Carburetor Adjustment Stihl Fs 450

Transcript

3 Contents Original Operating Instructions Printed on bleached chlorine-free paper. Printing inks contain vegetable oils, paper is recyclable. Adreas STIHL AG Co. Kg, A. M8.A.Fst _003_GB To these operating instructions 2 Safety and operating instructions 2 Permitted combinations of cutting tools, guards, stops and suspension belts 3 Mounting the handle with two handles 4 Adjusting the throttle control cable 5 Mounting guards 6 Mounting the cutting tool 7 Fuel 2 Refueling 22 Putting on a two-shoulder belt 23 Balancing the device 23 Starting / stopping the engine 24 Operating instructions 27 Cleaning the air filter 27 Setting the carburet ra 28 29 Winter mode Electric heating handle 30 Spark plug 30 of the motor 3 assists Job Grease 32 Substitution starter rope / return spring 32 Storage unit 34 Sharpening metal cutting tools 34 Maintenance and maintenance instructions 36 Minimizing wear and avoiding damage 38 Important components 39 Technical data 40 Special accessories 43 Repair instructions 44 CE certificate 45 Quality certificate 45 Dear customer, dear customer, thank you very much for that that you decide to purchase a high-quality product from STIHL. This product has been manufactured using modern technological methods during extensive quality assurance activities. We are ready to do our best to make you happy with this device and can work with it without problems. If you have questions regarding your device, please contact your sales agent or directly to our sales company. Ba Hans Peter Stihl

4 To these operating instructions Symbols in pictures All symbols in the pictures that are marked on the device are explained in these operating instructions. Designation of sections of the text Warning about the danger of an accident and personal injury as well as serious material damage. Warning about the possibility of damage to the device or individual components. Technical development STIHL is constantly working on the further development of all machines and devices; therefore, we must reserve the rights to all changes in the configuration of delivery in the form, technique and equipment. Therefore, no claims can be made regarding the instructions and drawings of these operating instructions. Safety and operating instructions Special precautions must be taken when working with this motor vehicle, as work is carried out with a very high speed of the cutting tool Before first commissioning, carefully read the operating instructions and save them securely for future use. Failure to follow the instruction manual can be life threatening. Observe the safety regulations in force in the country, for example, professional societies, social insurance offices, labor protection authorities and other institutions. Everyone who works with the device for the first time: must be instructed by a sales agent or other specialist how to properly handle the device or take a special training course. Minors are not allowed to use the device, with the exception of persons over 6 years of age who are trained under supervision. Children, animals and spectators should be at a distance. When not in use, the motor device should be set aside so that it does not interfere with anyone. Protect the motor vehicle from unauthorized use. The device user is responsible for accidents or dangers that threaten other people or their property. A motor vehicle may only be handed over or rented to those who are familiar with this model and are trained to use it. The use of loud noise generating devices may be temporarily limited by both national and local regulations. Those working with a motor vehicle should be rested, healthy and in good physical condition. Anyone who, for health reasons, does not dare to strain, should consult a doctor if he can work with this motor device. Only for people with an implanted pacemaker: the ignition system of this device generates a very slight electromagnetic field. Impact 2

5 of the electromagnetic field for certain types of pacemakers cannot be completely excluded. To avoid a health risk, STIHL recommends contacting your doctor and pacemaker manufacturer for advice. Using the device after using AL-KOgol, drugs that reduce the ability to respond, or drugs is not allowed. Depending on the cutting tool used, a motor vehicle should only be used for mowing grass, as well as for cutting lush vegetation, shrubs, small bushes, bushes, small trees, and the like. The device must not be used for other purposes. Risk of accident! Only mount cutting tools and accessories approved by STIHL for this device or similar in their technological properties. If you have questions, contact your specialist dealer. Use only high quality tools or accessories. Otherwise, there is a danger of accidents or damage to the vehicle. Stihl recommends using genuine STIHL tools and accessories. They are optimally coordinated in their properties with the product and meet the requirements of the user. Not to make any changes to the design of the device may adversely affect safety. Stihl declines all responsibility for damage to persons and property resulting from the use of installation equipment not approved by STIHL. Do not use a high pressure cleaner to clean the device. A strong jet of water can damage the device. The protective device of a motor vehicle cannot protect the user from all objects (stones, glass, wire, etc.) thrown away by the cutting tool. These items can bounce somewhere and hit the user. Clothing and equipment Wear prescribed clothing and equipment. Clothing should be appropriate and should not interfere with work. Tight-fitting clothing is a jumpsuit, not a work dressing gown. Do not wear clothing that could catch on wood, shrubs, or moving parts. As well as a scarf, tie and any pyccian jewelry. Tie and fix long hair (shawl, hat, helmet, etc.). Wear protective boots with a rough, non-slip sole and socks with a steel overlay. Only when working with mowing heads, as an alternative, you can wear sturdy shoes with ribbed, non-slip soles. Wear a protective helmet when thinning, in high dense thickets and in case of danger of injury from falling objects. Wear a face shield and be sure to wear safety glasses. Risk of injury due to swirling or thrown objects. A face mask is not sufficient eye protection. Wear “personal” noise protection, such as hearing capsules. Wear sturdy gloves. Stihl offers an extensive personal protective equipment program. 3

