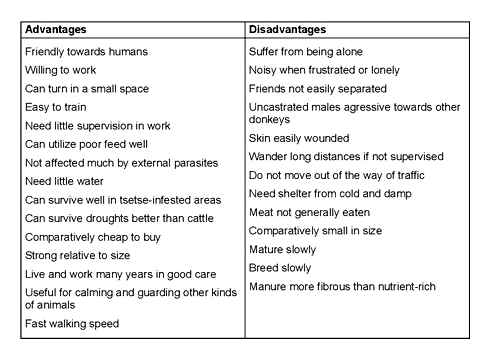

Do -it -yourself cultivator. Advantages and disadvantages

How to make a homemade mower on a single tractor

A walklet for a walk.behind tractor will help to quickly and effectively remove from the site not only grass, but also weeds and even small shrubs. It can be bought in finished form, or you can assemble it yourself, home.made options work no worse if you are made correctly and from reliable nodes. The main thing is to choose the optimal type of design that is suitable for equipment.

This type of attachment equipment differs from other options not only for its intended purpose, but also in the method of mowing grass. over, there are different types of mowers, but all of them perform similar functions, have the same nodes in the design. As for the main features, they are:

- You can mow grass or weeds with thick solid stems, small shoots. It is important to choose an option that will cope with the load, will not fail through a short time.

- Different species performance varies. It should be selected under the area of the site, if it is small, it is best to use the simplest systems. For large areas, more complex and productive systems should be used.

- The drive from which the attachment equipment works depends on the type of walk.behind tractor, the mounting location. Most often it is attached through belt gear, much less often. using a power shaft.

- The main nodes are fixed on the frame, so it should be strong, withstand the loads. An important element is the connection with the walk.behind tractor, if there is no special connecting unit, you will need to use an additional adhesion, it can be bought in a finished form.

- The working node can have different configuration, it all depends on what the grass or other plants need to mow. If you choose a segment or disk options for hay harvesting, they carefully cut the stems. When you just need to remove weeds, a cart-mulcher is more suitable, after which the crushed green mass remains.

- The performance of different models is different. Therefore, it is worth selecting on the basis of them what areas will have to be mowed.

In the manufacture of a home.made mower for a walk.behind tractor, it is better to first see the finished options, see them in reality. Then it will be much easier to assemble the structure, plus it is easier to understand the device of some nodes to implement them on your own.

Types of structures

Mowers to motor blocks do not differ in diversity. 3 basic varieties can be distinguished, each has its own characteristics, so you should understand them, choose an option for themselves. In addition, it is necessary to take into account the complexity of the assembly, if the experience is not enough, then it is best to choose what is easiest to do at home.

Segment models

One of the simplest solutions. They differ in compact dimensions, which simplifies installation, removal from the walk.behind tractor, one person will cope with work. Put it both in front and behind. As shown, practice, the front version of the location is much more convenient and safer, when managing you do not need to constantly look under the feet. Features are:

- Two metal strips are installed on the frame. Triangular teeth are fixed on them, small notches are made to improve work on the edges.

- When the mower is turned on, only the upper bar begins to move, the lower one is fixed motionless. The cutting of grass is carried out according to the principle of scissors, since the knives move right and left.

- Small sizes make this option maneuverable. It is convenient for them to work in areas with complex relief, on slopes, near buildings.

- The design can rely on wheels or the simplest metal sling, fixed at the edges. They must be adjustable in order to adapt to the site, change the height of the mowing.

- The system copes well even with thick stems of weeds, as well as with high dry. It is suitable for mowing grass when harvesting hay, as it does not spoil the stems, they carefully fit to the ground. But to work on low soft grass, this is not the best solution.

- The system is quite reliable, almost never breaks, requires minimal maintenance. The only thing to follow is the sharpness of the knives, the quality of work largely depends on this.

For all its simplicity and compactness, this option is complicated in the manufacture of. If there is no experience in metalworking, assembly of equipment in the workshop, it is easier to choose another solution.

Due to the independent fastening, the work is easy to stop, turn off the equipment in any dangerous situation. When using vibration from a mowing, it is not transmitted to a single tractor, it is comfortable and easy to use it because of a small mass.

Rotary options

This variety is used on different models of motoblocks. Sometimes it is sold complete with equipment, but more often you need to buy separately, the price is not the smallest. The models are called disk, since the main working elements have this shape, the size depends on the width of the processing. Peculiarities:

- Two disks are fixed on the frame, in which several blades stand. They are not visible when the equipment does not work, but when rotating, they are advanced under the influence of centrifugal force.

- Due to the fact that the discs move towards each other, mowed grass, or weeds are formed in neat mowing. This option is convenient to harvest animal food.

- By the type of fastening of the rotary mowing to the walk.behind tractor, hinged, semi.wow, trailed. The first option usually weighs a little, the rest is an order of magnitude harder.

- Can be located in front, back, or from the side of the walk.behind tractor. It all depends on the model of the technique, as well as the design through which the force is transmitted from the engine to the mower.

- When choosing, take into account the power of the motor, the area that must be processed. The larger it is, the wider the working part should be.

Rotor mowers are easy to maintain, it is necessary to lubricate moving joints from time to time, replace the knives as it is worn. It is important to first inspect the site so that there are no stones or metal objects there. The discs rotate very quickly, when such elements gets, they can be badly damaged.

Pitchers

Differ in that they are placed on wheels. When working, you can sit, which greatly simplifies the process. This option is called the mower muffler, since the equipment not only mowing grass and weeds, but also grinds the green mass, so that then there is no need to remove the remains. Features are:

- Joins behind. It is a single.axis design with a seat, the working part should rise and fall, so you can move to the site without danger to damage the knife, as well as other nodes.

- The case is closed so that the crushed residues do not fly around. It performs the function of protection, since if a stone falls, it flies out at high speed and can injure.

- Working element. a bilateral knife fixed on the axis rotating at high speed.

- It is easiest to connect through a belt, but sometimes they use a power shaft.

It is not difficult to make an adapter for a walk.behind tractor with your own hands if you collect everything you need to work, to understand well.

This option is used to mow weeds, potatoes before cleaning. You can use it when processing lawns. It is necessary to correctly adjust the height so as not to rest against the ground, while not leaving high stems.

How to make a cultivator with your own hands

Cultivator. equipment required for any farmer. It allows you to treat the soil without turning large layers of the Earth, without violating its fertile layer. But he has one important drawback. his value. Therefore, quite often in the vastness of our country you can find a manual or electric cultivator made by yourself.

