DIY Cultivator Plow

How to make a plow for a mini tractor with your own hands, comparing the price of a homemade and factory one

Any craftsman can assemble a plow for a mini tractor with his own hands.

With the acquisition of land ownership, many peasants organized personal subsidiary plots, some became farmers and formed large tracts of land. The experience gained in working for the state now began to work for the rural workers themselves. Large equipment on small land plots became unnecessary, and mini tractors became fashionable. Accordingly, the equipment for such a technique is also specific, and it is often cheaper to make the necessary device yourself. The main agricultural equipment for cultivating the land is the plow. Buying a ready-made tool is not always available, and everyone can try to assemble a plow for a mini-tractor with their own hands.

Which design to choose?

Do-it-yourself plow moldboard plow.

The designs of the plow are varied and depend on the types of cultivated soils and the types of work performed. The following modifications are distinguished:

- Plowshares-moldboard. have a working tool in the form of wedges, with the help of which the soil layer is cut, shifted and painted. Used on mini tractors and tillers in small farms.

- Disc. used on hard and heavy soils for preliminary plowing. Freely rotating knives in the form of metal discs cut the top layer, and the dump elements located further away turn the layer.

- Rotary. a modern model of a plow, where several working knives are mounted on a movable shaft. This design provides high performance, but is difficult to do it yourself.

The most common option is a homemade two-body plow with working tools in the form of plowshares and dumps. This model has been tested by time and the experience of numerous farmers. Such designs are often complemented by skimmers that cut the top soddy soil layer.

Drawbar making and wheel fastening

Connecting the main plow units.

The frame is attached to the mini tractor using a standard pin hitch or a homemade drawbar. The former can be taken from old worn out equipment and welded to the front of the supporting structure, the latter are made by hand in the form of a drawbar with a handle (examples can be viewed on various videos on the Internet). Distinguish between a straight and V-shaped drawbar, with the latter being more preferable. It dampens lateral vibrations of the plow and provides straight-line movement.

One of their additional and control parts of the homemade earth tool is the field wheel. It serves to ensure ease of movement and prevent the working tool from sinking into the soil. These tasks can be performed by one wheel, but on advanced designs these functions are divided into two elements. The field wheel is attached to the frame on an adjustable bracket to provide the required plow settings.

Description of assembly work

Drawing of a simple plow for a mini tractor and a tiller.

The main bearing element of the equipment under consideration is the frame on which the rest of the components are attached. It is made of a round or rectangular metal profile with a thickness of 2-3 mm. The working bodies and auxiliary elements of the plow are attached to the frame part. The shape of the frame corresponds to the number of working tools of the plow and the selected control elements.

The advantages of self-manufacturing and assembly

Plows collected by craftsmen from the remains of iron.

The main advantage of a self-produced plow is its low cost. You can make tooling from materials you already have or use parts from old farm equipment. After the dissolution of state-owned enterprises, a lot of unnecessary equipment remained, which can be inexpensively converted to fit your needs.

The next advantage will be the practical compliance of the produced plow with your requirements for the processing of a particular type of soil and the necessary procedures for the cultivation of certain crops. You can make different working tools for different cultivated areas.

The use of materials known for their quality guarantees the successful use of hand-made devices. Shop counterparts often do not justify the specified technical characteristics and require revision and strengthening of the main elements. Spare parts and various metal structures accumulated on the farm will save you substantial finances when making a plow yourself.

It is more convenient to adapt self-made equipment to the existing agricultural equipment. The design of the plow is calculated for a specific mini-tractor in terms of power and productivity. It is also possible to complement the equipment with various tools for combined processing of a land plot.

Plow tine attachment

The tine is made with adjustment holes for setting the required plowing depth. It is made of a metal plate with a thickness of 8-12 mm to give sufficient rigidity to resist high loads during operation. The stand is bolted to the frame, the angle of inclination of the body should ensure the normal entry of the cutting edge of the share into the soil.

