Cutting pipes at an angle macro

The telescopic one has a carriage, a roller and guides, which can optimally fix the pipe, depending on the required cutting angle. Perfectly copes with cutting thick pipes or made of durable materials, since due to the assembly it can create strong pressure on the surface of the cut object.

The ratchet cutter is portable and can cut thin pipes. Its design is the simplest among devices of this class. 2 handles and a cutting blade.

Electric equipped with an electric motor

thanks to which the efforts of the worker for cutting the pipe are minimal. it is only important to set up the tool correctly, he will do the rest of the work almost independently

At the same time, it is a tool of universal action. it cuts pipes of any diameter and from any materials. Application is limited only by engine power. However, such a pipe cutter also has a significant drawback. it will be inconvenient to use it in hard-to-reach areas of work (for example, sewer pipes).

With its help, it is possible not only to carry out mechanical cutting of pipes, but also to carry out work on their facing, to chamfer with bluntness, as well as from the outer surface of the pipe.

2 Smooth Cutting Tricks (90 Degree) Angle Grinder for Profile and Round Tube

Large diameter pipe cutting

When a large diameter pipe needs to be cut, a variety of special attachments and tools can be used. This may be required if, for example, a pipeline needs to be repaired.

Angle Grinder. The use of an angle grinder is justified from the point of view of the availability of the tool and the relative cheapness of work. However, in this case, you should not count on high productivity, in addition, carrying out work in this way is fraught with considerable risk.

Roller machine. Such attachments are also often referred to as pipe cutters. In fact, such a device is the same angle grinder, but more adapted for this type of work. The machine includes a special bed, where the cut-off element is fixed, as well as a cage with installed cut-off rollers, which do the direct work

It is important to understand that each machine must be purchased for specific tasks, that is, for the size of the pipes.

Gas cutting. This option is most often used when working with large diameters.

Cutting is carried out using a high intensity flame, and the waste produced is blown out by the pressure of the gas. The method can be considered the most practical and effective.

Gas cutting is the fastest option in this case.

There are other options for the implementation of the task, such as the use of plasma, waterjet or laser cutting, but in private use they are practically not used.

Large diameter pipe cutting

If you want to cut exactly a large-diameter pipe, for the sewage system or under the entrance to the site, the following tools are used:

Angle Grinder. An affordable, but not very secure way. A certain skill is required. Be sure to use personal protective equipment.

Roller cutter. This is a rather complex unit specially designed for this kind of work. It is mounted on the pipeline, covering it from the outside. The pressing force of the cutting rollers is adjustable mechanically or automatically. Each diameter requires its own tooling.

Gas cutter. The most commonly used method

The method is quite safe with sufficient qualifications of the gas welder and the observance of precautionary rules. Requires a torch, acetylene or propane cylinders.

What you need to work

To make a tool yourself, you need a small set of tools and materials:

- set of wrenches;

- screwdrivers;

- hacksaw for metal work;

- square wire rod;

- spring;

- hacksaw blades.

Also, in the work you will need a bolt and screws of special sizes, which depend on the parameters of the device itself. Metal rivets are selected in regular sizes (diameter 0.4 cm).

The sequence of work is associated with the stages of manufacturing the left (1), right half (3) of the tool and their assembly. An example drawing is shown below.

Number 2 denotes blade trims, 4. clamping screw. Dimensions are in millimeters and can be proportionally recalculated for your specific model.

The pneumatic pipe cutter is powered by rarefied air pressure. This device is used in production for cutting pipes with a very large diameter (up to 1500 mm). At the same time, it copes well with cutting dense material (cast iron) and light plastic.

Orbital pipe cutters are designed not only for mechanical cutting of pipes, but also for chamfering from thin-walled pipes. For this, they are equipped with special chamfering cutters.

Often, add-ons are offered to different types of pipe cutters that allow you to provide the safest conditions for working with pipes. So, with the help of the fast swaging mechanism, large pipes can be quickly fixed in the device without the use of a special screw. Also, the pipe cutter can be equipped with additional removable cutting elements oriented to pipes of various thicknesses, and rollers that move the device around the pipe.

Thermal applications

In addition to mechanical, thermal methods for cutting pipes are widely used. Here, the tool is a gas torch (propane or acetylene) or an electric arc welder. Even the thickest large diameter pipes are subject to the torch. The performance is also quite high. In addition, only these methods provide exceptional mobility. you can cut the pipe in a trench, basement. in places where a high-performance stationary machine simply cannot be dragged and connected.

