Miter saws are versatile woodworking tools created for cutting a variety of building materials such as lumber, siding, flooring, or even PVC pipes. Used primarily for crosscuts, which are cuts that go across the grain of the wood, miter saws have mounted circular saw blades that you pull down to cut the workpiece. Many miter saws are stationary saws, as you bring the mounted blade downward, rather than running it horizontally along the workpiece. One that slides horizontally across the piece as you cut would be a “sliding” miter saw. Miter saws go by many other names, such as a chop box saws, chop saws, and miter box saws.

A miter saw’s standard cutting angle is 90 degrees. However, both single and dual bevel miter saws allow you to make bevel cuts, which are cuts that are along the material’s thickness at an angle other than 90 degrees. The bevel of a miter saw is useful for intricate work and often a major differentiator for buyers. The saw blade rotates — either to the left or right — allowing you to adjust the saw positioning to different angles, such as a 45-degree angle. Typical miter saw applications include making trim, molding, baseboards and other fine carpentry work. Miter saws allow you to achieve complex angles that are often required with woodworking and carpentry projects.

This guide to miter saws will explain the different ways you can achieve bevels cuts with two different types of circular saws: single and dual bevel miter saws.

Single Bevel Compound Miter Saws

A single bevel miter saw only adjusts its positioning in one direction: to the left or right. Therefore, a single bevel miter saw allows you to make one-directional bevel cuts. Single bevel miter saws can make both bevel cuts and miter cuts independently or together.

Depending on your project, you may need to make bevel cuts on both sides of the workpiece. Because a single bevel miter saw can only make bevel cuts in one direction, you’ll need to turn your workpiece around to achieve an additional bevel cut on its other side.

Even though a single bevel miter saw can only make bevel cuts in one direction, the saw can still accomplish the same thing a dual bevel does, just with a little more brainpower. If you need to make multiple cuts on both sides of your workpiece, it will take longer and require more effort using a single bevel miter saw.

Dual-Bevel Compound Miter Saws

The blade angles of a dual bevel miter saw can adjust to both the left and right, as opposed to just one side, like the single bevel saw. Some people call this type of tool a double bevel miter saw because it can be adjusted to make cuts in any direction.

Because the saw head can rotate on a fulcrum towards both the right and the left, you can make identical bevel cuts in your workpiece without having to turn your material around. Double bevel miter saws allow you to make precise and uniform cuts on both sides of your workpiece. It also makes the job easier and quicker, as you can make faster repetitive cuts even on longer workpieces.

For contractors or highly committed hobbyists, a dual bevel miter saw will improve your workflow and efficiency.

Single vs. Dual Bevel Miter Saws

Both single and dual miter saws can make miter and bevel cuts, and both use circular saw blades for cutting. They are also both referred to as “Compound” miter saws because they can make miter cuts and cuts in 1 or 2 directions. Despite these basic similarities, there are some differences between each.

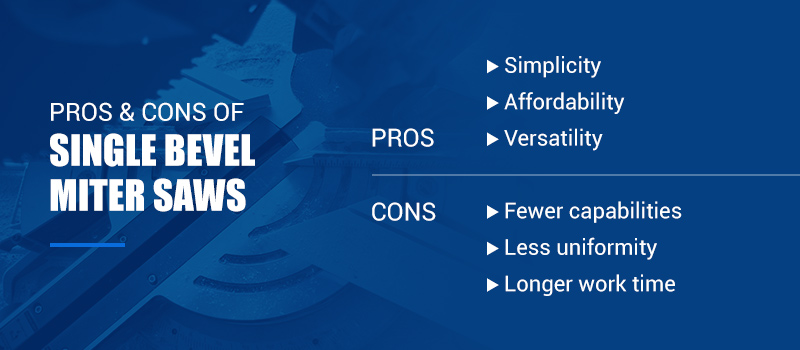

Pros and Cons of Single Bevel Miter Saws

Single bevel miter saws are more straightforward machines, ideally suited for the beginner craftsman or home improvement hobbyist. If you’re new to woodworking or looking for a lower maintenance saw, consider these pros of single bevel miter saws:

- They’re Cheap: Single bevel compound miter saws are typically a few hundred dollars cheaper than dual bevel saws of the same brand.

