Drilling holes for dad in a log. The form

DIY s for timber: how to drill, fix, dimensions

Today we will analyze what is it. Nagel and how to install the dumbfounds. Nagel from German Nagel means a nail.

The walls of any wooden house, even built of high.quality and well.dried profiled beams, are prone to small shrinkage and deformation. The guilt of this is the residual moisture, the inclusion of heating devices and the suction (twisted fibers) of wood. To avoid the consequences of the drying of the tree in the form of unattractive interventional cracks, the builders use the bastards.

Therefore, the nagel serves to connect any materials, in this case, the tree. Nagel is a pin and prevents the displacement of individual elements relative to each other. Can be round or square, made of metal or wood. The main condition of the nagel should be smooth. The use of reinforcement, especially corrugated, is unacceptable.

So what to choose metal or wood? The main purpose of the bastard is to prevent the beam with bend and hold it in a strictly defined position. It is best to cope with this task, t.e. homogeneous material.

What Happens If You Put A Giant Propeller On A Bike?

Wooden dumbfounds, unlike metal ones, do not respond to temperature changes by the formation of condensate and do not rust. In addition, wooden bends do not interfere with the natural shrinkage of walls from the beam, decreasing in diameter with them. The heated, as a rule, have the same humidity or slightly less than the bars, thereby the high strength of the connection is achieved, during a natural, gradual shrinkage.

For bars made of soft wood, such as pine trees, it is recommended to use the waddling of more solid trees. This explains the popularity of birch dugs manufactured on industrial equipment and ready to install. As they say, she-day and angrily.

When building a house from a bar. Usually the upper crown is attached to the lower. The assembly stages look as follows: having fastened the first two crowns, they lay the next row of bars and drill a hole in order to capture the upper (below) timber, already firmly connected with the lower.

When installing the bastards, some rules should be followed:

- The holes for the heaves must be drilled strictly vertically, this must be observed so that during the shrinkage of the beam, the nagel does not prevent slipping.

- The indentation from the corner is 300-500 mm. and then after 1500-2000 mm. In a checkerboard pattern.

- A hole for the wax, in the center of the beam, is drilled.

- Hugs are clogged with a little effort.

- Nagel length by 20-30 mm.In short, a drilled hole. So that, when shrinking, the beam does not hang on the bastards.

- Optimum thickness f 20- mm.

Observing all the technologies for building a house from a beam and using wooden waxes as fasteners for walls, you can completely avoid such common problems as the effect of painting wood and the formation of cracks between the crowns.

How to install we disassembled. Further in the next article, the device of joints.

Which all the same, the bend is better round or square! I want to put a log house for a bath 6 3, which is better to choose a sawn or usual beam? I think to make a warm angle method.

Alexander, the waughs no difference is square or round, the main thing is to clog with effort, tightly. Which beam is better to choose for you is a matter of price and taste. Square beam, non.driving after installation, it is desirable to sheathe.to. When a protective layer is removed from the tree, it is subject to various influences of both weather and fungal. The profiled beam is usually strict and it is enough to soak it with an antiseptic and covered, for example, varnish, this will be enough. And it will look good.

Collapsing floor by filling room with water

I made square dumbfounds. I was advised to make them so that they crawl into the hole. The shrinkage of the house did not interfere at all, but the fact that they bent there now do not hang out (suddenly even more dried up) and hold the crowns, I’m sure. About the iron. I am categorically against! Do only wooden!

How to choose the right baches for assembling a log house?

When buying a naga for assembling a wooden house, it is necessary to take into account the following:

- It is still desirable to purchase wooden nagels. The most durable are the doughs made of birch. You can also purchase a dagger made of oak, but at their cost they are too expensive.

- It is advisable to buy a round section, it will be easier for them to prepare a hole in the crown.

- Both short and long nagales can occur on sale. It is recommended to dwell on long, they can already be cut on the required length on the spot.

