DIY Chainsaw Adjustment Champion

Briefly about the device

Before adjusting the chainsaw carburetor, you need to understand a little about the device and the principle of operation. If you understand how the device is functioning and which nodes are most vulnerable, it will be easier to diagnose the problem and fix it. Adjustment in this case will not be a problem at all.

Just like in a car, in a chainsaw, the carburetor is a very important and responsible unit, which is necessary for the preparation and mixing of the fuel-air mixture before it is sent to the internal combustion engine. But often these same proportions are violated, and the engine is fed, either too rich or, on the contrary, a lean mixture. This does not lead to anything other than a bad motor condition. As a result, he starts to junk.

By itself, the carburetor filling is 4 elements. This is a tube with a cross damper for air flow regulation. A diffuser is a device for accelerating or decelerating air flows entering the carburetor. Fuel needle (nozzle) from which fuel comes. There is also a float chamber for adjusting the fuel level.

General information

As noted above, the chainsaw cannot be classified as complex tools. There is a minimum number of units and mechanisms that can fail, and most of the parts are not repaired, but simply simply changed. But this does not apply to the carburetor, which must be periodically adjusted.

Often, more time is spent not on repairs, but on troubleshooting. But the chainsaw, the carburetor adjustment of which will be discussed a little later. the device is small, so the work is more jewelry than purely mechanical. Let’s take a look at all the nuances and features. It will be especially interesting for the owners of domestic models, since they most often need such repairs. But first things first.

Chainsaw: do it yourself carburetor adjustment

Chainsaw carburetor adjustment instructions

There are three screws directly on the carburetor, although some models have only one, but this is a rarity. So, each screw has its own letter designation and is used to adjust the speed and idle. The screw marked “L” is required for setting low rpm, “H” for high rpm. The last screw marked “T” is needed to debug idle.

The factory setting can be considered optimal. However, these settings can get lost over time. It is not uncommon for small adjustments to be made in a climate that has become either too cold or too hot.

So, the adjustment work is carried out with the screws “L” “H” “T”, in that order. When you manage to reach the optimal mark, you can stop there. Often no idling is required and only screws “L” and “H” are taken into account. To decrease the speed, turn it counterclockwise, to increase it, turn it clockwise. This is how the carburetor of the Ural, Panther and any other chainsaw is adjusted, regardless of the manufacturer.

We disassemble the tool

We have already figured out how a chainsaw works. Carburetor adjustment requires almost complete disassembly of the tool. Since in all models the carburetor is located in the same place, the disassembly process is the same for all.

The first step is to unscrew the top plastic cover, which is held by three screws. Then we remove the foam rubber, which is an integral part of the air filter. In the next step, the fuel line hose and the drive rod are removed. It remains only to dismantle the cable tip. After the fuel hose has been removed, you can dismantle the carburetor itself and start adjusting it. If you need to disassemble, then put all the structural elements in one place, since many parts are small and can easily be lost.

When you need to adjust the carburetor of a chainsaw with your own hands

The principle of the device can be described in a few words. The fuel flows through the pipe to the diffuser, where it is sprayed. At this time, a fuel-air mixture is created. It would seem nothing complicated, and it really is. But here’s one small violation and adjustment will be required. Although this procedure is performed very rarely. In most cases, we are faced with trivial wear and tear of parts.

However, there are several symptoms to determine if adjustments are needed rather than repairs. A striking example of this: start the chainsaw, and the engine immediately stalls or the tool does not start at all. Most likely, we are dealing with a lean mixture. In this case, a large amount of air and insufficient fuel enters the cylinder. The same applies to the oversaturated mixture. True, in this case the engine does not stall, but fuel consumption increases, as does the amount of exhaust gases. Often the reasons for such failures are wear of the engine piston group, blockages, etc.

In principle, we have dealt with the main aspects of this issue. In fact, there is nothing complicated here, the main thing is to understand at least a little what to shoot and where to turn. If you are not confident in your own abilities, then use the services of specialists. Such adjustments are inexpensive. But a lot depends on which manufacturer your chainsaw is. Adjusting the carburetor of European models is more expensive than domestic ones, in the same way as parts for a similar tool. In principle, this is all that can be said on this topic.