What materials are needed

Making a cultivator with your own hands for a tractor, a mini-tractor or a walk-behind tractor is an extremely simple matter, it is only important to have a desire and the necessary tool. For assembly you will need:

- compact corner grinder;

- metal disks;

- welding machine and electrodes to it;

- An emery with two disks that have a different abrasive value;

- Drill and a set of various drills to it.

The materials from which the cultivator will be made are also needed:

- metal square plates, the size of which depends on the specific model of the walk.behind tractor (most often there are enough plates of 15 × 15 cm);

- flat rectangular plates that will play the role of milling. Their length and width also depend on the specific model of the walk.behind tractor. The optimal size is 25 in length, and in width. 4 cm;

- bolts and nuts in the amount of 16 pieces (in pairs);

- Long pipe made of durable steel.

After reading the following article, you will realize that for the maintenance of a garden plot clean, you need a chopper of grass and branches.

When selecting materials, it is important to consider the following factor: they should be not only very strong, but also immune to corrosion.

This is important, since during cultivation on the work surfaces there will be a moisture that is a strong oxidizing agent.

After everything you need is prepared, you can start assembly. With the help of a drill on metal in each square and rectangular plate, a hole should be made.

After that, it is necessary to combine them in such a way that one mill is present on each side of the square. With the bases, they are fastened with the help of bolts of a suitable size.

In the absence of such fasteners, you can use welding. But in this case, the connection will not be very durable, so the disk cultivator made by yourself will be able to process only loose black soil.

McPVP Hunger Games: How to Tower Solo

The hinged cultivator, which is necessary for the processing of complex soils, should be as strong as possible, since when working on rock or clay soil, the working part (cutters and their base) carries the maximum load.

Further, when the details are a single whole, a hole of the required diameter should be made in the center of this design. A steel tube is drawn through it.

It is cut in half and a platform with mills is “put on” for each part. It can be attached to both bolts and contact welding.

Upon completion of the above operation, it is necessary to attach both parts of a home.made cultivator to the motor block shaft. This is best done using a drill on metal and bolts of the corresponding diameter.

Pipe with cutters and a motor block shaft are drilled through and through. Further, the holes are combined, and through them a bolt is stuck, which is fixed by a nut and a counter.hawk.

What will be required for the manufacture of a chainsaw cultivator with your own hands

This type of equipment is quite expensive. With a lack of finances, a home.made unit made from the engine of the usual firmica “Friendship” can be a way out of the situation.

For the manufacture of such a simple device with your own hands, only time, patience and some details will be required:

- Engine from the Gas Play “Friendship”;

- muffler;

- starter;

- fuel tank (can be used from the old motor bicycle);

- a chain with a z4 step (suitable from a conventional bicycle, but the best option is from a light Minsk or Sunrise motorcycle);

- shaft, which acts in the role of intermediate;

- wheel for support on the ground;

- metal corners from which a supporting frame will be collected;

- wheels, the diameter of which will depend on the design of the frame and other features of a home.made motor.cultivator.

You will also need a tool with which the metal will be processed:

First of all, the frame is going. It can connect with bolts or contact welding.

Of course, the connection using bolts is much more reliable, but it can not always be used. Also, if necessary, instead of corners for the construction of a frame, you can apply a pipe made of steel of large thickness.

The frame itself is a complex shape. She looks like a trapezoid with an inclination of both sides in one direction. Between two identical forms, crosses holding them are welded.

They have already installed an unit from the Gazette “Friendship”. There is a shaft at the bottom of the frame, on which there are two wheels for the future cultivator made by yourself, and an asterisk. On it through a chain gear, the engine transfers the torque.

The working part is a shaft on which mills are located, fixed using square sheets of metal. The rotation to the shaft is transmitted using the same bicycle stars (Z4).

How to make a cultivator from a trimmer for grass with your own hands

If necessary, you can easily design a mini-cultivator from a regular garden gasoline trimmer for grass with your own hands. To carry out this simple operation, you will need:

- working trimmer for grass;

- metal processing tool (angular grinder, welding and manual tool);

- ordinary garden pitchfork;

- A steel tube, the diameter of which will connect it to the shaft of a trimmer for grass.

As a working part, you can use in a special way curved rods from ordinary garden forks. Their optimal length is approximately 10-15 cm. It is to such a depth that the soil is most often loosened.

First of all, the working part should be made. It will be flattened teeth of the foriles, their width should be approximately 1 cm.

With the help of an emery on which a disk with a small abrasive number is installed, the resulting cutters are pulled. After that, it is necessary to make a round nepota, the diameter of which will be approximately 10 cm.

It should be ideal in order to place cutters on equal removal from each other, the optimal number of which is 3 pieces.

Nazadka-cultivator for a trimmer for grass: nuances when working and mounting methods

What is the device?

In a set of interchangeable nozzles, Motokos, manufacturers have recently been increasingly mentioning such a device as a cultivator or proof.

Unlike classic nozzles in the form of discs for mowing grass or mowing head for a synthetic fishing line for a trimmer, the cultivator is designed to work directly with the soil.

A trimmer nozzle for grass is designed to loosen the soil in the processed areas and partially in places where there is a turf cover.

A trimmer nozzle for grass was weeding potatoes

A trimmer nozzle for weeding is put on a bar instead of a lower gearbox. Converting a trimmer for grass into a prosperger is carried out within 1-2 minutes and does not require additional tools and equipment. The entire process is carried out using hexagonal keys included in the tool of the tool motorcycle.

The use of motorcycles greatly facilitates the weeding

Rivets for rivets: types, dimensions, application

The case of the device collapsible. The housing has special devices for adding lubrication. Corps material. aluminum alloy, cutters are made of steel. Shaft on which milling cutters, forged, gear bronze.

The principle of operation of the trimmer for the grass is simple. from a two.stroke engine through the clutch, rotational movement is transmitted to the shaft in the bar. Further, through the shaft, the movement enters the connecting shaft with a worm mechanism, from which a working shaft with mills begins to rotate through a bronze gear.

The speed revolutions are adjusted by adjusting the number of engine speeds through the gas handle. the more the carburetor shutter opens, the higher the rotation speed of the milling.

From corner grinders

Most often, a homemade electric trimmer for grass is made on the basis of a conventional corner grinding grinder, which is available to every home master. This tool is almost perfect for remaking into a trimmer for grass.

