacksaw

A budget and quite neat way to cut tiles. It can be used to obtain straight lines and curly cuts. Of the minuses, we can note the low speed. All that is needed is a hacksaw and a thread coated with tungsten carbide or diamond spraying.

Sawing the tile with this device is not difficult even for beginner finishers. Tighten the thread in the hacksaw and proceed to cut. If it is necessary to make a circle inside the tile, then first we drill a hole in it, then we thread a thread into it, fasten it in a hacksaw and saw it from the inside.

Jigsaw

Like the previous method, it is based on sawing tiles with carbide cloth. It has a fairly high speed, but can be used mainly for direct cuts, rather than curly ones. You can cut a circle with an electric jigsaw, but the chance of chipping tiles is several times higher compared to a hand hacksaw. For work, special paintings on ceramics or metal will be required.

To improve the quality of cutting and reduce chips, it is recommended to work at medium and low speeds.

Safety comes first!

Most owners of apartments or private houses do home repairs on their own, of course, when there is time for this. As with any other business, safety precautions must be taken when working with glass to avoid serious injury. Simple ignorance of how to cut glass with a glass cutter correctly can lead not only to cuts, but also to wounding the eyes with fragments.

Can I Cut Mirror Glass Cutter

Cutting glass on knees or moving objects is highly discouraged, for this you need to use a solid and even surface. Do not grab onto the rough edges, it is better to lift the workpieces from the side edges. To work with glass, you need work clothes made of thick, dense fabric. Shoes should be closed so as not to injure your feet. Having dressed in it before starting work, you also need to take care of the safety of your face and hands. To do this, always wear gloves and safety glasses. At the end of the work, it is necessary to change clothes and change shoes so that the fragments (and they will certainly be on clothes) do not leave the working area.

Glass selection

As experts in glass craft say, the main thing is to choose a good material, otherwise glass cutting will lose its meaning. This is especially important when deciding to replace the window glass yourself.

When choosing glass on the windows, you should choose the optimal thickness, which depends on the dimensions of the frame. For example, its height is no more than 60 cm, then the thickness of the sheet can be from 2 to 2.5 mm. Otherwise (more than 60 cm) you need to select a larger thickness. Up to 3.5-4 mm. When cutting glass, a sheet should be formed 3-5 mm smaller than the frame. Otherwise, at the slightest distortion, the glass will not fit into the opening.

Types of glass cutters

For cutting glass, a special tool is used, which everyone knows. It can be of several types:

Glass Cutter have a cutting tip of a round shape. An alloy of cobalt and tungsten is usually used for its manufacture. The number of rollers in one tool can vary from one to six. Unlike other analogues, such an instrument is inexpensive, due to which it received great appreciation.

Diamond glass cutter used by professionals. Despite the high price, he was, remains and will always be the undisputed leader in the field of glass cutting. It is better for home craftsmen to choose a professional diamond glass cutter, which has a beveled cutting edge, since it will cut more linear meters of almost any thickness. Only need to be stored in a special case. A diamond crystal is used for the cutting tip, and it is known to be the hardest mineral that can be found on Earth. It is worth leaving a small scratch on the glass, as it will crack at the slightest effort. Diamond glass cutters need periodic sharpening by means of a special bar.

Oil tools similar to roller counterparts, with the only difference being that there is a capsule with oil in the handle. It is automatically fed to the roller during operation and to the glass surface. Such a cutter is well suited to solve the issue of how to cut thick glass with a glass cutter.

With help compass it is convenient to cut round or oval shapes. It consists of several elements and looks like a well-known school stationery.

Workplace preparation

Before proceeding to cutting glass, it is necessary to prepare a workplace. Usually this is given little attention, but in vain. It is important to prepare the material itself for work. If the glass is new, then there is no need to wash it. Otherwise, it may contain small chips, cracks, scratches or plaque. Then you need to rinse the sheet well with detergents, and then dry it by wiping it with paper or newspaper. It is better not to use the fabric, because there are fibers and stains that are useless. Dry glass must be degreased. To do this, you can use rags soaked in kerosene. After this operation, the sheet is dried, but without wiping dry and indoors to avoid dust.

It’s not enough to know how to properly cut glass with a glass cutter, it will not hurt to cut it in order to minimize unnecessary waste of material. A competent drawing drawn up on a piece of paper will make it possible to achieve virtually no waste home production. It will be especially useful if you need to cut out a complex or uneven shape. In this case, it is optimal to position the longest side of the workpiece on the same glass parameter. Sheets need to be cut on a flat surface, excluding slopes. As an impromptu table, plywood or fiberboard is suitable. You can lay an oilcloth or soft cloth on top.

