Convert Screwdriver To Lithium Battery 12

Industry has been producing screwdrivers for a long time, and many people have old models with nickel-cadmium and nickel-metal hydride batteries. Converting a screwdriver to lithium will improve the performance of the device without buying a new tool. Now many companies offer screwdriver battery remodeling services, but you can do it yourself.

Converting a screwdriver to lithium batteries

Benefits of Li-ion batteries

Nickel-cadmium batteries have a low price, withstand many charging cycles, are not afraid of low temperatures. But the battery capacity will decrease if you put it on charge without waiting for a full discharge (memory effect).

Lithium-ion batteries have the following advantages:

- High capacity, which will provide a longer working time for the screwdriver;

- Smaller sizes and weight;

- Well keeps a charge in an idle state.

But the lithium battery for a screwdriver does not withstand full discharge, so the factory tools on such batteries are equipped with additional boards that protect the battery from overheating, short circuit, overcharge in order to avoid explosion, complete discharge. When the microcircuit is installed directly in the battery, the circuit is opened if the unused battery is located separately from the instrument.

Alteration Difficulties

There are objective flaws in Li-Ion batteries, such as poor performance at low temperatures. In addition, when converting a screwdriver to lithium 18650 batteries, a number of difficulties can occur:

- Standard 18650 means that the diameter of one battery cell is 18 mm with a length of 65 mm. These dimensions do not match the sizes of nickel-cadmium or nickel-metal hydride elements previously installed in a screwdriver. Replacing the batteries will require placing them in the standard battery case, plus the installation of a protective microcircuit and connecting wires;

- The voltage at the output of lithium cells is 3.6 V, and that of the nickel-cadmium cells is 1.2 V. Suppose that the rated voltage of an old battery is 12 V. Such voltage cannot be provided with a series connection of Li-Ion cells. The scope of voltage fluctuations during charge-discharge cycles of an ion accumulator also changes. Accordingly, reworked batteries may not be compatible with a screwdriver;

- Ion batteries differ in the specifics of work. They poorly withstand a recharge voltage of more than 4.2 V and a discharge of less than 2.7 V until failure. Therefore, when the battery is redone, a protective board must be installed in the screwdriver;

- An existing charger can not be used for a screwdriver with a Li-Ion battery. You will also need to remake it or purchase another.

Important! If a drill or screwdriver is cheap and not very high quality, then it is better not to rework. This may be more expensive than the cost of the tool itself.

Battery Choice

Often, 12 V batteries are used for screwdrivers Factors to consider when choosing a Li-Ion battery for a screwdriver:

- In such tools, elements with high discharge currents are used;

- In many cases, the capacitance of an element is inversely related to the discharge current, so you cannot select it only by capacitance. The main indicator is the current. The value of the operating current of the screwdriver can be found in the instrument passport. Usually it is from 15 to 30-40 A;

- It is not recommended to use cells with different capacities when replacing the battery of a screwdriver with a Li-Ion 18650;

- Sometimes there are tips to use a lithium battery from an old laptop. This is absolutely unacceptable. They are designed for a much lower discharge current and have unsuitable technical characteristics;

- The number of elements is considered based on an approximate ratio of 1 Li-Ion per 3 Ni-Cd. For a 12-volt battery, you will need to put 3 new ones to replace 10 old cans. The voltage level will be slightly reduced, but if you install 4 elements, then increased voltage will shorten the life of the electric motor.

Important! Before assembly, it is necessary to produce a full charge of all elements for equalization.

Disassembling the battery case

The case is often assembled on self-tapping screws, other options. Using latches or glue. The glued block is the most difficult to disassemble, you have to use a special hammer with a plastic head so as not to damage parts of the case. Everything is deleted from the inside. Only contact plates or the entire terminal assembly can be reapplied for connection to a tool, a charger.

Battery Connection

Compound Li–Ion batteries for screwdriver performed in several ways:

- The use of special cassettes. The method is fast, but the contacts have a large transition resistance, can quickly collapse from relatively high currents;

- Soldering. A method suitable for those who know how to solder, since you need to have certain skills. Soldering should be done faster, because the solder cools quickly, and prolonged heating can damage the battery;

- Spot welding. It is the preferred method. Not everyone has a welding machine, such services can be provided by specialists.

Soldering elements

Important! The elements must be connected in series, then the battery voltage is added, and the capacity does not change.