6 Transporting the motor vehicle 002BA079 K Always stop the motor. A motor vehicle is worn suspended on a belt to be worn or balanced by a shank. To protect the metal cutting tool from a touch to apply the protective device during transportation. On vehicles: Protect the vehicle from tipping over, damage and fuel spills. Fueling Gasoline is extremely flammable to keep at a safe distance from open flames. Do not spill fuel. Do not smoke. Switch off the engine before refueling. Do not refuel until the engine cools completely. Fire hazard! Fire hazard! Open the fuel tank lock carefully so that the overpressure drops slowly and the fuel cannot be sprayed out. Refuel only in well-ventilated areas. If fuel has been spilled, the motor vehicle should be cleaned immediately to ensure that fuel does not get on clothing, otherwise change clothing immediately. Motor units can be supplied as standard with various types of fuel tank locks. After refueling, tighten the threaded lock of the fuel tank as far as possible. This reduces the risk of unscrewing the tank lock due to motor vibrations and, as a result, the risk of fuel leakage. Pay attention to leaks in the event of a fuel overflow; do not start the danger to life due to burns! Before starting Install the tank lock with the flap correctly (the fire lock), turn it all the way and close the bracket. To check the perfect working condition of the device, pay attention to the corresponding chapter in the operating instructions: The combination of cutting tools, protective equipment, handles and wearing belts must be approved for operation and all parts must be perfectly mounted. The combined shutter / stop switch should be easily set to the stop position STOP or 0. The throttle lock (if equipped) and the throttle should easily move the throttle should spring back independently to the idle position 4

7 Check that the plug of the ignition wire is tight if the plug is loose, sparking is possible, sparks can ignite the air-fuel mixture risk of fire! Check cutting tool or attachment: proper mounting, tight fit and perfect condition. Check protective devices (e.G. Protective equipment for cutting tools, work plates) for damage and wear. Damaged parts must be replaced. Do not work with damaged guards or worn working plates (if the inscription and arrows can no longer be recognized). Do not make any changes to control devices or safety devices. The handles must be clean and dry, free of oil and dirt for reliable control of the vehicle. Adjust the girdle to wear the grip (s) to suit your height. Stick to chapters “Installation of a belt for wearing” “Motorcycle balancing” The motor vehicle must only be operated in a reliable operating condition. Risk of accident! When using the wearing belt for an emergency: practice quick removal of the device to the ground. When training, do not drop the device on the ground to avoid damage. Start the engine. At a minimum distance of 3 meters from the fueling point, not indoors. Only on a flat surface, take a reliable and stable position, hold the motor device firmly, the cutting tool must not come into contact with any objects or the ground, since the cutting tool can rotate when it is started. A motor vehicle is serviced by only one person. Unauthorized persons are not allowed in a zone with a radius of 5 meters. During the start, there is a risk of injury due to discarded objects! Avoid personal injury from cutting tools! English Do not start the engine by hand; start as described in the operating instructions. After releasing the throttle lever, the cutting tool continues to move for some more time by inertia! Check that the engine is running idle: the cutting tool at idle should stop when the throttle lever is released. Highly flammable materials (eg wood chips, bark, tava, fuel) keep away from the hot exhaust stream and from the surface of the hot muffler! How to hold and drive the device Always hold the motor device securely with both hands on the handles. Always maintain a reliable and stable position. 5

8 Modifications with a two-hand grip handle. The right hand is on the work handle, the left hand is on the tubular handle. Modifications with a round handle For Modifications with a round handle and a round handle with a clamp (step limiter), the left hand is on the round handle, the right one on the work handle is also on the left-handed person. During operation 002BA055 K 002BA080 K Always maintain a firm and stable position. In case of imminent danger and / or in an emergency, immediately stop the engine; set the combined valve / stop switch to STOP or 0. 5m (50ft) There must not be any unauthorized persons in the area with a radius of 5 meters, danger of injury from dropping objects! This distance must to observe also in relation to objects (vehicles, window panes) the danger of material damage! Pay attention to the engine running idle so that the cutting tool no longer rotates after releasing the throttle lever. Regularly check the idle setting or adjust. If the cutting tool continues to rotate at idle, then the motor device should be returned for repair to a specialized dealer. Stihl recommends a specialized STIHL dealer. Caution when icy, in wet places, on snow, on ice, on the slopes of mountains, on rough terrain, you can slip! Pay attention to obstacles: stumps, roots can stumble! Work only while standing on the ground, never on an unstable base, on a ladder or on a lifting work platform. When using protective auditory capsules, you need to be especially careful and prudent since the perception of hazard-warning sounds (screaming, signaling tones, etc.) is limited. Observe timely interruptions in work, to prevent fatigue and exhaustion, the danger of an accident! Work calmly and deliberately only in good light and visibility. Work carefully, do not endanger other people. When the engine is running, toxic exhaust gases are released as soon as the engine starts. These gases may be odorless and invisible, and may also contain hydrocarbons and benzene. Never operate the motor vehicle in closed or poorly ventilated areas while also using the motor vehicle with a catalyst. When working in ditches, troughs or in cramped conditions, it is imperative to ensure that there is sufficient air exchange hazard to life due to poisoning! 6

