Cutting Mirrors With Glass Cutters At Home

Required materials

Work protection

Safety is considered to be one of the most important factors in any type of work, and glass cutting is no exception. This material, in its raw form, has sharp edges and its fragile structure can contribute to the formation of small fragments. When working with glass or mirrors, it is strongly recommended to protect your hands and eyes to avoid injury. To do this, you can use the following things:

Construction gloves (preferably rubberized). You can use any others, the main thing is that they do not slip much on the glass surface. For added safety, fingers can be wrapped with adhesive tape over gloves.

Protective glasses. It is not necessary to use special construction. You can wear regular reading glasses or sunglasses. If only they do not obstruct visibility.

How to properly cut a mirror with a glass cutter

Wonderful mirrored surfaces, in all shapes and sizes, are firmly rooted in the design of modern homes. This stunning material that magically expands the space has become a real source of inspiration for creative people. Unfortunately, because of the fragility and peculiar way of cutting, creative work with mirrors is not available for many. In this article, we will try to help novice designers and show that everyone can cut a mirror with an ordinary glass cutter.

Glass cutting of a mirror

The fragile structure of glass can become a serious obstacle when working with this material. If you do not know how to cut a mirror with a glass cutter and are faced with such a task for the first time, we strongly recommend that you strictly follow the following instructions. This will increase your success.

How to cut a large mirror

The first thing to do is to prepare the base on which the cutting will be done. This can be done on a table, floor, stool and other places that are suitable for the size of the mirror. The working surface must be flat, otherwise the mirror may crack during the cut. In order to avoid small cuts, as well as for a tighter fit of the mirror, it is better to cover the base with a soft cloth.

The next step will be the preparation of the processed material. The mirror must be dry and clean, free from heavy streaks. You can wash the mirror with ordinary soapy water and then degrease it with an alcohol-containing liquid. You can use special solutions for cleaning glasses, which contain alcohol or a similar component. Wipe the washed mirror dry with a rag or paper (newspaper) and leave for 10 minutes to evaporate the remaining moisture.

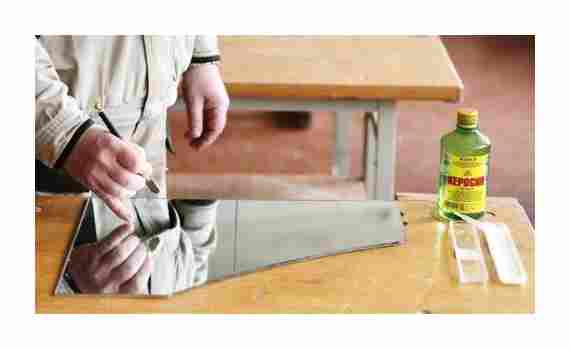

When the workplace and the material to be processed are ready, we proceed to the marking. We take a marker, ruler or pattern and draw the line along which it is necessary to cut. If you do not know from which side to cut the mirror with a glass cutter, then this should be done on the front, reflective surface. Next, we take a glass cutter and with a confident movement we draw the cutter along the markings.

It is best to hold the cutter perpendicular to the glass, but you can also with a slight tilt (like a ballpoint pen). The cutting pressure depends on the type of tool. The diamond one requires minimal pressure, and the roller is slightly above average. If the cutter is sharp and the pressure is optimal, you will hear a slight crunch. A squeaky sound indicates too much pressure or a worn cutter.

The line formed after the glass cutter should be uniform and transparent. If the fishing line is white and periodically disappears, it will not work exactly to break the mirror along it. In this case, it is better to draw a new one, stepping back a couple of millimeters from the original mark. To avoid such incidents, it is recommended to check the sharpness of the glass cutter in advance and practice the force of pressing on unnecessary fragments.

Having received the correct cutting line, you can proceed to the culmination stage of the work. controlled chipping. You can break the mirror on the flat edge of the table by placing a glass cutter under the cutting line and pushing from 2 sides or lightly knock with the head of the same glass cutter from the back side. This does not require much effort. The crack will run from the beginning to the end of the cut, like a path. When the required piece is separated, all that remains is to clean its edges with a fine-grained sanding sheet.

If you want to see the main stages of the process more clearly, we recommend watching the video on how to cut a mirror with a glass cutter. Hopefully the above guide will guide you through this jewelry creation process.

Work technology

At first glance, the job seems daunting. But if you perform it in the established sequence, observing accuracy and precautions, the result will please.

The mirror is cut as follows.

- You need to lay a cloth on the work surface to protect the mirror when pressed.

- Clean the surface of the mirror first with a solution of soda, then with alcohol. Failure to do so will cause grease (e.g. fingerprints) or dust particles to dislodge the cutter, especially if it is a roller cutter.

- Apply line marking. It should correspond to the cutting line of the movement of the glass cutter (that is, in fact, it should be at a distance of about 2 mm from the true position of the future notch).

