DIY motoblock hooks

Stage # 2. production of main parts

When making and assembling the frame, it is important to provide for the arrangement of a fork with a sleeve. It is necessary to ensure free rotation of the trailer.

The frame of the structure is made of metal pipes and corners

The body of the structure is made of steel sheet. The height of its sides is made no less than 30 cm.

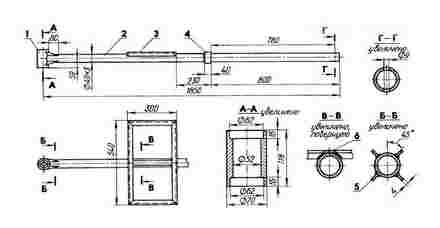

When making stands for the adapter wheels, you can use the diagram below

The simplest option for manufacturing a coupling assembly is a 15 cm long pin, which is stuck into the hole in the drawbar of the U-shaped motoblock “tow bar”. The disadvantage of this option is quick wear: under the action of a freely rotating trailer, the hitch holes are quickly broken. To reduce wear, it is advisable to lengthen the U-shaped chain.

What adapter designs exist?

With the help of this attachment, you can greatly simplify the use of the walk-behind tractor. After all, it acts as a transitional link connecting the unit itself with other functional elements: nozzles for planting and hilling potatoes, flat cutters, a plow. By installing the equipment, you can automate gardening work as much as possible. For example, when using special equipment with attachments, you can increase the working speed from 5 to 10 km / h.

There are several types of adapters. In general, the structure is a trolley attached to the back of the walk-behind tractor, equipped with a comfortable seat

Some models are equipped with a lifting lever, which greatly simplifies the control of the mechanism and the movement of the unit itself on the site. Other adapters, in addition to agricultural work, can also be used for transporting goods. They are equipped with a special body. The adapters can have short or long drawbars, depending on their function. Models with short drawbars are designed to work with light walk-behind tractors, and with long ones. with heavier units.

There are also models with a telescopic drawbar on sale, as well as those in which you can adjust the track width.

The adapters are fixed to the walk-behind tractor using a single enlarged hitch, which consists of two parts: the first part is needed to connect the equipment to the unit. And the second acts as an adjustable adapter between the equipment itself and its lifting mechanism. To increase the number of implements used simultaneously, the adapters are equipped with a double universal hitch.

Arrangement of a multifunctional model

For the manufacture of a multifunctional device, you must prepare:

- Steel pipes and corners;

- Sheet steel;

- Two wheels;

- Comfortable sitting;

- Welding machine and tool kit.

This adapter is a multifunctional model. It can be used for basic agricultural work and for transporting goods over uneven terrain over short distances. The structure can be equipped with such agricultural implements as a plow, harrow, tiller, potato digger. Snow scraper can be attached to adapter during winter months.

The main elements of the equipment are: the frame and hitch devices, as well as the wheelset and seats

The manufacturing process of the adapter at home takes place in several stages.

Stage # 1. drawing up a kinematic diagram

To ensure the balance of the structure and prevent additional overloads at the design stage, it is necessary to draw up a kinematic diagram. You can make it yourself or use a ready-made version.

This circuit is designed for the manufacture of an adapter designed to work on the “Neva” walk-behind tractor

Adapter for walk-behind tractor: how to build a good do-it-yourself cart with a seat?

Assembling a simple structure

A simple adapter model is a metal frame. It is made from a pipe with a rectangular cross-section 1.7 meters long. At one of the ends of the pipe, a 0.5 meter long pipe is welded perpendicularly, which will serve as the basis for attaching the racks for the adapter wheels. The height of the struts themselves from the wheel axis to the top point is 0.3 meters.

For the manufacture of the structure, you can use the wheels removed from the garden cart. They can be installed on bushings, which are quite simple to perform on a conventional lathe. Bearings of the appropriate size are put on the finished bushings

After that, the braces must be attached to the central pipe and the hubs of the wheels of the adapter by welding. The length of the products depends on the angle of their inclination relative to the structure. The square adapter frame can also be made in any size. In our case, this is a frame of 0.4×0.4 meters. To equip the attachments, a channel 0 with a length of 0.4 meters is welded to the rear end of the frame. The assembly and connection of the side pipes of the structure is carried out using bolts.

The seat is placed on a metal support that is welded to the central tube. The adapter is ready for use.

Stage # 3. installing the seat

On the backbone frame of the adapter beam, stepping back 80 cm from the front edge, fix the seat. It is fixed with bolts. The adapter is ready. It remains only to check the functionality of the multifunctional device.