Blade assembly

The dump is made of a sheet of metal 3-4 mm thick with subsequent bending by gas welding or on a roller machine. It is easier to make a homemade blade from a pipe with a diameter of 500-600 mm. First, a template drawing is made, then it is superimposed on the workpiece, cut off with a gas cutter and processed on emery. The blade is rigidly mounted to the plow post by welding.

Adjustment of equipment for a mini tractor is carried out on a flat, hard surface. The field wheel is mounted on a support that is adjusted to the plowing depth. The ploughshare is lowered to the stop with the support plane, and the heel must be parallel to the ground. The stand is fixed in the selected position and the rig is ready for use. To check the correct plow setting, you need to do a test plowing.

details on the plow assembly are shown in

Plow design

There are several types of plows installed on the Neva tiller, and each of them has its own design features. Currently, single-hull, rotary and revolving structures are used to cultivate the land on personal plots.

The single-body plow is the most popular design and a large number of drawings of this particular variety can be found on the net. In addition, it is considered the most optimal option for those who do not have the appropriate skills.

The most difficult to manufacture is the rotary plow design. It looks more like a cultivator, since not one, but several plowshares are provided, fixed on one axis. In the process of cultivating the land, the axis is scrolled, due to which the overturning of the soil layer occurs. The advantage of the design is that the soil can be worked up to a depth of 30 cm with little effort. In addition, the rotary plow allows you to plow the area along different trajectories.

Video of this plow

Plow drawing

Currently, making a plow for a tiller with your own hands is not a problem, especially since now you can find drawings of a wide variety of designs. Very often they are accompanied by detailed instructions for creating and assembling a plow.

- pipe handle. 2 pcs.;

- frame;

- fixing the rack with an M10 screw;

- plow;

- fastening fork of the hinge to the frame;

- drawbar;

- wheel;

- nylon bushing for bearing;

- jumper between the handles;

- hinge axle made of M10 bolt;

- lock-nut;

- axis;

- distance washer;

- drawbar handle;

- tee.

The main thing to be guided by when creating such a structure is to adhere to all instructions exactly and observe all the parameters of the selected drawings. Even an insignificant inaccuracy, which at first glance may seem insignificant, can greatly affect the performance of the plow or subsequently negatively affect the operating parameters during operation.

Benefits

Creating a plow for a tiller yourself has certain advantages. The parameters of the share and blade will meet all the requirements for processing a particular type of soil. These parameters include:

- blade angle;

- quality and depth of plowing of the land;

- capture area;

- efficiency.

Considering the power of the tiller, it is possible to make a plow that will not cause excessive loads on the engine and slip, but at the same time will have maximum grip. It is necessary to use only high-quality materials, which will make it possible to significantly increase the life of the plow. It is also possible to provide for the attachment of various attachments, which will significantly expand the functionality, which will make a full range of land cultivation possible.

Manufacturing and fastening of plow working elements

The main elements of the single-body design are the blade and the share, for the creation of which durable sheet steel 3-5 mm thick is required. First of all, a ploughshare is made, for which it is worth using an old disc from “circular”, since it is made of high-strength steel. To sharpen the cutting edge of the share, it must be beaten off on the anvil.

Next, you need to make a dump from a metal pipe with a diameter of 50-60 cm and a wall thickness of about 5 mm. A template is created from cardboard or thick paper, which is applied to the metal and traced around the entire contour with chalk. Then, according to the lines obtained, a workpiece is cut out by gas welding, which is brought to the required size using an “angle grinder” or a hammer and emery.

How to make a plow for a tiller with your own hands? just use our drawings and photos

Plow shank attachment

To fix the plow stand, holes 31×16 mm are drilled or cut out on both sides in the wide part of the pipe that was used to create the frame. Through holes of 10.2 mm are also made in the narrow walls of the frame for fastening, using M10 bolts, a handle.