How To Tune A Chainsaw | Adjusting The Carburetor

Chainsaws Champion 137

Chainsaw Champion 137 is well suited for use in the garden and in the garden. Among the many advantages of a garden tool, the excellent quality of its components and factory assembly, a fairly high working resource, as well as a relatively low fuel consumption stand out. With proper and timely maintenance, the Champion 137 chainsaw delivers high speed and good cutting quality, leaving a smooth, clean cut line. This allows the model to be used not only for garden maintenance, but also for construction work.

Chainsaw characteristics Champion 137

Thanks to the powerful and durable standard engine, the Champion chainsaw in the 137th modification received solid factory parameters.

They include:

- gas engine power. 1.4 kW / 2 liters. from.;

- crankshaft rotation speed at idle / maximum speed. 3000/13000 rpm;

- the tire length recommended by the manufacturer is 35–40 cm;

- the pitch of the chain used for cutting is 3/8 “;

- weight in ready-to-use form. 4.5 kg.

The Champion chain saw comes with a redesigned muffler to reduce operator noise. When operating at maximum engine speed, this parameter of the model is 100 dB.

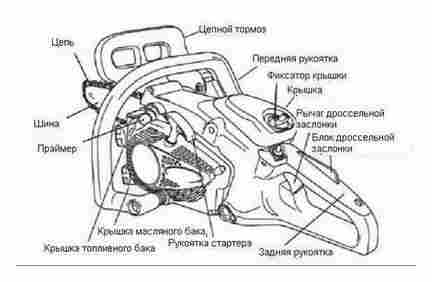

Chainsaw Champion 137. model device

Chainsaw Champion in the 137th modification is distinguished by a good supply of traction and torque. The basis of the complete set of garden tools consists of a 2-stroke gasoline 1-cylinder engine with a forged piston, which has received an increased stroke range, as well as a chrome-plated cylinder with a volume of 37.2 cm3. For a quick start of the engine, the model has a manual starter and a durable clutch. Fuel tank, with a capacity of 310 ml, has a wide neck for cleaning the tank from small debris.

Chainsaw Champion 137 is equipped with an enlarged Japanese brand Walbro carburetor with metal jets and an improved float that allows you to precisely control the amount of fuel supplied to the engine. For simplified starting of the built-in cold internal combustion engine, the model is equipped with a transparent plastic pump for pumping fuel into the cylinder.

Champion has included in the basic equipment of the 137th model a modified anti-vibration system, consisting of 6 metal springs. When the engine is running at the maximum permissible speed, the springs take over the vibrations of the crankshaft. Thanks to this, vibration on the handles of the model is practically not felt.

The Champion saw headset includes a metal bar and chain. For self-tensioning of the chain by the operator, the manufacturer has included a side sprocket with the garden tool. The chain is lubricated fully automatically using an oil pump. To add the oil required for the operation of the headset, a separate 210 ml tank is included in the chainsaw device.

To protect the interior from dust, sawdust and shock, Champion has equipped the 137 with a durable, reinforced plastic casing. Individual parts can be removed for self-repair and quick replacement of consumable parts.

At the rear of the saw body, the manufacturer provides all the controls necessary for work. This allows the operator to adjust the operation of the garden tool directly while cutting wood without the need to turn off the chainsaw engine.

Adjusting the carburetor of the Champion 137 chainsaw

There are several occasions when you need to tune your Champion’s factory carburetor.

Their list includes:

- wear or formation of defects in the engine’s CPG;

- a sharp increase in motor vibration;

- arbitrary shutdown of the engine;

- increased fuel consumption and an increase in the volume of exhaust gases;

- carburetor blockage.

How to independently adjust an incorrectly working saw carburetor will be described in the operating instructions for the model. The correct procedure, in any case, should look like this:

- First, on a chainsaw with a cold engine, all the adjusting screws available in its device will need to be returned to their original position. It is indicated in the garden tool manual;

- Then you need to start the saw motor and wait until it warms up;

- Next, you need to start turning the screw L in different directions until the optimal low engine speed is found. Immediately after this, bolt L must be turned a quarter of a turn in the opposite direction;

- By the same principle, you need to adjust the screw H, which will allow you to find and set the highest possible engine speed. To more accurately determine the speed of rotation of the motor at the permissible speed, you will need to connect a tachometer to it. Then start slowly turning screw H. Once the revolutions on the tachometer and in the Champion’s instruction manual match, the screw must be loosened;

- If, after adjustment, when the saw is idling, the chain rotates on the bar, then you need to alternately turn the bolt T in different directions until the chain stops.