At the second stage, wires are soldered to the contacts of the assembled battery and to the protective board according to the connection diagram. Wires with a cross-sectional area of 1.5 mm² are soldered to the contacts of the battery itself for power circuits. For other circuits, you can take thinner wires. 0.75 mm²;

Then a piece of shrink tubing is put on the battery, but this is not necessary. You can also use heat shrink on the protective microcircuit to isolate it from contact with the batteries, otherwise the sharp protrusions of the solder can damage the shell of the element and provoke a short circuit.

Battery assembly

Further battery replacement consists of the following steps:

- Disassembled parts of the case are well cleaned;

- Since the dimensions of the new battery cells will be smaller, they must be securely fixed: stick to the inner wall of the housing with Moment glue or sealant;

- The plus and minus wires are soldered to the old terminal block, it is placed in its original place in the case and fixed. The protective board is laid, the parts of the battery pack are connected. If they were previously glued, then “Moment” is used again.

Tips for choosing a security chip

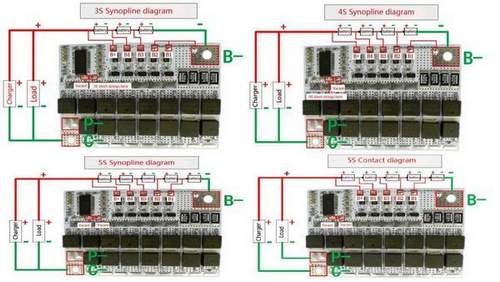

A lithium-ion screwdriver battery cannot function properly without a BMS protection board. Selling items have different parameters. Marking BMS 3S assumes, for example, that the board is designed for 3 elements.

What you need to pay attention to choose the right chip:

- The presence of balancing to ensure uniform charge of the elements. If it is present, the value of the balancing current should be in the description of the technical data;

- The maximum value of the operating current maintained for a long time. On average, you need to focus on 20-30 A. But it depends on the power of the screwdriver. Low-power enough 20 A, powerful. From 30 A;

- The voltage upon reaching which the batteries are switched off during recharging (about 4.3 V);

- The voltage at which the screwdriver is turned off. It is necessary to select this value based on the technical parameters of the battery cell (minimum voltage. About 2.6 V);

- Overcurrent trip current;

- Resistance of transistor elements (minimum value is selected).

Important! The value of the tripping current during overload does not matter much. This value is tuned to the current of the workload. For short-term overloads, even if the tool is turned off, you need to release the start button, and then you can continue to work.

Connection diagram of elements with a protective board

Whether the controller has an autostart function, it is possible to set by the presence of the entry “Automatic recovery” in the technical data. If there is no such function, then to restart the screwdriver after the protection has been activated, it will be necessary to remove the battery and connect it to the charger.

Charger

The lithium-ion screwdriver battery cannot be charged by connecting to a conventional power supply. A charger is used for this. The power supply simply provides a stable charge voltage within the specified limits. And in the charger, the determining parameter is the charge current, which affects the voltage level. Its meaning is limited. In the memory circuit there are nodes responsible for terminating the charge process and other protective functions, for example, shutdown with incorrect polarity.

The simplest memory is a power supply with resistance included in the circuit to reduce the charging current. Sometimes they also connect a timer that works after a specified time period has elapsed. All of these options do not contribute to long battery life.

Charging Methods Li Ion batteries for a screwdriver:

- Use of factory charger. Often it is also suitable for charging a new battery;

- Alteration of the charger circuit, with the installation of additional circuit elements;

- Purchase of ready-made memory. A good option is IMax.

Suppose there is an old Makita DC9710 charger for charging a 12 V Ni-Cd battery, which has an indication in the form of a green LED that signals the end of the process. The presence of the BMS board will allow you to stop the charge after reaching the specified voltage limits for the element. The green LED will not light up, but the red will simply turn off. The charge is over.

Charger Makita DC9710

The Makita DC1414 T charger is designed to charge a wide range of rechargeable batteries 7.2-14.4 V. In it, when the protective shutdown is triggered, at the end of the charge, the indication will not work correctly. There is a blinking of red and green light, which also signals the end of the charge.

The cost of replacing the screwdriver’s batteries with lithium-ion batteries depends on the power of the tool, the need to buy a charger, etc. But if the drill screwdriver is in good functional condition, the charger does not require a thorough alteration or replacement, then for a couple of thousand rubles you can get an improved power tool with increased battery life.