The plow arms must be made separately from a pipe, about half an inch in diameter. You can use an old water pipe, which needs to be flattened with a sledgehammer on both sides. Drill holes with a diameter of 10.2 mm in the planes obtained and fasten them to the frame with bolts. To give greater rigidity between the handles, weld the cross member.

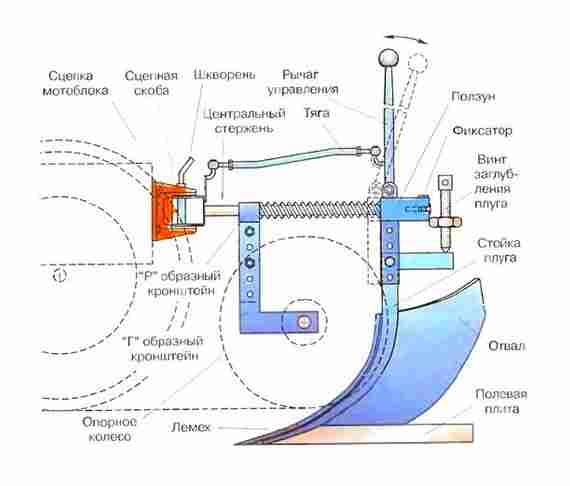

Plow coupling

Tiller hitch parsing

The hitch is an important structural element that ensures reliable attachment of the attachments with the Neva tiller. The most popular option is the U-shaped mount from the channel, and which is installed under the wheel of the tiller.

When creating the hitch, you will need to drill the holes to attach the bracket and mounting pin. The bracket for attaching to the tiller is either at the top or at the bottom, so as not to interfere with hanging.

2.1 Single hull

First of all, you need to remember that a homemade design must be collapsible. Before each plowing, you can remove the disc or share and sharpen it. Secondly, it is best to take your disc to your own tiller unit from a circular circular (alloy steel saws).

You will need rollers and steel up to 4mm thick to make the blades. We cut out the shape by welding or with ordinary scissors, and simply bend it in the shape of a cylinder on the rollers. There is an option when the dumps can be made from a piece of pipe or cylinder, with a diameter of 500 to 600 mm, with a thickness of no more than 5 mm.

To do this, the shape must be cut out by welding, rubbed with emery, and if necessary, as in that long-forgotten anecdote, carefully brought to mind with a hammer. Then you will need to make other parts of the future unit.

Thus, according to the drawings, you need to make 6 parts:

- steel share or disc;

- spacer plate;

- side shield for the rack;

- a plate for the base of the plow itself;

- field board with an angle of 30X30 millimeters;

- pipe for rack 42 mm in diameter.

Homemade plows on a tiller

Then, using wedges, we install the finished share (on the auxiliary sheet), fasten it with two-point welding, and join the stand with the side shield so that the shield is 7-9 mm higher than the share, and the edges of the shield go over the edge of the blade by 6-7 mm. All parts are welded together again.

Then you need to weld the blade so that it becomes a single whole surface with the share. If the angle between the blade and the ploughshare is more than 7 degrees, they need to be finished with a hammer. So, the blade is welded to the share, the share to the side shield. Now we attach the side shield first to the base plate and then to the spacer bar.

The share corners are welded to the base plate last. Then we separate the auxiliary sheet, clean up the welding traces, and grind the share with the blade with sandpaper.

to the menu

2 Preparation of parts and assembly of a homemade plow to the tiller

This model has many modifications, drawings and adherents. The tiller plow for dummies usually describes the design of a single-body plow. No special tools or skills are required to make it. Even a beginner in mechanical engineering can handle this model.

Tiller-mounted single-body reversible plow

2.5 Testing a homemade tiller plow

2.2 Double-hull

A two-body tiller plow is needed for working large areas. In addition, made by hand, it can perform several functions at once. plowing and harrowing the ground. Linking several frames with different tools allows you to create various modifications of models according to ready-made drawings.

to the menu

How to make a plow for a tiller with your own hands?