After completing the tuning of the saw carburetor with your own hands, you need to check the operation of the fuel unit. If the chainsaw is steadily gaining momentum, its engine is running stably, and the chain does not rotate on the tire when the engine is idling, then the adjustment was made correctly.

Regulation rules

Regardless of which manufacturer’s tool you have to deal with, adjusting the carburetor requires certain requirements:

To properly adjust the carburetor, you must first warm up the engine. To do this, turn it on for 10 minutes;

In the process of adjusting the carburetor, there is a risk of harm to your health. Therefore, in order to minimize such unpleasant consequences, it is necessary to make sure that the chain is directed in the opposite direction. In turn, the saw must be positioned on a level surface and make sure that it does not come into contact with the cutting part with any objects.

The process of fine adjustment of the screws requires adherence to a certain order: L. H. T. Screw L is used to select the maximum engine speed. This is done by turning the screw clockwise or in the opposite direction until the maximum is reached.

Considering that everything is done by “feeling”, a tachometer or a clear ear for music will not interfere here. It is very important that you have a clear idea of what sound the engine speed limit is. Then you can stop in time. First of all, you need to be careful with the H regulator, because otherwise it may result in engine failure. And to repair it, you will have to spend a large amount of money. For this reason, it is desirable that such work be performed by a qualified specialist.

Chainsaw carburetor device

Even before you start adjusting the carburetor, it will be useful to familiarize yourself with the device and the principle of operation of this tool. Subsequently, this information will help prevent many problems.

A number of mandatory elements can be distinguished in the design of the carburetor, however, in some modifications of this tool, additional ones may be present. Therefore, you need to look at the chainsaw model. These elements are:

A tube. The main element, made like a wind tunnel, which provides air intake. There is an air damper across it, which changes its position and thereby contributes to an increase in the force of the incoming air or its decrease.

The carburetor itself works as follows: the air channel provides a fast flow of air, which can have different speeds depending on the position of the damper. The level of the float allows you to adjust the degree of opening of the fuel supply channel, and it itself depends on the position of the above-mentioned air damper. When air enters the diffuser, it begins to lift the incoming fuel along with it and atomizes it. At this stage, a mixture is formed, which goes into the cylinder, bypassing the intake manifold.

As a rule, the pressure level in the float chamber does not differ from the atmospheric one. In the air channel, a different picture is observed, since a rarefied pressure is maintained there. It is the difference in fuel pressure that ensures its flow through suction through the nozzle, from where it goes into the air channel. It is very important that with an increase in the degree of opening of the air damper, the amount of air also increases, which, accordingly, allows more fuel to be supplied. In turn, it is the volume of fuel that affects the speed at which the engine will operate.

Chainsaw carburetor adjustment

The process of adjusting the carburetor of the Partner chainsaw, as well as other manufacturers, is carried out by manipulating three adjusting screws. However, in some models only one screw is provided for this case. For the standard tool, you can see the screws on the carburetor body, which correspond to the following designations:

- L. this screw is needed to change low engine speed;

- H. this screw allows you to change the high speed;

- T. this screw is used to adjust the idle speed.

Usually, to adjust the carburetor of Goodluck chainsaws and other manufacturers, two screws, L and H, are used, which allow you to create a fuel mixture of the required quality. If a lean mixture is required, the screws must be turned clockwise, which will increase the number of revolutions. In other words, the purpose of the operation is to set high RPM. If the screws are turned counterclockwise, this will allow for a richer mixture. Accordingly, such an operation allows the setting of a low engine speed.

When is adjustment necessary?

Most often, the owners of the Husqvarn chainsaw and other manufacturers do not often have to adjust the carburetor. To understand that it is time to perform this operation, you need to focus on the following signs:

- After starting the engine, it stalls rather quickly or it is generally impossible to start it. This is most often associated with the use of a lean fuel mixture;

- During the operation of the tool, fuel is consumed in an increased amount. There may also be an increased generation of exhaust gases. As a rule, this happens in the case of using a supersaturated mixture.

It should be noted that an adjustment failure is quite rare, but it can occur in the following situations:

- In case of failure of the fastening of the adjusting screws This could be due to vibration or breakage of the protective cap. In principle, the likelihood of this is rather low if no one has touched them.

- Serious wear of the engine, primarily the piston engine. In this case, the factory settings will be of little use. A temporary solution in this situation is to adjust the carburetor of the chainsaw. However, you shouldn’t expect this to permanently fix the problem. After performing this operation, you need to be prepared for the fact that soon you will need to repair the engine.