- An inexperienced carver must make sure that his tool is perfectly sharp, otherwise there is a high probability of failure.

- Next, you need to make the incision itself. according to the rules set out above.

- Now you need to put the mirror so that the incision protrudes slightly beyond the edges of the table, press it with one hand, and with the other one sharp downward movement break off the cut part (you need to break it in the opposite direction from the notch).

- If the “trick” is not successful, a hammer will help, with which you need to gently tap the line of the cut from below, starting from the far edge, and then repeat breaking.

- If the width of the cut area is small and not enough to fully grab the piece with your hand and break off, you can use the grooves of the glass cutter itself and grab the desired area with it. Or pick up the pliers with rubber pads. If there are none on the farm, you can put rubber tubes on the lips of ordinary pliers, or wrap several layers of electrical tape or plaster.

- The resulting sections must be carefully sanded with sandpaper.

Following the above tips, even an inexperienced beginner can cut a mirror with a glass cutter. The main thing is to show accuracy and patience.

The necessary conditions

Cutting mirrors differs from cutting glass in that it is done from the front. The rest of the conditions are the same, which means you must have:

- table, surface area is greater than the size of the mirror;

- a long ruler or strip of hard material about 8 mm thick;

- glass cutter;

- small hammer and pliers.

It is desirable to have a soft and non-slip natural cloth and a few small thin pieces of rubber or leather. By the way, leather pieces are much easier to find.

All this is true when it comes to simple cutting of the mirror.

Curly will require additional conditions:

- availability of sheet material for the manufacture of patterns (plywood, fiberboard, HDF);

- jigsaw or boot knife.

What tools will be needed?

Before you start cutting the mirror with a glass cutter, you need to prepare all the tools, materials and fixtures.

- First of all, the mirror itself.

- The table on which the work will take place. It should be flat and smooth. And necessarily larger in area than the mirror itself.

- Cutting agent. The highest quality cuts can be made with a diamond glass cutter, roller requires a lot of effort and skill.

- Long and straight ruler, at least 8 mm thick.

- Fine sanding paper. for finishing edges at the notch.

- Rubber pliers.

- Fabric, any fabric can be used, but linen works best.

- Measuring tape or meter.

- Small hammer.

- Rags.

- Water tank.

- Alcohol and soda.

- In order to make the markup, you must have writing accessories (marker, chalk or pencil).

- If you need to cut out curly parts, you will need patterns. They can be made from chipboard, plywood or plastic.

It is imperative to worry about the safety of eyes and hands, it is required to protect them from fragments that may appear during work.

In this case, you will need glasses, thick cloth gloves and a medical plaster.

Film application

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.RUB.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.rub.

Name of sheet glass

Price for 1 m 2.RUB.

Cutting mirrors starts with preparation

It is required to prepare not only the tool and the workplace, but also the mirror itself. It is washed and degreased. A dirty, dusty or “oily” surface can cause the cutter to slide to the side.

Then the mirror is wiped dry and placed face up on a tabletop covered with a cloth.

They make markings, apply a ruler so that the marks coincide with the working part of the glass cutter (roller or diamond), and this requires a small indent.

The glass cutter itself is held perpendicular or at a slight angle to the surface, but the diamond one has its own peculiarities of position.

The crystal is inserted into a metal frame in such a way that it can have an acute or obtuse angle with respect to the mirror. It is the acute angle that is the working one. For the correct orientation of the glass cutter, a mark is made on the rim, which during the cutting process must face the ruler.

To facilitate the work with a roller glass cutter, the surface of the mirror at the cutting site can be moistened with turpentine.

It is necessary to cut the mirror with a glass cutter in one motion. repetitions are unacceptable, this is a direct way to spoil it. Therefore, the movement should be progressively uniform with the same force along the entire length, except for the edge itself (at the edge, the pressure is slightly loosened so as not to damage it).

The trace from the diamond glass cutter is thin and almost colorless, from the roller the strip is slightly wider and whitish in color. By the way, the cut on the mirror is easier to control than on the glass. The force for a roller tool is usually slightly higher than for a diamond tool.

A wide streak or whitish glass dust indicates excessive force. Alternatively, for a roller, this may mean that it is dull, and for a diamond, that cutting takes place at an obtuse angle.

The incised mirror is shifted (without turning it over) to the edge of the table top so that the trace from the cut goes beyond it at a distance of no more than the thickness of the mirror (from 3 to 5 mm). With one hand they press the mirror to the table, and with the other they break it down in one sharp movement (but without fanaticism).

If necessary, use the grooves in the glass cutter or pliers. Pliers jaws can be wrapped with electrical tape or strips of rubber (leather).

DIY cutting mirrors

What is glass cutter?