The plow is an agricultural tool for plowing the land with a metal share. The evolution of the movement of this installation has gone from traction force in the form of a man, a bull and a horse to a tractor. The main purpose of this implement is to flip and loosen the top layers of the soil to facilitate the seeding process. In addition, the ploughshare easily cuts weeds by plowing them into the ground.

a tiller with a plow can perform several functions at once: plow, mow, huddle. At the same time, more and more questions arise about which unit is better. Install a plow of industrial assembly or try to assemble a plow for a tiller with your own hands.

2.3 Rotary

A rotary or rotary plow for a tiller is a separate topic altogether. The newest and most unexpected version of the unit that can be attached to the tiller. The swivel mechanism of the rotary device allows easy operation on difficult soil, overgrown with roots.

Rotary plow device

The design of several plowshares attached to one axis allows you to process even hard-to-reach areas of vegetable gardens to a depth of 30 cm.At the same time, the question of how to plow correctly with a rotary device is not worth it at all. it is easier to use than a conventional unit.

to the menu

1 Varieties of plow

Traditionally, depending on the specifics, the models of these devices can be divided according to the following principles:

Installed type of working bodies:

- disc plow;

- ploughshare;

- rotary;

- moldboardless;

- combined.

There are three types of plowshares: cylindrical, semi-cylindrical and screw. For a homemade option, it is better to choose a cylindrical shape. Moldless machines are widely used on dry, erosion-prone soils.

Reversible tiller plow

By the type of traction force used, the units are divided into:

- equestrian;

- cable cars;

- tractor.

Tractor, in turn, are:

- hinged;

- trailed;

- semitrailer structures.

By the number of working bodies, devices can be:

- monohull;

- double-hull;

- multihull.

In addition, plows can be designed for flat or furrow plowing for general or special purposes. And according to the operations available when working with a seam of the earth and variations in the attachment of the plow to the tiller, they are divided into reversible and conventional.

to the menu

From a horse plow

This configuration of the plow, coupled with a mini-tractor, is considered the easiest to manufacture. All work on the reconstruction of an equestrian plow is reduced to adapting a frame to it, which has a special fastening mechanism, equipping it with a wheel (if necessary) and a weighting agent.

The equestrian plow consists of a body and a double-sided frame, which serves as a mechanism for attaching to the animal’s harness and as a means of controlling the plowing process. Its simplest configuration is shown in photo 4.

In this case, it is necessary to reconstruct the fastening part of the horse plow into the one that will be installed on the mini-tractor with the least effort. This process can be simplified by making a towbar for a tractor attachment. His copy is shown in photo 5.

The towing hitch is easy to manufacture. The wide plate, which has two horizontal holes with an internal thread at the edges, is complemented by a protrusion in the middle, into which a forefoot ball with a leg is screwed / welded. In the center of the plate, an L-shaped part is attached, which serves as a locking mechanism for the plow frame, put on a hitch. The plate is placed between the two “ears” of the tractor attachment, fixed with four bolts.

The modification of the horse plow shown in photo 4 is equipped with a special wheel. It serves as a stop for the frame of the structure, with its help you can adjust the depth of entry of the plow into the soil.

The adjustment is carried out using a simple mechanism. a threaded bracket into which a clamping bolt is screwed. The wheel stand can move vertically inside the shackle. The bolt fixes it in the desired position. This design allows, if necessary, to move the bracket along the plow frame.

Mantis Tillers Attaching the Plow

The wheel itself is made of a metal rim, spokes and an axle drum. For its manufacture, you can use a metal tape 300×50 mm, reinforcing bars, a piece of pipe with a diameter equal to the diameter of the wheel axis.

The metal belt is bent in the form of a hoop, its edges are welded together, the weld seam is ground with a grinding or cut-off wheel with an angle grinder. A piece of pipe equal to the width of the tape fits into the center of the circle. The distance from the rim to the outer surface of the pipe. drum is measured. The reinforcement spokes will be equal to this distance. The resulting blanks are welded together. To improve the rolling characteristics of the wheel, a bearing of the appropriate diameter can be welded into the drum. This will reduce friction and reduce the load on the wheel axle.

