Do-it-yourself fracture mini tractor from a tiller

Frame and body

To build the frame, it is allowed to use metal pipes and corners. Bolts should be used as fasteners, but welding will be required to create a strong connection.

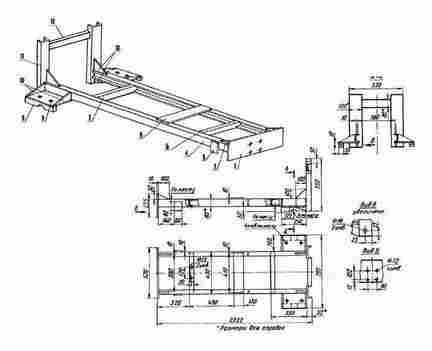

Drawing 1. structure frame

A mini tractor with your own hands can be equipped with a body. This will give the equipment not only a presentable look, but also protect the components from dust, mechanical and climatic influences. In this case, stainless steel sheets are used.

Assembly instructions

Having decided on the model of the tiller, you can proceed to its modernization. This instruction will be useful for owners of units “Centaur”, “Agro”, as well as “Zubr”.

Step-by-step instruction

Kinematic diagram of a mini tractor.

First of all, a kinematic diagram of the future minitractor should be developed. If you have some experience, then you can make such a scheme yourself or find ready-made options on the Internet. It is quite possible that you will be lucky enough to find drawings of alteration of a minitractor from a tiller for a specific model. This will greatly facilitate further work. In addition, on the Internet you can find a lot of video material showing the assembly and modernization of such units.

Instructions for assembling a mini tractor from a tiller

Those who are interested in how to make a mini-tractor from a Tiller Neva, Forte or from Bison equipment, you need to know that the manufacturer does not really matter, this does not affect the efficiency of the tractor. The main thing is to correctly develop a drawing and a construction scheme. Also, the owner of the equipment can use ready-made developments.

Homemade tractor drawing

Kinematic diagram of a mini tractor

Steering

At the next stage, you need to install ready-made elements: the steering rod, hubs and the axle on which the wheels are bolted. The first element must be installed on the rear axle.

That and the whole assembly. now you can start trial runs. It is important to run the machine on a level surface. Often it is necessary to additionally adjust the steering and wheel alignment. If there are no complaints, then you can attach attachments and go to field tests.

Not everyone is engaged in self-alteration of the tiller, since this process is painstaking and requires attention. And if you consider that there is already a ready-made design for a tractor from the Neva Tiller, then there is no point in this. But this is the case when you need to do small work.

If the work will be carried out on an uneven surface or a viscous type of soil, then you cannot do without a mini-tractor.

Required tools and materials

The first stage of work consists in drawing up the drawing and preparing the equipment. A diagram of nodes and mechanisms, if you have the appropriate skills, can be developed independently or you can use those presented below.

As for the accessories, ready-made factory conversion kits are suitable. in any case, they are cheaper than the mini-tractor itself. But this option is suitable only for those who do not want to save on absolutely everything.

Making a homemade tractor will become impossible without:

- angle grinder and discs.

- Fasteners and hardware (bolts and nuts).

- Channels and pipes with a metal base.

- Drill coming with drill sets.

- Welding equipment.

- Tool kits.

You cannot do without two suitable wheels, together with a hitch and a driver’s seat, steering gear, pedals, and the tiller itself. It must have a sufficient power level.

Heavy class diesel tiller. ideal for a homemade mini tractor.

Recommendations for choosing a tiller

The choice of the model of the original technical means must be approached with the utmost responsibility. Special attention should be paid to several characteristics:

- Engine power. a more powerful tiller will be needed to handle a large plot of land.

- Fuel. it is advisable to opt for models using diesel fuel. They are more economical and are great for working on large land plots.

- Weight. the lower this indicator, the easier it is to control the tiller. However, if the unit is the basis for a mini tractor, then preference should be given to more massive models.

- Cost. no need to focus on expensive units, because it is to save money that the tiller is purchased.

The basics of the technology of self-assembly of a mini tractor

The natural primary task will be a clear layout of the alteration itself, the need to install specific equipment for the shed, for example, a mower, a tiller plow or a blade for a blade, is being considered.

Briefly, the process of breaking a tractor with your own hands can be described as follows. we place the tiller on a frame that was previously equipped for this purpose and made by hand. The brake system is based on a drum type and the steering rack can be used from Zhiguli.

Below you can see a selection of photos of self-assembly of the tractor.

Mini tractor based on tiller “Zubr

If you have a high-power diesel engine with a Zubr tiller, you can do it yourself into a mini tractor. You must also have the appropriate tools, assembly instructions, photos (diagrams) and the following parts:

- frame;

- brake system (cylinder);

- footrests on which the pedals are placed;

- steering column with rods;

- front beam (assembly includes brake discs and hubs);

- rear fenders;

- hitch with manual lifting mechanism, assembled;

- wheels that will be installed in front (suitable from a Zhiguli car or other tillers).

Suitable tools include: hammer, drill, wrenches, welding machine.