9 If you experience nausea, headache, visual impairment (for example, decreased visual field), hearing impairment, dizziness, decreased ability to concentrate, stop working immediately, these symptoms can be caused, among other things, by an increased concentration of exhaust gases, the risk of an accident! Whenever possible, work with a motor vehicle silently and with a little emission of exhaust gas; do not leave the motor running unnecessarily; let gas only at work. Do not smoke when using the motor vehicle and near a working motor vehicle, fire hazard! Combustible gasoline vapors may escape from the fuel system. Dust, fumes and smoke generated during operation can cause serious damage to health. If dust or smoke is strong, wear a respirator. If the motor vehicle was subjected to an improper load (for example, the effect of force as a result of a shock or fall), then before further work it is imperative to check the operational state of the motor vehicle. “Before starting work”. In particular, check the tightness of the fuel system and the functioning of the safety devices. Never work with a device that is not reliable in operation. If in doubt, contact a specialist dealer. Do not operate in starting gas mode when the gas lever is in this position, the engine speed cannot be controlled. Never work without suitable guards for motor vehicles and cutting tools. Risk of injury due to dropping objects! Inspect the area: solid objects stones, metal parts, etc. May be thrown to the side with danger of injury! And may damage the cutting tool, as well as objects (e.G. Parking machines, windows). (Material damage). Use extreme caution when working on difficult to survey, densely overgrown areas. English When mowing in a high shrub, under bushes and near a hedge: the working height of the cutting tool must be at least 5 cm, do not injure animals. Before leaving a motor vehicle: be sure to stop the motor. Check the cutting tool regularly at short intervals and immediately with noticeable changes: Stop the motor, hold the motor device firmly, stop the cutting tool. Check the condition and firmness of the fit, pay attention to cracks. Pay attention to the sharpening condition. Damaged or blunt cutting tools should be replaced immediately, also with minor cracks the size of a hair. Fasten the cutting tool mount regularly from grass and branches to remove clogs in the area of the cutting tool or guard. Stop the motor before replacing the cutting tool with a risk of injury! Damaged or cracked cutting tools should no longer be used or repaired, for example by welding or dressing, changing the shape (imbalance). 7

10 Separated particles or debris can be seriously injured in a worker or bystanders at high speed! Use of mowing heads. Protect the cutting tool guard with the appropriate attachments in the operating instructions. Use only a guard with a properly mounted knife so that the mowing rods are cut to the permissible length. When adjusting the mowing harness while manually adjusting the mowing heads, it is imperative that the motor be stopped, danger of injury! Unauthorized use of a motor vehicle with mowing rods that are too long reduces the operating speed of the motor. This results in overheating due to prolonged slippage of the coupling and damage to important functional parts (for example, the coupling, plastic parts of the housing), for example, as a result of rotation of the cutting tool at idle, risk of injury! Application of metal cutting tools STIHL recommends the use of original metal cutting tools STIHL. These parts are optimally matched in their properties to the device and meet the user’s requirements. Metal cutting tools spin very fast. In this case, efforts arise that affect both the device and the cutting tool, and the material being cut. Metal cutting tools should be sharpened regularly according to the sharpening instructions. Unevenly sharpened cutting tools cause an imbalance that can extremely damage the device and the risk of breakage! Dull or improperly sharpened blades can cause an increased load on the metal cutting tool, the risk of injury from cracked or broken parts. After each contact with solid objects (e.G. Stones, rock fragments, metal parts), check the metal cutting tool (e.G. For cracks and deformation). Burrs and other visible accumulations of material must be removed (best with a file), as in the future, during operation, they can be released at any time and be thrown aside the danger of injury! To reduce these hazards arising from the operation of a metal cutting tool, the diameter of the metal cutting tool used should in no case be very large. The tool should be made of a sufficiently high-quality material and have the proper geometry (shape, thickness). A metal cutting tool made by manufacturers other than STIHL must not be heavier, thicker, or any other shape, and no larger than the maximum diameter of a metal cutting tool for this motor vehicle, which is a risk of personal injury! Vibrations Prolonged use of a motor device can lead to disturbances in the circulation of the hands caused by vibration (syndrome “white fingers”) The generally accepted duration of use of the device cannot be established, as this depends on many factors. The duration of use of the device is increased due to the following measures: hand protection (warm gloves); breaks in work. Duration of use is reduced due to: 8