- It is necessary to pay attention to existing defects when buying. They should be at a minimum, it is advisable to purchase perfectly smooth and without knots.

It is believed that the naga must be purchased only for the gallery logs, in fact, they will bring great benefits to the beam and even chopped logs. They will give the walls strength, stability, reduce the risks of the formation of deformations of crowns, their torsion, and the appearance of cracks on them.

These fasteners prevents the movement of crowns relative to each other. The main thing is to purchase the nagales that meet the recommendations with these experienced builders.

Furniture dumplings of Nagel

The universal bite is furniture. this is a special mounting device made of wood, which is used in the manufacture and assembly of furniture. He has a cylindrical elongated form, there is a corrugation on the surface. In some cases, the penet not only replaces metal fasteners, but also works better. At the same time, the price of the dough is more affordable.

Application area

Before describing the ways of applying this fastener, you should figure out what a dough is. The dough in the design allows you to stabilize and position details. It does not interfere with disassembly of products if necessary.

The dough will allow you to accurately combine the elements. During the operation of the already finished product, such a mount takes over the entire transverse load. This is a universal reliable fastener.

Wooden doughs are actively used for the manufacture and assembly of furniture, their length and diameter are selected in accordance with the thickness of the parts. The diameter should be approximately a third of the thickness of the walls of the product. this is how you can provide the most reliable assembly, maintaining a high degree of strength. The length is selected individually.

Varieties

In fact, the dough is a small spike. this is a hidden type of furniture fasteners. In appearance, it resembles a cylinder.shaped rod, with slightly rounded or simply truncated ends on both sides. Sometimes for assembling furniture on doughs, not only wooden elements are used, but also plastic. They have a little different purpose:

- Wooden are needed for the positioning and joints of furniture made of wood-fiber slab, wood-brown stove, plywood, massive rocks;

- Plastic ones mainly connect the parts when installing a collective-discharge case of case shield furniture.

Wooden plastic

There are also metal products. They have improved strength characteristics, they are called differently-dowels, nagas.

But the most commonly used are wooden doughs in size 30 by 8, that is, the length is 30 mm, and the diameter is 8 mm. There is a smaller diameter. 6 mm.

You can purchase different types in construction stores or markets. If desired, you can make dowry dips with your own hands.

There are different grooves on wooden doughs:

- Straight vertical;

- Screw.shaped. located at a slight angle to the vertical axis;

- Complex. there are transverse and longitudinal recesses. they also allow you to make adhesive compound stronger;

- Horizontal. help to make the adhesive compound as strong as possible;

- Smooth. do not have rifting.

Reefting helps air to pass during the installation of doughs, improving the adhesion of glue in the “adhesive” method of connecting parts.

Vertical direct sophisticated smooth

Characteristics and dimensions

Spams can differ in length and diameter. The dimensions of the diameter are from 4 to 30 mm, and the length is from 15 to 200 mm. By order of the buyer, they are made in any variations, where D is the diameter, and l is the length of the product.

The skirt is a demanded fastener, and therefore professionals try to purchase the details in advance in advance, so as not to waste time and money on permanent purchases. The advantages of fasteners include:

- The surface corrugation on the rod. this helps to qualitatively fix the details, providing their strong adhesion;

- An improved type of furniture, because the mounts are completely hidden from the eyes;

- The possibility of selecting the necessary products and lengths necessary for the assembly, in accordance with the design features.

Determine the size of the dimensions

Methods of installation and removal

Furniture doughs make it possible to significantly increase the strength of the compounds. But this is not such a simple way as it might seem right away: the connection cannot be fixed if any hole is shifted. Depending on the size of the displacement, the result will be unsatisfactory.