It should be noted that thermal methods do not allow achieving high accuracy, and it is also not always possible to cut off exactly. However, in a number of applications, such as operational repair of heating mains or main pipelines, it is not required. After a thermal cut, the resulting edges have to be additionally processed with mechanical tools, the cut line should be leveled and the bevels should be removed to the design values.

Plasma cutting of pipes

The thermal cutting method is also used when working with polymer tubular products. In thermal guillotines, the cut is carried out by an oblique thin cutter heated to a high temperature, sliding in guides.

Devices can also cut at an angle and very smooth, but are only suitable for working with soft materials that have a low melting point.

Precision cutting machines

Band saws are distinguished by high stability of the blade plane and cutting accuracy. They are also widely used in the procurement areas of small-scale and medium-scale production. They are characterized by versatility, reliability and high performance.

For private use, the Italian company MASS offers a compact band sawing unit. It is equipped with a manual clamping device and can evenly cut pipes with a diameter of up to 65 mm, as well as rolled products of any profile of the same thickness.

The rotary device allows you to set an arbitrary cutting direction from 0 to 45 °. Cutting blade movement frequency. up to 45 strokes per minute. An economical 370 watt motor allows you to use a regular home single-phase 220 V power grid.

The nuances of working with a rectangular section

To perform cutting of products of rectangular cross-section, it is recommended to prepare template cuts of the corners in advance. They are easy to make from a metal corner, having previously marked with the same protractor.

Marking can be done at different angles. To use a template in business, it is enough to attach it to a rectangular pipe in the right place and mark the cutting line. Then, with any suitable tool, cut along the intended mowing line.

Templates can be printed in full size

When making a knee, the cutting angle should be equal to half of the knee angle.

An example of determining a cutting angle for making a 135 degree elbow (9045). Not to be confused with a sharp 45 degree knee! Formula: 135/2 = 67.5. We cut the pipe at an angle of 67.5 degrees, we get two pieces of pipe with cutting angles of 67.5 degrees, we connect them along the mowing line of the cut with reference to a common generatrix, we weld and get a knee (67.567.5) at 135 degrees.

In the process of work, I made the following observation. When working with large diameters, the fabricated piece when wrapped around the pipe was clearly shorter, did not overlap the entire pipe, there was a gap of 20-30 mm.

The Gostovsky pipe diameter was specified correctly, and the pattern is shorter. In my opinion, this error is caused by the fact that it is impossible to press the piece tightly against the pipe and the outer diameter of the pipe has increased (rust, dirt). I had to measure the circumference with a “belt” and divide by π (3.1416). Enter the resulting diameter into the table.

DOMOSTROY Plumbing and construction

- Thursday, 12 December 2019 1:05

- Author: Sereg985

- Comment

- Category: Construction

- http://firmmy.ru/

Cutting a pipe at an angle is a typical task in the manufacture of metal structures. There is often a need to cut the pipe at an angle. The cut pipes are welded at a predetermined angle to the walls of the structures, from which two-link bends are made.

Before cutting, using patterns (templates) applied to the pipe, outline the cutting line. For each diameter and each angle of the selected diameter, a separate unique piece (template) is required. The proposed Excel table allows you to obtain dimensions for constructing a pattern for marking pipes of any diameter, cut at any angle. Enter in the yellow cells of the table the outer diameter of the pipe, the cutting angle and you will instantly receive the ordinates and abscissas of these points. Transfer these points to paronite or cardboard and smoothly connect them together. The mold (template) is ready.

Simple tooling for cutting

Round and rectangular metal products with fairly thick walls are conveniently cut at an angle using simple electromechanical equipment.

The cutting element of such a tool is a cutting disc or a circular saw attached to the shaft of an electric motor. In turn, the electric motor with a cutter is part of the entire equipment, which includes a work table, a pendulum support, a clamp.

To install the pipe at the desired angle with its subsequent fastening, a conventional clamp and two metal corners are used. One corner (short) is attached to the base of the swing mechanism. the pendulum. The second corner (long) is in a free state.

Pipe laying and cutting procedure:

- The swivel mechanism sets the required cutting angle (for example, using a ruler and protractor).