11 personal predisposition of the worker to poor circulation (signs: often cold fingers, itching of the fingers); low outside temperatures; great effort when capturing a motor device (strong grip interferes with blood circulation). With regular, prolonged use of the motor device and with the reappearance of the corresponding symptoms (for example, itching of the fingers), it is recommended to conduct a regular medical examination. Maintenance and repair Perform regular maintenance on the vehicle. Only carry out maintenance and repair work as described in these operating instructions. All other work is entrusted to a specialist sales agent. Stihl recommends that you only carry out maintenance and repair work with a STIHL sales agent. Sales agents STIHL specialists regularly attend continuing education courses and are provided with technical information. Use only high quality spare parts. Otherwise, there is a danger of accidents or damage to the device. If you have questions, contact a specialist sales agent. Stihl recommends the use of genuine STIHL spare parts. These parts are optimally matched in their properties to the device and meet the user’s requirements. When repairing, servicing and cleaning, always turn off the engine. Danger of injury! Exception: carburetor and idle setting. When the plug of the spark plug is pulled out and the spark plug is pulled out, start the engine with the starter only if the combined engine / stop switch is set to STOP and / or 0 fire hazard due to ignition sparks outside the cylinder. Never carry out maintenance or store the equipment near open flames. Danger of fire due to fuel! Check regularly for leaks in the fuel tank shut-off device. Only use flawless STIHL approved spark plugs, see”technical details”. Check ignition cable (flawless insulation, firm connection). English Monitor the muffler in perfect condition. Do not operate with a defective muffler or without a muffler. Fire hazard! Hearing damage! Do not touch the hot muffler. Danger of burns! The state of anti-vibration elements affects the behavior of the device during vibration. Check regularly anti-vibration elements. Symbols on the guard The arrow on the guard for the cutting tool indicates the direction of rotation of the cutting tool. Wearing belt Use the guard only with mowing heads, not with metal cutting tools. A hanging strap is included in the scope of delivery or can be obtained as special accessories. 9

12 Mowing head with mowing strings 002BA364 K 002BA77 K Application of a hanging belt Use a motor vehicle with a running engine on a hanging belt Grass cutting blades, knife knives and choppers should be used together with a hanging belt (two-shoulder hanging belt)! Saw blades must be used with a two-shoulder suspension belt with quick release tool! For soft “cutting” for clean cutting also the edges with cracks around trees, hedge posts, the bark of trees is less damaged. Stihl PolyCut plastic mowing head with knives. For mowing the open edges of the meadow (without stakes, fences, trees and similar obstacles). Pay attention to the marked wear markings! 000ba05 K Never replace mowing strings with steel wire. Risk of injury! If on the PolyCut mowing head one of the markings is broken in the downward direction (arrow): do not use the mowing head again and replace it with a new one! Risk of injury due to debris from broken tools! Be sure to follow the maintenance instructions for the PolyCut mowing head! Danger of kickback when using a metal cutting tool When using a metal cutting tool (grass blade, young knife, chopper knife, saw blade), there is a risk of kickback if the tool encounters solid obstacles (tree trunk, branch, stump, stone or something like that). The device is accelerated, in this case, in the opposite direction against the direction of rotation of the tool. 0

13 An increased risk of kickback exists if the instrument encounters obstacles in the black sector. Grass cutting blade For grass and weed only. Drive like a scythe. 002ba35 K 000BA020 K Abuse can damage the grass blade. Risk of injury due to dropping objects! Sharpen the cutting blade for grass with noticeable dullness according to the instructions. Knife for thick young growth For fallen grass, wild growth and dense shrubs, for thinning out stands with a maximum trunk diameter of 2 cm. Do not cut thicker trees. Danger of an accident! Cane knife “immerse” grind the cut material into the wild growth and dense shrub at the same time, do not hold the cutting tool above the thigh. With this technique, you must be extremely careful. The greater the distance from the ground to the cutting tool, the higher the risk of particles dropping to the side. Danger of injury! When mowing grass and thinning out a young tree stand, drive the device like a scythe close to the ground. Attention! If abused, you can damage the knife for young animals. Danger of injury from dropped objects! 002ba066 K English To reduce the risk of an accident, be sure to observe the following: Avoid contact with stones, metal objects or the like. Do not cut stands or shrubs with a diameter of more than 2 cm. Use a saw blade. Check the knife for young animals regularly for damage. Defective knife for young animals do not use again. Grind the pole knife regularly (if there is a noticeable dullness) according to the instructions if you need to balance it (STIHL recommends a specialized STIHL dealer) Chopper knife for thinning and chopping hard, fallen grass and small thickets.