As a rule, countertops on dining and written tables are attached with a dough. Put them in the working position as follows:

- On the end side of the parts are first marked, and then the holes are drilled to the desired depth. The same holes are made in countertops. They must coincide;

- A cylindrical fastener is installed in the end opening, the upper end protrudes at a distance equal to the depth of the opening of the covering part;

- To strengthen the dough in the hole, it is abundantly lubricated with glue, fixing in the right position. Sometimes the glue is poured into the holes, where the mount is then inserted. this will completely cover its ribbed surface with glue, improving the adhesion of the elements;

- The second part of the structure is superimposed on the installed penet.

Drill the material, clog the penet, connect the work is ready for glue

There are 3 main problems of assembly of furniture by means of cans:

- It is possible to assemble the connection “edge to the edge”, but at the same time there is a discrepancy in the planes in the details of the structure. Solution: the holes of the guide bushes of the drill were not leveled with the central part of the edges of the parts. The device must be constantly aligned on the basic planes of two fastened parts. Even in the absence of a central arrangement of holes in the connection, shifts or sagging are not formed;

- Holes in one detail do not coincide with the other. Solution: For combining holes, special markers are used, designed just for connections. The openings in one part are originally made by a drill. Then a marker is inserted into each hole, and both parts are pressed to each other as they should hold after assembly. Thus, the second details will remain markers in places where should be drilled;

- The holes are made in the right places, but the installation of the cans is violated: the fasteners do not crawl or, conversely, falls out. Solution: It is important to make sure that the diameter of the mounts corresponds to the diameter of the holes. Factory mounts are massively produced, can have a diameter of a little more or less than the declared. In addition, the tree can swell or dry with a change in humidity. Когда диаметр сверен и он идентичен, то проблема в изношенности сверлильного кондуктора и, как следствие, отклонении сверла. This leads to deformation. It is enough to change the bushings or purchase a new device.

Drilling holes under the faint

The use of doughs in the manufacture of furniture originates from the “Soviet” times. But, despite its “antiquity”, this type of furniture fittings is sometimes used by modern furniture workers.

Stories are also known for some personalities who to this day continue to use doughs to combine all furniture nodes, despite the fact that they live in the age of high technology and the development of Chinese industrial plagiarism of all the most modern elements of accessories developed in Europe.

It is difficult to explain the reason for such a “love” for doughs. The fact is that the installation of a dough requires high accuracy from the master.

An error, even a fraction of a millimeter, can lead to a displacement of details, which is almost impossible to fix without “victims”.

You have to either drill a hole (which leads to an unreliable connection of parts), or put a plug in a drilled hole and drill it again (which takes a lot of time and nerves).

In general, we take a chance to assume that masters who continue to work with cans, either masochists, or work in a very cheap market segment (since the only advantage of the skirt is its low cost).

Or maybe they live somewhere high in the mountains and work with “grandfathers” stocks of a wood-brown slab and accessories, so they simply do not know about the existence of confirmation, corners, and even minifixes.

Despite our “dislike” to minifixes, the dough can be attributed to an even more “hard” type of accessories in terms of its installation and adjustment.

Nevertheless, we decided to consider the technology of drilling holes under the pant. Immediately note that in the manufacture of furniture with your own hands, you will not have to use the skirts everywhere.

In our drawings of furniture, doughs are used only in those compounds where, according to technology, their use is the most optimal.

There are few such compounds, but, nevertheless, since they are present in the drawings of furniture, it means for the successful manufacture of furniture with your own hands, you need to consider the issue of drilling holes under the dad.

Step 1

According to the drawings of the furniture, we make a marking for drilling on the flat side of the part. You can read about how to make such markings here.

Step 2

Now we take a drill with a 8mm drill and make a hole to a depth of not more than 10 mm.

The hole must be drilled very accurately, therefore, so that the drill does not swim on the details, place the spacing place well or use the drill on the tree, just make sure that the tip of the drill does not come out from the opposite side of the part.

Also, when drilling holes under the dump, it is very important to “withstand” the perpendicular angle of drilling. Otherwise, problems may arise when connecting parts.

Step 3

Now you need to mark the end of the second part, the one that will joke with the already marked. About how to mark the end of the part, read in this article.