- Also, the need for adjustment may be associated with the appearance of a blockage in the carburetor. This can result from the use of not the best quality gasoline, breakdown of the air filter or the formation of scale. In such cases, adjustment alone is not enough. It is necessary to disassemble the carburetor and remove it from dirt.

Adjustment procedure

If you were able to get hold of a tachometer and you know what the maximum number of revolutions your engine has, then you can try to adjust the carburetor yourself. The process itself involves the following actions:

First, you need to find the closest possible speed value using the L regulator;

Finally, we need to perform an operation to adjust the idle speed. First, you need to ensure that the engine runs evenly in any position until it starts moving. The screw for adjustment must be turned counterclockwise until the chain stops. In the event that you fail to do this, you should entrust this work to a specialist, since using a chainsaw with a broken adjustment is dangerous to health.

How to adjust the carburetor on a chainsaw with your own hands?

The owners of the suburban area often have to perform work that requires a tool such as a chainsaw. However, over time, even he begins to cope worse with his functions and at some point may simply stall. This can happen due to various reasons, including the use of low quality fuel or the presence of problems in the engine. This question is, of course, important, but for us the most interesting is the carburetor, which is an important element of the engine. In order for the engine to work normally as long as possible, you need to know at what moments the carburetor of the chainsaw should be adjusted and how this operation should be carried out.

- 3.1 Regulation rules

- 3.2 Adjustment procedure

A tool such as a chainsaw greatly simplifies many operations. However, it can fail at some point. One of the reasons for this may be a carburetor adjustment failure. But any owner can solve this problem on their own. In principle, adjusting a chainsaw with your own hands is a fairly simple procedure, since it requires manipulating three adjustment screws. However, experience here will not be superfluous, so it is recommended not to experiment with a working tool, but to invite a specialist.

When is adjustment necessary

In general, the need to adjust the carburetor of a Stihl chainsaw, or any other brand, arises quite rarely. Signs of a misaligned carburetor are indicated by:

- the engine starts and stalls, or does not start. in this case, the cause may be a “poor” fuel mixture;

- fuel consumption has increased significantly and there has been an increase in the amount of exhaust gases (fuel does not burn completely). oversaturated mixture may be the cause.

The adjustment itself gets lost in very rare cases, namely:

- when the fixation of the adjusting screws was broken, there are three of them. Vibration or damage to the protective cap may be the cause. It is quite rare that the screws have not been touched.

- in case of significant engine wear, namely piston. Then the factory settings are not suitable. In this case, adjusting the carburetor of a Patriot chainsaw, or another model, can save the situation for a while. But here it is time to think more about repairing the engine, rather than adjusting the carburetor of a Husqvarna chainsaw or the like;

- the reason may be due to the formation of a blockage in the carburetor, the reason may be poor quality gasoline, damage to the air filter or scale. In this option, in addition to adjustment, it is necessary to disassemble and flush the carburetor.

Tools

The chainsaw is an indispensable tool, both in the home garden and in the summer cottage. But even the most reliable “iron” assistant begins to mope, then it does not start, then it stalls. There can be many reasons, both related to the quality of the fuel mixture and the engine.

There are a lot of nuances, we will not consider all of them in this article. And we will “take a closer look” at that part of the engine, which is called the carburetor. And we will try to find the answer to the following questions: when is it necessary to adjust the carburetor of a chainsaw and, in fact, what is the scheme of such an adjustment.

Chainsaw carburetor device

Before proceeding with the adjustment, you need to know the structure and principle of operation of the carburetor. This will help avoid many “complications”. So, to begin with, let’s recall the principle of operation of an internal combustion engine. The cylinder contains fuel, and when burned, a small “explosion” is created, which creates a lot of pressure. This pressure pushes the piston, the piston, when set in motion, rotates the crankshaft. Ultimately, the pressure energy is converted into torque, which drives the chain through the sprocket.

During normal operation of the engine, it burns up to 10 milligrams of fuel in each cycle. And the fuel mixture is prepared and supplied in the carburetor.

Thus, the purpose of the carburetor is to mix the combustible mixture with air in the required proportions. If these proportions are violated, the operation of the engine is disrupted. For example, when mixing little fuel comes in, but on the contrary a lot of air, then such a mixture is called “lean”. Conversely, if there is not enough air, but on the contrary there is a lot of fuel, then this is a supersaturated mixture. Both cases lead to malfunctions in the normal operation of the engine and require adjustment.