Cutting technology

A clean and dry sheet is placed on the table for cutting glass, and it should be located entirely on the work surface. It is more convenient to first make notes with a marker or a special pencil. For straight lines, you need a ruler, and for complex cutting, you need a pre-harvested pattern. The thickness of the ruler should be at least 7 mm for a snug fit. And so that it does not slip on the glass, you can glue small rubber pieces to it.

A diamond glass cutter should be held, like a pen or pencil, at a slight angle, with little effort. If a thin, colorless fishing line is visible, then everything is done correctly. The roller tool must be held strictly perpendicular to the surface of the glass, holding it with the thumb and middle fingers, and pressing the index finger from above. In contrast to diamond glass cutter, when cutting 3 mm glass, a little more effort is needed here. The trace remains white.

Tool guidance should usually be accompanied by a slight crackle, indicating good performance. Simple rules will help to avoid mistakes:

- The speed of reference should be uniform and not interrupted.

- It is better to drive the glass cutter faster than slower, but not too fast.

- Regardless of the type of instrument, the movement is always directed towards itself, that is, the instrument follows the hand.

- It is not necessary to press the tool strongly on the glass; uniform force must be applied throughout the entire segment.

- Along the line, glass cutters must be carried out only once, no more so that the glass does not crack.

In the absence of experience, it is better to pre-train on some pieces. So you can avoid mistakes, learn to hold the tool and gain experience working with different materials, including corrugated glass.

Correct breaking glass

After an incision, the glass breaks. Thin and small pieces can be broken off with your hands. Larger sheets need to be moved to the edge of the table so that the cut is 3-5 cm from its edge. You need to gently tap the tool handle along the entire line from the back of the glass. Do not forget to hold the hanging part of the sheet. After a while, tapping will give the desired result.

But there is another safer way. Matches are placed under the sheet on one side and at both edges, and then you need to gently and sharply press the glass. The fault should go exactly along the notch line.

In some cases, the cut-off part of the glass is too narrow. For this, the glass cutter has special recesses in the “head”. They need to be inserted into the edge of the detachable strip, for example, 4 mm window glass, after which it should be pulled down with a little effort. The material will break off just by an incision.

Edge processing

After breaking the glass, there is a risk of cutting into sharp edges. Therefore, they need to be “disarmed.” At home, this can be done with an ordinary donkey, which is usually used to sharpen kitchen knives. Only previously it should be moistened with water.

An angled oselok having diamond spraying will allow to process both edges at once. A diamond-coated sponge also works well for handicrafts. But if there is a drill, then the process can be accelerated. It is enough to use a grinding nozzle.

Corrugated glass

Corrugated or patterned glasses are sheets on which a relief pattern is periodically repeated. Such material performs various functions:

- Is a decorative ornament;

- Able to partially scatter light;

- Limits pass-through visibility.

At the same time, corrugated glass does not interfere with the penetration of sunlight or artificial light. As for the pattern, it can be on one or both sides. The pattern is obtained by knurling a special roller with some kind of pattern. Mostly widespread corrugated glass received in the field of decoration of doors and furniture. For cutting such sheets, it is better to use a glass cutter. Over, the work should be performed on their smooth surface.

Tempered glass

Sometimes some home craftsmen are interested in the question of how to cut red-hot glass. The answer is simple. No way! There is no way to cut or drill it, because when you try to act on it mechanically, it crumbles.

Such material long before the advent of technology “triplex” was used in the automotive industry. In the event of an accident, the glass simply shattered into small fragments, which eliminates the possibility of injury to drivers and passengers. Therefore, in relation to such a material, one should not even wonder about how to properly cut glass with a glass cutter.

How to cut circles?

Next, you need to tie a thread to it, and preferably a fishing line, the length according to the desired radius of the circle. The other end is tied to a glass cutter. It remains to pull the fishing line as far as possible and guide the tool. After the incision, it is necessary to make radiation incisions from the circle to the periphery of the glass. If it is necessary, on the contrary, to cut a hole in the glass, then the rays should be carried out inside the outlined circle. And so, as a result, to get equal sectors.

Complex cutting

To cut out a complex arch or different geometric shapes for stained glass using a glass cutter, you need to prepare a tracing paper. But it is better to make a template from plywood or very thick cardboard. Just take into account the allowance for the width of the tool. The template should be firmly held and lead the glass cutter along its edges, preferably without interruption. After the contour is outlined, you need to cut a line perpendicular to the curves at a distance of 7-14 cm from each other. Then you can proceed to tapping. Thin strips break off the grooves of the glass cutter. In conclusion, you must remember to grind off all the edges.

The device and principle of operation of tile cutters

In the market of construction tools, there are many models of tile cutters. All their diversity in the type of energy due to which the work is carried out is divided into two main types:

Via mechanical variety carry out a direct or curly (curvilinear) cut of the tile, create holes in it. Over, the thickness of the processed material is limited to 16 mm. Electric Tile Cutters They are characterized by high productivity: they are able to cut tile material with a thickness of more than 16 mm.