Step 4

It remains only to drill a hole in the end of the part. Again we need a drill and a drill with a diameter of 8mm. Drill a hole to a depth of at least 25mm.

Nuances:

- You need to drill holes under the faint very accurately. Unlike other types of joints, the connection on doughs is almost impossible to regulate during the assembly process.

- Make sure that the holes in the ends of the details are drilled perpendicular.

- Do not drill too deep holes from the flat side of the part, otherwise when connecting, the penet can come out, pushing the thin layer of laminated woody plate. But the penet sticking out is unlikely to enter your plans for the manufacture of furniture with your own hands.

Unpredictable wood

To predict where the moisture will go and where it begins to accumulate, even experienced builders can not always.

Alexey Galimov

A very recent case. Grinded inside a log house of chopped log. There were very hot days. The heat presses. moisture goes inside the house. The inner surface of the walls was more wet than expected. Sawdown, formed during grinding, sticking on the walls and under it Sineva went. Well noticed in time, cleaned up. So that the moisture inside the log house does not form anywhere, the log house should be well ventilated.

Production of doughs

This task is quite feasible. For this, logs are usually birch, since oak is too expensive wood, split into several parts, forming a square blanks. Then the dugs are handed over manually to give them a rounded shape.

On a lathe, the same operation takes much less time.

Since the beam with a cross section of 150150 mm is the most used in private construction, sometimes the manufacture of doughs is reduced to the search for the product of the corresponding diameter. 25 mm. The most suitable, as experience shows, are cuttings from shovels and mop. The product is simply cut in length and used for the new purpose.

Formation of the beam

It is important to carry out work correctly, since it depends on how reliably the design will be fixed, the list of events is as follows:

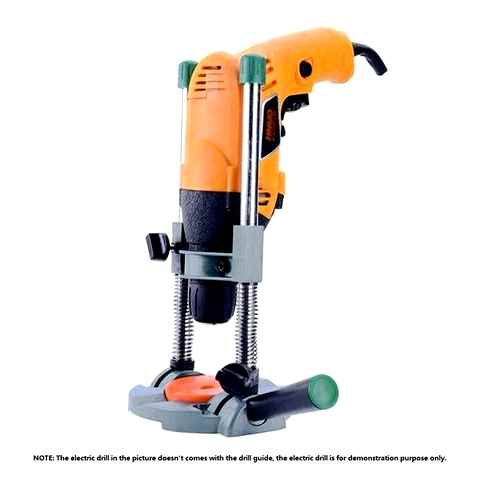

- First you need to choose a high.quality drill for bars. Too weak options are very often used, so cases when the power tool burns when drilling is frequent. Low.cost modifications with a three.stage reducer with a capacity of 1300 or more watts are best suited, they cope well with work, as they are designed for high loads;

Choose modifications with a handle on top, it will be much more convenient for you to carry out work on drilling

- As for the drill, the screw version of the desired length is selected, it is better not to save and purchase a product of a well.known brand, since cheap analogues usually do not differ by strength and can fail to almost at the first hole. The length depends on how thick you have a beam, and the diameter varies depending on the width of the walls, products from 20 to 30 mm are most often used;

Drills with a diameter of 30 mm. one of the most popular

- The drilling is carried out from the third row, while it is very important to observe the vertical position of the equipment during operation, because the penet will serve as a guide, and if it is located under the slope, the surface may bend over time. The work should be entrusted to a physically strong person, since the drill sometimes seals and can crank the tool, which is unsafe when working at a height;

When working, you need to keep the drill very tightly

- Remember the simple rule-the hole should be 1-2 mm larger than the size of the penet, this will provide a fairly dense location, while the mount will not interfere with the shrinkage of the structure. That is, with a drill diameter of 30 mm, the wax should be 28-29 mm;

- The indentation from the edge of the beam should be at least 300 mm, the distance between the mounting points is from one and a half to two meters. Sometimes you can increase the number of cans, placing them in places that can be deformed;

- The waddles are clogged with a heavy hammer or sledgehammer weighing 2-3 kg to drown elements, stock up in advance with a spacer.

