Chainsaw Malfunctions And Troubleshooting

Chainsaw ignition

A chainsaw, like any device running on an internal combustion engine, has an ignition system. She is responsible for the ignition of the fuel-air mixture in the engine cylinder. This occurs through the supply of an electrical discharge, which pierces the space between the electrodes of the spark plug.

It is clear that without ignition of the fuel, no engine will start and will not work. However, the problem is not only this: the quality of the chainsaw depends on how accurately the ignition is set. In other words, the fuel ignites on time or at the wrong time. Therefore, a chainsaw with lost settings needs to be repaired. Troubleshooting can be entrusted to an experienced mechanic, but you can repair the ignition of the chainsaw with your own hands.

Important: new chainsaws come with adjusted ignition, there is no need to disassemble and assemble the tool immediately after purchase.

Some Chinese chainsaws come with low-quality candles. It may make sense to have several spark plugs in the kit. In our review we will introduce you to the device and the principle of operation of the ignition system, its main problems and how to solve them.

Structural components

All gasoline two-stroke engines have a similar principle of operation, and therefore the ignition system in them has a typical structure and device.

Chainsaw ignition device:

- Magneto: a device that converts mechanical energy into electrical energy, provides a current impulse to a chainsaw spark plug;

- Spark plug: designed to ignite the fuel-air mixture, through a discharge arising between the electrodes;

- Power cable;

- Engine shut off button.

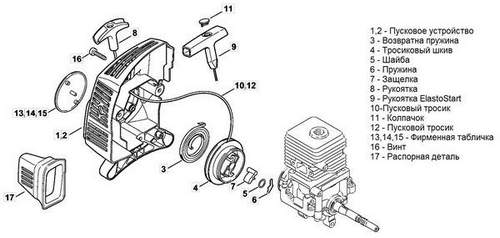

Candles are spark, arc, glow and catalytic. Chainsaw devices use spark plugs for 2-stroke engines. The schematic diagram of the ignition of a chainsaw is shown in the image.

Ignition problems

Most often, we think about repairing after the chainsaw has stopped starting, or there are visual signs of serious damage.

Symptoms of ignition failure:

- The chainsaw starts up, but it works unevenly (troit), often sneezes and shoots;

- The power of the chainsaw fell noticeably;

- With a sharp press on the accelerator trigger, engine dips are observed;

- A chainsaw starts badly on a cold one, troits a lot, until it warms up;

- Significantly increased fuel consumption;

If similar flaws appeared in the work of your chainsaw, then it is time to carry out diagnostics, adjustments, and possibly repair the ignition system.

Determination of fault location:

First of all, it is necessary to inspect the candle, if either a lot of soot has accumulated on it, then the cause of the malfunction is most likely associated with the operation of the carburetor, piston group or fuel quality. If visually the candle looks good, it does not throw and it is dry. Make sure there is a spark.

- Unscrew the candle, put on the ignition cable;

- Using pliers with insulated handles, press the candle thread onto the motor housing;

- Pull the starter handle toward you and make sure there is a spark;

If there is no spark, change the spark plug to a new one and test again. After making sure that there is a spark, we start the engine. But what if there is no spark even on a working candle? We continue the search:

- Testing the power cable for breakage and insufficient contact with the spark plug. We check the serviceability of the spring in the cap of the holder and the presence of contact with the armored cable;

It is best to use a tester to check the wiring.

- Check the gap between the ignition module and the flywheel magnetic circuit. It should be no more than 0.3. 0.4 mm.

The correct clearance can be set using the probe, they are not a deficit and are available for a small fee.

Diagnostics of malfunctions with a multimeter

It is possible to determine the malfunction of the ignition coil by the so-called hardware method. However, for this you must have a multimeter with which to diagnose.

Step-by-step diagnostics of ignition with a multimeter:

- We set the multimeter to the position at which the needle is at around 200 ohms.