The described plow design can be operated in two ways. In the first case, you will need a second person who will operate the plow from behind, adjusting the line of the furrow. In this case, the “manager” exerts pressure on the frame, which is necessary for a sufficient immersion of the share in the ground.

In the second case, the presence of an assistant is optional. The plow becomes heavier and moves by itself. The weight can be a piece of heavy metal or a stone enclosed in a frame. The weight is placed on the edge away from the tractor. In this case, the pressure on the share will be maximum for the available weight. To prevent the load from overturning the plow, it should be secured from the underside of the frame.

When operating the plow without a second person, it is worth considering the furrow curvature factor. The simplicity of the described design assumes that the plow floats from side to side. To eliminate this problem, it is necessary to equip its “rigid” coupling with the tractor. In this case, the traction mechanism will steer the furrow strip.

How to make a plow for a mini-tractor with your own hands?

- General characteristics

- Features of a homemade model

- Materials and tools

- How to make?

- From a horse plow

- From skimmers

- Safety engineering

The plow is a tool designed for plowing hard soil and has been used by humans since ancient times. The intended use of the plow determines its technical and quality characteristics: the design of the frame and cutting element, fastening mechanisms and stops, material of manufacture and its thickness.

General characteristics

The plow for its purpose is of several types:

- manual. for plowing soft land of a small area;

- equestrian. used in situations when you need to cultivate land, access to which is limited for special equipment;

- with cable traction. helps to work the soil in hard-to-reach places, for example, in the mountains or in a swamp;

- mounted. works in conjunction with special equipment, allows you to reduce the turning radius during sequential plowing;

- trailed. general purpose plow.

The mentioned types of plows, in turn, are subdivided into the following subspecies:

- single-hull;

- double-hull and more;

- disk. revolving;

- rotary.

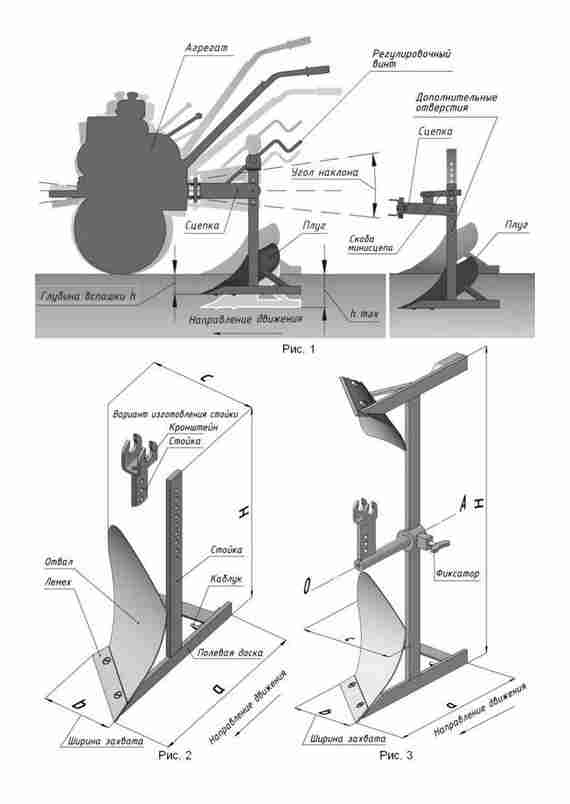

A common configuration for a DIY plowing tool is shown in Figure 1.

The main parts of the body structure have the following details:

- chisel. overlay on the cutting part;

- ploughshare. removable “knife”;

- wing, chest and blade feather;

- shallow. cuts corners from soil layers;

- post. fastener.

Modern technologies allow you to make a plow yourself. You can design it according to your drawings or modify the finished one to suit your needs. A self-made labor tool has a number of advantages and characteristic design features.