As you can see, the work on conducting work is not difficult, it is important to have a reliable tool on hand and use the fasteners of the desired size.

Production material

Two types are actively used:

- Wood. Most experts strongly recommend using a wooden spike in the construction of wood structures. The main advantages are given when choosing such fasteners:

- Uniform drying.The beam and nagel should be approximately one moisture. This will allow the process of shrinkage by virtually no apparent changes;

- Not subject to temperature differences. The tree practically does not change linear dimensions at various temperatures, so the fastener element will always be in its place;

- There is no rust. The metal rust over time, which leads to decay of the wooden surfaces in contact with it;

- There is no condensate. With a sharp change in temperature, moisture forms, which is completely inside the carrier wall.

- The penant fuses with the wall. After a certain time, the house will become monolithic, wooden surfaces are soldered.

- Metal. This option also refers to the budgetary method of fastening, waste (pipes, reinforcement) is often used). Although experts prefer the previous method, the metallic nagel has their advantages:

- The upper layers of wood are protected from twisting;

- The durability of the design.

DIY

As already mentioned, depending on the scope of use and design, some options can be done yourself, so that you will save a significant amount.

Before work, find the required drawing of the device and make everything strictly on it.

To make with your own hands the easiest version of the conductor, we perform the following actions:

- Take the reinforcement 10 by 10 mm with a square section;

- Cut a piece of the required length and clean it with sandpaper;

- make markings for template holes. At the same time, it is not allowed that the center is approaching the edge more than 8 mm, this is almost half the thickness of the sheet of the wood-based stove. Also, according to the standards, a distance of 32 mm should be observed between the centers;

- After the marking of the centers, make holes in them 5 mm in diameter;

- To focus, take a plate of metal with a 2.5 mm wide and 1 mm thick. Bend it at an angle of 90 degrees, and then, along with a piece of prepared reinforcement and mounting in a clamp, make a place for thread;

- Cut the thread and combine two parts into one design. The device is ready.

As you can see, such a device is very simple in terms of independent manufacture, but it will greatly simplify the work if you are engaged in the manufacture of furniture. If you do this exclusively as an amateur, then this option will be enough. If you do not succeed yourself, buy a ready.made option, perhaps the easiest and most inexpensive.

But professional equipment will cost much more, the feasibility of its acquisition is already available when it comes to at least small production production. But with it you can simply and quickly connect furniture or repair it.

So, you learned what a conductor is to make holes and how it helps in the production of furniture. This device can both be purchased in the finished form, so do it yourself.

Natural wood houses have now gained popularity again. But wood is far from homogeneous material, therefore, in the process of shrinkage, a small deformation occurs, different parts of the house take the final appearance unevenly.

Hence the problem of attaching the beam among themselves, which will ensure reliability, on the one hand, and uniform shrinkage on the other. The solution was found for a very long time. heated. The element differs in size, cross.sectional shape (circle or square), manufacturing material.

General principles of drilling

Drilling holes is the most common occupation of the repairman, so it is important to know several basic rules that will avoid errors during repair work:

- The choice of suitable tools. In stores specializing in the sale of items to carry out repair work, many drills are presented. Each is used for a specific kind of materials, so you should not choose for drilling a tree, a brick drill.

- Determination of marking. Marking is indicated on the material using a marker. To avoid sliding a drill based on the material, paper tape should be glued under the marker.

- Determining the optimal drilling rate. In this case, the value of both the material and the diameter of the blade are of value. If drills with a diameter of not more than 3 mm are used, then all manipulations should be carried out at low speeds.

Repair work should be carried out in gloves

The main manufacturers of low.speed drifts

The quality of the tool depends on the reputation of the manufacturer. Experienced craftsmen distinguish a number of models that deserve attention.