- The found position is fixed with clamping screws.

- A pipe is laid between the short and long corners and pressed with a clamp screw.

- Voltage is applied to the electric motor.

- By applying a slight pressure to the cutter blade, the pipe is cut in the right place.

The advantages of this technique are fast work, accurate cut, the ability to process a large number of pipes in a short period of time.

Disadvantages: restrictions on use in domestic conditions, increased noise, work with pipes of only small and medium diameters. In addition, the process of cutting with equipment is carried out stationary at a distance from the installation site, which is not always acceptable.

If you are going to make a copper pipeline at home, then you will need special pipe cutters, we advise you to familiarize yourself with the selection rules.

Miter box for cutting pipes

There is a simple tool, often used in everyday life, mainly for working with wood. It is called. miter box. So, the same device is suitable for cutting pipes, and at different angles.

The miter box is commercially available, but if you wish, you can always make it yourself and adjust the structure to the required pipe diameter:

- Take a wooden board with a width equal to the diameter of the pipe, 400-500 mm long.

- Take two more boards of the same dimensions, but in width increased by the thickness of the first board.

- From three boards to assemble a structure in the form of an inverted letter “P”, where the first board is installed as a base.

- In the central part of the structure, mark a rectangle, the two sides of which pass along the inner boundaries of the side boards.

- Divide the rectangle with diagonals and along the lines obtained on the upper edges of the side boards, make cuts down to the base.

In this way, a template for cutting at an angle of 45º is made. But with the help of a protractor, you can mark almost any angle and make cuts for a pipe cut for a specific angle.

The advantage of the miter box is that the tool is suitable for repeated use. Working with the tool is permissible until the walls of the slots are worn to such an extent that they can provide high cutting accuracy. It is recommended to make the walls of the tool from a material of higher strength than wood.

The advantages of the method are obvious. simplicity, ease of making a tool (miter box), cost-effectiveness, versatility. The disadvantages of working with this type of equipment are the need to adjust the dimensions of the miter box to the pipe diameter, provided that an accurate cut is made. That is, for each pipe you will have to make your own instrument.

Also, using a miter box, you can only cut a pipe with a hacksaw for metal or pruning shears (for plastic products). This tool is not suitable for working with thick-walled metal pipes for cutting an angle grinder.

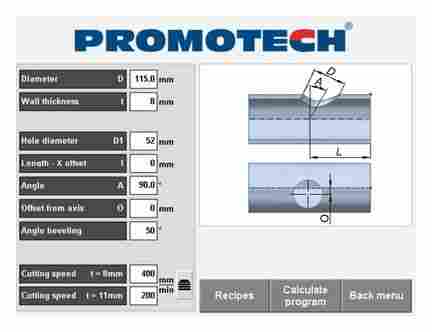

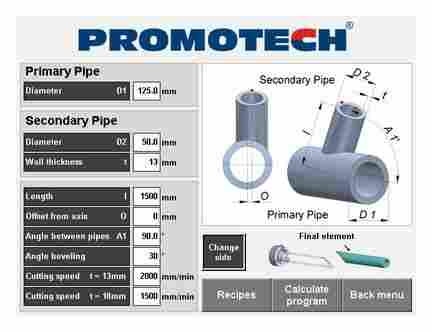

Programs for calculating cutting angles

Curve cutting technology allows you to obtain different cutting angles. But to form a piece at angles other than 45º, it will already be necessary to perform mathematical calculations and, according to the calculated data, cut out a template from paper or similar materials.

True, there are computer programs designed to save the master from the production of calculations. Patterns for cutting pipes such programs are printed on a printer.

A simple calculation program based on the MS Excel application allows you to calculate and compose a pattern for almost any values of pipe diameters and required cutting angles.

All the user needs to do is enter the corresponding values into the “Outside diameter” and “Cut angle” cells. According to these parameters, a pattern will be formed that can be sent to print.

Watch the demo

(Pictures, descriptions, formulas were taken from the book by I.Kh. Brodyansky “Marking of welded fittings of pipelines”, 1963)

Upon successful payment, you will immediately receive a link to download the worksheet.

For homemade.

Everything is clear with the calculator, with the calculation of the arc too, but with cutting the pipe, I suffered.

I checked it with a ruler on a piece of paper, then cut it out, put it on the pipe.