The principle of cutting tiles with mechanical and electric tools is different. But models of equipment of both types are used both in everyday life and in professional activities in accordance with their functionality.

Mechanical tool construction

The mechanical tool is divided into manual and stationary (desktop) models. Manual tile cutters There are two varieties:

- In the form of nippers, the design of which is presented in the photo below;

- In the form of a roller cutter having the device shown in the photograph below.

The device of manual models is very simple, but with their help it is possible to work only with thin tiled material.

Stationary Products represented by a large number of different modifications. But in all cases, the device of the tile type tabletop has the following structural elements:

- A carriage with a cutting roller and a handle that moves along the guides;

- Base (also called a platform, table or bed);

- The lever by which the incised tile is broken;

- Tile fixing paws.

Guides are fixed on racks. Details of all the details discussed are shown in the photograph below.

Some models have measuring rulers, which allows cutting without preliminary marking. If the mechanism has accessories, such as ballerinas, then you can use them to cut holes of different diameters.

Hand torches and stationary models work is carried out according to the following principle:

- Make a cut in the sawed material with a roller;

- On the cut line break the tile.

With the help of a tile cutter, small pieces are bitten off from the tile. This tool can only be used at the edges.

The device of electric cutters

Electric stoves in their design resemble a circular saw. They are divided into two varieties:

- Hand models

- Machine-tool (stationary) electrical equipment.

The main nodes of any model are:

- Electric motor;

- A head with a diamond disk fixed to it;

- Lever;

- Power button.

An electric motor for network electrical equipment can be single-phase (operates on a voltage of 220 V) or three-phase (rated at 380 V).

There is equipment equipped with diamond band saws instead of discs.

Hand models have a support sole. Some products have special rollers on it to make it convenient to move the power tool over the surface of the material.

Some electric cutters are equipped with stops, rulers, goniometers, as well as tanks under water to cool the place of cutting. These structural elements are clearly visible in the photo below.

For dust removal, some modifications are equipped with a dust collector. There are device options with the ability to connect a vacuum cleaner, for example, as in the photo below.

Handheld electric cutters can work on batteries. Such models are marketed by RYOBI (e.G. Lts180 M) and Makita (4191 DWD, CC 300 DWE).

Machine electrical equipment, Depending on where the electric motor with a saw head is installed, there are the following modifications:

- With the bottom placement of these nodes;

- Cantilever (the table with the workpiece moves, and the disk is stationary) and the bridge (the cutting head moves relative to the material) with the upper position of the electric motor.

The detailed design of the bridge electric tile cutter using the example of Elitech PE 1000 / 92P is presented in the following photo.

Electric the tile cutter works on the same principle as the circular saw. When you press the power button, the electric motor starts to work, causing the diamond disk to rotate. He completely cuts the tiles laid on the table at angles of various sizes, and not just 90 degrees.

Cooling consists in supplying water to the cut area. At the same time, the liquid prevents the formation of dust, cleans the disk of tile particles.

Preparation for work

Before you start sawing porcelain tiles, glass or tile, you need to prepare a working tool, and in some cases. Set it up.

Any tool is pre-inspected for external damage. For mechanical models check:

- Condition of the roller. Free rotation, defects, sharpness, reliability of fixation;

- Smoothness of the carriage, the presence of play;

- Bed for contaminants, removing them if necessary;

- Defects on the handle;

- If there is an emphasis, then measure the angle between it and the axis of the cut.

The cutting roller must rotate freely, be clean and of the correct shape (without dents, dents). It should fit the thickness of the sawn tile.

After preliminary inspection and cleaning, the guides and the cutter are applied small amount of grease (engine oil). Then, using a construction pencil, marker or felt-tip pen, marking lines are applied to the surface of the tile materials, along which the cut will be carried out.

If the modification is equipped with an emphasis and a measuring ruler, then marking is not necessary.

Before cutting the tile with an electric plate cutter, check the reliability of the fastening of the disk. The contaminated disc is cleaned of adhering debris. If the power tool is equipped water cooling system, they maintain the right amount of fluid. Dirty water is completely replaced so that the cut point is well cooled.

For electrical equipment, the power cord must be solid and dry: only in this form is it allowed to insert the plug into a power outlet. Also, during the operation of the device, the water circulating in the cooling system should not fall on the cable. After the electrical equipment has worked, you need to make sure that the fluid supply is continuous.

Typically, the power tool is adjusted at the factory, but the settings may not be made during transportation. For this reason, you may need to setting the cutting angle and the length of the working movement of the disk. The adjustment of each model has its own characteristics. The setup process of the installation used is described in the operating instructions for it. To set the angles, you will need to use a protractor, a goniometer or a square.

Mechanical tile cutting of tiles and porcelain stoneware

To correctly tile the tiles, it is recommended to hold it in water for some time beforehand. This makes it easier to cut.

