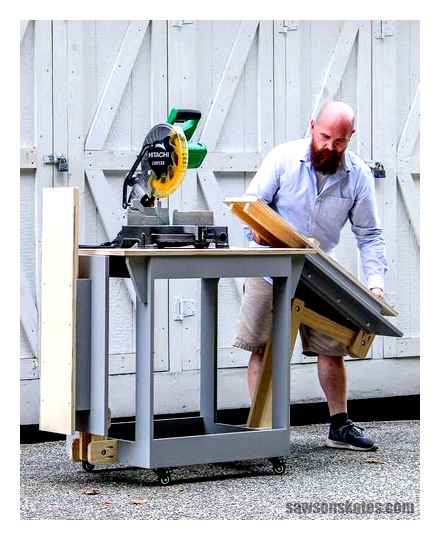

DIY saw stand

Preparing Materials and Tools to Create a Miter Saw Table

After the decision has been made to make the necessary tool, it is necessary to prepare everything necessary to complete this work in a short time and not to clutter up the workshop with materials and tools.

Important to remember! The better the materials, the more reliable the tool will turn out, and the better the cut on a wooden blank will be.

Saws from DeWALT

A distinctive feature of this device is the presence of a unique XPC system, which allows very precise sawing of material of any strength.

From this brand, one can distinguish DeWALT DWS 780, which has a fairly rigid and reliable structure base, which makes it possible to work on it as safely as possible. The device has a 1.65 kW engine and a speed control system. For such a copy you will have to pay 53 thousand rubles.

DIY Evolution rage 2 chop saw stand

Do not forget that when you buy a tool, you will only overpay for the brand. But still, when choosing, it is best to be guided by the opinion of experienced craftsmen who have tested different specimens in working conditions.

Assembling the product

It is recommended to start the assembly of the entire product by studying the drawings and all the parts necessary for assembly. It is also necessary to check the availability of plumbing tools, without which it will be impossible to assemble the table. It is important to consider the order in which each of the assemblies is assembled. These nodes are described below.

We begin the manufacture of a table for a miter saw from the assembly of the base or platform on which the tool itself will be installed directly. The dimensions of this plate largely depend on the dimensions of the miter saw itself. over, if we want to make a universal table so that it is possible to install other compatible tools on it, for example, such as a slotting machine, then the size is taken according to the maximum size of the tool.

DIY Portable Miter Saw Stand / Station | Shop Projects

It is better to use 19 mm plywood as a material, in the absence of such, you can use chipboard or Fiberboard of a plate of suitable sizes, but plywood is more reliable.

- Installing side extensions. Quite often, parts of a much longer length are used than the saw frame, and for processing such parts, removable side extensions are installed. over, you can use those, both on the right and on the left of the bed. The extensions are usually made of the same material as the bed itself. That is, 19 mm plywood will be enough.

- Upper shelves: an important part of the table. In order for the part to be freely attached to the extension, as well as for a more comfortable attachment of the extension itself to the bed, it is necessary to make the upper shelves. They are fastened with screws to both the frame and the extension. The shelves are also usually made from 19mm plywood. An important feature of the shelf is the presence of a tongue along the entire length of the part, 19 mm wide and 3 mm deep. Its purpose will be explained later.

- Application of clamping plates. The clamping plates allow the most accurate and reliable alignment of the bed and the width extensions. To do this, it is best to use clamps that will pull together the extensions and the base of the table. After such fixation, the extensions can be fixed to the base of the table.

- Joint work of machines. When working together several machines, as mentioned earlier, it is necessary to align their planes. If, for example, you want to use a slotting machine in conjunction with a miter saw, then it must be installed so that the working planes of both machines coincide. This means that it will be necessary to align the heights of both machines. It is they who are inserted into the grooves made in the shelves installed on the extensions.

- Sliding stops are also important. The movable stops are designed to fix the part using guide rails made of hardwood bars. The quality of the trimming of parts also largely depends on the quality of their manufacture.

- How else can you use extensions? Extensions allow you to attach parts of a sufficiently long length. In order to use them correctly, it is necessary to reconfigure the table for such a detail. Of course, this will take some time, but then it will pay off when manufacturing a large number of long-dimensional parts.

So, to summarize: you can even make a table for a miter plate in your home workshop. over, the result of making parts on this table will be much better than on an ordinary workbench.

One of the most important tools that are used on the construction site and for some repair work is the miter saw, which is able to cut workpieces and material at any angle and any inclination. This possibility is provided by the existing turntable, the movable working part of the device and, accordingly, by the disc itself above the bed. Using it, you can cut wood, plastic, hardboard, OSB, laminate and other materials of not increased strength.

To choose the right tool, you should consult with a specialist who understands not only the order and way of performing work, but also miter saws with a broach.