14 Immerse the chopping knife in a frequent shrub and small thicket, the material being cut is chopped, and do not hold the cutting tool above the thigh. With this technique, you must be extremely careful. The greater the distance from the ground to the cutting tool, the higher the risk of particles dropping to the side. Danger of injury! Attention! Overuse can cause damage to the chopping knife, risk of injury due to thrown parts! To reduce the risk of an accident, be sure to observe the following: Avoid contact with stones, metal objects or the like. Do not cut trees or shrubs with a diameter of more than 2 cm; chopper knife regularly check for damage, defective chopper knife no longer apply; When chopping, noticeably blunt, grind the knife according to the instructions and, if necessary, balance it (with a specialized sales agent). Saw blade For cutting bushes and trees: with a trunk diameter of up to 4 cm in combination with motor scythes; with a barrel diameter of up to 7 cm in combination with free cutting devices. The best cutting performance is achieved with a full supply of fuel (full gas) and a uniform pressure when feeding. Use saw blades only with a stop corresponding to the diameter of the cutting tool. Avoid contact of the saw blade with stones and earth, risk of cracking. Make timely sharpening according to the instructions. Dull teeth can cause cracking and damage to the saw blade. Risk of accident! When felling, keep a safe distance to the next workplace, at least two lengths of wood. Hazard of kickback 002BA068 K Increased danger of kickback in the black sector: Never bring tools in this area or cut. In the gray sector there is also a danger of return: in this area, work must be carried out by experienced personnel trained in the methods of special work techniques. In the white sector, light work with weak returns is possible. Always bring the tool in this area. 2

15 Permissible combinations of cutting tool, guard, stop and suspension belt Cutting tool Protection, stop Wearing belt BA003 K 3

16 Permissible combinations Choose the correct combination from the table, depending on the cutting tool! For safety reasons, only cutting tools and guards should be combined, as well as stops located on the same table line. Other combinations are not allowed. Danger of an accident! 4 Saw blade 225, spiky tooth 2) 5 Saw blade 225, chisel tooth 2) 6 Saw blade 225 (carbide) 2) Cutting blades for grass, knives for young animals, chopper knives and saw blades of materials other than metal are not allowed. Protection, stop Mounting the handle with two handles 3 2 Cutting tools Protection Cutting heads STIHL SuperCut STIHL AutoCut STIHL AutoCut 40-4) 4 STIHL TrimCut STIHL PolyCut 40-3 Metal cutting tools 6 Cutting blade for grass Cutting blade for grass Cutting blade for grass Spezial 9 Spezial young growth knife 0 Young growth knife Knife chopper Saw blade 200, spiky tooth 3 Saw blade 200, chisel tooth 7 Protection for mowing heads 8 Protection with 9 apron and knife for mowing heads (see “Installation of protective devices”) 20 Protection without an apron and a knife for mowing tools, positions from 6 to 0 2 Protection for the chopper blade Stop 22 Stop for saw blades Stop for saw blades 225 Suspension belt 24 A two-shoulder suspension belt must be used 25 Two-shoulder suspension belt “Komfort” ) only for FS 450, 480 2) only for FS 400, 450, 480 Hold the clamp hemisphere () 256BA00 K Unscrew the clamp screw (2) and remove the clamp hemispheres after unscrewing the clamp screw. Remove the upper clamp hemisphere (3) from the lower clamp hemisphere. 4

17 4 A Insert the tubular handle (4) into the lower clamping hemisphere () so that the distance (A) does not exceed 5 cm. Place the upper clamping hemisphere and press down. Screw in the clamping screw. Align the tubular handle in the transverse direction relative to the shank. Tighten the clamping screw to the full. 256ba002 K Unscrew the screw (5), the nut (5) remains in the control handle (7), the control handle together with the fuel control lever (8), pointing in the direction of transmission, push the end of the tubular handle (4) until it matches holes (9). Screw in the screw and tighten to the full. Next Throttle control cable control 002BA256 K Throttle control cable control Depending on the equipment on the operating handle, the throttle control cable can be adjusted. A properly adjusted throttle control cable is a prerequisite for the correct functioning of the start gas, idle and full throttle. Adjust the throttle control cable only with a fully mounted device, the control handle must be in the working position. Press the latch on the control handle at the end of the groove with the tool. 002ba63 K For generous transport and storage: unscrew the clamping screw, fold the tubular handle parallel to the shank, turn the handles down. 5

18 STOP Mounting the guards Mounting the apron and knife 2 Press the lock of the fuel control lever () and the lever (2) (feed position fully) “full throttle”), the throttle control cable is adjusted correctly. 249ba07 K Protective device Protective device for mowing tools 2 Protective device for mowing heads 3 Protective device for chopping knife 4 Support Mounting the protective device Put on the protective device and support. 4 Screw in the screws and tighten all the way. 256ba082 K Slide the apron (2) onto the guard (), use the guide groove (4) for all strings. Insert the knife (3) into the upper guide groove (5) of the apron and, together with the first mounting hole, bring it to the coating. Screw in the screw and tighten to the full. Polycut 40-3 mowing head These accessories, when using mowing heads, must be mounted for protection (). For the PolyCut 40-3 mowing head, slide the apron into the guide groove (5) 002BA293 K 6