This is a tool designed for cutting thin glass. The glass cutter is a diamond roller, but there are glass cutters made of extremely refractory and durable metal. Of course, diamond glass cutters have quite good characteristics, but, unfortunately, they are too expensive, so not every customer is available.

For the category of people for whom cutting mirrors and glass is a daily activity, the rules for performing this procedure are familiar firsthand. Of course, it will be much more difficult for a beginner to cut such a fragile material.

So, glass cutting should be done as follows:

A lot depends on how you hold the glass cutter correctly. It should be at right angles to the plane (this is especially important when cutting mirrors). In order for the trajectory of the cutter roller to be straight, it is necessary to use a flight tire. In an extreme case, even an ordinary ruler or a perfectly flat rail will do. Perhaps it is obvious, but nevertheless, we note that the mirrors are cut not from the amalgam side, but from the front (glossy).

In appearance, the incision should be thin and transparent. A faint crackling sound is usually heard during work. It is he who testifies that the process is going right.

It is very important to practice on unnecessary pieces of glass before starting work. Otherwise, simply cutting mirrors may not go as you planned.

You need to cut so that the forces with which you press on the glass cutter are evenly distributed over the entire surface.

It is necessary to break off the glass very carefully so that the break occurs only in the place of the cut. It is advisable to put matches under the plane, and then press on it with your hands.

How to cut a mirror with a glass cutter at home?

- What tools will be needed?

- Precautions

- Things to consider when working?

- Step-by-step instruction

Probably not a single room is complete without mirrors. They are needed not only to look, they can be used in various design solutions for interior decoration.

If there is a need to cut a mirror, then you need to keep in mind: the material is fragile, which can cause certain difficulties. To avoid this, you can use the services of professionals. But if you are a neat person and use the recommendations of this article, then it will be quite possible to cope on your own.

Mirror cutting

It is required to prepare not only the tool and the workplace, but also the mirror itself. It is washed and degreased. A dirty, dusty or “oily” surface can cause the cutter to slide to the side.

Then the mirror is wiped dry and placed face up on a tabletop covered with a cloth.

They make markings, apply a ruler so that the marks coincide with the working part of the glass cutter (roller or diamond), and this requires a small indent.

The glass cutter itself is held perpendicular or at a slight angle to the surface, but the diamond one has its own peculiarities of position. How to cut a mirror correctly.

The crystal is inserted into a metal frame in such a way that it can have an acute or obtuse angle with respect to the mirror. It is the acute angle that is the working one. For the correct orientation of the glass cutter, a mark is made on the rim, which during the cutting process must face the ruler.

To facilitate the work with a roller glass cutter, the surface of the mirror at the cutting site can be moistened with turpentine.

It is necessary to cut the mirror with a glass cutter in one motion. repetitions are unacceptable, this is a direct way to spoil it. Therefore, the movement should be progressively uniform with the same force along the entire length, except for the edge itself (at the edge, the pressure is slightly weakened so as not to damage it).

The trace from the diamond cutter is thin and almost colorless, from the roller the strip is slightly wider and whitish in color. By the way, the cut on the mirror is easier to control than on the glass. The force for a roller tool is usually slightly higher than for a diamond tool.

A wide streak or whitish glass dust indicates excessive force. Alternatively, for a roller, this may mean that it is dull, and for a diamond, that cutting takes place at an obtuse angle.

The incised mirror is displaced (without turning it over) to the edge of the table top so that the trace from the cut goes beyond it at a distance of no more than the thickness of the mirror (from 3 to 5 mm). With one hand they press the mirror to the table, and with the other they break it down in one sharp movement (but without fanaticism).

If necessary, use the grooves in the glass cutter or pliers. Pliers jaws can be wrapped with insulating tape or rubber (leather) strips.

Cutting a mirror If we are talking about a small and not thick canvas, then cutting a mirror at home is not difficult. It is absolutely not necessary to go to a workshop or call a “husband for an hour”, it is enough to have a man in the house and a small set of tools.

Safety when cutting mirrors

Before you start cutting a mirror at home, you need to take care of safety:

- First, prepare heavy-duty fabric gloves so as not to injure your hands with the glass cutter and avoid cuts on the sharp edges of the mirror. Additionally, you can stick the strips of plaster on your fingers.

- Secondly, you need to protect your eyes with construction, bicycle or any other protective goggles, since the process of working with mirrors is often accompanied by the bouncing of small fragments.

Before cutting a mirror with a glass cutter for the first time, it is worth practicing on glass elements of a small area, and only after gaining modest experience. start the responsible part of the work.

Preparing the mirror for cutting

Before you start cutting the mirror with a glass cutter, its surface must be prepared. Small debris and dust are removed with a rag. The mirrors soiled with grease are wiped with a soda solution. Additionally, it is treated with alcohol and then wiped dry. Preparation of the mirror surface is very important, as grease and dust contamination can cause knocking down of the mowing line. If the mirror has just been in a cold temperature, then it is given time to warm up. Only after all these procedures should you start cutting.