But it turned out great, when welding it turned out to be a smooth seam. The pipe came to the pipe without gaps.

In the books you can see the methodology and calculation of the connection of pipes, curved surfaces.

Pipes are a widespread building material. They are used in the installation of various systems. During the installation process, there are situations when the pipes must be joined at an angle. The technology for the production of such works is not standard, but you need to know about it.

To create complex joint configurations, bevel cutting of pipes is required. We will tell you how such operations are performed and what cutting methods exist.

Paper mold for pipe

To perform a relatively accurate cut, you can use a simple technique, where a regular sheet of paper acts as a kind of pattern. For example, A4 printer paper is well suited for creating patterns.

Previously, the sheet is marked out under a square using a ruler. The size of the diagonal of the square must be equal to the circumference of the pipe to be cut. The excess parts of the sheet are cut off.

Then the following steps:

- Bend the sheet diagonally by aligning opposite corners.

- Turn the resulting triangle so that the hypotenuse line is perpendicular to the pipe axis.

- In this position, wrap the tubular surface with paper, aligning the extreme points of the hypotenuse together.

- Use a marker to mark the cut along the mowing line of any of the legs of the triangle.

- Cut the pipe to the intended mowing line.

This way it is quite convenient to mark and cut pipes at an angle of 45º in the range of diameters from 32 to 63 mm. For better markup convenience, it is recommended to use thick, but soft paper. Paronite and similar materials can also be used.

How to correctly choose a pipe cutter for plastic pipes and how to use it in practice is described in detail in our article.

Competently made patterns for true shape cutting of pipes allow you to make cuts with extremely high accuracy. In this case, the gap between the prepared workpieces is still not excluded. In the connection of metal pipes, it is “closed” with a welded seam, when connecting plastic parts, a specialized cord for soldering is used.

Pipe cutting methods

To cut a profile pipe, including at a certain angle, you can use the following tool:

- angle grinder. angle grinder (picture above). This method is most often used for domestic purposes, as it is characterized by simplicity and availability of equipment;

- hacksaw for metal. Using a hacksaw is not difficult, but the process of doing the work is quite laborious;

The use of a hacksaw for metal for cutting pipe

- electric jigsaw. To cut metal, you will need to purchase a special diamond-coated file. The work is done quickly enough;

Cutting professional pipes with a jigsaw

- special machine for cutting pipes. The equipment is most often used by professionals because of its high cost. Currently, specialists use two types of machines:

- equipment with mechanical cutting, which is performed with a cut-off wheel or a special file;

- equipment with a laser. Laser cutting is more accurate than mechanical counterparts.

Using a dedicated laser cutting machine

When choosing any method, it is important to pay special attention to safety precautions. During the cutting of the pipe, metal shavings are formed, which can damage the hands and eyes of the master, therefore, it is important to wear gloves and safety glasses before performing the work.

Using a miter box

The construction miter box allows you to correctly cut the professional pipe at any angle. The device is applied in the following order:

- the profile pipe is fixed inside the device and aligned at a certain angle;

- a preliminary cut is made using the built-in hacksaw;

Miter cuts with a miter box

- the pipe is removed from the miter box and cut through the workpiece by an angle grinder. In this situation, the cutting place will be highlighted and the risk of error is reduced to zero.

The finished measuring tool has a high cost. To reduce financial costs when performing construction work, you can make an analogue of the miter box yourself. For this, a wooden frame is made with a niche for pipes and with the help of measuring tools, notches are made at different angles.

DIY miter box for cutting a professional pipe

What other ways can you use to cut profile pipes at an angle, see the video.

How to cut a profile pipe

Profile pipes are widely used in everyday life. The material is used for the construction of greenhouse complexes, benches, tables and other garden furniture, awnings, swings and other small architectural forms. It is for this reason that it is important to know how to correctly cut a profile pipe at an angle of 45 degrees, 90 ° and so on, as well as along.

How to cut a professional pipe angle grinder

The most popular household cutting method is the use of an angle grinder. How to cut an angle grinder straight into a profile pipe? The main problem with getting the job done is correct markup.

For marking, you can use:

- tape measure, square, marker (pencil), building level. The simplest tools allow you to accurately mark the cutting angle, but during the work, the angle grinder may deviate from the specified mowing line (the equipment does not rest on stands, but is suspended, that is, in the hands of the master), which will lead to an error. For this reason, this method is rarely used;

Cutting with an angle square

- paper pattern;

- miter box.