In principle, the construction of the saw is simple and consists of a motor on a gearbox, a saw blade, a platform and a handle with a convenient location of the start button. The engine uses a collector motor, which has a greater number of revolutions, but requires periodic replacement of brushes. And asynchronous, which is quieter in operation, but at the same time more durable to use.

The transmission of torque for the disc is provided by a gear or belt transmission through a gearbox. To avoid slipping the product, use the first gear. When shifting to second gear, vibration is reduced and disc rotation is stabilized, which is more suitable for a long service life. The most reliable is direct transmission. which is used in some copies, but they are disadvantageously distinguished by low revolutions.

To turn a regular saw into an end machine, a broaching mechanism is built into it. With this option, the module itself is located in the structure on parallel rails. This design approach makes it possible to cut large-sized products.

For the bed, magnesium or aluminum is used, and the base itself is a rounded part, set at the desired angle and stop. And the kit also includes a cover to protect body parts from injury.

The basis and very important element of the design is the table. If you have the right tools and some knowledge, you can set up a miter saw table with your own hands. It has two sides that are attached to the rack. The neck fits exclusively on feed saws.

To measure the position when rotating the table, angular scales are located on the base. The rotation angle can be between 0 and 45 degrees. A special groove on the latches reliably fixes the rotary part and provides the most accurate fixation.

There are some tilt stand designs. But such a design requires more complexity and more nodes, which will lead to a greater likelihood of breakage. And the need for tilting is not so great and arises only when trimming some types of skirting boards and moldings.

DIY metal cutting mobile chop saw stand

Built-in clamps provide a secure fixation of workpieces on the table. And when using sufficiently long workpieces, retractable stands and stops are used, which are installed in the bed and expand the dimensions.

What it is

The working table for installing the miter saw is a solid base on which this cutting tool is mounted, the miter saw. This design can be made of a metal profile of various sections and different metals, as well as durable types of plastic. Additional elements (side extensions, shelves and stops) can be made from lumber (board, plywood, chipboard or OSB board).

The dimensions of the table depend on the geometric dimensions of the material being cut (lumber, metal profile, tubes or reinforcement). The design can be permanent or sliding, allowing you to change the surface area of the table, which also depends on the material being processed and the working conditions.

The table, depending on the nature of the work performed, can be made stationary or portable installation, with a device of legs or providing for installation on a flat horizontal surface located above the floor level.

Saws from Metabo

A unique feature of Metabo miter saws is the ability to tilt and swivel the blade using a special adjuster. Cutting accuracy is ensured by a projection system that gives a shadow on the workpiece from the disc.

The most used model belongs to the Metabo KGS 305 model. The set comes with a 2 kW motor, quite convenient control of the adjusting levers. And the tilt angle reaches 47 degrees and rotates 60 degrees. The good quality of the tool is that it can cut efficiently and accurately, and also work even with a bar of 100 x 100 mm. This purchase will cost the buyer 26 thousand rubles.

Preparatory stage

During this period, you should answer for yourself the questions that were described above, and then draw a sketch of the product being built.

Prepare construction tools and required materials, and then proceed to work.

Facing settings

To block the mechanism for replacing the disc and, accordingly, to stop the engine, the device is equipped with a soft start. For safety reasons against electric breakdown through the case, the models are equipped with protection.

To adjust the cutting of metal products, electronic units are built in, which allow you to adjust the process depending on the properties of the material. Electronic components are also installed as a precautionary measure to ensure safety and prevent breakage from overheating, jamming, braking when the tangential load is exceeded. And it also allows you to more accurately cut the workpiece. Although usually saw models come without the listed units.

In order to be able to calculate the number of parts produced for a certain period in an exact quantity, newer models are released that have the option of setting the exact number of revolutions. Another useful but expensive feature in the machine is the laser guidance system for precision cutting. This system can operate both from the mains and from batteries. Its essence is simple and very suitable for beginners, as they see the line of the future cut, indicated by the laser beam. And beginners, if they have drawings, will be able to make a miter saw with a broach with their own hands.

In the process of this production, a large mass of sawdust and small parts from blanks remains. Some models have a built-in vacuum cleaner, which later saves time on cleaning and keeps the workplace always relatively clean.

The quality of the cut is affected by the disc with which it will be made. And you can distinguish between saw blades by the following criteria:

- configuration and geometry of teeth;

- outer diameter;

- landing hole.

The inner diameter in conventional configurations is 3 cm, and the outer diameter can be from 21 to 30 cm. This information is indicated on the side of the disc without fail. A large value of the outer diameter indicates that the load on each of the teeth during operation will be less. And this will lead to a longer operation of the disk. Also, the disc indicates its marking, the permissible maximum rotational speed and how compatible it is and with which tool.