Do-it-yourself ride from a walk-behind tractor

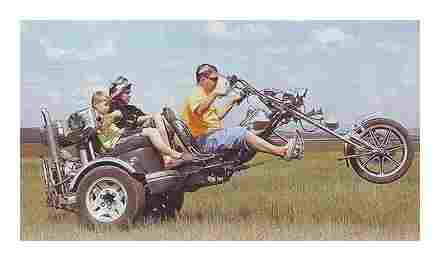

Delirium becomes a reality, do-it-yourself trike.

Andrey KATKOV, Chita region.,

Krasnokamensk

It is not the gods who burn the pots: it was the professionals who built the Titanic, and the trike is capable of creating an amateur.

Once on vacation, I ran into a crowd of onlookers and squeezed through it. What I saw led me to think: a fantastic film is being shot here! It did not fit into my head that the 3-wheeled yellow monster, to which the crowd pressed me. real. A pretentious bearded man, the owner of this miracle of technology, allowed me, crazy, to be photographed at the wheel of his helicopter. On that summer day my quiet life was over.

Within a month I brought to my garage the Zaporozhets I had just bought for 3000 rubles, or rather, what was left of it after 23 years of brutal exploitation. The poor man had less than a day to live.

From the car tore off the body, front suspension and other rubbish. the trike does not need it. Remaining: engine with gearbox, rear suspension parts, brakes, clutch actuator, part of the wiring and foam rubber from the seats.

Construction began from afar. from the search for a tank from M-72 and flashlights from GAZ-51. And since he aimed to build two trikes at once, he collected two sets. And as many as 20 flashlights were needed! How I looked for them, polished and chrome plated. a separate story: I spent more than a month of painstaking work on them. Probably, I was latently delaying a simple and understandable work. I could not decide how to approach the main thing: where and how to sculpt the motor. But as soon as I bought the cast rear wheels, a plan ripened in my head. And when I spread the rear suspension arms of the Zaporozhets, the wheels and the engine on the floor in the garage, everything finally, albeit schematically, fell into place. For hours I sat with a pencil over pieces of paper and drew sketches of the frame, traverse, brake mechanisms. In terms of drawing speed, I could compete with an inkjet printer (well, maybe with a small jet). I cleared all the nearby garbage dumps of suitable pieces of iron, bought a semiautomatic welding machine, a bunch of “grinders”, drills and other tools. Then he ran to the factory to turners and milling machines. At first, they hardly understood what I wanted from them. Soon the rear of the trike and the front fork were ready. when the work slowed down: the frame did not want to become what I imagined it to be. But the stagnation time was not wasted. brains were experiencing the torment of creativity, hands went over the motor and gearbox. And then the frame is “ripe”.

A friend helped me to lay the wiring. The motorcycle fuel tank remained fake, but I hid the real one under the passenger seat. However, it turned out that there was no room left for the battery. Rather, it was, but under the feet of the passengers. where the gearshift rod passes. How to be? I bent the rod around the battery with the letter P. and I’m proud of this trick!

The seat frames are bent from the water pipes. On top I glued foam rubber from the Zaporozhets seats and took it all to China (fortunately, he is nearby), where the local handy masters covered the chairs with leather. In China, I bought headlights, handlebars, air signals, “kengurin”, front shock absorbers, wardrobe trunks.

I assembled the mufflers myself. Housing. made of stainless steel, pipe. from the Chinese railings, lattice. from the KAMAZ air filter, tips. I don’t know why. The exhaust sounds pretty deep. The pedal assembly and mirrors are homemade too. The steering wheel is bent out of stainless steel. Receiver for signal too. withstands 10 atmospheres! But the nerves after the beep do not stand up to everyone.

I also set up music. In front, speakers are built into the fog lights. I installed the rear speakers in the wardrobe trunks. And, of course, I didn’t forget about the subwoofer. MR-3 head unit. flash player. I connected all this to a powerful amplifier. In the evening, the trike is illuminated with neon light.