Mirror Cutting Algorithm

To properly cut a mirror at home, you must strictly follow the following algorithm:

- First, you need to prepare the workplace and lay out the mirror face up on it.

- Place a soft cloth under the mirror to avoid cracking the surface when pressed.

- The mirror needs to be put in order. First you need to clean it with a soda solution. After that, additionally treat the surface from stains and degrease with alcohol. This is important because traces of stains and dust can cause the line to move in the cut and the cutter will “slide” to the side.

- Next, you should start applying the markup. There is one important subtlety here: the marking line must correspond to the line of the glass cutter, that is, it should be 1.5-2 mm away from the future mowing line of the cut.

- After applying the markup, you need to attach a ruler to it. To control the movement of the cutter and to avoid displacement of the cutter, you can slightly raise the ruler. The easiest way to do this is by attaching regular erasers to the ends.

- Check the tool. For a beginner carver, only a perfectly sharp glass cutter is suitable, otherwise the process of work will take a long time or even end in failure.

- Now you can start directly with the cutting process. After making the cut, the mirror must be positioned so that it coincides with the edge of the table and even protrudes a few mm beyond it.

- This is followed by the most traumatic stage of work: the separation of the cut off part from the mirror. To do this, you need to gently press it against the table and break off the cut off part with sharp downward pressure. If you can’t do this with your hands, take a small hammer and lightly tap the bottom of the mowing line of the cut, starting at the far end. Use rubber-coated pliers if necessary, being careful not to scratch the glass.

- Sand the cut thoroughly with fine sandpaper. The mirror is ready! Can be fixed in the frame and hung on the wall.

The necessary conditions

Mirror cutting differs from glass in that it is carried out from the front. The rest of the conditions are the same, which means you must have:

- table, surface area is greater than the size of the mirror;

- a long ruler or strip of hard material about 8 mm thick;

- glass cutter;

- small hammer and pliers.

It is desirable to have a soft and non-slip natural cloth and a few small thin pieces of rubber or leather. By the way, leather pieces are much easier to find. How to cut a mirror

All of this is true when it comes to simple mirror cutting.

How to Cut Glass. DIY Quick Tip

Curly will require additional conditions:

- availability of sheet material for the manufacture of patterns (plywood, fiberboard, HDF);

- jigsaw or boot knife.

Required tools and materials

Before proceeding with the mirror cutting process, be sure to prepare the following materials and tools:

- mirror;

- glass cutter;

- a flat, stable table (as an option, a drawing board or chipboard plate is suitable) of a larger area than a mirror;

- long and thick (8-10 mm) ruler;

- fine sandpaper;

- small hammer;

- pliers with rubber gaskets;

- linen (a linen tablecloth or an ordinary sheet is suitable);

- soda, alcohol;

- container with water;

- rag;

- roulette;

- “Tecnolux”, “steklograph” or other suitable pencil;

- patterns made of plywood or hard plastic will be needed only if curvilinear drawing is supposed.

Work technology

The mirror cutting technology is quite simple. First of all, you need to take care of the workplace: a clean work table covered with a cloth, a tool, and adjacent boxes for scraps. Before you start cutting the main piece of the mirror, it is worth practicing on some unnecessary glass, so your hands will get used to the instrument.

The material is placed on the work table with the mirror surface up. After that, markings are applied using a steklograph or marker. Intricate curved contours are outlined using a pre-prepared template. Detail requiring the attention of the cutter. the line of the cutter’s cut does not match the position of the guide fence by 1–4 mm, depending on its type. For roller glass cutters, including oil cutters, this distance is 1–2 mm, and for diamond cutters. 3–4 mm.

Cut a piece of the mirror in one motion, starting from the far edge and moving the cutter in your direction. The direction is set with a glass ruler or a piece. The master holds the glass cutter at an angle close to 90 ° to the surface, it cannot be changed in the process. All the time, the operator maintains a uniform pressure on the tool, the only exception is the edge of the mirror, the pressure is slightly weakened about 5 mm before the edge of the product, so that there are no chips. Squeaks during operation should not be heard, the correct sound is a slight crackle of glass.

There comes a responsible and rather traumatic stage, the separation of the cut piece. The mirror sheet is hung from the table top so that the cutting line is in the air at a distance of 3-5 mm from it. The worker presses the mirror against the table with one hand, while the other presses sharply downward. Sometimes it is not possible to immediately separate the segments, then they tap a small hammer on the mowing line of the cut from below. When necessary, use pliers with rubber pads. After cutting off all the clippings from our mirror. Its edges are carefully processed with sandpaper.

The breaking procedure for complex shaped cuts has several features. The unnecessary part of the sheet is divided with a glass cutter into small sections, each of which is broken off with pliers.