Makita

A brand from Japan, which specializes in the production of electric tools, has gained world trust due to the quality of products. Among the variety of drifts of this company, the 6300-4 model unit is popular. The copy is suitable for high.quality work by experienced masters. The tool allows you to perform all demanded tasks, including the preparation of solutions.

Felisatti

The manufacturer from Italy, under the brand of which everything necessary for construction work is produced, also produces low.speed drills. The professionalism of Italians was appreciated by the masters by choosing a DMF23/1150VSE device among popular models.

Metabo

Among the manufacturers of power tools, Germany occupies a high place, differing in reliable and high-class products. Metabo produces drills that any master will appreciate. However, not everyone can afford to work with an expensive tool.

When choosing a manufacturer, there is a question about saving funds, it is worth paying attention to the brands. Interskol or bison tools are at the level of foreign competitors. The availability of products of domestic firms forces masters to make a choice in their favor.

Features of construction from a bar

If logs are used in wooden construction, then their position is relatively fixed due to grooves. Groove. a recess selected on the entire length of the log. This groove is the upper log how the lower logs are covered by the same immobility of the logs. But a beam with even faces should have additional fixers.

Brus construction has a number of advantages. The wall remains even, which is practical for subsequent finishing. Choosing a drill for choosing a drill for OLEG-260290 A DRALE KEN 6110B. Deferam, yes. The thickness of the walls from the beam will be the same everywhere, in contrast to a log. The house is built in other words of the bath directly on the foundation, then there is no such additional problem as transportation is not installing the log house made there. However, the issue of fastening the beam with the wall should be taken extremely responsibly. This is what affects the strength of the structure.

So that this does not happen, it will be correct to drill holes for doughs in the beam. Skakt is a wooden rod with chamfers. It is made of solid wood, such as birch.

A large.sized pant, replacing a nail, is often called an embodiment. Both names correct do not mean the same system. 2000-in Bosch GDB drill 180 We Professional for dry and wet drilling

concrete, reinforced concrete. You will like the nagel as homemade, so not industrial production. Nowadays, it has become convenient to use sketches for rakes for rakes sold in every hardware store. This is due to the successful correspondence of the diameter of such a cuttings twenty.five mm with a diameter of the drill on wood. The size of twenty.five mm is optimal for fastening the beam of 150×150 mm, which is usually not used in construction.

Sale

To buy dumps d.25 or d.30 mm (region) recommend to make an order or call. With the wholesale purchase of these fasteners, we have delivery by regions with sending transparent companies from calling!

Round wooden doughs can simply be done at home.

The holes of the desired diameter at an angle of 45-60 ° to the surface of the plate are drilled in the steel plate-matrix.

The rail rack is clamped in the cartridge and, inserting the plate into the hole, gradually passed through it.

When the workpiece rotates, the sharp edges of the holes cut off excess wood and form a zillindry rod, which is cut into the s of the required length.

If you need www.Adidas.ru, in this case, the official Adidas online store with delivery in all will help you in solving this issue.

- Cloth cutting device for some projects requires a large number of cans of the same length. To quickly and carefully saw off short segments and at the same time keep your hands away from the saw disk, you can

- Homemade dumbfounds and round spikes knowing how to milling rounded spikes, you can turn any drilling machine with an installed Forester drill into a nest sampling machine. In addition, you can always make

- Round templates will help where the compasses can not cope before installing the workpiece on the machine, with the help of a strip saw she needs to be given a round shape. then it will be balanced, and, in addition, you will not have to do hard work on a rough

- “Rowder” from beds in families where many children and halves will be especially convenient for such folding cribs. This multi-tiered crib-“ebrid” during the day can stand in the corner of the room, without occupying the space for games and

- The cans template this template is designed for accurate marking of the openings for doughs when connecting the boards in the shield.

The construction of wood structures implies the mandatory use of special fasteners. Such elements are focused on ensuring that the design turns out to be high.quality, reliable, monolithic, as strong as possible.