Trike drove out of the garage door for the first time on its own. Feeling. inexpressible! Everything worked, everything turned on and switched. Where he was driving, commotion reigned: everyone honked, gave way, drove off to the side (some were driven onto the curbs). to examine an apparatus unprecedented in our area. Others screamed. persistently tried to find out how much I bought the trike. No matter how much they said that it was homemade, they seemed to be smiling knowingly: “Don’t fill it. “. Even when they recognized the engine from the “Zaporozhets” in the engine, they still did not believe.

And I needed to register the trike with the traffic police and get the numbers. Sent drawings of self-made assemblies, frame calculation, photographs and technical specifications to the Motor Vehicle Certification Center in Serpukhov. A month and a half later, the answer came: the motor vehicle meets the technical requirements and can be allowed to operate on public roads. Registration with the traffic police was quick. The crazy idea came true!

In the summer of 2006, at the international motorcycle rally “Facing the Ocean” in Vladivostok, my device took first place in the category “Coolest trike”.

General data: dry weight. 390 kg ■ length. 3780 mm ■ base. 2630 mm ■ seat height. 600 mm ■ total height. 1290 mm ■ width. 1580 mm ■ ground clearance. 220 mm ■ gas tank volume. 40 l. Engine. MEMZ 968 ■ working volume. 1197 cm3 ■ bore x stroke. 76 x 66 mm ■ power. 40 h.p. ■ carburetor. VAZ-2101 ■ fuel supply. fuel pump ■ air filter. VAZ-2101. Transmission: ZAZ. Chassis: frame. homemade ■ front suspension. lever, homemade ■ rear suspension. ZAZ. Brakes: front. hydraulic, manufactured in China ■ rear. ZAZ. Tires: front-3.25-19 “■ rear. 225 / 60-15”. Electrical equipment: generator. 350 W (ZAZ) ■ headlights and other lighting equipment. from different motorcycles.

Do-it-yourself all-terrain vehicle from a walk-behind tractor

How to make an all-terrain vehicle out of a walk-behind tractor? Very simply, we look at the photo, which shows in detail the design of an all-terrain vehicle on low-pressure tires, made from a conventional walk-behind tractor.

The all-terrain vehicle is an indispensable technique for a mushroom picker-fisher, as well as a hunter. On such a technique it is much easier to get to the cherished fishing places and hunting grounds, and you do not need to drag all the equipment on yourself, it can be loaded onto an all-terrain vehicle.

Not everyone can afford to buy an all-terrain vehicle, but everyone can do it with their own hands, if desired.

To make homemade products, you will need a walk-behind tractor or cultivator. The more powerful the engine on it, the faster the all-terrain vehicle will go. This walk-behind tractor is equipped with a 6 hp “Subaru” gasoline engine, and this power is quite enough.

The standard wheels of the walk-behind tractor will be too small, so you will have to make larger wheels. To do this, you can use cameras from trucks, this all-terrain vehicle has cameras from GAZ-66. For such cameras, you need to make homemade wheels as shown in the photo.

You will also need to make a trolley. an adapter for a walk-behind tractor. We attach a seat and a trunk for transporting goods and equipment on the trolley.

In the very design of the walk-behind tractor, nothing needs to be altered. The torque is transmitted from the engine to the reduction gear and to the axle with a pair of wheels. The power of the walk-behind tractor is enough to carry one person and a small load.

Low-pressure tires significantly increase the cross-country ability of the walk-behind tractor, it rides like a real all-terrain vehicle, through mud, swamp, snow and ice. The only thing you need to pay attention to is the wheel chambers, they are very easy to pierce. Some craftsmen wrap cameras with another layer of rubber or fire hose sleeves. In general, here you can experiment and improve your all-terrain vehicle.

Do you like the idea? Here is another home-made option. an all-terrain vehicle from a walk-behind tractor with tracks on wheels.

How to make a karakat from a walk-behind tractor with your own hands

No expensive materials are needed to make such a unit. It remains only to slightly adjust to the manner of driving this vehicle.

