Crawler Attachment To Tiller DIY

Modernization of a two-wheeled tiller

Today, there is a huge variety of models of wheeled trailers on sale, but tracked variants are much less common, and their price is higher, since they differ in design, power, and capabilities. Of course, the universal track attachment to the tiller will make the wheeled device more functional, but this pleasure, again, is far from cheap.

If you cannot afford such an option, but you are on friendly terms with your hands, you can make equipment for your iron “assistant” yourself. The track attachment for the tiller is mounted on four wheels, so if you have a two-wheeled model of the device, you need to transform it into a four-wheeled one. An additional pair of wheels can be fixed permanently or made removable so that, if necessary, you can quickly return the unit to its original design for gardening.

The second pair of wheels can be fixed to an existing axle by means of a rigid or flexible gear. This is the most expedient solution to avoid the need to weld on additional wheels.

Features of the caterpillar track for the tiller

The do-it-yourself track attachment to the tiller can be made from a variety of materials, but you should choose an option so that it matches the tiller model itself optimally. First of all, one should take into account the engine power of a particular technical device. Most often, such units are equipped with low-power motors, therefore, the track attachment to the tiller should be light. You should not use caterpillars, like those of a collective farm bulldozer, as they will simply be too tough for a weak engine. For low-power models, you can make a caterpillar track from car tires. The ideal option is rubber for off-road vehicles. Aggressive tread will provide reliable traction on any surface, including on snowy or icy surfaces.

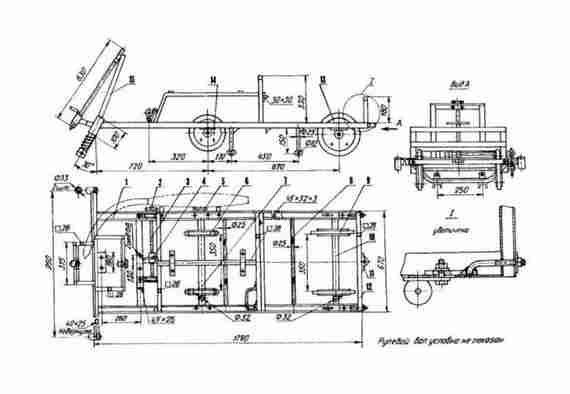

A suitable drawing of a crawler attachment for a tiller can be found without any problems on specialized sites and forums. There are also recommendations for the manufacture of such options. We will consider the most common options for tracked attachments, which can be easily made, as they say, from scrap materials.

Sleeve roller chain and conveyor belt

The do-it-yourself caterpillar attachment to the tiller is made from these materials quite simply. At the same time, there is no need to use special tools and machines. You can connect the conveyor belt into a ring by stitching or using a hinge. Stapling is not a very reliable way, so it is better to use a hinge.

Owners of tillers with high-power motors are advised to use tape with a thickness of 7-15 mm. These types of conveyor belts are usually used in agricultural machinery. At the same time, the installation of such a tape must be done very carefully due to its impressive weight.

In order for the homemade track attachment to the tiller to last longer, its edges must be stitched with fishing line with a distance of 2 cm.

Car tires

This material is ideal for creating a crawler track for light tillers. The main advantage of this technology is that there is no need to manufacture additional lugs. This attachment is carried out by trimming the side surfaces of the tires. Preparing the working path is a rather difficult task, especially if rubber with a deep “off-road” tread is used. Even with the sharpest knife, this operation is very difficult, so it is better to use an electric jigsaw. To prevent the rubber from burning during cutting due to the high friction of the blade, it should be periodically moistened with soapy water or water. If the tire tracks are too hard, you can remove excess layers from the wrong side of the tape.

The closed loop of the tracks provides them with high reliability, and this is the main quality that a track attachment to a tiller should have. The owners’ comments on the operation of such homemade products are only positive. The only problem is the limited width of the tires, but this problem is solved by the simultaneous use of two or even three tread strips on each pair of wheels.

Tracked attachment to the tiller: features of self-production

The processing of a land plot, even a small one, is a rather difficult and tedious task. Digging, loosening or weeding requires serious physical effort and a lot of time, so many gardeners acquire additional equipment, in particular, tillers. Any such unit performs a wide range of work and is an indispensable assistant in the household. However, its functionality and cross-country ability can be expanded even more, and the track attachment to the tiller will help with this.

Belts

The track attachment can also be made from belts. This method is convenient and simple. Belts must be used with a V-shaped profile. The connection is ensured by lugs, which are fixed with screws or rivets.

A more reliable version of the tracks is obtained from the old chains (they must be the same). One belt requires two chains. After giving the product the required size, the chain links must be connected and welded. The finished structure is fastened with lugs made of thick steel plates.

