Chainsaw Assembly Partner 350 Video

Chainsaw Partner 350: DIY repair, Chainsaw design features “Partner 350”. The main malfunctions of the ignition system, muffler, fuel system, cylinder-piston group of the chainsaw. DIY repair.

Chainsaw Partner 350: DIY repair,

Today, almost every household has a chainsaw, which is a worthy replacement for axes and hand saws. The Partner 350 hand-held chainsaw will be the ideal solution for people living in a private house or engaged in construction. This tool from the Swedish manufacturer is very convenient and compact, so it is suitable for any work on a personal plot.

However, improper care and intensive use of the unit can lead to its breakdown. In this case, it is not necessary to immediately contact a service workshop. Many faults can be corrected by hand. To do this, it is enough to study the saw device and instructions for its repair.

The main malfunctions of the Partner 350 chainsaw

Most often, the cause of a tool breakdown is associated with interruptions in the operation of the engine or other components and systems. Disassembly is required to eliminate any faults. To do everything right, you need to know the design features of the chainsaw and the main reasons for its breakdown.

Chainsaw fuel system repair

The reasons why the fuel-air the mixture does not enter the cylinder, there may be several:

- Clogged fuel filter;

- Clogged hole in the fuel tank cap (breather);

- Insufficient fuel;

- Improperly adjusted carburetor;

- Clogging of channels or violation of the integrity of the carburetor membrane.

To diagnose a clogged filter or breather, you just need to disconnect the hose and see how the fuel flows. The trickle from the tank should pour out a good head. If it is intermittent and weak, then the filter must be pulled out through the neck of the tank and washed or replaced, and the breather must be cleaned with a needle.

The chainsaw carburetor is a rather complex device, equipped with many small parts. Therefore, it is better to entrust its disassembly and repair to specialists.

If the carburetor filter is simply clogged, then it can be carefully removed, shaken out, washed with detergents and put in place.

The carburetor can only be adjusted with your own hands. This is done with three screws strictly according to the instructions.

Partner 350 chainsaw won’t start. How to fix the problem?

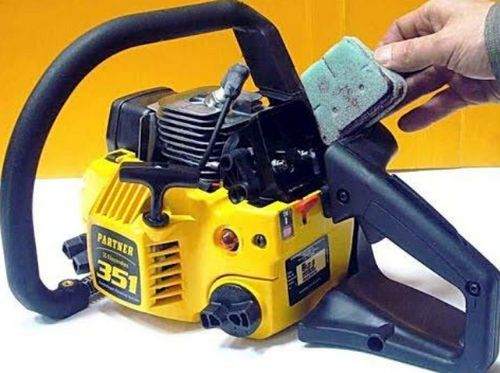

When this breakdown is found, the first thing to inspect is the condition of the air filter. If a large amount of dust has accumulated on it, then the filter will need to be rinsed using clean gasoline.

Another common cause of a malfunction is problems with the ignition system. To repair the chain saw, you need to remove its left protective cover and set the correct clearance between the flywheel and the ignition coil.

In some cases, replacing the fuel mixture will help solve the problem. To do this, the used fuel will need to be drained and a new mixture of pure gasoline and engine oil poured into the tank.

Chainsaw Partner 350. Malfunctions and their elimination

Breakdown of Partner garden tools can occur for various reasons, the most common of which are improper use and mechanical shock. To eliminate the malfunction, you will need to determine its exact cause in advance. After that, you can begin to repair the instrument yourself.

Chainsaw Partner 350 starts up and stalls

There may be several reasons for this malfunction. Most often, the engine of the tool starts up and immediately stalls due to a clogged factory breather, as a result of which fuel does not enter the engine cylinder in sufficient quantity for operation. To fix the damage, you will need to remove and clean the breather. If it is damaged, then it will need to be replaced.

Another reason is the missing contact of the plug with the electrical wiring cap. This can be due to mechanical shock or engine oil carbon deposits on the plug. To repair the Partner 350 chainsaw, the spark plug will need to be removed and cleaned. In some cases, replacing the plug completely can help.

The third reason for the malfunction is a strong blockage of the standard chain saw muffler. Over time, carbon deposits form on its walls, which prevents exhaust from the engine. As a result, gases build up inside the motor and interfere with proper operation. To fix the damage, it is necessary to remove the muffler and clean it with compressed air. You will also need to disassemble the motor and blow through its cylinder.