Consider how to make a karakat from a walk-behind tractor with your own hands. In the process of creating a karakat, the following stages can be distinguished:

- Frame fabrication. it is advisable to use a medium or high-weight walk-behind tractor (using a Neva walk-behind tractor is the best option for making such equipment), using this you will get a good quality all-terrain vehicle with three or four wheels. Some designers use spare parts from the Ural or IZH motorcycle as a frame.

- Suspension and Rear Axle Construction. The suspension structure consists of two parts connected by hinges. At the request of the developer, it is possible to design the front and rear suspension, ensuring their high independence.

- Production and installation of wheels is the most expensive and longest assembled part of a karakat.

- Most craftsmen do not buy ready-made discs, but use homemade products, which are tires and low-pressure chambers (it is preferable to use these products from trucks: Ural, KamAZ or from their trailers).

- Installation of the engine and systems (brake, clutch, output of combustion products).

Before assembling the karakat, it is necessary to draw up an approximate drawing of the proposed design. Examples of circuits are shown in the photo below. It is possible to construct a three-dimensional model of a karakat in various 3-D packages, for example, the KOMPAS-3D v18 program.

Before its full use on the off-road, the manufactured device should be tested. During the test, some design flaws may appear, and it will also be possible to assess the quality of control and ride comfort.

How to make a karakat and other homemade products from a walk-behind tractor

Many people ask how to make a karakat from a walk-behind tractor on your own. Now the craftsmen are trying to modernize any technique they come across and make something unusual. Every year there are more and more such people. Especially often craftsmen try to build all-terrain vehicles, one of the types is a karakat, which is built from an ordinary walk-behind tractor.

Homemade ATV from a walk-behind tractor

In addition to a karakat from a walk-behind tractor, you can also build a home-made ATV from a walk-behind tractor, which is a four-wheeled safe and maneuverable motorcycle.

The main thing is that it must be equipped with a high-quality motor.

But it is worth remembering that a homemade ATV will be quite maneuverable and hardy, like its original, but in speed it will be much inferior to it.

The simplest engine for an ATV is a walk-behind tractor. The process of transforming a walk-behind tractor into an ATV is carried out in 3 consecutive stages:

To create a good ATV, you need to draw up a preliminary drawing of it. Particular attention should be paid to the 4×4 all-wheel drive. Examples of drawings are shown below.

Tricycle from a walk-behind tractor

Consider how to make a tricycle from a walk-behind tractor. The creation of such a transport will differ quite a bit from the construction of an ATV. The only thing is that you can use a scooter or a motorcycle as a frame, and the walk-behind tractor itself will be located under the driver’s seat or immediately behind it. Similarly, the construction of a trike.

A tricycle is any three-wheeled vehicle from a bicycle to a car, and a trike is a three-wheeled motorcycle. At the same time, some experts claim that “trike” is translated from American English as “tricycle”.

The manufacturing sequence for a tricycle with an engine from a walk-behind tractor is similar to the above plans for a karakat and an ATV. There are several features:

- Optimal engine placement in front of the rear wheels approximately under the driver’s seat.

- The power structure is a motorcycle frame, which needs to be supplemented with reinforcements for structural rigidity and more spaciousness.

- As the front wheel, you can leave the standard one from the motorcycle. For the rear wheels from a scooter are ideal.

Examples of tricycle drawings are shown below.

Buggy from a walk-behind tractor

The buggy is a small, light enough vehicle designed for off-road driving. In the modern world there are many different modifications of such devices.

There is also a buggy with a walk-behind tractor engine. A do-it-yourself buggy is not created as often as the units discussed above. Since the buggy is more of a car than an ATV, more specialized parts will be needed to create it.

To create it you will need:

- trumpet;

- wheels from trailers, carts, scooters, sidecars or ATVs;

- wheel hubs, steering wheel, rear axle, brake disc;

- steering wheel, steering rack;

- braking system;

- springs, amartizers;

- walk-behind tractor;

- seat.

The proximity of the buggy scheme to the automotive design imposes certain difficulties. When making a buggy, you will have to independently assemble and configure the braking system, deal with the design of the suspension and drive the wheels. For the correct assembly and manufacture of the buggy, a preliminary drawing of the model should be drawn up. An example drawing is shown below.