Car tire use

For a tiller, caterpillars are often taken from car tires. Craftsmen claim that the design has high reliability when the specified element is included in it. For the resulting tiller to be practical, it is imperative to take care of the quality of the car tires. They must have the correct tread pattern. In this respect, tires from large cars and tractors are preferable. The tread pattern is of key importance as it acts as a lug.

The manufacturing process can be roughly divided into several stages. Here they are:

- After finding suitable tires, a track for tracks is cut out of them. This is a time consuming job.

- A well-sharpened knife is used for cutting. Better to take the one that shoemakers use. From time to time, it must be moistened in a soapy solution. This will make the rubber easier to cut.

- Both sidewalls are cut from the tires. To simplify the process, you can use a jigsaw with fine teeth for this. Remove excess fragments inside the tire, if necessary. If the track is too hard inside, this manipulation can be repeated.

The advantage of this method is that there is no need for a ring connection. The tire already has a closed structure.

Thanks to this, it is possible to improve the reliability indicators of the tracks, which is especially important in conditions of heavy loads. Yet such tracks are of a rather limited length. It corresponds to a similar parameter for a car tire.

Application of the conveyor belt

It is considered one of the simplest methods. In addition to the conveyor belt, a bushing roller chain is required. The simplicity in this case lies in the fact that manufacturing does not require a large number of auxiliary materials and tools. To extend the life of the conveyor belt in the device, you need to circle it around the edges with fishing line. In this case, it is important to ensure a step of 10 mm. To connect the tapes, in this case, a ring is necessary, you need to sew it along the ends or use hinges.

Particular attention is paid to the thickness of the conveyor belt. The level of load on the unit directly depends on this. Optimal will be the selection of a tape with a thickness of at least 7 mm. Among other things, you will have to take care of an additional wheel on each side. You can remove it from the old car, but it is important that its diameter coincides with the same parameter for the wheel on the tire.

How to make a track attachment for a tiller

Additional Tips

Before you start making a homemade caterpillar, you need to identify the appropriate parameters for it. The fact is that in the case of the production of a very high caterpillar, you will have to change the center of gravity of the tiller, which will inevitably lead to some problems during turns, since the unit will roll to one side.

Air cooling is not very effective at high loads, which is fraught with significant overheating of the motor. It turns out that it is better to give preference to water-cooled engines, showing stable performance levels.

Attaching the track to the tiller can significantly improve the flotation performance of the device. Due to this, it is possible to increase the range of potential jobs that a hand-made device can handle. In other words, the resulting base in certain cases outperforms the usual wheelbase. But the alteration of the tiller is far from always suitable for the owners of these units.

How to make caterpillars for a tiller with your own hands?

Many experts often ask themselves how to make tracks for a tiller with their own hands. In fact, making a caterpillar attachment to the tiller with your own hands from improvised devices is very simple. First you need to collect the necessary materials, in particular, to make caterpillars for the tiller with your own hands, you need:

- drill;

- screwdrivers;

- nuts;

- keys;

- chains;

- jigsaw;

- knives;

- pliers;

- bolts;

- sanding belts;

- welding machine;

- Angle Grinder;

- wire.

Now you know all the detailed information about motoblock tracks. Using it, you can plan the purchase of this equipment or estimate your strength in advance in order to design such elements on your own according to the described algorithm.

What caterpillars can be made from

Nowadays, many people try to design and make improvised all-terrain vehicles with their own hands, but it is very problematic to make a caterpillar for a tiller, since it must be light and strong at the same time. Below we will provide several ways to implement this idea.

You can use available tools to make a tracked module for a tiller. The easiest way is to make homemade tracks using a roller chain and conveyor belt.

In order to make a caterpillar with your own hands from these materials, you do not need special tools or machines. Homemade conveyor belt and chain tracks can be stitched from the edge with fishing line to extend their lifespan. When flashing, observe a step of 1-2 cm.

You can connect the tape into a ring in various ways:

Crawler rotary tiller

- you can use a hinge that will look like a piano hinge;

- you can sew the edges of the tape, but this method will not be reliable.

Tip: Select the thickness of the future caterpillar depending on the power of your tiller.

Homemade Rotary CULTIVATOR For TRIMMER !?

For high-power units, a tape with a thickness of 7-15 mm can be used. It is also used for agricultural machinery. However, remember that you need to carefully install such a tape, since its weight is quite large.

What can be done?

When choosing material for tracks, it is important to consider that it should not be excessively heavy. Since the tiller itself does not have a powerful engine, it simply cannot cope with weighty material and, most likely, will break. The caterpillar mechanism, as a rule, is made of motorcycle tires, chains, pipes, belts, or a conveyor belt in combination with a sleeve-roller chain.