Having collected all the above details with your own hands, you will get a homemade fracture mini-tractor from a tiller.

tiller “Neva”. the basis of a homemade mini tractor

If you decide to take the Neva tiller as the basis of your tractor, then be sure to choose it together with the coupling, and it does not matter whether it is factory installed or it was designed by hand. This will make it possible in the future to engage in the transportation of goods by hitching a trailer with a body. The comfort and convenience of the model will add attributes such as a steering wheel from a car, a car seat and pedals.

Of course, you can choose any tiller for the purpose of making a homemade mini-tractor, but it is still better to choose the Neva units. This is due to the fact that they are more reliable and powerful, and their volume can reach 8.5 liters. These properties guarantee that the mini tractor will be made with the least number of modifications.

The next step will be the manufacture of a dump adapter, which is quite simple to make, just having the necessary material, electric welding and an angle grinder. The trailer can be tilted and rotated, as it is provided by a special system of the frame fastening structure itself. The controls in the tiller are duplicated, which allows you to use the tiller as a separate unit, having previously disassembled the homemade mini tractor.

The practicality of this design makes it possible to operate a mini tractor for transporting not only building material (bricks), but also interact with loose soil components. The loader, which is designed for dumping and was installed earlier, makes it possible to dump soil to any place without limiting the choice.

To your attention a selection of high-quality video material on homemade mini tractors.

Do-it-yourself fracture mini-tractor: create an assistant

Making a homemade mini tractor

First you need to figure out exactly what a mini tractor is. This is a conventional tractor, which is constructed on the basis of a tiller. They come in 3 types: completely homemade, reworked with factory tools and manufactured at the factory.

Making Tiller Tines Out of Scrap Metal! DIY Rototiller Blades

How to self-assemble a tractor from a Centaur brand tiller

Naturally, the most durable, reliable and powerful version of the fracture tractor will be the model, the design of which was based on a professional or semi-professional trailer. Thanks to their use, the performance of the device and the resource of use increase.

One of the optimal types of such units is the Centaur tiller, whose diesel engine power reaches 9 hp. Of course, the decisive factor when choosing components, such as a tiller, will be the purpose and functions assigned to the tractor.

It is necessary to think in detail about the body structure, how it will be connected to the engine block. The body and frame are made using profiled pipes, and metal corners can also be used. When installing a powerful engine, the body can be made from a small trailer to a car or motor vehicle, only you need to take into account in advance how it will be attached to the tiller.

Advantages and disadvantages of a homemade design

In a crisis, the defining moment that affects many areas of life and industry is the issue of saving money. It is this circumstance that pushes many enthusiasts to independently manufacture not only mini tractors, but also other agricultural equipment.

Modern grain crushers are quite compact and energy-intensive, they are easy to use and delight their owners. Household grain crusher. ideal in terms of price and quality.

To facilitate labor and increase productivity, various types of manual cultivators have been created for cultivating the soil in the country. gasoline, electric, manual, light and heavy. By clicking on the link, get acquainted with the manual cultivator for summer cottages.

In the last decade, among summer residents and gardeners, an apparatus has become famous. a sprayer called “Beetle”.

Here is all the information about this wonderful device.

This fact, in many respects, becomes decisive, especially for rural areas, where there has been no employment for a long time, and, as a result, no money. All that people living in villages and villages have is their personal economy, which feeds them throughout the year.

Therefore, homemade units in rural areas will be popular for a long time.

In addition to the obvious cost savings, self-assembly has a number of advantages:

- Due to its compact dimensions, a home-made unit is capable of performing work in fairly small areas. Given that most private gardens are small, this circumstance becomes important, because the use of large-sized equipment, in this case, is inappropriate.

- A quick return on investment. literally in one season. This is a consequence of the savings on components that were described earlier.

- Quite good performance, which is demonstrated by a homemade unit.

However, no matter how you might want it, homemade mini tractors also have certain disadvantages that must be pointed out:

- When assembling, there is a certain problem of finding the right parts and spare parts.

- A consequence of the previous problem is the issue of repair, because if a certain part fails, it will be quite difficult to find it.

- Self-assembly requires certain knowledge in technology, as well as the ability to work with a welding machine and a lathe. In other words, the assembly is not suitable for everyone.

- Due to the fact that an all-wheel drive home-made mini tractor is made mainly from old components, this may affect the frequency of equipment breakdowns.

As we can see, there are a lot of disadvantages. But, at the household level, self-assembly becomes almost the only alternative, due to its relative cheapness.

Application area

Of course, the power of a home-made unit may be somewhat weaker, but at the level of domestic use, this fact is almost imperceptible.

The main area of application of this do-it-yourself unit is agricultural work. This term covers a fairly wide range, including many related works. In other words, a homemade mini tractor is needed for the following purposes:

- plowing of land holdings for the purpose of their further use;

- cultivation of the soil, as well as getting rid of weeds;

- soil harrowing;

- sowing operations on treated soil;

- planting and digging potatoes.

In principle, this is the main purpose of the mini tractor, for which it is made. But, its application can be significantly expanded if a special connection for additional equipment, mounted and trailed type is provided in its design.