It has a larger power than store machines and more than a minute.

In addition, the standard nut used in the corner grinding for fixing the disks already has holes through which it is easy to insert a fishing line for a trimmer (cord).

So, there are many options from which to make a bar (holding). The simplest is the longer a wooden holder than for a shovel. To the end of it, an angular grinder is attached at the right angle with a conventional tape. The fishing line for the trimmer is inserted into 2 holes of the nut, after which it is twisted. Thus, in a few minutes you get a trimmer for grass, which can be mowed without problems.

For the safety of the operation of a home.made apparatus, you can improve it by making a protective casing (how to do this, will be considered later).

For advanced masters with a welding machine, you can advise a more advanced design to fix the angular grinder and protective casing. It is made from an aluminum tube (serves as a holder) and a metal square profile. Looking at the picture below, you can understand the principle of manufacturing the holder.

The corner grinder is fixed on the holder with bolts inserted into the holes that are designed to attach the handle to the device.

The following photo shows how this design looks below.

How to make a pipe bastard with your own hands: examples of the best self.use

Next, the “native” casing of the corner grinder is removed, and instead of the disk, either a fishing line for a trimmer or a metal disk knife is installed.

By the way, you can fasten the holes for fastening the handle (bar) itself, when you want to make a simple trimmer for grass, which is easily assembled and is also easily versed if you need to use the corner grinding for its intended purpose.

To make it more convenient to hold a trimmer for grass in his hands during work, and it did not rotate around the axis of the bar, you can attach a side hand made of a bent pipe to it.

Read also: Why do you need a gas burner

The principle and effectiveness of the weeding method

Weeding as a cultivator processing aims to destroy the weed by weed by exhausting. plants after processing need time in order to recover and gain the desired force. At this time, potatoes or other vegetable crops will be able to continue successful growth.

The weeding of potatoes with a trimmer is usually carried out by three methods:

- sparing weed grass with a mowing head or disk nozzle;

- cultivator processing with a drum nozzle;

- Cultivator processing with saber or disk nozzles.

Speasing is usually carried out when weeds reach a height of 7-10 cm. In this case, only the part that is above the ground is mowed, and the roots remain in an untouched state. Usually after this begins rapid growth of green mass, so that the effectiveness of such processing is small.

When the weeding with a trimmer is carried out using a drum cutter, the roots of weeds are also processed.

A big plus of this method is that the upper soil layer is scared, and thus increases the air exchange of soil.

The effectiveness of this method is much higher than a simple weeding manually or work by a mechanical cultivator. The drum mill allows you to loosen the soil to a depth of 3-5 cm.

When using saber or disk nozzles, effectiveness increases even more-the processing depth increases to 5-7 cm. At the same time, the roots of plants, like the green mass of weeds, are repeatedly grinded, which contributes to the rapid decomposition of plant residues in the ground.

After such a weeding, repeated weeding is usually carried out after at least 10-14 days. True, there is one nuance that needs to be taken into account. when working with drum mills, the width of the processed strip is about 30 cm.

, But when working with saber or disk mills, the width is no more than 15-20 cm.

Pros and cons of the method

Weeding a trimmer of the garden, and even more so the site on which the potato grows has its own characteristics and specifics. First of all, you need to pay attention that for work you need to choose the right tool.

It is preferable to choose powerful four.stroke engines as a working engine. Such motorcycles have a lower gasoline consumption and greater performance compared to two.stroke.

Cultivator nozzles for benzos. technical specifications

Thanks to the modern garden electric and gasoline tools, many routine problems can be solved today throughout the calendar year. Each such tool can be supplemented with special nozzles. It is nozzles that will be able to help both in the garden and in the personal plot.

Cultivator nozzle

A gas-cultivator nozzle for grass is used for loosening soil in small areas, such as a flower bed, a greenhouse or around bushes and trees. The tool can be:

The difference in these two nodes only in their design and names, the essence of the work performed is the same. loosen the ground.

Important! Gear models are less weighty, therefore, it is best to process light soils, unlike disk.

Such a nozzle from the engine works with a special rod (sold separately). There are slots on the rod, they can be from 7 to 9. That is, you need to know exactly what nozzle to buy, since it may not come from one model to another.

When the cutters and discs are fixed with the help of slots, the cutting organs will shift freely, you can loosen the soil to a width of 20-25 centimeters.

note! Long beds are more convenient to process than short. In the first case, you need to do less turns.

When choosing a nozzle, it is necessary to take into account the power of a trimmer for grass. If the power of the device is not more than 1,500 watts, then only loosened land will be processed. For example, you can only cumber potatoes.

The disadvantages of the design include the fact that the soil will not work deeply deeper. Only the top layer can be processed, and then if it is plowed recently. On solid grounds, such a cultivator prefix will simply “jump”, it does not like the soil. And pressing it is denser to the ground either, the bar will spring and bend, which will lead to a breakdown of a trimmer for grass.

But still sometimes it makes sense to purchase such a nozzle. Given it sometimes not a small price, many craftsmen decide to make a cultivator for motorcycles on their own.

Universal cultivator for a trimmer for grass with your own hands

If there is a summer cottage, then the presence of a cultivator’s nozzle will greatly facilitate the work when processing the soil (when working, a lot of effort and time is spent). Special factory equipment is not cheap, which means that you need to assemble the nozzle- cultivator for motorcycles on your own.

The following is a simple example of how to make a cultivator based on a trimmer for grass. To do this, you need the following tools and materials:

- corner grinder with metal disks;

- drill in the kit with drills;

- welding machine;

- electrodes;

- Kryzuvka for metal;

- sandpaper;

- Garden forces;

- steel tube for shaft trimmer for grass;

- hammer, flat trays, roulette and so on;

- Metal sheet.

Nozzle cultivator on a motorcycle (lawn mower)

Production begins with a loosening element. To do this, you need to bend the rods of garden forks. Their length should be about 15 cm.

Then the working nozzle is made. To do this, the teeth of the foriles must be flattened to a width of 1 cm, then the resulting mills should be sharpened with emery. After that, cut a circle of durable metal with a diameter of about 10 cm and weld cutters to it, it is best only 3 pieces.

The next step will be the attachment of cutters for weeding on a trimmer for grass. If there is a reverse thread at the end of the trimmer shaft for the grass, then the resulting part is simply screwed. It is enough to weld a pipe with a nut to the cutter. Everything, a trimmer from a do.it.yourself trimmer is ready.