19 Stop Locking the cutting tool Dismantling the fasteners English 2 Locking the shaft Stop for saw blades Stop for saw blades 225 Mounting the stop Place the stop. Screw in the screws and tighten all the way. 002ba339 K Push the insertion shaft () all the way into the hole (2) in the gearbox 2 turn the shaft until it locks in place 002BA294 K BA295 K Lock the shaft Using the combination wrench (), release the nut (2) clockwise and remove Remove the movable disc (3) and thrust washer (4), depending on equipment. 7

20 Mounting the safety ring Mounting the mowing head STIHL SuperCut, STIHL AutoCut, STIHL TrimCut Mounting the mowing head STIHL PolyCut The safety ring (, 4) is included in the scope of delivery or is supplied as special accessories. For optimal protection against winding during operation of mowing tools Mount the cutting ring () for mowing, install the movable disk (2) and the protective washer (3) Before mounting the saw blades Remove the protective washer (3) and the clamping disk (2) Remove the protective ring () for mowing Mount the safety ring (4) for sawing Install the clamping disk (2) 002BA296 K Lock the shaft. Screw the mowing head counterclockwise onto the shaft () and tighten. Carefully store the attached data sheet to strong head. Dismantling the mowing head Shaft lock Unscrew the mowing head clockwise Remove the tool to lock the shaft. 68ba24 K Lock the shaft Install the mowing head Install the thrust washer () with the bulge downward Screw the nut (2) counterclockwise and tighten Remove the tool to lock the shaft. Dismantling STIHL PolyCut 40-3 Shaft lock Loosen the nut clockwise. Loosen the loose nut! 002ba298 K 8

21 Adjusting the mowing string For a detailed description, see the attached data sheet for the respective mowing head. The SuperCut String mowing head is automatically adjusted during mowing and shortened with a knife on the guard to the optimum length. Adjustment is made only if both ends of the string have a length of at least 6 cm. Autocut mowing head Hold the device together with the engine running (the mowing head must rotate) above the lawn surface. The mowing head touches the ground slightly and the string is cut to the optimum length with a knife to protect Adjustment is only possible if both ends of the string have a length of at least 2.5 cm. Trimcut mowing head Stop the engine; slide the combination valve in the direction of the arrow on the stop sign nips (h) to the STOP-0 position Lift up the coil body counterclockwise by approximately / 6 turns to the locked position and release again so that it springs out Pull the ends of the string out If necessary, repeat the process until both ends of the string are approx. 4 cm. When turning from one locking groove to another, the string is released approximately 4 cm. Cutting blades for grass, knives for young animals, chopper knives Cutting tools with 2, 3 or 4 wings (, 4, 5) can indicate these cutting tools in any direction Turn tools over regularly to avoid one-sided wear. 5 68BA33 K English For grass cutting blades (2) and Spezial (3), the cutting edges should point in the direction of the arrow. Fit the mowing safety ring 4 3 b a Fit the cutting tool () The shoulder (a) must go into the hole (b) of the cutting tool! With the chopper knife (2), the cutting edges must point up. Install the thrust washer (3) with the bulge up. Install the movable disk (4) (for mowing) and the retaining ring (5) (for the chopping knife) BA299 K 9

22 Shaft lock Screw the nut (6) counterclockwise and tighten 4 Dismantle the cutting tool Shaft lock Remove the shaft lock tool. 3 Loosen the nut clockwise Dismantle the cutting tool 2 Replace the loose nut. Shaft lock Loosen nut clockwise b a Replace loose nut. Saw blades 200 and 225 Install the cutting guard ring. Install the cutting tool (). The cutting edges must point in a clockwise direction. Install the thrust washer (2) with the bulge up. Install the movable disk (3) (for sawing). Shaft block. The collar (a) must go in. Into the hole (b) of the cutting tool! Screw nut (4) counterclockwise and tighten. Remove tool to lock the shaft. 002ba300 K 20