The carburetor consists of the following basic elements, and although the design may differ depending on the model, the design and principle of operation are approximately the same:

- the basis of the carburetor is a tube, which in its characteristics resembles a wind tunnel, an air flow enters through it; an air damper is located across the tube; by its position, it either increases the air flow or decreases it;

- the tube is constricted. a diffuser that increases the speed of the air flow just in the place where the fuel inlet is located;

- the fuel itself enters the air channel from the atomizer, into which it enters through the nozzle from the float chamber (indicated in the photo as a fuel needle);

- the float chamber itself serves as a kind of reservoir, the purpose of which is to ensure a constant fuel level at the entrance to the air channel.

The principle of operation of the carburetor is as follows. A fast air stream flows through the air channel, its speed will also depend on the position of the damper. The float level ensures the degree of opening of the fuel supply channel and depends on the position of the same air damper. The air flow passing through the diffuser picks up the incoming fuel and sprays it. At this moment, a mixture is formed, which is sucked through the intake pipe into the cylinder.

In the float chamber, the pressure level is approximately equal to atmospheric, but in the air channel it is rarefied. Due to the pressure difference, the fuel is sucked through the nozzle into the air duct. The more the air damper is open, the greater the air flow, and, accordingly, more fuel comes in. fuel. engine speed increases.

This is how the carburetor works. There may be nuances in its structure, but knowing how the simplest carburetor works, you can always understand and determine the purpose of other elements.

Chainsaw carburetor adjustment

Although quite rare, carburetor adjustments may still be required. Immediately, we note that not everything can be done independently, unless you have a tachometer and at least once personally see how to do it correctly.

To adjust the carburetor of the Makita chainsaw, like most other models, there are three adjusting screws. Although some manufacturers have carefully removed two of them, leaving only one for the user’s experiments. So, three screws, on the carburetor body, they are indicated by the following letters:

- L. this screw is used to adjust low engine speed;

- H. high speed adjustment;

- T. to adjust the idle speed (it is left for experiments).

In general, the carburetors have already been adjusted by the manufacturer for optimal operation, and the screws are designed for more precise carburetor adjustment of Champion chainsaws and others, in difficult climatic conditions such as high altitudes, etc. Since the air is thinner there, more precise tuning is required for the instrument to operate. Under normal conditions, this is not necessary.

To adjust the carburetor of the Goodluck chainsaw, as well as other brands, two screws L and H are used to create the appropriate quality of the fuel mixture. To create a lean mixture, the screws are turned clockwise, this allows you to increase the number of revolutions, i.e. thus, set high revs. Accordingly, when the screws are turned counterclockwise, the mixture turns out to be more saturated, this regulates the low number of engine revolutions. Thus, when adjusting the carburetor of the Partner chainsaw by turning the screws clockwise, we increase the number of revolutions, counterclockwise, we decrease.

With any adjustment of the carburetor of a Chinese chainsaw or other, a number of requirements must be observed:

- fine adjustment is always carried out with a warm engine (engine operation for at least 10 minutes);

- the condition of the air filter must be satisfactory, i.e. clean and not clogged;

- when rotating the chain with the adjusting screw T, it is necessary to achieve its complete stop, for this the screw is turned counterclockwise.

And do not forget about our own safety, the chain should be directed in the opposite direction to us, the saw should stand securely on a flat surface and not touch any objects with the cutting part. With fine adjustment, the screws are adjusted in the following sequence L. H. T. With the screw L it is necessary to “find” the maximum number of engine revolutions. To do this, turn the screw clockwise, or in the opposite direction, until we “grope” the maximum. This is where a tachometer is needed, or a sensitive ear for music, and you should know the sound of the engine speed limit, if you overdo it, especially with the H regulator, the engine will fail. Repair will cost a pretty penny, therefore we strongly recommend entrusting such work to a professional.

If you have a tachometer in stock and you know the maximum number of revolutions of your engine, then you can, at your own peril and risk, try to bring the adjustment to the end. It will look something like this: we find the closest value of the revolutions with the L regulator, then with the same regulators we return them counterclockwise by a quarter of the screw turn. We leave and go to the regulator H, and if you tighten it too much, the engine will fail.