The manufacturing process itself resembles previous homemade products.

So you can use conventional cultivators. Just a few additional parts, a little cunning, ingenuity and imagination, and you can make all kinds of ATVs with your own hands that are not afraid of ravines, hills or even swamps.

What type of transport would you prefer for DIY making?

Mini tractors. Homemade from a walk-behind tractor

Manufacturing a mini-tractor “by eye” or even according to ready-made drawings, as a rule, implies the need for modifications after the first tests. Not everything can be fixed only with a grinder and welding.

Often there is a need for additional turning or milling work. Often, a design that looks perfect on paper turns out to be unusable after manufacturing.

For those who want to create a homemade mini-tractor from a walk-behind tractor, but have no design experience, there is an affordable option. to purchase a ready-made conversion kit. It is not cheap, but all of its components are made in a factory. They are tested and precisely matched to each other and to the power plant.

This kit usually includes: a frame with mounts for the engine; secure seat; footrests with control manipulators; front beam with steering rods, wheel hubs and brake discs; protective fenders for wheels; hand-lifter attachment.

The owner, having purchased such a kit, can independently disassemble his walk-behind tractor into its components and, according to the scheme, mount all the parts on a new frame.

Attachments

Buying a walk-behind tractor without a hitch or with only one plow for plowing and turning the soil layer is in most cases impractical. A set of additional equipment allows you to significantly expand the capabilities of the unit.

In this case, it can be used for planting and harvesting root crops, for processing row spacings and hilling beds, for mowing hay, tedding it and picking it up. Trailed trolley with a seating position allows you to transport goods.

In winter, the walk-behind tractor can be equipped with a front scraper and use it to clear snow from the road. All equipment can be purchased, rather than using different homemade products. For the “Neva” walk-behind tractor, for example, the manufacturer produces enough attachments.

Choremaster Walk Behind First Ride

However, often the owners still alter it for themselves. For some, the factory hitch is not powerful enough and does not withstand loads, for others there are not enough adjustments to adjust it to work in certain conditions, and still others are simply used to making the tool themselves.

Homemade walk-behind tractor

Despite the fact that there is a sufficient choice (in terms of price and power) for small-scale mechanization on sale, there are sometimes original homemade products in everyday life. Not everyone can assemble a walk-behind tractor from scratch with their own hands. However, a person who is familiar with technology, who has the necessary equipment and components at his disposal, can make it himself. In some cases, such designs can even compete with factory samples.

The materials for the manufacture of homemade products are usually parts of their used motorcycles and all kinds of scrap metal. The engine can be used even from the Druzhba chainsaw. There are craftsmen who prefer motor scooter drives. Such motors have good forced cooling and can be used for a long time under loads even at minimum speed.

Motoblock. affordable mechanization for field work

You can solve the problem of processing a garden by using a walk-behind tractor and using attachments to it. With the help of such devices, it is possible at a sufficiently high level to ensure plowing and cultivation of the soil, preparing it for planting major crops, as well as harvesting. This saves time and labor costs, since manual digging and weeding even on six acres of a vegetable garden is not an easy job.

When working in a confined space and with an abundance of various crops on site, the operator should have good two-wheel drive skills. Do-it-yourself homemade hinges for a walk-behind tractor are made taking into account the experience of their use for specific economic conditions. Although such structures have an unpresentable appearance, they ensure the fulfillment of the main tasks.

DIY homemade motoblock

Complete equipment is not always suitable for business conditions. In order not to constantly cut off individual parts, not to weld stiffeners to strengthen the structure or additional brackets for fastenings, you can do everything yourself.

Even the plow and disc hiller are made by craftsmen at home. For this, one desire, drawing and material is not enough. Additional equipment will be required: a gas cutter, a welding machine, a grinder and practical skills in working with them.

DIY homemade products for a walk-behind tractor can be made using spare parts from old cars. The trailer can be made using the rear axle from the “passenger car”. If you throw out the gearbox and connect the axle shafts with a pipe, you get a reliable rear beam. Welding the frame and sheathing it with tin or board is not a problem. The springs can be taken from “Moskvich”. you get a reliable design with a decent carrying capacity.