An integral part of the structure is the dug, or dowels. It is the quality of this part that determines the reliability of the entire structure. You can easily make cans for a beam even with your own hands. The procedure does not constitute something particularly complicated. The main thing is to follow the chosen methodology.

Subtleties of fastening of wood of wood

How to fasten the beam with cins? It can also be done with your own hands, without the use of professionals. The order of work is extremely simple. The use of wood spikes first will require finding the middle of the plane used. At this point, it is necessary to make the appropriate markup. It is here that a hole will be created in the future.

Now you need to drill a recess using a drill. It is in it that then it will be necessary to fix the dowels. That is why it is very important to competently choose the diameter of the drill. Its sizes should be identical to the same spike parameters. As for the depth, it is 1.5 timber. The question is, what are the scans for the beam 150×150 is completely simple. On you can see how this procedure is performed.

At the same time, the task itself is disappeared: how to drill a beam for dadies. Of course, the best option is a modern drill. It is much more important to monitor the correct processing of the hole. The entrance angle depends on the drill position. It should be strictly perpendicular to the very reason. The literacy of this step will further avoid problems with the installation of fragments. It is also worth remembering that if the penet is located in the beam extremely freely, this will deprive the design of all the advantages of this kind of fasteners. It is also worth avoiding excessive density. The length of the nagel should not be more than the set sizes. The protrusion of the part above the surface leads to problems in the process of inevitable shrinkage of the structure.

What is a wooden ballerin

The circular adjustable drill “Ballerinka” is a device that is designed to drill round holes of large diameter. The tool has a simple design. It is a shank with a transverse bar, on which movable carriages with incisors are fixed. The bar has a marking by which you can set the necessary expanse of the incisors relative to the center of the proposed hole. In the middle of the shank, a drill-hearth is fixed. It serves as a central element and support when drilling.

In addition to structures with two cutting elements located symmetrically, there are ballerinas with one cutter or even three. In the latter case, they are located on the basis of a disk with grooves.

The optimal choice is birch baked!

This mounting element is very important for the correct and high.quality assembly of wooden structures. logs of logs and sawn beams. Birch bark is optimal in an important ratio. the ratio of price. the quality of the fasteners. It was bent from oak wood is somewhat stronger than birch, but in cost much higher than fasteners from birch.

DIY manufacturing processes

As a rule, the construction of any wooden building is associated with the use of fasteners in the work. They help create a strong, monolithic structure that does not depend on the type of structure. Spams, or bent, are an integral part of any building. Their quality determines the reliability of the structure. Do.it.yourself cams can be made with your own hands by following a certain methodology.

Scheme of the interventional connection using the nago.

Nagel is a small element, but it is impossible to do without this part. It provides reliable fasteners of walls from a bar and log house. These fasteners were called dowels even during antiquity carpenters from Vyatka. In the XVIII-XX centuries, the construction of huts from timber and logs began to develop there. In that era, one could observe the active development of woodworking production, as a result of which the construction boom arose.

Then the houses made of natural wood were formed using birch spikes. The construction of log cabins in those parts and throughout our country began to be carried out using this particular type of material. Any carpenter knew that.

Blitz-councils

There is a set of tricks during installation, allowing you to build a house of your dreams that will last for many years:

Chess order. The condition is not mandatory, but strongly recommended by carpenters of all stripes;

In order to avoid sagging, it is necessary to use wooden dug in a rounded shape. Square products are mainly promoted by manufacturers, since they are easier to manufacture;

When clogging, you can and need to reduce friction. To do this, it is enough to use soap solution;

It is recommended to use birch fasteners. This guarantees the reliability of the structure, gives a certain charm, while it does not increase the cost of construction;

Similar humidity between the spike and the beam is a fundamental condition for the durability of the structure

This must be paid close attention to this;

Feel free to use additional fastening elements. Science does not stand still, modern devices can greatly facilitate the task.