Using a paper pattern

The simplest device for correct cutting at an angle, for example, for making a greenhouse, is a template made of thick paper.

To make a cut at right angles (90 °), you must:

- wrap the pipe with a thick sheet of paper and achieve full alignment of the edges;

- fix the sheet in this position;

- cut the profile tube along the edge of the paper.

Pipe cut at right angles

To cut a pipe at an angle of 45 °, it is necessary to fold a sheet of paper in half (along the hypotenuse) and wrap the pipe so as to combine the sharp ends of the resulting triangle.

Curve for cutting off at an angle of 45 °

Automatic production of a paper pattern by a computer program

Features of cutting pipes along

With the help of an angle grinder, you can make not only a transverse, but also a longitudinal cut of a profile pipe. How to cut a multi-profile pipe lengthwise? The work is done in the following order:

- as with cross cuts, work begins with marking. It is important to determine as many anchor points as possible on the lateral surface of the pipe in order to get the most even line;

Marking for longitudinal cuts

- to improve visibility and eliminate the possibility of getting an uneven cut, it is recommended to highlight the resulting line (with paint or masking tape);

- the pipe is fixed, for example, with clamps. If possible, you can fix the angle grinder, as an option. using a special stand;

- the cut is gradually made along the specified mowing line.

Pipe cutting along an angle grinder fixed on a rack

A similar technology is used to cut thick-walled shaped pipes. Before performing the work, it is required to fix the pipe, which excludes the possibility of the workpiece breaking under its own weight.

Cutting pipes at an angle macro

Cutting the pipe at an angle. a typical task in the manufacture of metal structures. There is often a need to cut the pipe at an angle. The cut pipes are welded at a predetermined angle to the walls of the structures, from which two-link bends are made.

Before cutting, using patterns (templates) applied to the pipe, outline the cutting line. For each diameter and each angle of the selected diameter, a separate unique piece (template) is required. The proposed Excel table allows you to obtain dimensions for constructing a pattern for marking pipes of any diameter, cut at any angle. Enter in the yellow cells of the table the outer diameter of the pipe, the cutting angle, the length of the segment and you will instantly receive the ordinates and abscissas of these points.

Transfer these points to paronite or cardboard and smoothly connect them together. The pattern (template) is ready. For the convenience of manual construction, the user himself enters the length of the segment on the X axis (multiples of 5, 10 mm) and receives up to 40 construction points, depending on the length of the segment and the length of the piece. You should get a curve like this.

When using a table with a macro, there is no need for manual construction. The program itself draws a sweep based on the entered data. It remains to print and cut it. The allowances on the printout are added by the user.

When making a knee, the cutting angle should be equal to half of the knee angle.

An example of determining a cutting angle for making a 135 degree elbow (9045). Not to be confused with a sharp 45 degree knee! Formula: 135/2 = 67.5. We cut the pipe at an angle of 67.5 degrees, we get two pieces of pipe with cutting angles of 67.5 degrees, we connect them along the mowing line of the cut with reference to a common generatrix, we weld and get a knee (67.567.5) at 135 degrees.

In the process of work, I made the following observation. When working with large diameters, the fabricated piece when wrapped around the pipe was clearly shorter, did not overlap the entire pipe, there was a gap of 20-30 mm.

The Gostovsky pipe diameter was specified correctly, and the pattern is shorter. In my opinion, this error is caused by the fact that it is impossible to press the piece tightly against the pipe and the outer diameter of the pipe has increased (rust, dirt). I had to measure the circumference with a “belt” and divide by π (3.1416). Enter the resulting diameter into the table.

Watch the demo

(Pictures, descriptions, formulas were taken from the book by I.Kh. Brodyansky “Marking of welded fittings of pipelines”, 1963)

Upon successful payment, you will immediately receive a link to download the worksheet.

Pipe cutting at an angle of 45 and 90 degrees

If you need to cut the pipe at an angle of 45 degrees, which is more often required when laying water, heating pipes. Steel, cast iron pipes that are cylindrical in shape are often used. In installation work, rectangular or shaped pipes are used. However, the pipe of the angle grinder should be cut correctly so that it can be easily connected later. Therefore, you should carefully mark the pipe.