A homemade scraper can be made from sheet metal 1–2 mm thick. If you weld stiffeners to a sheet curved along the profile, they can not only remove snow, but also be used as a bulldozer bucket for leveling soil or humus.

Advantages of a mini tractor

The walk-behind tractor is adapted for field work, but not everyone can manage it. For example, an elderly person who does not have good health will have to expend a lot of effort when maneuvering. Another point is the constant load on the legs. In order for the walk-behind tractor to work the soil, it must be driven “by the horns”.

Anyone who has ever worked with a walk-behind tractor on plowing, cultivation or other tillage, understands how much effort it takes to control it. Hold during a jerk, direct into a rut, turn around, take back. At the same time, do not get confused in the control levers and do not go where you do not need to. often this is work in the sweat of your brow. Many owners of walk-behind tractors, having tried such mechanization, sell their units without adapting to managing them.

Controlling a mini tractor is a completely different matter. Why walk around the field behind the machine, wasting energy, when you can operate it while sitting on horseback. The drive is the same, the speed is the same, but all this is sitting and without load. Homemade products from a walk-behind tractor provide a sufficient level of comfort. Control levers under the hands, there is a brake.

An additional pair of wheels, set at a sufficient distance (1–1.2 m), provides reliable support. Another advantage is the ability to transport loads in a trailed trolley or a body mounted on a rear driven axle.

Mini tractors. homemade products from the walk-behind tractor. Self-propelled from a walk-behind tractor

The benefits of a walk-behind tractor for gardeners and summer residents are invaluable. Still, it cannot be compared with the mechanization of work with a full-fledged tractor. Anyone who had experience with a walk-behind tractor must have thought about how to improve their uniaxial drive.

Some craftsmen even decide to convert it into a miniature four-wheeled tractor. Currently, homemade products from a walk-behind tractor can be found everywhere. Despite the fact that manufacturers produce quite a lot of attachments for them, our craftsmen alter them at their discretion.

Design features of the walk-behind tractor

Such an assembly consists of a drive, transmission, chassis and wheels. The walk-behind tractor is controlled using levers and rods mounted on the steering wheel. For light and medium-sized units, the drive is usually a gasoline internal combustion engine. Heavier motoblocks are equipped with diesel drives.

Lubrication, ignition, gas distribution, cooling, fuel delivery systems and a starting mechanism are mandatory. They have their own characteristics depending on the type of engine used as a drive for the walk-behind tractor.

The gearbox, clutch and gearbox (in some models also a differential) ensure the conversion of the engine shaft torque into the rotation of a pair of wheels. They can be pneumatic or weighted metal with additional lugs for work under load.

Homemade mini tractors from a walk-behind tractor have a seat and an additional pair of wheels. They can be controlled or driven. Depending on the design, the walk-behind tractor turns into a four-wheel unit with a drive on the rear or front axle.

Tractor undercarriage

The front wheelset is secured as follows:

- First, a part of the metal pipe is cut.

- Then the wheel hubs are fixed on this part.

- After completing the described steps, you need to drill a hole in the center. It is necessary to secure the frame.

When creating a rear wheelset, a pulley is attached to the axle, which is necessary to transfer power from the engine.

Assembling the frame

First, you need to supplement the walk-behind tractor with a second pair of wheels. This requires details such as a metal profile pipe and corners. The section of the products should be selected taking into account the loads for which the tractor will be designed. When choosing pipes, it is worth purchasing products with a larger wall thickness, since with a greater weight, the tractor is more efficient.

After drawing up a drawing of a homemade minitractor from a walk-behind tractor, all elements are cut with a grinder, and then connected by welding. You can fasten parts both by welding and bolting.

During the creation of the frame, you must immediately create a mount that will allow you to work with attachments. The mount can be installed on either the rear or the front of the frame.

Choosing a walk-behind tractor

Unlike a motor-cultivator, a mini-tractor allows you to work on a large area. At the same time, such a mechanism allows you to work the area with greater comfort than when using a cultivator.