Purpose and varieties

The lugs are designed to increase the weight of the motoblock unit and improve the contact of the equipment with the ground, especially in areas with too wet and / or loose soil. They are a spike construction that is worn on the axle instead of / over pneumatic wheels with soft tires.

Several lug configurations can be found on the market today. Distinguish between universal and special lugs. The first ones can be used on any walk-behind tractor, the main thing is to choose the right size. The latter are made for a certain brand (model) of the unit.

If we take the place of production, then the products can be divided into homemade and factory.

By design features, lug attachments are divided into those requiring dismantling of wheels with pneumatic tires and worn over the tires. The first type requires fixation on the wheel axle.

The use of lugs allows:

- it is better to process the soil layer;

- improve the cross-country ability of both the motoblock unit itself and the attached trailer with a load;

- increase the stability of equipment due to an increase in its weight

- attach other additional equipment.

What are the lugs for the walk-behind tractor for??

Motoblock grousers are special devices that outwardly resemble ordinary metal wheels, supplemented with studded pads. The name itself indicates their main functional purpose. to guarantee perfect adhesion between the cultivator and the underlying surface. the soil. Thanks to these devices, the walk-behind tractor can move freely on any terrain, regardless of weather conditions.

In addition, the lugs for the walk-behind tractor perform other functions:

- contribute to better soil cultivation;

- simplify the transportation of both the walk-behind tractor and the loaded trailer connected to it off-road or on loose soils;

- increasing the weight of the unit, provide it with good balance and stability in space;

- allow the use of other attachment adapters, for example, for seedbed cultivation.

general information

- By design, these devices are spiked wheels. Today, there are many different device transformations, and you should choose them wisely. To a greater extent, the quality of work determines the weight of the unit. The most functional sheds can be hung only on heavy walk-behind tractors or medium-weight units. If it is of high quality, the unit does not give the desired result, you need to additionally purchase wheels with lugs.

- Standard fixtures are metal wheels with spikes that bite into the ground and engage the walk-behind tractor. To make devices with your own hands, you will need to know their device, which will be seriously helped by drawings and diagrams. You will need to determine the diameter of the canopy, choose the material of manufacture, and, of course, select the necessary tools. The first thing you need is a welding machine and a grinder.

- The first step is to determine the size of the fixtures. Their height and width depend on the tasks for which the hooks are mounted on the walk-behind tractor. You also need to take into account the requirements for the mass of devices, because the wheels are put on with them to improve the adhesion of the walk-behind tractor to the ground. For this, wheels of solid weight are needed, which may not be enough for a walk-behind tractor. The minimum wheel weight is 20 kg. If necessary, weights are hung on the soil hooks. This is necessary to achieve better results, or is used when the weight does not reach the norm.

For “Neva”

The walk-behind tractor of each brand has hinged options that are more suitable for its design than others. It is better, of course, to purchase a universal walk-behind tractor, for which almost all canopies are suitable. Wheels with lugs Ø 340 × 110 are produced for Neva.

By design, these lugs are slightly larger than the homemade ones we have described. Follow the instructions above, but select other rim sizes. The height of the wheel for the “Neva” hook should be 340 mm, the width of the self-made device. 110 mm.

How to make do-it-yourself grousers for a walk-behind tractor

With the help of a walk-behind tractor, you can do a lot of different work if, in addition to the unit, there are appropriate attachments. The main task of any walk-behind tractor is soil cultivation: plowing, hilling, possibly planting and digging out potatoes with a certain canopy. Plowing requires cultivator lugs. They are reliable assistants to each owner of the unit, and you can make lugs for a walk-behind tractor with your own hands within a few hours. Lugs are a fairly common attachment that allows you to increase the weight of the equipment and provide better grip of the walk-behind tractor with the soil.

- general information

- Self-production of hooks

- For “Neva”

- For “Centaur”

- For “Zubr”

For “Centaur”

Grousers for a walk-behind tractor of this brand differ only in size. Above, the dimensions were described, which had to be guided by, converting the old wheels into lugs for the “Neva”. The same scheme is used to make wheels with large hooks. The wheel height is chosen 450 mm. The wheel width should be 110 mm, as for the Neva. Such hooks are suitable for the Centaur 2060 and 2090 walk-behind tractor and units with similar parameters. The factory version will cost about 30.

Optimal dimensions

Thus, the following popular walk-behind tractors can be distinguished:

- “Neva”. Walk-behind tractors are common, which adapt to any conditions. But in the case when the farm already has a Neva tractor, which by its characteristics is not considered universal, you can make soil cutters yourself. It should be borne in mind that the diameter of the device should not be more than 36 centimeters, and the width should not be more than 11.