Most crafters create tracks from car tires. these parts are easily converted to the desired design. It is necessary to choose tires for large trucks, taking into account the existing tread pattern and shape, because the correct pattern will improve traction. It is better if these are spare parts that previously belonged to tractors or other large-sized models.

A properly selected tread will be in good contact with wet ground, ice-covered and snow-covered surfaces. In addition to materials for the tracks, a tiller with a gearbox, as well as a pair of additional wheels, will be required to construct a full-fledged device. If necessary, an additional cart is attached to the tiller and, if desired, even on skids to transport goods in deep snow.

Features and device

Tracks for the tiller greatly simplify both the transportation of the load and the movement of the device itself. Due to the fact that the track mechanism covers a fairly large surface, the tiller moves much more evenly, exerts less pressure on the surface and does not get stuck on difficult soils. the tiller on tracks is able to work even in bad weather, and in good weather it becomes even more maneuverable.

The maintenance and use of the tracked module does not cause any particular difficulties for the owners, and it is not difficult to do it yourself. It should be borne in mind that when the tiller is equipped with a tracked module, its speed decreases. However, the device’s ability to navigate difficult terrain, transport goods and even clear snow from the area increases.

Tillers with tracked modules are otherwise identical to conventional tillers. The engine must be four-stroke with the ability to lock the axles so that the device can turn without making a whole circle. There is also a requirement for water cooling to cope with high loads that cause the motor to overheat. This type is more effective than air. The clutch system, gearbox and gearbox for tracked mechanisms are presented in the traditional version. The tiller on tracks is controlled by a handle.

When creating tracks on your own, it is important to understand that if you design them too high, the tiller’s center of gravity will change, and he will begin to experience difficulties turning, and even tilt to one side or another. To prevent such a situation, the second driven axle will have to be made longer by a couple of centimeters. Also, with the help of a bushing, it will be possible to expand the wheelbase that already exists on the tiller.

Step-by-step manufacturing instructions

To make a caterpillar mechanism for a tiller with your own hands, in addition to the materials used, you will need certain tools: an angle grinder, and sometimes a drill, a boot knife and a set of screwdrivers, bolts, nuts and wrenches, a welding machine, wire, chains and a sanding belt. Of course, drawings will also be necessary, which are easy to find on the Internet in the public domain.

If home-made tracks are made from car tires, then the first thing the tires are freed from the sides to the state of a running belt. a track for caterpillars. This is easier to do with a well-sharpened knife, for example, designed for working with boots. The adjustment process is lengthy, but it can be accelerated by periodically smearing the blade with a soapy substance.

It is more convenient to cut the sides of the tires with an electric jigsaw, which has small teeth. At the next stage, the wrong side of the tire is also corrected: excess layers are removed from it. This should be done when the tape is too dense inside. Such a track attachment made of auto parts turns out to be quite durable, since the tire is initially closed, which means that it will be more difficult to damage the tracks during operation. Unfortunately, the available tire width will not give the user the opportunity to use a large surface. However, some craftsmen solve this problem by using multiple tires.

The simplest track module can be made from a conveyor belt and sleeve-roller chains. First, depending on how powerful the engine is, the required thickness of the tape used is selected. This is followed by the processing of the edges, which can begin to shaggy and, because of this, fail earlier. For this, a fishing line is used with a pitch of ten millimeters. The finished edges are then sewn into a ring, with a special hinge, or simply along the end parts.

Despite some primitiveness of the mechanism, it will serve for a very long time. It is important to add that the thickness of the tape must exceed seven millimeters, otherwise the device will not be able to withstand the required loads. The optimal interval is considered to be from eight to ten millimeters.

The track module can be made from belts if they have a wedge-shaped profile. It is best to connect the parts with a lug, which is fixed on the straps with screws or rivets. Another common solution is to construct tracks from chains of equal size. Such a versatile part, as a rule, is abundant in any home workshop, so this method is also economical. To make caterpillars, you have to take a pair of equal chains and unclench their extreme links.

Now two chains can be connected into one circuit, the links can be clamped back and for reliability everything can be welded. For greater strength, the chains can be fastened again with lugs, which, by the way, are also simply made from scrap materials. metal sheets of the required thickness. In general, this part can be not only steel, but wooden and even plastic. In the latter case, wood bars or plastic tubes are used as it. Which material will be most suitable can be determined depending on the purpose of using the tiller.

In the case when the cargo expected for transportation does not differ in large weight, the lugs should be made plastic. The same applies to moving devices equipped with weak motors. When the tiller is planned to be used as a tractor, and it has a rather powerful engine, steel parts should be preferred.