But it is worth remembering that the unit must meet certain characteristics. If you do not take them into account, the mini-tractor will not be able to perform all working functions. When choosing a mechanism, attention is paid to the following characteristics:

- Product power. The larger the area that needs to be processed by the mini-tractor, the more the power of the purchased product should be.

- The type of fuel used. It is better to purchase devices that run on diesel fuel. This is due to the fact that the engines of such motoblocks can more easily cope with soil cultivation in large areas. It is worth noting that they use less fuel.

- Weight. If the walk-behind tractor is purchased for use as a separate device, it is worth giving preference to models that have less weight. But when choosing a mechanism for creating a mini-tractor, you need to look closely at models with a large weight, since if the machine is light, it will not be able to process hard soil with high quality.

- Cost. It makes no sense to choose the most expensive walk-behind tractor, since this mechanism is purchased in order to save money. Many inexpensive models are suitable for building a quality mini tractor.

Several common motoblocks are suitable for all these parameters:

- “Zubr”.

- “Neva”.

- MTZ.

- “Centaur”.

If you wish, you can find a kit for converting a walk-behind tractor into a mini tractor. This will allow you to assemble a reliable structure without looking for materials and creating a frame yourself.

It is worth noting that the Agro walk-behind tractor has a drawback, which is insufficient axle fracture strength. To prevent damage to the mini-tractor when using this walk-behind tractor, it is necessary to strengthen the problem area. This can be done by installing wheel reducers. Before you make a mini tractor from a walk-behind tractor, it is worth learning about the most common products that are being altered by the owners of the plots.

Tractor engine and accessories

Most often, the engine is located on the front of the frame, and the seat is installed in the back. At the place where the engine will be installed, a fastening system of metal pipes is created in advance.

Only after the engine is installed and secured to the frame, the brake system and hydraulic valve are installed. The second element is required to secure attachments. If the tractor will move on roads, it is necessary to install parking lights and headlights on the structure.

Tools

For the listed units, the process of assembling homemade mini tractors from a walk-behind tractor is the same, so the owners of such units can follow the same rules.

Before you start, you should prepare all the tools in advance and think about what parts will be needed to create a tractor. The easiest option is to purchase a ready-made kit for such devices. Converting a walk-behind tractor into a mini tractor is carried out using the following tools:

- grinder with discs for cutting metal;

- electric drill;

- welding machine;

- fasteners.

Motoblock “Zubr

Like the previous specified walk-behind tractor, this unit is equipped with a diesel engine. Re-equipment of a walk-behind tractor into a mini-tractor will require the use of the following elements:

DIY mini tractor from a walk-behind tractor

Despite the fact that the cultivation of the land with the help of a walk-behind tractor is fast enough, it is more efficient to use a mini-tractor. But factory models are quite expensive, so many site owners create such designs on their own. To do this, make a mini-tractor from a walk-behind tractor with your own hands.

Motoblock “Centaur

This unit belongs to professional tools, so you can make a tractor from it, which will be distinguished by high performance. Engines with a capacity of 9 horsepower are installed on such motoblocks.

To make a mini tractor with your own hands, you just need to make a metal frame on which the second wheel pair will be fixed. Such products can be equipped with a trailer for the transportation of various goods.

How can you make an ATV and a tricycle?

If we talk about an ATV, then it is important to know that this is a fairly powerful four-wheeled motorcycle. It has a high speed, and you can drive such a unit anywhere. One of the most important parts in it is the motor. That is why ATVs and tricycles, converted from motoblocks, have shown themselves perfectly. For this, you can use any model, however, motors from the “Neva” are best suited.

In order to make such devices with your own hands, you do not need to redo the walk-behind tractor especially. The only thing you need to get or do yourself is the drawings. After that, you can proceed to the alteration itself.

The work can be divided into several stages:

- first you need to expand the wheels;

- further. you need to install more powerful wheels;

- after that, you should deal with the frame.

After that, you can start altering the frame. For an ATV or tricycle, you can take a frame from a bike or motorcycle. If it is not there, then any cuttings from water pipes may do. You can attach such a frame with two pins, using a pivot hinge for this.