- MTZ. Even despite the fact that such units are Belarusian, and more. The bottom line is that the wheels of these motoblock models are quite large. It takes a lot of labor to make high-quality lugs. It is important that the dimensions are correct and that the triangular plates that engage the ground are carefully welded to the main lug wheel.

- “Salute”. Such a device is being assembled according to the “Neva” scheme.

- “Centaur”. The wheels in such an apparatus are somewhat similar to the “Neva”. But the first car has 11 centimeters longer wheels. If a grouser is made for “Centaur”, then its length should be 450 millimeters, and width 110. It can also fit other models of motoblocks, including other manufacturers.

It is also helpful to make a lug extension. They are designed to increase the angle of rotation of the structure and the width of the potassium and counterweight. To do this, you must attach a slotted sleeve to the hub. An additional axle is inserted into such a sleeve, which is fixed with a bolt. In conclusion, you need to fix the soil cutter wheel on the axle.

Thus, there are many options to make do-it-yourself soil cutters without much labor and emptying the for expensive factory models.

Originally posted 2018-03-28 15:28:41.

DIY trailer adapter

With the help of this unit, the walk-behind tractor can be easily converted into a mini-tractor, which makes it possible to automate a large number of work on the processing of the personal plot. The design of the trailer adapter consists of the following elements:

- Metal supporting frame.

- Hitch.

- Cross bar.

- Braces.

- Chassis.

- Governing bodies.

- Seat.

To make a supporting frame, you should use a pipe of any section, the length of which ranges from 1.5 to 1.7 meters. On the one hand, a device for attaching to the walk-behind tractor is welded, and on the other, a transverse beam. The width of the second element is selected in accordance with the dimensions of the wheelbase of the walk-behind tractor. Then braces are attached to the bar to increase the rigidity of the structure and wheel stands.

Most often, additional units are attached to the motoblock adapter by means of a single hitch. You also need to think about controlling the equipment, and the best option in this situation will be a lever, switching which will lead to a change in the position of the auxiliary devices.

The final step in creating a trailer adapter is to install the seat, and for this, a stand is attached in the middle of the crossbeam.

How to make attachments for a walk-behind tractor with your own hands

The walk-behind tractor is one of the most useful and demanded technical devices among those used on the personal plot. However, this statement is only valid with optional equipment. If the size of the cultivated land plot is small, then it is advisable to purchase branded units. That is why the question of how to make attachments for a walk-behind tractor with your own hands is popular.

- Homemade devices for a walk-behind tractor

- DIY trailer adapter

- Homemade disc hiller

- Making a potato digger

Homemade devices for a walk-behind tractor

The list of accessories is not limited to a mower, plow or harrow. This list is large enough, and no other walk-behind tractor has such a strong package. After calculating the amount that will cost to purchase all the necessary equipment, many refuse this venture. It should also be remembered that not every model can be considered universal.

Simply put, when purchasing units for one walk-behind tractor, it is very difficult to guarantee their operation on another. However, if there is a desire and a certain baggage of knowledge, many additional devices can be made independently.

Their drawings are often found on the Internet, but it is important to make sure that they are compatible. When developing attachments from scratch, you need to focus on the available walk-behind tractor model.

Homemade disc hiller

The optimal type of hiller for a personal plot is disc. When working with it, it is not required to apply great efforts, and when the speed of movement is reduced, the power increases. Do not forget that the disc hiller is a universal tool, because it can be used not only after planting crops, but also during their growth.

The design of this type of attachment is not very complex and includes:

- Ramu.

- Disks.

- Screw type talers.

- Racks.

Thanks to the presence of talers, it becomes possible to adjust the angle of inclination of the working discs. It is this factor that affects the depth of their immersion in the soil and the force applied during work.

Discs can be taken from worn-out agricultural equipment, for example, an old seeder, or made of high-quality steel, the thickness of which is 1.5-2 mm. The outer edges are bent, and a hole is drilled in the center for attaching to the frame.

Making a potato digger

This unit is able to significantly facilitate the work of harvesting all tuberous crops, not only potatoes. Among the main structural elements of the unit, it is necessary to highlight:

- Welded frame.

- Ploughshare.

- Drum cleaner.

- Editorial node.

A ploughshare is a movable element of a potato digger and can be made of sheet iron. The cut plates should be sharpened, but at the same time all edges should be blunt so as not to damage the tubers. Frame fabrication should also be straightforward. To solve this problem, you will need a corner, channel No. 8 and a profile pipe. Frame sizes are selected on an individual basis, and the required amount of materials is determined on site.