Some craftsmen try to mark the place of the cut using a tape measure, but we warn you that the result is likely to be negative. And for a positive result, consider the following professional recommendation.

Take a sheet of paper or cardboard, preferably A4, fold it diagonally and wrap it around the pipe where you plan to cut it evenly. The edges of the paper must be in perfect alignment with each other. And the side of the paper that is closer to the end of the pipe was perpendicular to the axis. Then mark the cut line in a circle.

If you need to cut exactly at an angle of 90 degrees, then solve the problem quickly using paper or masking tape again. Wrap around the pipe so the ends match. Make even lines and saw off.

How to cut a profile pipe straight?

Masters advise using a square when cutting a profile pipe. To do this, apply the square in turn to the sides, and turn and mark with smooth movements. After action, fix the pipe and cut. Prepare yourself a template that will come in handy in the future and save time. It is better to produce an angle grinder, so the cut will be smoother.

How to cut a cast iron pipe?

When working with a cast iron pipe, keep in mind that it is a brittle material. Therefore, we will point out a way with which it will be possible to cut such a metal without damage.

Before starting work, make notes for the cut, just like with steel pipes. Place a piece of wood for support. Run an angle grinder around the circumference of the pipe making small cuts. Then take the chisels, insert into the groove and hit hard with a hammer. Note that bakelite-based cutting discs are used to cut cast iron pipes.

How to cut a gas pipe?

Cutting a gas pipe is dangerous, so it is best to entrust it to professionals. But if you are confident in the strength, then to cut the metal, take an angle grinder, welding, hacksaw, gas welding.

- Shut off the gas riser before work. Then release the rest of the gas from the pipe. To do this, set fire to the gas in the burners and wait for it to go out.

- After the steps taken, cut. Using the welding method, the metal base burns out when exposed to high temperature. The result is fast and effective. But remember that cutting or rooting gas pipes again requires experience.

How to cut a pipe straight angle grinder?

When dealing with construction or plumbing tasks, you need to know how to cut the pipe straight from an angle grinder. In the article, we will consider quick and easy ways of how to properly cut an angle grinder pipe so that the result is perfect.

news

Methods for cutting large diameter pipes

There are a number of reliable tools available for cutting large diameter pipes such as sewers. Let’s consider some of them in detail below:

- An angle grinder is an inexpensive and affordable option, but it is considered not the safest when working with such materials. Once you decide to use this method, then be careful and use protective equipment.

- A roller machine (pipe cutter) is such a tool adapted for such manipulations. The device is attached and material removal begins. The clamping force is adjusted using mechanical devices. It is important to note that the models of the machine differ in shape, so consider the ratio of dimensions to the pipe before use.

- Flame cutting is the most popular option for cutting large diameter pipes, sheet metal. The cut occurs due to the action of a high intensity flame, the metal melts and leaves the cut zone with a gas flow. This method is convenient and effective.

How to cut a pipe lengthwise correctly?

A quick way to cut a pipe lengthwise with an angle grinder:

- Focus on the markup.

- Use for such a case the painter’s thread, which has found distribution when marking walls.

- Before starting work, fix the pipe and with small movements, carefully saw the pipe.

- Better not to rush, but delicately and slowly process the parts of the pipe, so the cutting disc will not jump off the marking lines. Remember safety.

How to cut thin-walled pipes?

Thin-walled pipes are made of non-ferrous metals: aluminum, copper. Such work should be done delicately, since there is a high probability of deformation of the material. Fillers such as sand are used for cutting. Actions can be carried out using an angle grinder, a special machine.

Summing up, we emphasize that cutting metal pipes is a complex process, but anyone who wants to enhance it can enhance it. With the advice of a professional, you can easily cut pipes in a variety of sizes and materials. Also remember to use a file or emery paper to clean the edges of the pipes after cutting. And the most important thing to remember when starting such actions is safety precautions. Wear a special suit (casing), mask or goggles when getting started. Hands should also be reliably protected from sparks, so use thick gloves.

Cutting pipes at an angle: the pros and cons of different ways

Luxury yacht charter: luxury yacht charter goodcapitan.ru.

Pipes are a widespread building material. They are used in the installation of various systems. It is common during the installation process when pipes need to be joined at an angle. However, the technology for the production of such works is not quite common. To create such a joint configuration, bevel cutting of the pipe is required. Consider how such operations are performed and what cutting methods exist.