Then you can start installing the wheels. First, you need to determine which disks you can use. Discs taken from a car will work best. It is necessary to take rubber with a low profile so that it fits more tightly to the disks themselves.

By altering the walk-behind tractor in this way, as a result, you can get a wonderful device that can move on any road, and the costs will be completely small.

Other rework options

In addition, it will also be possible to make other equipment from the walk-behind tractor. For example, you can get a dumper, pneumatic drive or vibrating plate. Also, some craftsmen make a loader or snowmobile from a walk-behind tractor. Many people use walk-behind tractors for harvesting corn.

We make a wood splitter

Among other things, a wood splitter can be made from a walk-behind tractor. To do this, you need to carve a cone on a special machine, as well as a thread. After that, the already finished cone must be mounted on a shaft that has suitable bearings. Then a flange and an asterisk must be installed on the end of the shaft. It can be taken from the wheel of a motorcycle.

You can fix the cone to the shaft with a bolt. After that, a spacer made of pipes, as well as a pair of nuts, must be installed between the motor and the shaft itself. This will help tighten the chain. In order to make supports for the shaft, you can take supports from the Zhiguli. The motor must be taken from the walk-behind tractor. With this redesigned structure, you can easily cope with the splitting of firewood.

Tips for making a karakat

To assemble a homemade karakat, first you need to decide which technique you can take the frame from. A frame taken from a Ural motorcycle is perfect. Next, you need to make a suspension, as well as a rear-wheel drive. Then you need to use a corner to connect the steering column, side members and a special bracket.

After that, you can start attaching the wheels. You can take rubber from cars such as “Ural” or “KamAZ”. The last is the motor from the walk-behind tractor, as well as all additional systems. it is necessary to connect the brakes and the clutch, and also to take up the system for the emission.

After assembly, it is imperative to test the made karakat. With the help of such a homemade all-terrain vehicle, you can easily drive even to swampy places.

Converting a walk-behind tractor into an ATV, a karakat and other equipment

- What materials may be needed?

- How can you make an ATV and a tricycle?

- Tips for making a karakat

- How to properly design a mini tractor?

- We make a wood splitter

- Other rework options

- Snowmobile

- Motorized towing vehicle

- Excavator

- Motobur

- Motor winch

Those who created motoblocks did not even know what folk craftsmen could transform them into. And the latter did their best: from ordinary motoblocks they were able to make not only ATVs, but even snowmobiles and tricycles.

Excavator

As a result of the alteration, such a technique will turn out to be quite compact and convenient. However, to cope with this work, you first need to make drawings. All work with drawings must be done in great detail. this will greatly facilitate further work. After that, you can do the design itself. First you need to make a frame, you can use a channel. After that, you need to attach the beam (up to 11 meters) to the frame. Springs and springs are not needed. For a simpler option, you can use a homemade axle on which the wheels are mounted. The result is a chassis. Further, using a special machine, it is necessary to grind out all the mechanisms that are needed for movement, as well as brackets and mounts for hydraulic cylinders.

When all the parts are purchased, you can start assembling. Then it is necessary to connect the power take-off shaft of the walk-behind tractor, as well as the oil pump through the cardan. After that, you need to connect all the hydraulics with high pressure hoses. Further. the finished structure must be painted, as well as all the details must be lubricated, after which it must be tried in work.

How to properly design a mini tractor?

Breaking a walk-behind tractor into a mini-tractor is carried out in several stages. First you need to tackle the frame. It is made of durable metal, which is cut into pieces of the required length, and then welded together. When the frame is ready, you can start assembling the undercarriage.

If the motor is placed in the front, then the width for the wheels can be left the same as in the walk-behind tractor. In order to attach the wheels to the back, you will need an additional axle. It is made of the required length, an ordinary piece of pipe is suitable for this, the main thing is that the width fits. Bushings and bearings must be installed at the ends of the pipe. Then you can install wheels on them.

If the motor is decided to be located at the back, then the width of the wheels must be increased, otherwise the mini tractor will not have the necessary balancing. So, you need to remove its wheels from the walk-behind tractor, after which you need to make the bridge a little wider.

