Choosing a Band Saw For Metal

Band saws for wood and metal are widely used in production and in domestic conditions by home craftsmen. The main cutting tool of these units is a band saw, which wears out over time and requires sharpening or replacement with a new one. You should know that not only the quality of material processing, but also the performance of the unit as a whole depends on the correct choice of blade for a band saw machine.

Choice of band saw blades for metal

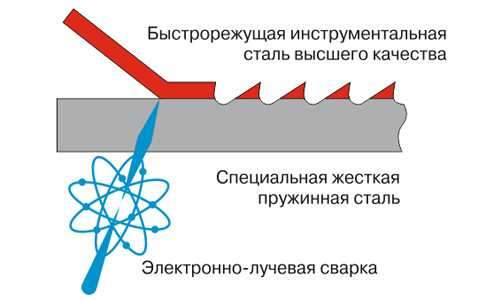

The cutting blade for this type of saw is a band with a certain number of teeth welded in the form of a ring. The basis of the tape is made of spring-spring steel, which has high elasticity. A tape made of high-speed steel is welded to the base, on which tooth milling is subsequently performed.

Each band saw for metal and not only is marked. For example, the marking M42 20 x 0.9 x 2362, 8 / 12TPI, is deciphered as follows:

- M42. Material from which the teeth of the tape are made;

- 20. This value indicates the width of the canvas, mm;

- 0.9. Tooling thickness, mm;

- 2362. The circumference of the saw tape, mm;

- 8 / 12TPI. Tooth pitch on the saw blade, per inch.

Cutters can be made of other materials, for example, from M51, PQ, TSX and others. M42 is characterized by high wear resistance and has an edge hardness of 67–68 HRC. Therefore, saws made of this material can be used for cutting steel with a hardness of not more than 45 HRC. Saws with cutters made of M51 material are more resistant to abrasion than the ones mentioned above. The hardness of the edge of the cutters of these saws is already 68 HRC, so that stainless steel is cut with this tool, as well as steels characterized by high strength and heat resistance. In addition, the material of the saw M 51 allows you to cut thick steel billets, that is, parts with a large cross section.

When choosing a band saw, special attention should be paid not only to the material from which the cutters are made, but also to their pitch, as well as their geometry.

Tooth pitch

This is the distance between the edges of two adjacent incisors.

A large step loads the engine of the aggregate harder and gives poor cut quality. A small pitch of the incisors leads to longer sawing, increases energy consumption, but gives clean cut with a smooth surface.

For cutting sheet material, pipes (thin-walled) and profile, select a blade with a minimum pitch between the cutting elements (1 inch). But if you need to cut a large workpiece solid metal, it is required to install the canvas with the largest pitch of the incisors. The fewer teeth (per inch) the snap will have, the deeper the groove they will form. Due to this, the cut is less clogged with chips. Also, a large tooth pitch on the tool increases the performance of the unit.

Tooth height

The height of the cutter is the distance from the lower point of the depression between the teeth to the top of the cutting element. Due to the presence of a hollow chips are removed, formed when cutting metal. The height of the tooth should be sufficient so that the cavity does not become clogged with chips, and the sawing process takes place without difficulty. In addition, insufficient tooth height causes the blade to overheat, resulting in microcracks.

Tooth front angle

The rake angle or the angle of sharpening is responsible for the degree of mesh engagement for the workpiece material. A large angle of sharpening will not allow to achieve high accuracy when cutting metal. At the same time, a small angle allows you to provide good quality cut, but at the same time reduces the productivity of the tool.

Choosing a band saw blade for wood

First of all, in order to choose the right blade for a band saw, you should look into instructions for your machine. It will indicate all the parameters of the band saws that can be installed on this model of equipment (maximum and minimum width of the tape, as well as its length). The length of the blade should be exactly as indicated in the passport to the unit.

Snap width

The width of the tape is selected based on the operations that will be performed on the machine. Also, the width of the tape is limited not only by the width of the pulley, but also by its diameter. With a small pulley diameter, the wide belt installed on it will collapse and eventually burst. Therefore, for each unit there is a limit on the width of the equipment.

For straight cut Saws with a width of 20 to 30 mm are usually used. Of course, on a circular machine it is possible to make a longitudinal cut faster and more accurately. But there is a height restriction on it, which equals no more than 80 mm. On bandsaw machines, it is possible to process workpieces with a height of up to 200 mm and more.

But the main task of the tape units is figured cut. The smallest equipment that can be installed on a band saw is a 3 mm wide tape. It cuts a circle with the same radius.

Choosing a Band Saw For Metal

The larger the width of the tape, the greater the minimum radius that can be cut with it. For example, a tape with a width of 12 mm cannot cut a radius of less than 60 mm. And for a tape 25 mm wide, the minimum radius will be about 100 mm.

On average, the width of the blade should be three times smaller than the required cut radius on the workpiece. Therefore, the equipment is selected in accordance with the tasks.