Universal plow. soil processing in any areas

Cultivator for motorcycles

Before making a purchase of this nozzle, you need to decide on its type. To date, the following types of special nozzles are presented in the consumer market:

- Cultivator nozzles for benzos: you can perform plowing of the earth on the beds or in greenhouses;

- Highway nozzle on a motorcycle: an indispensable nozzle in the garden for cutting knots and excess branches;

- Freak nozzle on a motorcycle to trim the bushes.

This is a minimum set of special nozzles that can become reliable assistants on a personal plot and summer cottage.

Trammer trammer for grass

For many summer residents of weeding weeds, it is a problem especially if the site has been purchased recently, and before that it has not been processed a couple of years. And often gardeners dream of a mechanical pull. It will not be difficult to make it if there is a trimmer for grass. Such a nozzle is attached to the trimmer according to the principle of a trimmer knife.

Production of nozzles-straps

From a dense sheet of iron (better stainless steel), cut a circle, there should be a landing hole in the center, and holes must be drilled on the entire surface. To fix the sharpened bolts with a washer and nuts in them. It turns out a design resembling a hedgehog. These very thorns-bolts will be weeding.

Advantages and disadvantages of the nozzle-cultivator

The prefix-cultivator for a trimmer for grass is becoming more and more popular among customers. Here are some advantages of this device:

- Simplicity in maintenance.

- Noticeably cheaper in comparison with equipment for a motorbike.

- Such a cultivator is simply indispensable for those people who have many greenhouses. Using this device, you can quickly loosen the ground in the greenhouse and saturate it with oxygen.

- The design is made very high quality, which makes it possible to use the cultivator for a long time.

- Protective shield. Protects from the garbage of the operator.

There are not so many disadvantages:

- Each nozzle weights the structure, with prolonged work, a person will feel fatigue.

- You need to select a nozzle and a trimmer for grass with the same connecting nodes.

- Due to vibration, control the button of the trimmer switching for grass and holding a difficult unit is often uncomfortable.

Important! The model of the cultivator nozzle should be produced by the same company as the trimmer for the grass. If the loosening tool is produced by Husqvarna, and the lawn mower is Oleo-Mac, then it will not work to process the soil: the nozzle simply cannot be attached.

Varieties of cultivators

Tornado

Tornado is the simplest version of the cultivator, which can be made with your own hands. Outwardly it looks like a corkscrew, which is fixed on a vertical tripod. The design is equipped with a horizontal handle on top. For its manufacture, use simple pitchfork and nozzle for the cuttings. You can buy a nozzle at a hardware store. It has the shape of a handle and is used to work with forks and shovels.

- In the cultivator, the handle should be long. Therefore, the nozzle must be increased. For lengthening, use a plastic pipe, slightly larger diameter than the thickness of the plastic nozzle. The length of the pipe should be about 0.5 m. So that the pipe can be put on the handle of the handle, it is carefully cut along and twisted.

- The pipe is chopped with island. Fixed, during operation it will not slide, and jump from its place. The finished handle on both sides will turn out protrusions about 25 cm long.

- Using a simple hammer, the teeth of the foriles are changed under the shape of a corkscrew. Stronging strong blows to metal teeth, they will begin to bend in the necessary direction. Original photo of the cultivator, help to repeat its exact bends.

Cultivator from a bicycle

The design of this manual cultivator is more complicated. It is made from parts of the bicycle: frames and wheels.

- A do.it.yourself cultivator head from sharp metal rods is fixed on a bicycle frame. As a head, you can take a part from the old cultivator. From a small plow create a frame of the device.

- From a metal or aluminum pipe with a diameter of 2 to 2.5 cm, the handle is built.

- All compounds are rigidly fixed by bolts. Structural elements should not hang out.

- A medium.sized wheel is fixed on the frame. As fasteners, barashika nuts or simple counter-hacks are used as fasteners. The wheels are too large or small do not fit here.

The cultivator is designed to remove weeds. It processes a row.

Disk rotary equipment

The disk rotary cultivator is designed for harrowing, and alignment of the surface of the earth. They are good to break large soil pieces. Assembly of technology:

- Convex spherical disks installed in the cultivator is the main working tool. It is very difficult to make discs yourself. Metal plates with a thickness of 44 mm from a simple form, you need to make a spherical. Stronging strong beats with a hammer in the center of the plate, they knock out the bowl. Convex discs are obtained. Ready elements are welded to the axis dressed on the axis.

- The axis is inserted into the brackets and fixed with chlobs.

- A special ledge is located in a large bracket. A pipe with handles passes through it.

- Rod, 24 mm in diameter, 25 cm long to a small bracket.

- A 16 mm thick rod is screwed into the rod. A small part of the rod will protrude above the crossbar.

The angle of disk installation can be adjusted using a barashka nut, which is installed on the crossbar. Turning the nut, the rod will rise up and the big bracket bend, changing the direction of the disks.

Cultivator from a meat grinder

In addition to the manufacture of manual devices, you can assemble an electric model yourself. The design of the cultivator assembled from a meat grinder is very simple.

- For the manufacture of handles, two corners are screwed to the gearbox, and two pipes are welded to them.

- For convenience, the ends of the pipes are bent, and a suitable segment of the pipe is welded between them, which will create an additional strength to the handles.

- Wheel axis is welded to the corners. The size of the wheels choose the average.

- The nozzle from a meat grinder is beaten with a sledgehammer until the sleeve becomes cast.iron.

- The shaft is pulled out of simple scrap and set it in the nozzle. A screw-zaucard screw is also welded here.

- To make a cultivator conveniently turn on and off, the engine switch is installed on the handle.

If you need to do neatly loosening the earth, the cultivator is slowly moved. Grury plowing is obtained with the rapid movement of equipment, while the earth is soldered by large Комментарии и мнения владельцев.

From a chainsaw

The basis of the design is the engine from the chainsaw. Additional details that you need to buy: a metal corner, a tube and fuel tank, wheels, a moped star and a star with 41 teeth.

- From the metal corners we make a frame size 32 × 32 cm. The shape of the frame should resemble a cube. The engine is installed on the transverse corners, and the fuel tank below the brackets. Intermediate shaft. mount on vertical corner racks. Bearings are attached to the longitudinal corners. They are designed for the running shaft. The same.based tractor with the center of gravity on the wheel is ready.

- Handles are made from a pipe with a diameter of about 30 mm.