We turn this regulator by ¼ turn of the screw counterclockwise (the engine is warmed up before this). We listen carefully or orient ourselves to the tachometer. If to sound. our ideal, when the engine at maximum works like a four-stroke engine. If the mixture is too rich, the sound is squealing. You can try to achieve an average value, not have an ideal, but remove the squealing sound with a screw. And if the work of the saw suits you, it is better to leave it as it is, it is better than to be left without an engine.

If it was possible to more or less adjust the screws L and H, then there is little left. to adjust the idle speed. The ideal here is to ensure that the engine runs evenly in all positions until the chain starts to move. Turn this screw counterclockwise until the chain stops. If this cannot be achieved, the help of a specialist is needed. An unadjusted chainsaw is a very dangerous thing.

A well-adjusted carburetor is:

- idling chain “stands”;

- the engine accelerates quickly;

- engine operation resembles a four-stroke engine.

Below is a video of adjusting the chainsaw carburetor

Do-it-yourself chainsaw carburetor adjustment

Chainsaw carburetor adjustment ensures efficient operation of the tool at full power while saving fuel. Adjustments must be made with a clean fuel and air filter. For a larger number of carburetors, the adjustment is carried out with three screws: for maximum and minimum revolutions and idle speed adjustment.

The H and L screws adjust the ratio of the mixture of gasoline and air, which is determined by opening the throttle valve of the carburetor. When the screws are unscrewed, the mixture is enriched, and the revolutions fall accordingly, when the screws are tightened, the mixture becomes leaner. the revolutions grow.

The designation H refers to the maximum speed screw that controls the main jet, L. to the minimum speed screw that controls the idle jet. The S screw is used to fine-tune the idle speed. Sometimes, to simplify tuning, the number of available carburetor adjusting screws is reduced.

Chainsaw carburetor tuning is divided into two stages. basic (factory settings), carried out with the engine off. and the final, produced on a running warm engine. The exact value of the angles of rotation should be taken from the operating instructions for the particular chainsaw. Failure to follow the manufacturer’s instructions may result in engine damage.

Chainsaw Carburetor | How to Tune & Adjust ‘Correctly’

Basic carburetor adjustment.

The adjusting screws for maximum H and minimum L turns are slowly turned clockwise until they stop, then turned back 2 turns, other settings are also possible

Checking and adjusting idle speed.

We find the highest idle speed, for this we slowly turn the screw L in different directions. After finding the position of the highest engine speed, turn the screw L 1/4 turn counterclockwise. If the chain rotates at idle speed, screw T or (S) should be turned clockwise until it stops.

Checking and adjusting the maximum speed.

The maximum number of revolutions is changed by screw H. When screwing it in (clockwise rotation), the revolutions increase when it is turned out. decrease. Chainsaw engines have the highest rotation speed of 11500 rpm. up to 15,000 rpm. A higher speed does not provide ignition, moreover, it becomes dangerous for the engine. The rpm limit can be determined from the ignition interruptions. If they come, turn the screw H slightly counterclockwise.

If the engine is not checked for acceleration and maximum speed, then the adjustment of the chainsaw cannot be considered complete.

When the throttle trigger is smoothly pressed, the engine should confidently and quickly gain speed from idle to maximum (from 2800 rev. To 11500-15000 rev. Depending on the unit). If revolutions are gained slowly, with a lag, screw L must be slowly unscrewed counterclockwise, but no more than 1/8 of a turn.

After adjusting the acceleration and maximum speed, the saw should be checked again at idle speed. the engine must run steadily and the chain must not move. Chainsaw tuning should be repeated if this condition is not met but with the exception of the basic adjustment step.

DIY chainsaw repair and maintenance

Chainsaw are falling and this makes them more popular and affordable not only for professionals, but also for simple, so to speak, amateurs. However, it is a common addiction. the lower the price, the less reliable the device and more often malfunctions appear, for a chainsaw is also relevant. But for a chainsaw of any price range, most malfunctions can be avoided with proper operation, care and timely maintenance of equipment. But from the breakdown of the chainsaw, as well as any other equipment, no one is insured. Therefore, it is proposed to consider the main types of chainsaw malfunctions, methods of diagnosing, eliminating and repairing.

All the main malfunctions of chainsaws can be roughly divided into two main categories:

– malfunctions of the engine and its various components: fuel preparation and supply system, ignition, piston group with crankshaft, exhaust system;

– malfunctions and breakdowns of other components: lubrication system, clutch, chain brake, tire and others.