The main element of the entire structure of the unit is the editorial unit. To make it, you need two metal cylinders, into which the connecting sleeves are then installed. After that, it is necessary to make the hubs from a metal pipe, the diameter of which is 25 mm. They are used for attaching sprockets, pre-fastened to bushings by means of dowels.

The most difficult to manufacture is the cleaning drum, which consists of two roller chains with 94 links each. The chains, in turn, are mounted on special rods, and then the finished element is attached on two axes. The result is maximum mobility.

The torque from the engine of the walk-behind tractor is transmitted to the ploughshare connected to the casing. During movement, the angle of inclination changes, and digging movements are performed. To adjust the angle of inclination of the working element of the structure, and, consequently, the depth of the dig, you can make a slider. An excellent material for the manufacture of this part will be fluoroplastic.

Blueprints

Assembling a hitch for a walk-behind tractor with your own hands involves the use of drawings. There are quite a few different options available, but it is optimal to take the most suitable one as a basis and adjust it taking into account the parameters of your technique. The drawing should show the following details:

- two U-shaped components, identical in all respects, but with a different number of holes. 6 in one, 8 in the other;

- body, including two threads with diameters M12 and M16 and equipped with a connecting structure for fastening with one of the nodes;

- adjustment component. a lever located on the body of the part, its design consists of a screw connected to the bracket and for convenience has a handle; it is important to provide for the correct direction of the bracket. only up or down and in such a way that it does not interfere with the operation of the walk-behind tractor;

Since the unit in any case provides for a connection with a hitch, the details of the placement of the connection can be studied in its standard instructions.

Required tools and materials

There is a certain set of tools that are required to make a coupler, but they do not include anything exotic. Usually, everything that is required to assemble such parts is on the farm of any owner who cultivates his land plot. The following tools are required:

- welding machine;

- Bulgarian;

- drill or drilling machine, drill bits for metal;

- measuring instruments (tape measure, ruler, square);

- keys;

- fasteners (bolts, studs).

It must be emphasized that in this case it is very important that the holes that you will drill into the parts exactly coincide with the bolts and studs. a backlash in diameter is undesirable, since it will shorten the service life of the used attachments and trailers. At the same time, during the manufacturing process, it makes sense to first make holes in the part with a smaller diameter (from 5 mm), and then expand with wider drills (up to 12-16 mm, depending on the diameter of the bolts). this approach will speed up and facilitate this part of the work, at the same time allowing you to align the holes as accurately as possible.

For the manufacture of the case, you can use a channel of a suitable size, and if there is none, you can cut out a part from a metal sheet.

The option of an adjustable hitch is very convenient. this design will allow you to attach attachments of different classes, generations and brands. Even if at the moment this design is not relevant, one should not forget that different devices may appear on the farm over time, and the possibility of convenient aggregation of any of them will significantly expand the choice, allowing only to proceed from the desired performance characteristics of the equipment.

Choosing a hitch for a walk-behind tractor

Any hinged or trailed device for a walk-behind tractor, be it a harrow, a hiller, a mower, a trailer or any other equipment, is attached with a hitch. If the basic part is not suitable, the owner has a choice. to purchase a suitable one or to make a coupler for the walk-behind tractor with his own hands. In any case, when deciding which version of the node can most closely match the tasks that the unit performs, a number of points must be taken into account, including:

- features of a walk-behind tractor or cultivator;

- the scope of the unit. the functions that it performs;

- equipment that must be aggregated with it;

- loads;

- the need for versatility.

Based on this, you should carefully familiarize yourself with the most frequently used structures and navigate in the choice, based on the features of the one that is best suited in this case.

In this video, you will learn more about the hitch:

When choosing a hitch for a walk-behind tractor, it is worth taking the most suitable type of part as a basis. There are several types:

- single / double. used in the presence of different types of weights, depending on which ones are used and in what quantity;

- reinforced. optimal for heavy units; its distinctive feature is that it is more massive. it has a greater thickness and length, which allows additional equipment to go deeper into the ground;

- adjustable. providing the ability to change the angle of the shaft, due to which you can adjust the level of attachment attachment and thereby increase the efficiency of work;

- universal hitch. allowing aggregation with several models.

If the hitch to the walk-behind tractor of the desired design is not on sale or there are some of your own requests for it, it is not so difficult to make it yourself, since we are talking about a fairly simple device. Some craftsmen, who prefer to make many “accessories” to the walk-behind tractor with their own hands, make a “pipe-in-pipe” hitch for the walk-behind tractor trailer, make it from a cardan, from a crosspiece, from other improvised parts left over from various mechanisms. The owners of such devices note that it is not difficult to make such a unit, and share their experience and drawings of a hitch for a walk-behind tractor.