23 Fuel The engine must run on a fuel mixture of gasoline and engine oil. Avoid direct contact with fuel and inhalation of fuel vapors. Stihl MotoMix STIHL recommends the use of STIHL MotoMix. This fuel mixture does not contain benzene, tetraethyl lead, has a high octane rating and always offers the correct mixture ratio. The STIHL MotoMix blend is matched to STIHL engines and guarantees a long engine life. Motomix is not available in all markets. Preparation of the fuel mixture Unsuitable consumables or improper fuel mixtures can result in serious damage to the drive mechanism. Lower quality gasoline or engine oil can damage the engine, o-rings, fuel lines, and fuel tank. Gasoline Use only branded gasoline with a minimum octane rating of 90 ROZ with or without tetraethyl lead. Devices with a catalyst for neutralizing exhaust gases should only be operated on gasoline that does not contain tetraethyl lead. After many refueling with leaded gasoline, the effectiveness of the catalyst can be significantly reduced. Engine oil Use only high-quality engine oil for two-stroke engines, best of all STIHL brand engine oil for two-stroke engines, this oil is compatible with STIHL engines and guarantees a long engine life. If STIHL brand engine oil for two-stroke engines is not available, use engine oil for two-stroke engines with air cooling, in no case engine oil for water-cooled engines with separate oil circulation (for example, common for four-stroke engines). For motor vehicles with a catalyst for neutralizing exhaust gases, only STIHL engine oil for two-stroke engines should be used to prepare the fuel mixture: 50. The ratio of the fuel mixture Engine oil brand STIHL for two-stroke engines: 50; : 50 = part of oil 50 parts of gasoline Examples Quantity of gasoline STIHL two-stroke engine oil: 50 Liter Liter (ml) 0.02 (20) 5 0.0 (00) 0 0.20 (200) 5 0.30 (300) 20 0.40 (400) 25 0.50 (500) Engine oils for two-stroke engines of other brands:: 25 = part of the oil 25 parts of gasoline Pour the engine oil into the approved fuel canister, then gasoline and mix thoroughly. Storage of the fuel mixture Keep the fuel mixture only in containers approved for fuel in a dry and safe place, protected from light and sun. The fuel mixture is oxidized; stock the mixture only for a few weeks. Do not store fuel mixture for more than three months. Under the influence of light, sun, low or high temperatures, the fuel mixture may become unsuitable faster. 2

24 Shake the canister thoroughly before refueling. Pressure in the canister may rise; open the fuel canister carefully. Clean the fuel tank and canister from time to time. Remove fuel residues and the liquid used for cleaning in accordance with the regulations and without harming the environment! Refueling Preparation of the device Refueling When refueling, do not spill or fill the fuel tank to the brim. Stihl recommends a STIHL fueling system (special accessories). Open the tank shut-off device. Fueling. Close the tank shut-off device. After refueling, tighten the tank lock by hand as tight as possible. Changing the fuel suction 256BA060 K Before refueling, clean the fuel tank shut-off device and the surrounding of the tank so that no dirt enters the tank. Position the device with the tank locking device pointing up. Replace the fuel suction annually, for this: 250BA05 K 22

25 Empty the fuel tank. Pull the fuel inlet out of the fuel tank and pull it off the hose. Insert a new fuel inlet into the hose. Insert the fuel suction head into the tank again. Overlay of a two-shoulder belt. Balancing the device. The device is balanced in a different way, depending on the mounted cutting tool. Wait until the swinging motor device suspended on the suspension belt stops. If necessary. Change the suspension point BA240 K Mowing tools Apply a two-shoulder strap (). Adjust the length of the belt so that the carabiner hook (2) is approximately on the width of the palm of the hand under the right thigh. After adjusting the belt length, too long ends can be shortened. Hang the carabiner hook on the perforated plate (3) of the device. In conclusion, determine the correct poke for hanging the mounted cutting tool, see Balancing the device. Mowing heads, grass mowing discs, pole knives and chopping knives should rest lightly on the ground. 256ba06 K 23

26 Saw blades Saw blades must “soar” above the ground at a distance of about 20 cm. 256ba07 K Starting / Stopping the engine Control knob Control elements STOP STOP 2 START Lock of the fuel control lever 2 Fuel control lever 3 Combined shutter Combined shutter positions 4 STOP-0 engine stopped ignition off 5 F operating position the motor is running or it can start 6 START start the ignition is turned on the engine can start 3 002BA82 K Symbol on the combination valve 7 h Stop sign and arrow to stop the engine move the combination valve to the right When the arrows on the stop sign (h) are turned to the STOP-0 position. Start Press the lever stop and fuel control lever in sequence. Both levers keep pressed. Move the combined valve to the START position and also keep pressed. Release the fuel control lever, combined valve and lever stop = start position of the fuel control knob Set the rotary button (8) of the air damper to position BA08 K 24

27 g When the engine is cold Start e When the engine is warm, also if the engine is already running but has not yet warmed up, press the fuel pump bellows (9) at least 5 times also if the bellows is filled with fuel 002BA038 K 002BA072 K With your right hand take the starter handle Pull the starter handle slowly to the first noticeable stop and then quickly and strongly pull out the decompression valve button before each start-up procedure, press it again 256BA094 K 002BA040 K Put the device on the ground in a stable position: motor support and protection for cutting tools ment form a stand. The cutting tool must not touch the ground or any objects. Do not pull the cable out to the end of the cable, risk of rupture! Do not release the starter handle quickly back, but take it slowly, against the direction of pulling, so that the starter cable can be wound correctly. Continue starting After the first ignition is activated Take a stable position Hold the device firmly with your left hand while touching neither the fuel control lever nor the lever lock the thumb is under the fan housing Turn the start valve rotary button to e position Press the decompression valve button again Restart until the motor starts. As soon as the motor starts to work Do not put your foot on the shank and do not become a knee! Briefly press the fuel control lever briefly; the combination valve slips to the operating position F the engine enters idle mode 25