From skimmers

Skimmer is an element of a tractor plow that serves to cut the top layer of the soil in the process of plowing. Photo 6.

Its shape is similar to the working body of a plow share, and its size is half the size. This fact allows you to effectively use the skimmer as a plow for a mini-tractor.

During the design process, you will need to weld a frame that will hold the skimmer and attach to the tractor hitch, as well as equip it with a stop wheel.

When creating drawings of this design, it is worth considering the power of the tractor, the condition of the cultivated soil, the amount of future work. If a large area of land is to be plowed, two skimmers can be used on one frame. In this case, the plow will turn out to be two-body. This is necessary in order to reduce the load on one share housing and reduce its wear.

The process of assembling a structure, its installation on a tractor is similar to the reconstruction of an equestrian plow. A frame of a similar configuration, a wheel, attachments for the plowshare stand and the entire structure to the towbar are made. Mounts a weighting agent or control knobs for manual furrow correction.

Materials and tools

Making a homemade plow for a mini-tractor requires a basic tool:

- welding inverter;

- Angle Grinder;

- drills;

- vice.

And an additional tool, the list of which is determined by the design of a specific mechanism and the conditions of its production.

The materials that make up the main structure should be solid steel blanks. Violations of their integrity. cracks, deformation, severe rust. are unacceptable.

List of materials that you may need:

- high-strength thick-section sheet metal;

- metal corners and plates of sufficient thickness;

- bolts of various calibers;

- additional names (washers, bearings, springs), determined by the characteristics of a particular design.

How to make?

In order to facilitate the process of assembling a plow for a mini-tractor, you can go by the reconstruction of another tool of the same name used in conjunction with draft objects: a horse plow or a skimmer from the plowing mechanism of a large tractor.

Assembling the required unit requires drawing up the correct drawings. Their presence will ensure design optimization, a decrease in the number of component parts, simplicity and quality of assembly.

The drawings should indicate the dimensions of the elements that are closely related to the dimensions of the mini-tractor, the properties of the cultivated soil. During the manufacturing process, it is important to adhere to these parameters.

At the design stage, it is worth drawing separately each part that has an irregular shape, in compliance with the actual size. In the future, from such drawings, it will be possible to create a template for transferring the image of a part to a metal workpiece. Some variations of the plow drawing are shown in Figure 2 and 3.

Consider two options for making a plow for a mini-tractor.

Features of a homemade model

A self-assembled plow is a tool that meets target needs and has a low cost. For its assembly, you can use the materials available, as well as parts of the structures of other agricultural units. The latter can be taken from old agricultural workshops, ferrous metal collection points, and other similar places.

A homemade plow is easy to orientate to fit your needs. It is possible to adapt it for different types of soil, draft mechanisms and even for the functions of processing crops. Your own plow can be made taking into account the power and productivity of tractor equipment, which will allow you to achieve the highest efficiency and reduce destructive loads on the plowing tool.

The cutting element of this plow can be interchangeable and made / sharpened independently, which significantly reduces the cost of maintenance of the mechanism. When self-manufacturing, it becomes possible to vary the intended use. the introduction of the function of replaceable elements: nozzles, mounts, parts of the body and frame. This allows you to perform work of a combined nature, for example, plowing and mowing shrubs.

Safety engineering

During the operation of a homemade plow, appropriate safety measures must be observed. Among them, the most important points can be highlighted.

- at the moment of movement of the plow along the furrow, its height adjustment, cleaning the wheel and ploughshare from the ground and other manipulations associated with the participation of a person are unacceptable;

- all connection nodes must be securely fastened. backlash is unacceptable;

- it is necessary to carry out timely cleaning of mechanisms and sharpening of cutting elements;

- perform all actions only with an immobilized plow with the tractor turned off.

To ensure labor safety, it is important to perform work that meets the technical characteristics of a particular agricultural machinery. Excessive loads can lead to rapid wear, damage to the unit and harm to human health.