Stars for the intermediate and running shaft, as well as the rest of the parts are collected in a single mechanism. The garden cultivator is ready.

How to make a manual cultivator for processing a row

To process narrow places between the rows, first of all, the cultivator must be compact. For such work, a manual device called “hedgehog” is well suited. Having all the necessary details, it is easy to make it yourself. For the assembly of the “hedgehog” you will need: the bracket of the P-forms with holes, shaft, stalk and wheels with metal spikes.

- So that the one.axic tractor easily moves around the site, you need good wheels. To do this, take a medium.sized steel pancakes and weld metal spikes to them. The spikes are easy to make, you need to sharpen the fittings in the shape of a cone.

- Ready cutters put on the axis.

- The axis is inserted into the bracket and fixed on both sides.

- The mount is welded to the end of the bracket and the stalk is inserted.

The technique is collected and ready for cultivation and weeding between rows.

From a trimmer for grass

A made cultivator from a trimmer for grass with your own hands will help to quickly and easily and easily and easily. You can assemble it from improvised materials: a working gasoline trimmer for grass, corner grinding or welding, garden forks, steel tubes.

- For the manufacture of cutters, the teeth from the foriles are bent in the desired shape. Usually the soil is loosened to a depth of 10 to 15 cm, so the length of the teeth should be no more than 15 cm.

- Next, we make the working part. The teeth of the foriles are flattened to the width of about 1 cm.

- The mills are pulled with emery and fixed on a round heel.

- A nickel with a diameter of 10 cm should be perfectly flat in shape. Mills in the amount of three pieces are located evenly on the heel. If you put more than three pieces, then the device will be strongly overloaded.

- The final part is a connection of the base with cutters and a trimmer for grass. Well, if the shaft tip has a thread. Then the trimmer for the grass is simply screwed to her.

The technique is designed for loosening the soil at a small depth.

Nazadka-cultivator for a trimmer for grass: nuances when working and mounting methods

What is the device?

In a set of interchangeable nozzles, Motokos, manufacturers have recently been increasingly mentioning such a device as a cultivator or proof.

Unlike classic nozzles in the form of discs for mowing grass or mowing head for a synthetic fishing line for a trimmer, the cultivator is designed to work directly with the soil.

A trimmer nozzle for grass is designed to loosen the soil in the processed areas and partially in places where there is a turf cover.

A trimmer nozzle for grass was weeding potatoes

A trimmer nozzle for weeding is put on a bar instead of a lower gearbox. Converting a trimmer for grass into a prosperger is carried out within 1-2 minutes and does not require additional tools and equipment. The entire process is carried out using hexagonal keys included in the tool of the tool motorcycle.

The use of motorcycles greatly facilitates the weeding

Rivets for rivets: types, dimensions, application

The case of the device collapsible. The housing has special devices for adding lubrication. Corps material. aluminum alloy, cutters are made of steel. Shaft on which milling cutters, forged, gear bronze.

The principle of operation of the trimmer for the grass is simple. from a two.stroke engine through the clutch, rotational movement is transmitted to the shaft in the bar. Further, through the shaft, the movement enters the connecting shaft with a worm mechanism, from which a working shaft with mills begins to rotate through a bronze gear.

The speed revolutions are adjusted by adjusting the number of engine speeds through the gas handle. the more the carburetor shutter opens, the higher the rotation speed of the milling.

From corner grinders

Most often, a homemade electric trimmer for grass is made on the basis of a conventional corner grinding grinder, which is available to every home master. This tool is almost perfect for remaking into a trimmer for grass.

It has a larger power than store machines and more than a minute.

In addition, the standard nut used in the corner grinding for fixing the disks already has holes through which it is easy to insert a fishing line for a trimmer (cord).

So, there are many options from which to make a bar (holding). The simplest is the longer a wooden holder than for a shovel. To the end of it, an angular grinder is attached at the right angle with a conventional tape. The fishing line for the trimmer is inserted into 2 holes of the nut, after which it is twisted. Thus, in a few minutes you get a trimmer for grass, which can be mowed without problems.

For the safety of the operation of a home.made apparatus, you can improve it by making a protective casing (how to do this, will be considered later).

For advanced masters with a welding machine, you can advise a more advanced design to fix the angular grinder and protective casing. It is made from an aluminum tube (serves as a holder) and a metal square profile. Looking at the picture below, you can understand the principle of manufacturing the holder.

The corner grinder is fixed on the holder with bolts inserted into the holes that are designed to attach the handle to the device.

The following photo shows how this design looks below.

How to make a pipe bastard with your own hands: examples of the best self.use

Next, the “native” casing of the corner grinder is removed, and instead of the disk, either a fishing line for a trimmer or a metal disk knife is installed.

By the way, you can fasten the holes for fastening the handle (bar) itself, when you want to make a simple trimmer for grass, which is easily assembled and is also easily versed if you need to use the corner grinding for its intended purpose.

To make it more convenient to hold a trimmer for grass in his hands during work, and it did not rotate around the axis of the bar, you can attach a side hand made of a bent pipe to it.

Read also: Why do you need a gas burner

The principle and effectiveness of the weeding method

Weeding as a cultivator processing aims to destroy the weed by weed by exhausting. plants after processing need time in order to recover and gain the desired force. At this time, potatoes or other vegetable crops will be able to continue successful growth.

The weeding of potatoes with a trimmer is usually carried out by three methods:

- sparing weed grass with a mowing head or disk nozzle;

- cultivator processing with a drum nozzle;

- Cultivator processing with saber or disk nozzles.

Speasing is usually carried out when weeds reach a height of 7-10 cm. In this case, only the part that is above the ground is mowed, and the roots remain in an untouched state. Usually after this begins rapid growth of green mass, so that the effectiveness of such processing is small.

When the weeding with a trimmer is carried out using a drum cutter, the roots of weeds are also processed.

A big plus of this method is that the upper soil layer is scared, and thus increases the air exchange of soil.

The effectiveness of this method is much higher than a simple weeding manually or work by a mechanical cultivator. The drum mill allows you to loosen the soil to a depth of 3-5 cm.

When using saber or disk nozzles, effectiveness increases even more-the processing depth increases to 5-7 cm. At the same time, the roots of plants, like the green mass of weeds, are repeatedly grinded, which contributes to the rapid decomposition of plant residues in the ground.

After such a weeding, repeated weeding is usually carried out after at least 10-14 days. True, there is one nuance that needs to be taken into account. when working with drum mills, the width of the processed strip is about 30 cm.