- We study the instructions of the chainsaw. We find out the optimal resistance for the winding of the coil installed on our model (in most modern chainsaws this figure ranges from 3-5 Ohms.);

- We connect the multimeter to the primary winding of the coil and measure the resistance, if it is normal. Continue testing;

- We connect the multimeter to the secondary winding of the coil, compare the readings with those indicated in the instruction manual;

- We connect the multimeter to the hole of the coil into which the wires are inserted. If the device gives normal values, we conclude that the coil is working. If the measurement results are far from optimal, you will have to replace the assembly (coil) with a new one;

review fault detection with a multimeter

Ignition adjustment

As we have already noted, you can adjust the ignition system both in the workshop and at home. To do this, you will need ordinary wrenches, a screwdriver and a 0.4 mm probe (you can make the probe yourself from improvised materials. Plain paper for Xerox, a plastic bottle, etc.).

Step-by-step ignition adjustment of a chainsaw:

- We diagnose a malfunction;

- Dismantle the protective cover;

- We remove the module with a candlestick and an electric cable. We carry out their visual inspection, if necessary, replace with a new one;

- We install the ignition module, but do not tighten the fastening screws to the stop;

-

We determine on the flywheel a section with a magnet;

- Set the gap properly, in accordance with the parameters specified in the instruction manual;

- Tighten the screws that secure the module to the stop, check the settings with a probe, and, if necessary, re-adjust;

- We install a protective cover and check for a spark on the candle;

- Screw in the candle, start the chainsaw;

Important: special attention when repairing the ignition of a chainsaw should be given to setting the correct clearance between the module and the flywheel.

You should also check to see if the flywheel is holding onto the module with a counterweight. If this happens, you may have a bearing out of order or a play on the shaft.

Starter device

Often, chainsaw manufacturers equip their units with starters that work on almost the same principle, namely: there is a handle in the groove of the saw body through which a cord is passed. With a sharp lifting of the handle, the cord is also pulled, which engages the ratchet drum. Thus, the drum with spitz, which is located on the shaft, is driven. At this time, the crankshaft makes several revolutions, leading to compression of the fuel mixture, which at this moment is between the cylinder head and the piston. When lowering the handle, on the contrary, the ratchet and spitz lose their contact, which leads to a shaft stop.

With an increase in the power of the chainsaw, the amount of the fuel mixture increases, which must be ignited when the chainsaw is started. In this case, to start the engine, it is necessary to increase the number of jerks of the starter cord. To accelerate the return of the drum mechanism, manufacturers use a special steel recoil starter spring with excellent elasticity.

In the event of a spring breakdown, it is necessary: to remove the clip of the mechanism, pull out the spring, fixing its upper part with a finger and slightly pulling the starter handle to the side. Then, wrap a new part, while avoiding kinks and twisting of a new spring element, then gently fix the clip.

review

Overview of how to set the clearance of the coil

Chainsaw clearance overview

Overview of how to replace the coil on a chainsaw

Yakov Sinelnikov, 56 years old, Khabarovsk

“I bought an old chainsaw. Well, as old. She lay with her grandfather for three years in the garage. I tried to start it. Nothing worked. He looked at the candle, as if it weren’t pouring, dry. Unscrewed, checked. There is no spark. I had to disassemble and set the gap. Instead of a dipstick, I cut out a homemade product from a plastic bottle, inserted and adjusted it. The chainsaw works fine. The main thing is to set the gap and assemble it correctly. By the way, I also changed the candle. ”

Yaroslav Stembitsky, 37 years old, Zhytomyr region

“After the winter, the chainsaw did not start. I pulled the starter for a long time. The hand was tired, but it did not start. Then I guessed to unscrew the candle and check for a spark. Deafly, there is nothing. He removed the protective cover, looked. The gap is normal. I collected everything, but it again does not start. I dig around the day until I guessed to check the contact on the candle. It turned out that the spring jumped out. Why and when. I can’t imagine. ”

Semen Starodubtsev, 54 years old, Krasnodar

“I cleaned the garden in the spring, the chainsaw began to sneeze, and then completely died out. I looked at the candle. It’s completely wet, it seems to flood. I cleaned the carburetor, changed the candle. It won’t start. Looked. There is no spark. I disassembled the ignition and found the reason. The high-voltage cable completely melted. Why this happened. Still do not understand. Changed the cable with the module. Now everything works fine. ”