Tooth pitch

Indicated by a number indicating the number of incisors per inch. The numerical value of the step is set before the acronym TPI. When choosing a step, consider:

- What is the thickness of the workpiece;

- What hardness the workpiece material has;

- What kind of cleanliness of the edge of the part is required after cutting.

To effectively cut plastic and saw wood, the tape must have at least three cutters per inch. The more incisors will be on one inch, the more high-quality the cut will be. But at the same time, the feed rate will decrease and the limit value of the thickness of the workpiece will decrease.

According to the pitch of the teeth, the blades are divided into two types: “skip” and “regular”. Type of canvas “skip” has a step of 3 to 6 TPI. Between the teeth there is a space for efficient removal of sawdust, as their poor removal reduces the quality of the cut. Type of paintings “regular” has teeth shaped like a triangle. They are placed on a snap in increments of 10 TPI and above. This type of tooth does not have enough space for quick chip removal. Due to the large number of cutting elements, the cut with such a blade is quite clean. The equipment can be used for sawing workpieces of small thickness and from hard materials.

These types of paintings have the following characteristics.

- 3 TPI “skip”. The canvas is used for rough sawing wood having greater thickness. Equipment produce sawing along the fibers. In order to at least slightly improve the quality of cuts, you can pull the tape on the machine to the maximum and reduce the feed rate.

- 4 TPI “skip”. This is a universal tool for sawing along the fibers. With this type of blade, most types of wood can be sawn, including blanks with many knots. If it is good to tighten the saw and reduce the feed, then the cut quality will be close to the finish.

- 6 TPI “skip”. This is a snap general purpose. It saws blanks up to 50 mm thick (along the fibers) and wood across the fibers up to 150 mm thick. These numbers are for sawing materials with a normal feed to the saw. If the feed rate is reduced, then parts of a greater thickness can also be machined. This saw gives a clean cut quality and is suitable for almost all types of wood.

- 10 TPI “regular”. Cloths are used for sawing sheet materials (chipboard, plywood, MDF, etc.), for cutting non-ferrous metals and plastic. But when machining metal workpieces, it is necessary to reduce the speed of movement of the snap. Not all machines have this feature.

- 14 TPI “regular”. You can cut plywood, MDF, particleboard and plastic. As for natural wood, its thickness should be no more than 25 mm. The cleanest cut with this blade is obtained when minimum feed rate. Also, with this snap you can cut soft metals at low belt speeds.

Cutter Shape

Tape blades can have the following tooth profiles.

- Wm Equipment with this profile of cutters is designed for sawing soft and hard wood species and is universal. The profile is used on saws with a width of not more than 50 mm.

- Av. Tooth profile allows you to handle with solid wood, including frozen. Also, such saws can be used to cross-cut material.

- Nv. It is applied on tapes up to 30 mm wide which can be used for curly cutting any wood species.

- Nu. The profile has a large cavity. Used for sawing soft wood.

- Pv. This profile is used on equipment with a width of more than 50 mm. Thanks to the PV profile, the saws have good stability when cutting soft wood.

- Kv. Use on wide tapes (up to 80 mm) for sawing soft wood.

- Pu. Used for sawing solid wood on tapes wider than 80 mm.

Tooth setting

The teeth on the saw are bred in order to reduce the friction of the blade on the workpiece and to prevent it from jamming. The width of the cut should exceed the thickness of the snap by approximately 30-60%.

The wiring of the incisors can be of three types.

- Classic wiring. The saw teeth are bent in opposite directions alternately and at the same distance.

- Stripping wiring.Every two teeth, the next (third) does not bend and has the shape of a trapezoid. The cutter is located in the center of the tooling and sets the direction for the entire band saw. This wiring is used for saws working on solid materials.

It is important to know that when making the tooth alignment, not the entire incisor is bent, but part of it: from 1/3 to 2/3 of the distance from the top of the tooth. Each tool manufacturer recommends its own tooth deflection value. But on average it is in the range from 0.3 to 0.7 mm.

The softer the material, the stronger the saw should be diluted, and vice versa. But you can not allow such a wiring of the incisors so that there are not cut sections in the center of the cut. Care should be taken that the teeth deviate to the side. Equal distance. If the wiring is uneven, then the band saw will be led away to the side where the teeth have a stronger inclination.

Sharpening Band Saws

Of course, it is better to sharpen the band saw on a special machine, in specialized workshops. Yes, and professional sharpening a saw is inexpensive. But if for some reason you don’t have the opportunity to take the saw for sharpening, you can do the editing of the tool yourself.

Sharpening the band saw with small file or file along the front and back edges of the incisor in several movements (3-4) for each tooth.

The band saw can also be sharpened. Using an engraver, using equipment designed for sharpening chain saws.

The tool is inserted into the engraver, and the sharpening of the incisors is carried out with neat movements along the upper part of the incisor.

Strongly remove the metal is not necessary, just lighten it.

You can also try sharpening and saws for metal. But usually they are not re-sharpened, since the cutting part of these saw tapes is either bimetallic or has a hardening zone. The teeth on such tapes work until they crumble and can have microcracks. If you re-sharpen them, then they will begin to crumble faster or will begin to cut even worse.