Starter cord breakage

Partner 350 is quite common on chainsaws, and on all chainsaws, therefore Partner 350 is no exception. This malfunction is not difficult to eliminate yourself. Having looked, it becomes clear how the broken starter cord is replaced.

Device

The general arrangement is traditional. Differs in simplicity, which means high reliability of the unit.

The diagram of the general device of the Partner 350 chainsaw clearly confirms this.

Engine starting is simple and reliable. This was made possible by the presence of electronic ignition. A primer (fuel booster pump) plays an important role during start-up.

The air filter is equipped with a double air purification system. As a result of equipping the starter drum with an impeller, large particles of debris do not reach the filter at all. Thanks to this, its service life is increased, and the degree of air purification is increased. In general, this has a beneficial effect on engine performance.

Safe handling of a working saw is achieved by the presence of a chain brake that operates in two modes. Manual and automatic.

The oil pump is only switched on when cutting. This means that the chain lubrication system is automatic. It must be borne in mind that different types of oils are used to lubricate the chain and prepare the working mixture. Find out what oil is used for the Partner 350 chainsaw will help

Saw chains. Oregon 91P052E 3/8 ″ 1.3 mm 52 links chain is installed on the Partner 350 saw. Replacement by analogs is acceptable: Stihl 39970000052s and others. For example, Husqvarna 5776151-22. Make sure that the number of links does not exceed 52 when the chain pitch is 3/8 ″ and the groove width is 1.3 mm. Less (46. 50) is possible, more is not desirable.

The anti-vibration system on the Partner 350 works somewhat harshly. Considering that this saw is not intended for professional use, the overall system can be considered satisfactory. By the way, on subsequent models, significant improvements have been made in this regard.

User’s manual

The manual contains recommendations, following which the owner of the Partner 350 chainsaw will not encounter problems when handling it. The safety measures and rules for operating the product during operation are described in detail. The issues of repair, maintenance and care of the Partner 350 chainsaw are covered.

The types of chainsaw repairs allowed to do it yourself are determined by the operating instructions. All other faults are rectified in a specialized workshop.

The operating instructions should always be at hand, especially if this is your first chainsaw and you just bought it. Be sure to read it first, and use it when questions arise while handling the instrument. You can download and print the instruction manual for the Partner 350 chainsaw using the link below.

Technical nuances, device and carburetor adjustment

When adjusting the carburetor, it is important to disassemble it in detail and clean it of any dust and dirt. Thus, providing additional care for the connecting elements and the body.

The Partner 350 chainsaw has several levels of protection, both for the oil pump and for the carburetor. This allows us to say that it is necessary to adjust and tune the operation of the carburetor taking into account future loads on the equipment.

When disassembling the chainsaw, it is important to properly disconnect the carburetor in order to adjust it afterwards. After accessing the internal components, the fuel hose and the drive rod are separated.

Disconnect the cable tip. On the left side of the union, you can remove the gas hose.

The result is a perfectly removed carburetor that can be repaired and fine-tuned.

If you are interested in knowing how to sharpen a chainsaw chain at home, then you can read about this in detail in our article.

Advantages when using this model

With a partner chainsaw, you can guarantee perfectly cut and cut wood. With all this, certain advantages can be noted, namely:

- Ease of maintenance and service repairs can be performed by almost anyone;

- Reliable body and practicality of use due to the lightness of the chainsaw;

- Minimal fuel and oil consumption;

- Ergonomics of each of the chainsaw elements;

- Possibility of use at high and low air temperatures.

These criteria make it possible to talk about the widespread use of chainsaws: in difficult weather conditions with the performance of a large amount of work in the shortest possible time.

Do-it-yourself partner 350 chainsaw repair.

Today, when carrying out repairs or any kind of construction, you cannot do without a chainsaw. The quality of its work will affect the entire process of dividing wood and the implementation of the planned building project. That is why it is worth considering carefully the choice of a high-quality chainsaw, which will make it possible to carry out the process of dividing building elements based on wood in a practical and more qualified manner.

The purchased Partner 350 chainsaw is an excellent example. But, like any other type of chainsaws, it can become unusable and require repair. To complete it, it will be important to correctly understand the cause of the breakdown and correctly replace the elements that have exhausted their resource.

As a rule, repairs can be done on their own, only you need to understand where to start. Considering the operation of an oil pump or an existing carburetor. To do this, you will need to study the device and the principle of operation of the Partner 350 chainsaw.