Via mechanical stationary tool cut tile material in the following way:

- Marking line is applied to the surface of the tile;

- Lay the tile on the bed so that the marking coincides with the paths along which the cutting wheel (carriage) moves;

- Slightly pressing on the carriage, conduct it once along the cut line;

- The handle is set into working position, then it is sharply lowered, breaking tiles along the cut.

To ensure that the edges of the resulting pieces are neat, the cut line should be at least a centimeter from the tile edge.

The pressure on the carriage must be so strong that the wheel cuts through the tile enamel, and the tile does not sell. It’s not worth spending several times, because the edges of the fragments will turn out to be uneven. When a face is obtained with bumps and chips, it will need to be additionally polished. Cutting porcelain tiles with a stationary type tile cutter is possible only with a tile thickness of up to 15 mm. The process algorithm is completely similar to the above.

Hand Roller Cutters work the same way as stationary devices. In this case, only tiles of the minimum thickness are suitable: such tools are not intended for professional use. For some beginners, quite often the question arises of whether it is possible to tile cut glass. This can be done, but only with ordinary material. To cut hardened varieties, you will need a special power tool.

Tile Cutter work as follows:

- They bring the tool to the edge of the tile, placing it with the wide part on the front surface of the ceramic, and the central part of the cutters is placed along the bend line directly above the groove;

- Then gently break off pieces of material.

With the help of nippers, you can make round holes, but for the quality performance of the work you need to have the appropriate skills and be careful.

Electric cutting

Electric cutters of different types work the same, so the technology for cutting tile materials with their help is similar. Working with an electric tile cutter is not particularly difficult, just be careful and attentive. Hand models are more difficult to handle: evenness of the cut depends mainly on the skills of the worker.

To use the electric type tile cutter correctly, you must adhere to the following rules:

- Before work, it is necessary to turn on the cooling system;

- Pre-mark the surface of the workpiece;

- Fix the tile on the desktop;

- After that, it is necessary to carefully advance the tile to the disk or vice versa (depending on the model of the unit being operated), constantly monitoring the pressing force;

- Before the end of the cutting line, the force of impact should be reduced to prevent the formation of bumps or chips.

In addition to a straight cut using electric cutters, various shapes are cut. In this case, the process occurs in the following sequence:

- Marking up;

- Make cuts with an electric plate cutter, cutting off excess fragments and breaking them off with pliers;

- They process the edges of the workpieces, for example, with a file.

The use of a power tool allows you to cut tiles into thin strips a few millimeters wide, while the cut is even.

Possible errors when using the tool

Errors when working with both mechanical and electric tile cutters, not only beginners make. It’s very rare, but there are mistakes among professionals. An inexperienced worker needs time to master the exploited device and achieve high quality tile cuts.

The most common are common mistakes when using tile cutters.

- Workers do not use personal protective equipment, the minimum set of which must necessarily include safety glasses with gloves.

- After the end of work, the operated tool is not cleaned of various adhering debris, for example, of small pieces of ceramic tile, porcelain tile or mortar. For subsequent use, this affects the quality, safety, and cutting efficiency.

- The sawed tile material is poorly fixed: as a result of accidental movement, the straightness of the cut is violated.

At operation of mechanical equipment The following additional errors are possible:

- A device is used for work, the cutting element of which rotates not freely, which leads to the formation of various defects (for example, potholes) along the edges of the cut line;

- When cutting the workpiece, they exert uneven pressure on the cutter, which causes damage to the tile enamel;

- In the presence of a special handle for breaking the tiles do not use it, but do everything manually by sloppy;

- Spend several times with a cutting element on the surface of the material, which leads to damage to the decorative layer and the curve of the fault line.

Work with electric cutter inexperienced users are also accompanied by errors, the main of which are as follows:

- In machine models, the coolant (water) is not timely replaced;

- The contact of the disk with the tiled surface is not smooth and easy, but sharply;

- Do not use headphones and a respirator;

- Electric stoves with signs of external damage or other malfunctions are in operation;

- When sawing porcelain stoneware or ceramics exert excessive pressure on a working tool, overloading it with this;

- Include electrical equipment in contact with the disk surface of the material being cut.

Mistakes in the use of devices for cutting tile materials lead not only to premature wear of the equipment and its failure, but are also associated with injuries of varying severity.

In order to learn how to work well with an electric or mechanical tile cutter, especially their manual models, you need to train in practice, constantly improving your skills. Before you start using the equipment, you should read the instructions for its use. It indicates the necessary measures for the periodic maintenance of the model, preparing it for work, and initial setup. Also, the operating manual contains the necessary recommendations, compliance with which allows you to safely perform work. Failure to follow these instructions will result in personal injury. It must be borne in mind that a power tool is more dangerous than mechanical analogues. When working with him, you must be very careful.