Idle speed adjustment

Before this stage of adjustment, it is necessary to warm up the engine for 5-10 minutes, avoiding high rpm.

Turn the idle speed adjustment screw (T / LA / S) counterclockwise until the engine runs to the minimum rpm. Make sure the chain does not move. That is, if the engine stops idling, turn the idle adjustment screw clockwise. If the chain is in motion, remove the screw counterclockwise.

To complete the adjustment of the chainsaw carburetor, it is necessary to check the engine for acceleration and maximum rpm.

Chainsaw engine malfunctions

Here are the various disturbances in the operation of the chainsaw engine that occur most often. The main such malfunctions are reduced to the following symptoms:

the engine does not start (it is quite general and the reasons can be quite different);

starts up, but often stalls;

does not develop power, i.e. works normally at idle, but stalls or “bugs” under load.

Smokes very much, power drops.

Rechecking at idle speed

After you have adjusted the acceleration and maximum engine speed, be sure to re-check the operation of the chainsaw at idle. With a properly adjusted carburetor, the following conditions must be met:

- at idle speed, the chain should not move;

- the engine should pick up speed quickly;

- engine operation should resemble a four-stroke engine.

If the operation of the chainsaw does not meet at least one of these conditions, the adjustment procedure (with the exception of the basic stage) will have to be repeated again.

Acceleration check

To check the engine for acceleration, gently press the accelerator and make sure that the engine quickly picks up speed from idle to maximum (from 2800 to 11500-15000 rpm. depending on the brand and model of the saw). If the engine picks up speed slowly, slowly unscrew the screw L counterclockwise (no more than 1/8 of a turn).

Adjusting the maximum speed

The maximum number of revolutions is adjusted with screw H. The revolutions increase when it is turned clockwise, and decreases when it is turned counterclockwise.

The highest rotational speed of chainsaw engines varies from 11,500 to 15,000 rpm. Higher speeds can be hazardous to the engine and simply cannot be ignited. Therefore, the maximum rpm can be determined by the occurrence of misfiring. If they appear, slightly unscrew the screw H counterclockwise.

Problems with starting the engine

It is very important to correctly determine the cause of the malfunction, because otherwise we simply cannot eliminate it. If, when trying to start the chainsaw, there are no extraneous sounds (knocking, grinding, etc.), then very often it turns out that there is actually no breakdown. For example, if it is not correct to start the chainsaw and pull on the suction for a long time, then the engine simply floods and it is very difficult to start it.

In order to properly start a cold chainsaw engine, set the lever or switch to the “throttle closed” position. Then you need to pump the mixture into the carburetor, if a fuel pump is available. Pull out the starter grip until the engine resistance is felt, and pull vigorously in amplitude while moving the hand to the side. After two. three such movements, the engine must first start and then stall. If this does not happen, then it is necessary to move the lever to the half-throttle position or simply to the working position and continue to start the chainsaw in this mode. In many chainsaws, the “half-throttle” is fixed automatically when the air damper is pulled. Some models have an ignition rocker switch, it is important to make sure it is on.

If the engine won’t start, the first thing to do is to unscrew and inspect the spark plug. There are cases, at the plant in the cold season, the combustion chamber is poured with fuel. Then you also need to unscrew the candle, dry the combustion chamber with an idle plant, clean the candle, screw in and start again. It is advisable to immediately check for a spark. put on the twisted candle on a cap with a high-voltage wire, put it on the cylinder and pull the starter. Visually, we observe a frequent blue spark. well. We screw the candle into place and start. If there is no spark, change the candle and try again. Again, no. we check the connection of the high-voltage wire to the candle, the coil and the ignition system.

In general, the condition of the candle can be judged on the type of malfunction.

- Dry. Most likely, the fuel mixture does not enter the cylinder. It’s not about the ignition system, so the plug is screwed back in and the fuel supply system is checked.

- Wet, heavily splashed with fuel. The reason for the excess fuel mixture lies either in the violation of the starting rules, as described above, or in the incorrect adjustment of the carburetor.

- Covered with black carbon. This may indicate the use of low-quality oil, an incorrectly adjusted carburetor, or an incorrectly calculated gasoline to oil ratio. The candle should be washed, cleaned of carbon deposits with a sharp object (awl or needle), wipe the electrodes with a sandpaper and put in place.

When checking the candle, you need to pay attention to the gap between the electrodes: from 0.5 to 0.65 mm is considered normal. A damaged or worn gasket must be replaced.