28 The device is ready to use. Stopping the motor With the carburetor correctly adjusted, the cutting tool must not rotate at idle speed of the motor! Move the combination valve in the direction of the arrow on the stop symbol h to the STOP-0 position. At very low temperatures. After the engine has started: Briefly press the fuel control lever = the starting position of the fuel control handle is released. The combined valve jumps to the operating position. F The engine moves to idle mode Give a little gas. The motor should warm up for a short period of time FS 400, 450: if necessary, switch to winter mode, see “Winter mode” If the engine does not start The rotary button for the choke After the first ignition of the motor, the rotary button of the choke was not set to the e position in time, the motor “choked”. Turn the start valve rotary button to position e. Adjust the starting position of the fuel control knob. Starting the engine; for this, a starting cable may need to be pulled with a force of 0 to 20 cable pulls. If the engine still does not start, move the Combined valve to the STOP-0 position. Remove the spark plug, cm. “Spark plug”. Dry the spark plug. Press and hold the fuel control lever fully. Extend the start cable several times to vent the combustion chamber. To install the spark plug, see “Spark plug” Slide the combination gate valve to the START position. Turn the choke knob to position e also with a cold motor! Restart throttle control cable adjustment Check whether the throttle control cable is correctly adjusted, see “Throttle control cable adjustment” The fuel tank was completely empty. After refueling, squeeze the bellows of the fuel pump at least 5 times also if the bellows is still full of fuel. Set the rotary button of the start valve depending on the temperature of the motor. Repeat the start of the motor 26

29 Operating Instructions First commissioning Do not operate a completely new device (directly from the factory) at high speed without load, up to the third refueling of the fuel tank, so that there are no additional loads during running-in. During running-in, the moving parts must rub against each other, in the drive mechanism there is an increased friction resistance. The engine reaches maximum power after 5 5 refueling. During operation, place away from sources of ignition. In case of a long interruption, see section “Device storage”. Cleaning the air filter English If the engine power drops noticeably FS 300, FS After long-term operation at full load, leave the engine idle for some time until most of the heat has been removed by the cooling air stream, thereby reducing the load on the drive parts (ignition system, carburetor) due to stagnation of heat. After work When stopping briefly: leave the engine to cool. Keep the device with a filled fuel tank dry until the next use. Turn the start valve rotary button g Press the bar (). Remove the filter cover (2). Clear the dirt on the inside of the filter cover and the adjacent surface of the air filter. Remove and check the air filter (3) when replace with dirt or damage; replace 250BA022 K 27

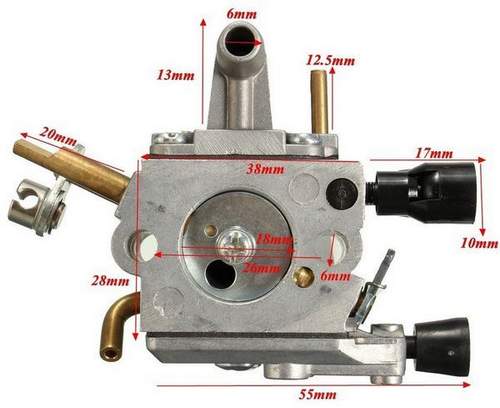

30 Install the air filter in the filter cover. Carburettor adjustment. Install the filter cover. Fs 400, FS 450, FS 480. Basic information. H 3/4 L Turn the start valve rotary button. G Loosen the fixing bolt (). Remove the filter cover (2) 2 3. Remove coarse dirt from the filter and the adjacent surface of the air filter. Remove and check the air filter (3) if it is dirty or damaged. Replace the air filter in the filter cover. Install the filter cover. 256ba074 K The carburetor is supplied with Odom with a standard setting. This setting is adjusted so that under all operating conditions, the engine is supplied with the optimal air-fuel mixture. For this type of carburetor, adjustment with the main adjusting screw is possible only within narrow limits. Standard setting. Stop the engine. Mount the cutting tool. Check the air filter if necessary; replace. Check that the throttle cable is correctly adjusted. “Throttle control cable adjustment” Turn main adjusting screw (H) counterclockwise to the max. 3/4 turn the idle adjustment bolt (L) fully rotated clockwise until it fits snugly, then turn it counterclockwise. The engine must warm up. Using the idle stop screw (LA), adjust the idle speed so that the cutting tool no longer moves Setting the idle speed The motor stops at idle LA Set the idle speed adjustment screw (L) as standard. Turn the idle stop screw (LA) slowly clockwise until the motor runs evenly. The cutting tool must not move. 255ba00 K 28