Sometimes homemade caterpillars are reinforced with pipes, which are welded together. Parts in this case are made of metal and have a rectangular cross-section. In this case, it is recommended to remove the drive shafts from the “Oka”, and take the spline part from the “Buran”. The equipment must be equipped with brakes that are mounted on the front shafts. This addition allows you to get a device with maximum capabilities.

It is worth mentioning that in order to convert a regular tiller into a tracked one on the go, you first have to put two additional wheels on it, one on each side. The result should be a four-wheeled structure, on which the tracks are already put on. Some craftsmen prefer to make these extra wheels removable rather than weld on new mountings. This can be accomplished by attaching the wheels to the axle using a flexible or rigid transmission. It should be mentioned that it is not necessary to make the tracks yourself. no less economical solution would be to use parts from old equipment, for example, “Buran”.

How to make a tiller on tracks with your own hands?

- Features and device

- What can be done?

- Step-by-step manufacturing instructions

- Recommendations for use

Recommendations for use

When using the tiller tracks, it is necessary to constantly check how well the chain is tensioned, and also regularly oil the parts whose friction occurs during movement. In addition, it is recommended each time before use to check whether any damage and breaks have appeared on the chain. After the trip, a scheduled inspection should also be carried out in order to detect any damage or broken hooks in time. When using the tiller, you should avoid driving over roots and stone massifs, as well as hemp, otherwise the track module will be torn very quickly.

For an overview of the tiller-all-terrain vehicle on tracks, see the following video.

Homemade caterpillars for a tiller with your own hands

To increase the throughput of the tiller and use it as an all-terrain vehicle or snowmobile, you can equip it with tracks. They can be purchased ready-made, but they are expensive, and it is not always possible to find the right option for your tiller. There are several ways to make a caterpillar for a tiller with your own hands.

Using our recommendations, you can easily turn your wheeled trailer into a tracked all-terrain vehicle. At the same time, you will not need expensive materials and too much time.

From conveyor belt

This method is the simplest, since it does not require a large number of special tools and auxiliary materials.

- When choosing a belt for a caterpillar, give preference to a strip with a thickness of at least 7 mm, because it has a fairly large load. Hitching with moving parts will be provided by a sleeve-roller chain.

- To give the tape strength and increase its operational life, it is recommended to sew along the edges of the tape with frequent stitches with a step of about 10 mm.

- It is also necessary to sew the tape along the ends in order to connect it into a ring of the required diameter, or use, for greater reliability, hinges resembling a piano canopy.

- Make sure that the additional wheelset you install on the tiller frame is the same diameter as the main wheels on the tiller.

Iron tracks

The most reliable are metal tracks made of high quality iron. For this purpose, metal pipes or a profile cut into pieces of the required length are suitable. A profile metal pipe is cut according to the same principle as a plastic one and is attached to a conveyor belt with bolts.

However, metal tracks, despite their noticeable strength, also have their drawbacks: they are heavy compared to plastic and wood, and can bend during use. To straighten the truck, you need to remove it from the goose, and this is a laborious operation.

When choosing the material from which the track links for your mini-all-terrain vehicle will be made, you should evaluate the degree of load and operating conditions. To overcome the snowy expanses on a homemade snowmobile, light plastic or wooden tracks are perfect, and to use the tiller as a mini-tractor it is still better to make a caterpillar with metal lugs.

Of belts and chains

In order to make a tracked all-terrain vehicle from a tiller, you can use conventional V-shaped belts. The connection of the belts to each other is carried out by grousers attached to them on rivets or screws. This gives us a belt track.

To make a goose from chains (chain tracks), you need to take two pieces of the same chain of the required length.

- The end links of both segments are expanded in order to connect them into two closed rings.

- The released links are clamped again, and then welded for strength.

- Sections are cut from steel of the required thickness, which will serve as lugs.

- The lugs are bolted at both ends to the links of both closed chains, thus forming a raised track on the tiller.

From wooden blocks

Sometimes, if the load on the goose is not very large, you can use birch blocks as tracks. They are not particularly durable for heavy loads, but they are lightweight, affordable, and a track with such tracks can be repaired in any convenient place.

From plastic pipes

You can use pieces of plastic pipe as tracks on a goose for a snowmobile. To do this, cut the plastic water pipe 0 into lengths equal to the width of the caterpillar. Use a circular saw to cut each piece lengthwise into two equal halves, or use a circular saw for wood.

The resulting tracks must be attached at regular intervals to the conveyor belt with furniture bolts with large hemispherical hats.

Homemade track links

You can also make your own goose tracks from any suitable material. The main thing to consider is how much work you are going to give your tiller.