How to make a plow on a mini-tractor with your own hands, see the next video.

How to make a plow with your own hands for a tiller and a tractor

Anyone can make a plow with their own hands, you just need to prepare the details and adhere to the algorithm. Having mastered the production technology, you will be able to open a profitable business! Our 3D models will help you with this, as well as detailed information on each stage of production. Everything is even easier than you think!

How to make a plow for a tiller and a tractor with your own hands

First, consider a plow for a tiller or mini tractor, which you can do with your own hands according to the drawings. For a visual analysis of the device, we recommend downloading the drawings of the PN-2-20 double-body plow free of charge.

This plow is aggregated with agricultural machinery of drag class 0.2. These can be heavy tillers or mini tractors:

- Belarus-082;

- Belarus-112;

- Belarus-132N;

- Belarus-08K;

- KMZ-012, T-0.2 (Uralets);

- HTZ-8 (Prykarpatets).

Brief technical characteristics of the PN-2-20 plow:

- capture width. 0.4m;

- tillage depth. up to 25cm;

- productivity. up to 0.05 hectares / hour;

- weight of the structure. 67kg.

The cultivation of a large plot of land is a labor-intensive and energy-consuming process, which cannot be done without the use of technical devices. Thanks to the plow, the soil can be properly prepared for sowing, and also processed to get rid of weeds and dead wood after harvest.

The plow is attached to mechanized equipment, which, by means of a high draft force, sets the unit in motion. In the process of working with the plow, the top layer of the soil is pushed off by the plowshare, and then simply turns over. This allows not only to loosen the soil, but also to improve its aeration. over, tillage with a plow eliminates up to 90% of the weeds growing on the site.!

How to make this useful unit, which is necessary in every household? First you need to take care of purchasing the necessary high quality materials. For the plow blades, you will need steel with a thickness of about 5 millimeters. The ploughshare itself should be made removable so that it can be periodically taken out and sharpened. For the body, use hardened steel, which will not hurt to treat with anti-corrosion solutions before welding.

To make a special functional plow blade, be sure to adhere to the following guidelines:

- Cut a cylindrical blade out of a sheet of metal.

- With the help of a listogib, the cut out parts are bent by 22-23 degrees, while the latter are strictly adjusted to the required shape and size.

- Note that the size of the hollow metal pipe for the blade is about 55-59 centimeters in length. Wall thickness should not exceed 5 millimeters.

- The blade blank itself must be preheated in order to then perform matrix bending.

Directly the body for the circle can be made of a metal sheet with a thickness of at least 3-4 millimeters. A square with sides of 50 by 50 centimeters is cut out of it, to which a ploughshare, side shields and a blade must be attached sequentially. At the same time, make sure that the required angles between the plow components are strictly observed. The presence of gaps or inaccuracies during installation can adversely affect the durability of the unit. Having welded all the parts together, you need to clean up the seams, and it is advisable to sand the ploughshare with a blade to avoid the appearance of rust.

When you master all the intricacies of making a plow for tillers and mini tractors, you can move on to more complex tasks.

5-case reversible plow on T-150 (PLP-5-35):

This is a 3D model of a 5-body reversible trailed plow PLP-5-35 for a T-150 tractor or other tractors with a pulling class of 3 and higher. Using this 3D model of a plow for production, you do not need any drawings. The structure is disassembled into more than 100 parts to the smallest detail. The project is created in 3D-format CAD STEP files. This format is supported by many CAD editors, including free FreeCAD.

Note. Working with the STEP format in FreeCAD is not very convenient. The program requires a lot of computer resources to load all the details of the device. Just opening a file on an average laptop takes about 10 minutes. If possible, use a paid professional AutoCAD program.

Is it possible to dig potatoes with a plow

Many experienced farmers use the plow in the process of harvesting potatoes. So they greatly simplify their lives, getting rid of the need to dig out hundreds, or even thousands of potato tubers. The only question arises, what plow to dig potatoes with?

