Convert A Screwdriver To A Lithium Battery

Accumulators and batteries What is the difference between a lithium battery and a nickel-cadmium battery. Calculation of t component schemes of alteration. Operating conditions of the lithium battery. Features of alteration of batteries and chargers from different manufacturers.

Conversion of a screwdriver to lithium batteries 18650 14 V

When converting screwdrivers of different power and flashlights from Ni-Cd to Li-ion, batteries of the form factor 18650 are often used. They easily fit into a container or a nest, since instead of two or three relatives, one lithium is installed. Alteration of the screwdriver battery should be carried out taking into account the peculiarities of lithium 18650 batteries.

This type of energy source does not tolerate deep discharge and excessive charge. Hence, it is necessary to use voltage control boards. Since each battery has its own character, their charge is adjusted by a balancer. The point of reworking a screwdriver with a voltage of 14.4 V lies in creating a device using lithium batteries to facilitate a hand tool and increase its performance. Lithium 18650 batteries are most suitable for these purposes.

When selecting components, it should be taken into account that the starting current of the screwdriver is high, it is necessary to choose the appropriate BMS for the required number of cans and at least 30 A.

- Lithium-ion cans in the amount of 4 pcs.

- 4-cell li-ion battery controller, CF-4S30A-A works well. It has a built-in balancer that controls the charge of each element.

- Hot glue, TAGS soldering flux, solder.

- Heat-resistant adhesive tape;

- Jumpers or thick insulated wire with a cross section of at least 0.75 squares, cut for bridges.

The procedure for converting a screwdriver for 18650:

- Disassemble the case and remove a bundle of 12 Ni-Cd cells from the container.

- Remove the garland, leaving the connector with the “” and “-” pins. Instead of a temperature sensor, a thermocouple from the controller will be installed.

- Solder the assembly, considering that you cannot use acid, only neutral flux and pure solder. During the connection period, do not warm up the covers. Work pointwise.

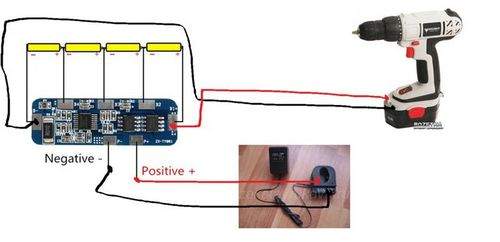

- Connect balancing points to the controller according to the diagram. The connectors are provided on the board.

- Connect the assembly to the plus and minus terminals.

- Check the functionality of the circuit. If everything works, the assembled battery, place the controller in the socket, secure with sealant.

If the charger is not universal, additional alteration will be required. Screwdrivers for 12 V with a universal charger are assembled in the same way, but a protective connection circuit 3×18650 3.7 V for lithium batteries is used. In the same way, a screwdriver is reworked using a set of 18650 batteries in the amount of 2 cells.

Conversion of a screwdriver to lithium batteries 18650

Every craftsman is faced with the problem of reduced tool performance, or complete failure due to the battery. Manufacturers use nickel-cadmium batteries in 12, 14, 18 volt screwdrivers. The sequential assembly of several elements creates the required voltage. Replacing nickel-cadmium batteries with lithium batteries extends battery life, making the design easier. Mandatory BMS board installation adds reliability. Therefore, the conversion of a screwdriver to lithium batteries, mainly to the 18650 form factor, is justified.

Replacing batteries in a screwdriver with lithium

First you should think about whether I need this alteration? After all, it will be an outright “self-propeller” and in some cases can lead to failure of both the battery and the screwdriver itself. Therefore, let’s consider all the pros and cons of this procedure. It is possible that after that some of you will decide to abandon the conversion of the Ni─Cd battery for a screwdriver to lithium cells.

The cons

- Lithium battery cells cannot be charged above 4.2 volts and discharged below 2.7 volts. In real conditions, this interval is even narrower. If you go beyond these limits, the battery can be damaged. Therefore, in addition to the lithium cans themselves, you will need to connect and install a charge-discharge controller in the screwdriver;

- The voltage of one Li─Ion cell is 3.6─3.7 volts, and for Ni─Cd and Ni─MH this value is 1.2 volts. That is, there are problems with assembling a battery for screwdrivers with a voltage rating of 12 volts. From three lithium cans connected in series, you can assemble a battery with a nominal value of 11.1 volts. Out of four ─ 14.8, out of five ─ 18.5 volts, and so on. Naturally, the voltage limits during charge-discharge will also be different. That is, there may be problems with the compatibility of the converted battery with a screwdriver;

- In most cases, 18650 standard cans are used in the role of lithium cells for conversion. They differ in size from Ni─Cd and Ni─MH cans. In addition, you will need space for a charge-discharge controller and wires. All this will need to fit in a standard battery case of a screwdriver. Otherwise, it will be extremely inconvenient for them to work;

- A cadmium battery charger may not be suitable for recharging a battery after a redesign. You may need to revise the charger or use universal chargers;

- Lithium batteries lose their performance at low temperatures. This is critical for those who use a screwdriver outdoors;

- The price of lithium batteries is higher than cadmium batteries.

Features of lithium ion battery

Before converting the screwdriver for a lithium-ion battery, you must carefully familiarize yourself with the intended modes of its operation as part of this tool. In this case, the following factors should be taken into account:

- The main operating parameter of these products is the load current (its nominal value can be found in the instrument’s passport);

- When choosing a suitable type of Li-Ion 18650, you should focus on a model that provides significant discharge (or load) currents, reaching values from 15 to 30-40 Amperes;

- In this case, it is not necessary to take into account the declared capacity of the selected battery, which can always be restored by additional charging of the li ion screwdriver.

Note! These features explain the inadmissibility of using a lithium battery from an old laptop, which is often mentioned on the Internet. Such batteries are not designed for a high discharge current and do not have the required technical parameters.

Note also that when choosing several 18650 cells to be inserted into one battery compartment, it is not allowed to use cells with very different capacities.

Based on the operating voltages of old and new batteries (1.2 and 3.7 Volts) indicated in the technical characteristics, the proportion of 1 to 3 should be adhered to when selecting their quantitative ratio. So, for a 12-volt battery compartment of nickel-cadmium cells (10 pieces), it is redesigned so that 3 lithium batteries can fit in it (this results in a slight undervoltage).

Let us also recall that before assembly, it is necessary to fully charge each of the installed elements, which will ensure the equalization of their potentials.

Conversion of a screwdriver to lithium batteries 18650

The domestic industry has long been producing samples of reliable and inexpensive screwdrivers, most of which are equipped with outdated types of built-in batteries. Self-conversion of a screwdriver to lithium allows its owner to extend the life of this product and even slightly improve performance. A modern li ion battery for a screwdriver looks like it is shown in the figure below.

Despite the fact that a large number of companies for a relatively modest price can remake a screwdriver for a new battery, it is more convenient to do it on their own.