, But when working with saber or disk mills, the width is no more than 15-20 cm.

Pros and cons of the method

Weeding a trimmer of the garden, and even more so the site on which the potato grows has its own characteristics and specifics. First of all, you need to pay attention that for work you need to choose the right tool.

It is preferable to choose powerful four.stroke engines as a working engine. Such motorcycles have a lower gasoline consumption and greater performance compared to two.stroke.

Nazadka-cultivator for a trimmer for grass: nuances when working and mounting methods

Owners of suburban plots and houses often buy a gasoline trimmer for grass with a rather powerful autonomous device that can cope with all kinds of agricultural work.

And given that manufacturers often equip the tool with various useful nozzles, for example, bluffs, grinders and bush cutters, then working with such a device becomes one pleasure! In today’s material, we will not deal with the features of the work of various nozzles, but let’s talk about one specific solution-about the nozzle-cultivator for a trimmer for grass.

Mounting methods and design

Modern nozzles-cultivators can be performed in two performance:

- Toothache, in which cutters are located sequentially on the shaft;

- Disk, when several cutting discs act as cutting organs.

Despite different names and designs, by and large the fundamental difference is only in the form of a loose knot.

Rosted nozzles for a trimmer for grass differ in a smaller mass, and therefore are better suited for processing light soils. As for disk models, they are used to loosen more heavy soils, as they have greater stiffness.

The torque is transmitted to the nozzle-cultivator from the engine thanks to the shaft, which is combined by means of a special bar. The latter, unfortunately, often has to buy separately.

The unit under consideration cannot be called interchangeable, while the number of slots on the end part of the bar may vary from 7 to 9. Based on this, buying a cultivator nozzle, for example, from Oleo-Mac it is worth knowing that it is not suitable for working with the Husqvarna trimmer, as vainly.

The slotted method of fixing the cutter or disks to the shaft provides for a free displacement of the cutting organs, so that the soil will be loosened with a fairly wide coverage-200-250 millimeters.

This option is perfect for the purpose of cultivating the Earth on the site, since it eliminates the large amplitude of the bastard of the bar during operation.

In addition, this method allows you to reduce or completely abandon restrictions on the density of the beds.

When processing long beds, the process of working with a nozzle and a trimmer becomes even more convenient, since in this case you will have to make turns much less often.

Nuances when working with a cultivator nozzle

It is important to emphasize that any kind of nozzle significantly increases the mass of the entire tool as a whole, and weight growth is often at least 5-6 kilograms.

That is why prolonged work with a trimmer in this case becomes far from far from everyone! In a series with this, when choosing a nozzle, it is important to consider mechanical restrictions on the power of the device drive.

For example, if you have chosen a model of a trimmer for grass with a engine of less than 1,500 watts, then when processing the soil, you will have to limit yourself only to hilling of potatoes and beds, since it will be possible to work only with regularly loosened land!

Since the drive bar has a considerable length, and the drive itself in trimmers operating on gasoline is usually placed behind the worker, then in the process of cultivation of the work they are accompanied by noticeable vibrations, the value of which can vary depending on the load on the cutters and wheels, as well as the length the bar itself.

Through the shoulder belt, the vibration data are transmitted directly to the person’s hands, and therefore it is difficult to hold a considerable node and at the same time control the button of soil cultivation is difficult.

Given this, it is important to emphasize that prolonged soil processing with a cultivator nozzle does not always remain safe for human health.

But there are advantages: so increased mobility of a hinged gasoline trimmer for grass with the absence of wheels makes it possible to easily work with soils on rows and beds without damage to already planted plants.

It is important to note that the cultivators “getting bad” with the cave-free soils, since when the first is the first to introduce into such a layer, the bar is sharply thrown back.

Taking this into account, many manufacturers equip disc cultivators with special safety covers, so there is a more chance that the toothed mills are more likely to bother than break.

However, in the latter case, at least a small protective panel for the legs will not be superfluous.

The presence of the safety screen significantly reduces the visibility of the employee!

Is it worth making a nozzle with your own hands?

The cost factor of the finished product is able to have a strong influence in the final choice, meanwhile to purchase a new nozzle-cultivator in the store or save and do it with your own hands. High-quality models for a trimmer for grass can be evaluated at 11-20 thousand.

This cost can only be justified if you assume large volumes of work with the tool! In addition, it is not worth buying an expensive device if there are heavy soils on the site, for example, loams and chernozems, since in this case the cultivator will not raise the ground, but it will only transfer the Комментарии и мнения владельцев to different places along with the roots of grass and weeds.

Choosing a nozzle, it is worth understanding the care technology: so the first thing you need to go through a nozzle-knife, breaking off all vegetation in the garden, after which you can proceed directly to loosening the earth!

Before you finally decide to make a chamber nozzle with your own hands for a trimmer for grass, you must first take into account the following points:

- The execution of the handle. The long-term practice of using tools and research has shown that the most convenient in the work was and remains a T-shaped handle that provides the most reliable and accurate direction. The handle used in some gasoline trimmers in the form of the letter “j” significantly complicates the work with the cultivator nozzle;

- The dimensions of the fuel tank. Since the nozzle for a trimmer for grass will be made of improvised materials, the overall level of fuel consumption will increase. Therefore, it makes sense to organize a tank with a capacity of at least one liter of fuel;

- Drive power, which should not be less than 1000 watts. Otherwise, the engine will often overheat, which will lead to a low productivity of the device;

Trammer trammer for grass

For many summer residents of weeding weeds, it is a problem especially if the site has been purchased recently, and before that it has not been processed a couple of years. And often gardeners dream of a mechanical pull. It will not be difficult to make it if there is a trimmer for grass. Such a nozzle is attached to the trimmer according to the principle of a trimmer knife.

Production of nozzles-straps

From a dense sheet of iron (better stainless steel), cut a circle, there should be a landing hole in the center, and holes must be drilled on the entire surface. To fix the sharpened bolts with a washer and nuts in them. It turns out a design resembling a hedgehog. These very thorns-bolts will be weeding.

Advantages and disadvantages of the nozzle-cultivator

The prefix-cultivator for a trimmer for grass is becoming more and more popular among customers. Here are some advantages of this device:

- Simplicity in maintenance.

- Noticeably cheaper in comparison with equipment for a motorbike.

- Such a cultivator is simply indispensable for those people who have many greenhouses. Using this device, you can quickly loosen the ground in the greenhouse and saturate it with oxygen.