DIY hitch for a walk-behind tractor

Auto mechanic specializing in agricultural machinery

Some owners of small agricultural equipment purchase it, initially counting on the multifunctionality of the unit, others buy it for one specific purpose, and over time they can expand the range of tasks that the walk-behind tractor can do. But in any case, the fulfillment of most of the functions on the arable or local area is provided by various attachments, which are attached with the help of such a part as a hitch to a walk-behind tractor and, in fact, serves as the key to its versatility.

Often, the owners of agricultural units find that the factory equipment is far from perfect, the design of the coupling is not suitable for the current needs of the land economy, or is simply not reliable enough. Fortunately, there is always the opportunity to equip your walk-behind tractor with such a hitch that will ensure the maximum efficiency of the device.

Make your own “S” Hooks…

The hitch can be done by yourself

Do-it-yourself hitch for a walk-behind tractor

The big advantage of a home-made device is that the owner takes into account his requests and makes it based on the input he needs: model of a walk-behind tractor, load, parameters of attachments.

But the first thing that must be taken into account is that in any case an increased load will fall on this node, therefore it is important to carefully approach the dimensions, design and level of strength of all parts of this part. Correctly specified parameters of the device will provide the most reliable aggregation with the walk-behind tractor, the necessary mobility of the unit and the durability of its use.

When deciding on the design, pay attention to the dimensions of the towbar of your walk-behind tractor and the features of the attachments (already available and the one that is planned to be purchased). The primary task is to ensure maximum compatibility of the unit with all necessary attachments and trailers. Equally important is the ease of use and the possibility of aggregation with equipment having different parameters.

The main working part, as a rule, has a U-shape and serves as a bracket, which is fixed to the walk-behind tractor through the holes in it. The attachment stand is attached to the other side of it.

How to Make Pegboard Hooks

Before assembling the hitch, carefully read the instructions.

Step-by-step instruction

To make a universal joint, you need the most even horizontal surface. a workbench or work table. The scheme for manufacturing a trailer device (coupler) for a walk-behind tractor is as follows:

- Make the markup in accordance with the drawing: mark the outlines of the parts on the workpiece.

- Use a drill or drilling machine to make holes according to the markings. Make sure of their accuracy using a caliper and a bolt (stud), which will be used for fastening. Achieve the optimum hole diameter where there is no play or jamming of the fasteners. Countersink the holes. this will facilitate further work and protect you from injury.

- Weld the joints. It is best to use electric welding, in which heating occurs only at the joints without much damage to the working qualities of the metal.

- Assemble the part. Connect the bracket and channel with bolts. If your design has an adjustment mechanism, fix it as well.

Important! Fasteners, with which the hitch is fixed to the walk-behind tractor through the holes in the nodes, must be of the same quality and strength as the part itself.

Let us remind once again that the part is made in order to maximize the multifunctionality of the walk-behind tractor. With an optimally suitable hitch, convenient aggregation and long-term effective operation of any mounted or trailed equipment, including a plow, harrow, hiller, potato planter, various types of mowers, trailers and any other devices, is possible. And since the fastening elements on different equipment may differ, which often complicates the possibility of their compatibility with the walk-behind tractor, it is the successful design of the hitch and the possibility of its adjustment that solve this problem.

After assembling the part, it is important to attach it correctly. The installation rules are simple enough, but it is important to stick to them. The actual connection of the equipment to the walk-behind tractor is reduced to a very simple action: you need to combine the holes of the hitch and hitch and fix them with bolts or pins. Radial holes allow you to adjust the position of the connector during operation. After installation, you need to tighten the elements of the threaded fastening of the unit with the walk-behind tractor. After that attachment is connected.

After the initial aggregation of devices, a final commit will follow, which must be done immediately before starting work. The adjusting components (screws) should be loosened, the optimum fixation level should be found, and then tightened with wrenches. Depending on the design, a removable threaded axle can be installed on the bracket, into which an M16 screw is screwed.

And there are a few more recommendations to be made. To preserve the working qualities of the metal and increase the durability of the part after its assembly, it is advisable to coat with an anti-corrosion compound or paint for metal.

Considering the possibility of adjusting the structure in different ranges, it is possible to set radius grooves and fix them to zero. After starting work, it is necessary to carefully observe the connection during the first meters of movement and, if necessary, make additional adjustments. The presence of a control lever allows you to change the level of fixation and fix the attachment for a greater or lesser plowing depth.