If everything is done correctly, then your homemade product can additionally perform the following work:

- transportation of various goods (transportation of firewood, construction waste, etc.);

- snow removal in the winter season;

- mowing lawns and lawns, as well as making hay for livestock.

As we can see, the mini-tractor breaking the classic 4×4 with its own hands is able to significantly facilitate the life of any villager, because with the help of this technique it becomes possible to perform all types of work that are required with competent maintenance of subsidiary farming.

The indispensability of a home-made unit is also due to the fact that a minimum of investments and funds are used in its manufacture, which is very important for rural areas.

For more information about the operation of an all-wheel drive mini tractor, see

Do-it-yourself 4×4 fracture on VAZ bridges. four-wheel drive minitractor with Lifan engine. drawings and diagrams

Here all sorts of craftsmen appear who have adapted to make such units out of all the rubbish that they have in the garage.

What a careless owner would have thrown into a landfill, a savvy and resourceful person is able to make a completely workable device out of this that can perform basic agricultural work.

Quite popular among such craftsmen is the do-it-yourself 4×4 fracture mini-tractor, which is a rather bizarre design.

Instructions on how to make an all-wheel drive mini tractor with your own hands. drawings and dimensions

Having appreciated all the advantages, many are wondering. how to make a 4×4 mini tractor? In principle, this assembly method is not much different from traditional methods, except, perhaps, the structure of the frame structure.

Basically, the frame is solid, but in the breaks, an option with a breaking frame is provided, from which the name itself comes.

Speaking of drawings. This is probably one of the most important stages of the entire assembly, because the success of the entire design depends on the correctness of leaving a detailed drawing and determining the exact dimensions.

The fact is that the specifics of self-assembly involves the adaptation of some parts to the individual characteristics of the frame or power unit. This is understandable, because the components are taken from completely different equipment, which leads to their dimensional mismatch.

The adjustment itself is carried out mainly on a lathe, which in itself presupposes the presence of a detailed drawing. After all, it is much easier to make certain holes or grind, looking at the drawing, than keeping all this abstraction in your head.

So, having made a drawing, we proceed to the assembly process:

- The frame itself will consist of traverses and side members. The spars, in this case, have a three-stage structure. The first stage is made of channel number 10, and the last one is a square steel pipe with dimensions of 80 × 80 mm.

- The rear traverse is made from channel number 16, and the front one. from channel number 12.

- If you are converting a tiller into a mini tractor, then the main power unit will be the engine located on the tiller. If not, you will have to purchase the engine separately. In principle, any diesel engine of the required power (at least 12 hp) can be used.

- However, experts advise taking a more powerful one. a motor with 40 hp. and water cooling.

- The gearbox and power take-off shaft, as well as the clutch, can be taken from the GAZ-53 and GAZ-52 cars, respectively. They will not work ready-made, so you will have to modify them a little. To do this, you need to re-make the engine flywheel, cutting off a little from the back and drilling one hole in the middle.

- The bridge can be installed in the unit in the desired form without any manipulation. It is attached to the frame structure with four ladders.

- Wheels can be taken from old cars, but 18 inches is considered the optimal diameter. The process of installing the wheels on the hubs is quite simple. It is enough to cut a hole of the required diameter from the center of the disk, and the center of the disk from the ZIL-130 is welded to this place.

- The front axle is not so important, because it will not be the driving one. Therefore, you can take a bridge from another technique.

- The steering is best hydraulically assisted. You can take it from old agricultural equipment, but for its correct operation you need an oil pump.

- By the way, the driver’s seat must also be installed correctly, because a person spends not a single hour controlling the unit. The seat should be positioned so that the steering column does not rest on the person’s knees.

In general, the assembly of a homemade all-wheel drive mini tractor is carried out using third-party spare parts, among which, mainly, automobile.

In particular, the drum brake will be used in the front wheelbase system, and the steering rack will be borrowed from the cars of the VAZ family.

Other components can be freely found on the spare parts market, where there are quite a lot of useful things. In addition, on specialized sites there are a sufficient number of advertisements for the sale of parts that can be purchased for mere pennies.

Additional tips and warnings about the mini tractor

If you have enough money, you can buy some old Zhiguli, Oka, a tiller to use it as a “donor” for a future homemade mini tractor.

You can buy without documents, while it is quite used, therefore, which is relatively small, in comparison with a ready-made mini tractor.

The essence of this advice is simple: in order not to look for spare parts and parts everywhere, you can take everything from one machine, i.e. gearbox, clutch, etc. By the way, the car body can then be sold.

Also, an important point is the registration of a home-made unit in the traffic police. Of course, you can not do it if you do not plan to leave your garden, but for those who plan to use public roads, this action is necessary.

The fact is that a mini-tractor, even a home-made one, belongs to special equipment, therefore, it requires mandatory registration with the inspection. If these rules are not followed, the employee may impose a financial fine on you, and the vehicle itself may be removed to a parking lot.

And for the household level, this is the very thing, especially since there is an almost ideal combination of those manufacturing costs and the quality that is obtained at the output and the scope for the selection and manufacture of additional equipment (see do-it-yourself rotary tiller).

with an article about a mini tractor with a cabin.