- The design is made very high quality, which makes it possible to use the cultivator for a long time.

- Protective shield. Protects from the garbage of the operator.

There are not so many disadvantages:

- Each nozzle weights the structure, with prolonged work, a person will feel fatigue.

- You need to select a nozzle and a trimmer for grass with the same connecting nodes.

- Due to vibration, control the button of the trimmer switching for grass and holding a difficult unit is often uncomfortable.

Important! The model of the cultivator nozzle should be produced by the same company as the trimmer for the grass. If the loosening tool is produced by Husqvarna, and the lawn mower is Oleo-Mac, then it will not work to process the soil: the nozzle simply cannot be attached.

Varieties of cultivators

Tornado

Tornado is the simplest version of the cultivator, which can be made with your own hands. Outwardly it looks like a corkscrew, which is fixed on a vertical tripod. The design is equipped with a horizontal handle on top. For its manufacture, use simple pitchfork and nozzle for the cuttings. You can buy a nozzle at a hardware store. It has the shape of a handle and is used to work with forks and shovels.

- In the cultivator, the handle should be long. Therefore, the nozzle must be increased. For lengthening, use a plastic pipe, slightly larger diameter than the thickness of the plastic nozzle. The length of the pipe should be about 0.5 m. So that the pipe can be put on the handle of the handle, it is carefully cut along and twisted.

- The pipe is chopped with island. Fixed, during operation it will not slide, and jump from its place. The finished handle on both sides will turn out protrusions about 25 cm long.

- Using a simple hammer, the teeth of the foriles are changed under the shape of a corkscrew. Stronging strong blows to metal teeth, they will begin to bend in the necessary direction. Original photo of the cultivator, help to repeat its exact bends.

Cultivator from a bicycle

The design of this manual cultivator is more complicated. It is made from parts of the bicycle: frames and wheels.

- A do.it.yourself cultivator head from sharp metal rods is fixed on a bicycle frame. As a head, you can take a part from the old cultivator. From a small plow create a frame of the device.

- From a metal or aluminum pipe with a diameter of 2 to 2.5 cm, the handle is built.

- All compounds are rigidly fixed by bolts. Structural elements should not hang out.

- A medium.sized wheel is fixed on the frame. As fasteners, barashika nuts or simple counter-hacks are used as fasteners. The wheels are too large or small do not fit here.

The cultivator is designed to remove weeds. It processes a row.

Disk rotary equipment

The disk rotary cultivator is designed for harrowing, and alignment of the surface of the earth. They are good to break large soil pieces. Assembly of technology:

- Convex spherical disks installed in the cultivator is the main working tool. It is very difficult to make discs yourself. Metal plates with a thickness of 44 mm from a simple form, you need to make a spherical. Stronging strong beats with a hammer in the center of the plate, they knock out the bowl. Convex discs are obtained. Ready elements are welded to the axis dressed on the axis.

- The axis is inserted into the brackets and fixed with chlobs.

- A special ledge is located in a large bracket. A pipe with handles passes through it.

- Rod, 24 mm in diameter, 25 cm long to a small bracket.

- A 16 mm thick rod is screwed into the rod. A small part of the rod will protrude above the crossbar.

The angle of disk installation can be adjusted using a barashka nut, which is installed on the crossbar. Turning the nut, the rod will rise up and the big bracket bend, changing the direction of the disks.

Cultivator from a meat grinder

In addition to the manufacture of manual devices, you can assemble an electric model yourself. The design of the cultivator assembled from a meat grinder is very simple.

- For the manufacture of handles, two corners are screwed to the gearbox, and two pipes are welded to them.

- For convenience, the ends of the pipes are bent, and a suitable segment of the pipe is welded between them, which will create an additional strength to the handles.

- Wheel axis is welded to the corners. The size of the wheels choose the average.

- The nozzle from a meat grinder is beaten with a sledgehammer until the sleeve becomes cast.iron.

- The shaft is pulled out of simple scrap and set it in the nozzle. A screw-zaucard screw is also welded here.

- To make a cultivator conveniently turn on and off, the engine switch is installed on the handle.

If you need to do neatly loosening the earth, the cultivator is slowly moved. Grury plowing is obtained with the rapid movement of equipment, while the earth is soldered by large Комментарии и мнения владельцев.

From a chainsaw

The basis of the design is the engine from the chainsaw. Additional details that you need to buy: a metal corner, a tube and fuel tank, wheels, a moped star and a star with 41 teeth.

- From the metal corners we make a frame size 32 × 32 cm. The shape of the frame should resemble a cube. The engine is installed on the transverse corners, and the fuel tank below the brackets. Intermediate shaft. mount on vertical corner racks. Bearings are attached to the longitudinal corners. They are designed for the running shaft. The same.based tractor with the center of gravity on the wheel is ready.

- Handles are made from a pipe with a diameter of about 30 mm.

Stars for the intermediate and running shaft, as well as the rest of the parts are collected in a single mechanism. The garden cultivator is ready.

How to make a manual cultivator for processing a row

To process narrow places between the rows, first of all, the cultivator must be compact. For such work, a manual device called “hedgehog” is well suited. Having all the necessary details, it is easy to make it yourself. For the assembly of the “hedgehog” you will need: the bracket of the P-forms with holes, shaft, stalk and wheels with metal spikes.

- So that the one.axic tractor easily moves around the site, you need good wheels. To do this, take a medium.sized steel pancakes and weld metal spikes to them. The spikes are easy to make, you need to sharpen the fittings in the shape of a cone.

- Ready cutters put on the axis.

- The axis is inserted into the bracket and fixed on both sides.

- The mount is welded to the end of the bracket and the stalk is inserted.

The technique is collected and ready for cultivation and weeding between rows.

From a trimmer for grass

A made cultivator from a trimmer for grass with your own hands will help to quickly and easily and easily and easily. You can assemble it from improvised materials: a working gasoline trimmer for grass, corner grinding or welding, garden forks, steel tubes.

Advantages and disadvantages of the nozzle-cultivator

The prefix-cultivator for a trimmer for grass is becoming more and more popular among customers. Here are some advantages of this device:

- Simplicity in maintenance.

- Noticeably cheaper in comparison with equipment for a motorbike.

- Such a cultivator is simply indispensable for those people who have many greenhouses. Using this device, you can quickly loosen the ground in the greenhouse and saturate it with oxygen.