To operate the mini tractor, you can take the handles from the walk-behind tractor. However, this will make the converted tractor look like a motorcycle, and it will be a little awkward to drive. For convenience, it is better to install a regular steering column.

DIY Ground Driven Mower From JUNK!

The driver’s seat can be made from a sled frame that needs to be welded. In addition, one must not forget to put the headlights, as well as the dimensions. After the complete assembly of the minitractor, it is imperative to lubricate all the parts, as well as run it in.

From all this it follows that almost every person, even a little familiar with the technique, can convert a walk-behind tractor into a mini-tractor.

Motorized towing vehicle

Sometimes, when buying a factory motorized towing vehicle, you have to face many disadvantages. Therefore, most often they are made by hand. They turn out to be strong enough if you use a walk-behind tractor for this. This design will do its job perfectly, and will also save fuel. In addition, it will be possible to attach compartments to such a structure in order to fold the necessary tools.

Tips for making a karakat

To assemble a homemade karakat, first you need to decide which technique you can take the frame from. A frame taken from a Ural motorcycle is perfect. Next, you need to make a suspension, as well as a rear-wheel drive. Then you need to use a corner to connect the steering column, side members and a special bracket.

After that, you can start attaching the wheels. You can take rubber from cars such as “Ural” or “KamAZ”. The last is the motor from the walk-behind tractor, as well as all additional systems. it is necessary to connect the brakes and the clutch, and also to take up the system for the emission.

After assembly, it is imperative to test the made karakat. With the help of such a homemade all-terrain vehicle, you can easily drive even to swampy places.

Tips for making a karakat

To assemble a homemade karakat, first you need to decide which technique you can take the frame from. A frame taken from a Ural motorcycle is perfect. Next, you need to make a suspension, as well as a rear-wheel drive. Then you need to use a corner to connect the steering column, side members and a special bracket.

After that, you can start attaching the wheels. You can take rubber from cars such as “Ural” or “KamAZ”. The last is the motor from the walk-behind tractor, as well as all additional systems. it is necessary to connect the brakes and the clutch, and also to take up the system for the emission.

After assembly, it is imperative to test the made karakat. With the help of such a homemade all-terrain vehicle, you can easily drive even to swampy places.

Motobur

Many fishermen no longer want to go fishing with a conventional drill, so some of them decide to convert the walk-behind tractor, which is not needed in winter, into an ice ax. You will not need to apply special efforts for this. You just need to rearrange the wheels of the “Zhiguli”, as well as make a nozzle to set the drill in motion. Then you can safely go fishing. In the summer, the walk-behind tractor will be used again for its intended purpose.

What materials may be needed?

To remake a walk-behind tractor, you will need simple tools, as well as drawings. Only when everything you need is at hand, you can start work on the alteration.

Tools you need:

How to Attach a Tiller to a Riding Mower

- a set of keys, as well as drills;

- electric drill;

- welding machine;

- Bulgarian;

- different elements for fasteners;

- screwdriwer set.

Motorized towing vehicle

Sometimes, when buying a factory motorized towing vehicle, you have to face many disadvantages. Therefore, most often they are made by hand. They turn out to be strong enough if you use a walk-behind tractor for this. This design will do its job perfectly, and will also save fuel. In addition, it will be possible to attach compartments to such a structure in order to fold the necessary tools.

We make a wood splitter

Among other things, a wood splitter can be made from a walk-behind tractor. To do this, you need to carve a cone on a special machine, as well as a thread. After that, the already finished cone must be mounted on a shaft that has suitable bearings. Then a flange and an asterisk must be installed on the end of the shaft. It can be taken from the wheel of a motorcycle.

You can fix the cone to the shaft with a bolt. After that, a spacer made of pipes, as well as a pair of nuts, must be installed between the motor and the shaft itself. This will help tighten the chain. In order to make supports for the shaft, you can take supports from the Zhiguli. The motor must be taken from the walk-behind tractor. With this redesigned structure, you can easily cope with the splitting of firewood.