Precision cutting machines

Among the branded devices that could be used in everyday life to perform an angle cut, you can pay attention to the technique of Italian production. The Mini Cut band saw from the MASS company is a small-sized device with a hand clamp, for working not only with pipes, but also with corners, rods, and profile elements.

The machine supports setting the cutting angle from 0 to 45º. The procedure is carried out using a tape belt at a speed of 45 reciprocating movements per minute. The device is equipped with a 370 W electric motor, which is powered by a household network. Maximum permissible diameter of the cut round pipe. 65 mm.

Industrial models (for example BSM)

There are dedicated industrial machines for precise bevel cutting operations. A good example: devices manufactured under the BSM brand. The machine tool is manufactured by the German company Rexinger. True, the BSM series machines are designed exclusively for working with polypropylene pipes of sufficiently large diameters. Supports processing of PP, PVC, PE, PVDF products.

The cutting tool of the machine is a band saw, thanks to which a cut is made at angles from 0 to 67.5º. The precision of the process is ensured by a laser cut recognition. Despite the configuration of the device for products of large diameters, a special table can be used, with the help of which pipes of small diameters (50. 200 mm) can also be successfully cut. A wide range of BSM devices is produced.

- Techniques for cutting pipes at an angle

- Paper mold for pipe

- Programs for calculating cutting angles

- Miter box for cutting pipes

- Simple tooling for cutting

- The nuances of working with a rectangular section

Programs for calculating cutting angles

Curve cutting technology allows you to obtain different cutting angles. But to form a pattern at angles other than 45º, it will already be necessary to perform mathematical calculations and, according to the calculated data, cut out a template from paper or similar materials. True, there are computer programs designed to save the foreman from making calculations. Patterns for cutting pipes such programs are printed on a printer.

A simple calculation program created on the basis of the MS Excel application allows you to calculate and compose a pattern for almost any values of pipe diameters and required cutting angles. All the user needs to do is enter the corresponding values into the “Outside diameter” and “Cut angle” cells. According to these parameters, a pattern will be formed that can be sent to print.

How to Cut Pipe at an Angle Accurately. Kevin Caron

The disadvantage of the program. it does not take into account the thickness of the sheet of the pattern, which leads to minor inaccuracies.

Techniques for cutting pipes at an angle

Considering the methods of work. cutting straight or at an angle. one should take into account the different material of the products being processed. So, sleeves made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Small diameter plastic products are cut at the desired angle using special scissors. At the same time, you can control the angle with an ordinary protractor.

The most frequent need for installation is cutting plumbing or other pipes at an angle of 45º. Let’s find out what devices can be used to cut at this and another angle.

Miter box for cutting pipes

There is a simple tool, often used in everyday life, mainly for working with wood. It is called. miter box. So, the same device is suitable for cutting pipes, and at different angles. The miter box is commercially available, but if you wish, you can always make it yourself and adjust the structure to the required pipe diameter:

- Take a wooden board with a width equal to the diameter of the pipe, 400-500 mm long.

- Take two more boards of the same dimensions, but in width increased by the thickness of the first board.

- From three boards to assemble a structure in the form of an inverted letter “P”, where the first board is installed as a base.

- In the central part of the structure, mark a rectangle, the two sides of which pass along the inner boundaries of the side boards.

- Divide the rectangle with diagonals and along the lines obtained on the upper edges of the side boards, make cuts down to the base.

In this way, a template for cutting at an angle of 45º is made. But with the help of a protractor, you can mark almost any angle and make cuts for a pipe cut for a specific angle. The advantage of the miter box is that the tool is suitable for repeated use. Working with the tool is permissible until the walls of the slots are worn to such an extent that they can provide high cutting accuracy. It is recommended to make the walls of the tool from a material of higher strength than wood.

The advantages of the method are obvious. simplicity, ease of making a tool (miter box), cost-effectiveness, versatility. The disadvantages of working with this type of equipment are the need to adjust the dimensions of the miter box to the pipe diameter, provided that an accurate cut is made. That is, for each pipe you will have to make your own instrument.

Also, using a miter box, you can only cut a pipe with a hacksaw for metal or pruning shears (for plastic products). This tool is not suitable for working with thick-walled metal pipes for cutting an angle grinder.