- The design is made very high quality, which makes it possible to use the cultivator for a long time.

- Protective shield. Protects from the garbage of the operator.

There are not so many disadvantages:

- Each nozzle weights the structure, with prolonged work, a person will feel fatigue.

- You need to select a nozzle and a trimmer for grass with the same connecting nodes.

- Due to vibration, control the button of the trimmer switching for grass and holding a difficult unit is often uncomfortable.

Important! The model of the cultivator nozzle should be produced by the same company as the trimmer for the grass. If the loosening tool is produced by Husqvarna, and the lawn mower is Oleo-Mac, then it will not work to process the soil: the nozzle simply cannot be attached.

Lawn mowers and trimmers for grass. review

You involuntarily compare with bright pictures from design catalogs and you feel. not that. Few people understand that a good appearance creates not so much a beautiful house as a neatly ennobled area. Among the elements of landscape design, the lawn took a special place. Perhaps no other detail can change the overall impression of the site so much, except that a reservoir or night backlight.

It would seem that the lawn is a simple matter: he sowed the grass, and let it grow, turns green. Only in practice everything turns out to be much more difficult: you need to “guess” with seeds, to sow them correctly and in time, regularly water the shoots, and even cut it from time to time.

Cutting, of course, a lawn mower. The usual “grandfather” braid for the grass is not an assistant, because you need to cut the stems at the same level, withstanding the same height along the entire area of the lawn. The grass is usually stunted, mowing it is inconvenient, dreary and physically difficult, and if there is no experience, then you should not try. Therefore, in order to maintain the site in order, you will have to go broke on the lawn mower, the benefit of the choice is wide and you can choose the model in terms of means.

Probably, the word “lawn mower” today will not surprise anyone anymore. Even the most distant people from the summer cottage know very well what this miracle of technology looks like: a sort of vacuum cleaner, put on large wheels and equipped with a long handle. The thing, by the way, is quite massive and clumsy. Such a lawn mower is good for large areas with a relatively even relief, but cut its places around the shrub, foundation, benches or flower beds. troublesome. Sometimes you have to stop the “Taratai” and pump the grass manually, a sickle.

For sites with a complex relief there is a more convenient technique. a light electric trimmer for grass. The people are often called the “electrocosa”, and the gasoline models. “motorcycles” or “benzokos”. There is a certain confusion with the names: some sellers call the trimmer almost any lawn mower, some. only manual braids for grass with the upper engine. In general, the word comes from the English “trim”, which means “haircut”, and in the outdated meaning. “hairdresser”. That is, in principle, any lawn mower is suitable for this name. For simplicity and clarity in the text, we will use the word “trimmer for grass” in relation to any mechanical braids. The main types of trimmers

Choosing the right cultivator for your farm

By type of engine, trimmers for grass are divided into two types. The braids for grass with an internal combustion engine operate on gasoline (usually AI-92), for which they are nicknamed “motorcycles” or “benzoocos”. There are also models operating on electricity (“Electrics”). In this case, the engine weighs less and can be “upper”, that is, fixed on the upper part of the bar.

Both gasoline and electric trimmers for grass, as usual, have advantages and disadvantages, so you need to choose based on your own needs and preferences. In general terms, the differences look as follows.

- less noisy;

- do not consume gasoline, do not give an exhaust;

- Less weigh, there are light “manual” models for haircuts in hard.to.reach places of the site;

- They are not afraid of wet grass (models with the upper engine), so you can cut even by dew and after rain;

- have relatively small power (up to 1100 watts);

- quickly overheated (it is necessary to periodically give the engine to cool);

- depend on the power source, you have to pull the wire behind the mower (though there are models on batteries with a small supply of energy).

- more powerful (modern models have a very solid 4-cylinder engine);

- completely autonomous (do not depend on the presence of a rosette nearby, the length of the wire, etc.D.);

- There are universals models to which you can attach a variety of nozzles;

- afraid of moisture;

- They are very noisy, plus they give a not very environmentally friendly exhaust;

- consume oil and gasoline, which uses to end at the most inopportune moment.

Knife workers and a petition loop to a trimmer

This, of course, is not about bandits, but all about the same trimmers. precisely, about their cutting heads, which are also different. There are three “standard” design solutions here:

a) a knife haircut (the model is equipped with a hard knife), b) a string haircut (the head cuts with a fishing line, cord string), c) a combined version (a trimmer for grass allows you to attach either a knife or a fishing line for a trimmer).

The cutting head of a trimmer for grass is equipped with a fishing line mainly for a “careful” haircut of lawns. A flexible cord string is not so sensitive to “clashes”: stones, branches and other obstacles will not cause harm to the fishing line, unless, of course, it is zealous. In turn, a fishing line for a trimmer does not injure the bark of trees and shoots of the bushes, so it is convenient for it to cut the lawn in the garden or park and generally in areas with complex relief, but soft herbs.

The width of confident capture of plants with string oblique can reach 45-50 cm. Some manufacturers produce a specialized cord for different types of grass and unusual “lotions”. For example, beloved by the wealthy “Husqvarna” (Husquarna), offers trimmer heads with manual, semi.automatic and automatic supply of fishing line, hard cord for hayfields, “Wisper” cord, t.e. “Whisper”) with a reduced noise level and others.

The knife can be plastic or iron. The plastic is quite tenacious, and it costs cheaper, and iron knives are indispensable for cutting tall and hard herbs, clearing the groomed area. Powerful gasoline motorcycles can quite successfully cut storms with a stem thick of 3-5 mm even in the fall, when it is rude.

One of the characteristics of the knife is the number of teeth (rays). The more of them, the more accurate and even more a mowed strip is obtained. 4- and 8-tozovar cutters have proven themselves well. Knives may have additional “specifications” by the type of lawn or design features. For example, the Khuksarnovsky Grass is well suited for harvesting hay of soft grasses, and the “multi” chips almost any, even hard, grass and grinds it.

The weaknesses of the metal knife. shock strength, sharpening and weight. The saying “found a braid for grass on a stone” for such cutting heads is still in force: in the rocky areas, the knife is quickly stupid, and from a strong blow it may crack. Due to weight, the load on the engine is larger, so in light trimmers iron cutters are ineffective. True, in recent years knives have appeared from a variety of alloys, including with low weight and increased strength. You can recognize them according to the prefixes “Heavy” and “Heavy Duty” (“Long service life”) in the name, but you will have to pay more for such a knife.