Having made a reversible plow with your own hands, you will make your life easier for many years during gardening and field work. And having mastered the business of manufacturing and selling this unit, you will certainly gain a stable income. It’s time to start your own business!

How to adjust the plow correctly

Due to the fact that you make a plow with your own hands, it becomes possible to adjust the dimensions of the share and blade to all the parameters you need. You can easily adjust the width or depth of the plow depending on what work you need to do in the field, in the garden and in the garden. Also, you can adjust the parameters of the plow, taking into account how much power your tractor (or tiller) has. This will allow using the assembled unit with maximum utility, avoiding overheating or damage to traction equipment.

Plow setting steps:

- We tighten the nuts on the mountings, but do not overtighten.

- We fix the plow with fastening using two metal pins.

- We carry out balancing, setting the desired angle of inclination.

- We check the quality of the plow in the field, and, if necessary, adjust the initially set parameters.

Remember that meticulous and precise tuning will allow you to complete all the necessary scope of work much faster and more efficiently with less fuel!

Making plows at home as a business

A reversible 2- or 5-furrow plow can be easily constructed with your own hands if you have all the details of the device. At the same time, financial investments will be quite affordable. Having mastered the process of manufacturing products, you should start implementing a business idea for the sale of self-made plows. This business is quite lucrative. According to experts, the profitability of such a business is about 70%. Therefore, by choosing this direction, you can secure yourself a profitable home business.!

Mover

The cultivator moves around the site due to the rotation of circular cutters. This method is not suitable for towing a plow. The cutters are replaced with metal wheels with grousers. To increase the grip of the wheels with the ground, additional weights can be placed inside the wheels.

How to make a plow?

Manufactured unit parameters:

- trailed type;

- plowing depth. 0.25 m;

- strip width 0.25 m;

- travel speed. up to 4 km / h;

- productivity. up to 0.06 hectares per hour.

General device diagram

The ploughshare is made of removable steel 9XC 3 mm thick. The fixing bolts are installed in a “countersunk” position. The blade blank is cut from steel 3 with a thickness of 3 mm. The part is fed onto the rolls of the bending machine at an angle of 20 °.

Plowshare and blade sketches

The stand, heel and other elements are made of steel strip and corner profile. Dimensions are specified as a trial assembly, the angles of joining of elements are shown in the sketch:

After the complete adjustment of the component parts of the product, the seams are finally connected by electric welding, cleaned and polished “angle grinder”.

Figure 3 shows the option of installing a second plow on the column, which allows you to exclude idle runs of the unit to the beginning of the strip when plowing in parallel rows.

Selection and installation of a plow on a cultivator

The motor-cultivator belongs to the category of garden machines that mechanize work on soil cultivation. The main executive oran of the product is a set of rotating cutters that loosen the soil layer and move the cultivator around the site.

DIY plow for a cultivator

A home craftsman, possessing the skills of working with metal-cutting and welding equipment, can independently make a plow and its suspension parts using used metal products.

Cultivator transmission

It does not require special alterations, but the unit was originally designed to work with a cutter. The feed rate may be excessive for the plow, and the wheels may spin (slip). Useful in this case is the installation of a creeper. a pulley of a larger diameter on the engine crankshaft.

What to consider?

For the correct selection of materials, the manufacture of the plow itself, the elements of its attachment to the cultivator, it is necessary to understand the principles of operation of the devices, to know their basic parameters.

When applied to a land mass, it overturns the upper layer of soil. Plowing removes weeds from the soil and damages their root system. The soil is loosened, making the sowing of crops efficient and increasing germination.

Hinge elements

The hitch is used to connect the cultivator platform with the plow, hiller, potato digger. Products are unified for different models of one manufacturer.

To increase the stability of the machine, taking into account the characteristics of the land, sometimes an increase in the lug track is required, which is solved by installing axle extensions.