- Simplicity: Single bevel miter saws are straightforward and easier to use. If you plan on making most of your cuts at 90-degree angles, then this will do everything you need.

- Versatility: Single bevel miter saws are great for beginners or professionals since you can accomplish what you can with a dual bevel, with a hair more effort.

Despite their advantages, single bevel miter saws do have some drawbacks:

- Fewer capabilities: The main disadvantage of the single bevel miter saw is that it makes one-directional angled cuts, meaning you have to turn your workpiece around to make matching cuts. This matters most when installing crown molding or other types of trim.

- Less uniformity: Because you can’t make double cuts at once with a single bevel miter saw, any matching bevel cuts you make on the other side of your workpiece might not appear as uniform.

- Longer work time: If you’re working on a more intricate project requiring double cuts, it will take you longer with a single bevel cut miter saw.

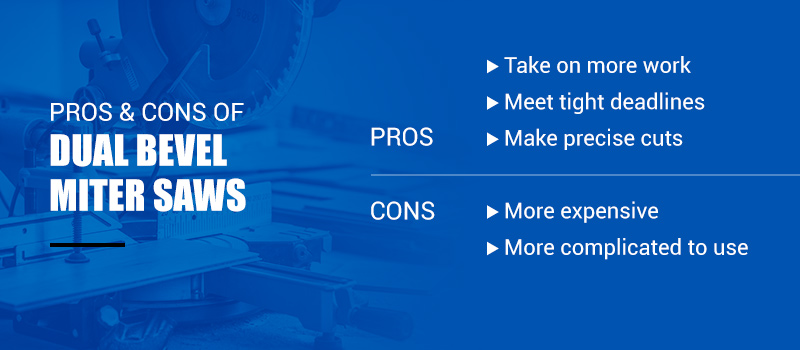

Pros and Cons of Dual Bevel Miter Saws

Many professional contractors and advanced woodworkers prefer double bevel miter saws. If you’re a more experienced craftsperson, then here are some of the benefits of investing in a dual bevel miter saw:

- Take on more work: With a double bevel miter saw, you can take on more projects because you’ll be able to cut in both directions efficiently. This is very helpful for crown molding projects and other projects with trim.

- Meet tight deadlines: Being able to make bevel cuts in two directions without rotating your workpiece saves time, meaning you can get more done faster if you’re on a tight deadline.

- Make precise cuts: Having the ability to rotate the saw head allows you to make more precise matching cuts on both sides of the workpiece, improving the quality of your work.

It’s essential to choose the right miter saw for you, so first consider some of these possible disadvantages of dual bevel miter saws:

- More expensive: Dual bevel miter saws are typically at least $100 more than single bevel miter saws from the same brand, so it’s important to consider the return you’ll get from your investment.

- More complicated to use: Dual bevel miter saws have more extensive capabilities, making them more complicated and not as suitable for beginners. Typically the projects where these are most helpful, such as crown molding as mentioned above, are not beginner woodworking projects.

The Miter Saw Says it’s Sliding. What does that mean?

Both single and dual bevel miter saws can be sliding. Sliding miter saws are designed to expand the capabilities of the miter saw. The blade sits on a rail and slides across the board you’re cutting. This will allow you to cut wider boards. Some sliding saws allow you to cut boards that are 12″ or even 16″ in width, which you couldn’t accomplish with a normal miter saw. Instead of “chopping” through the board, you’ll slide the blade across the board since the blade sits on rails. To use a sliding miter saw, you simply pull the blade toward your body and push away as you cut. Typically single and dual bevel miter saws that are sliding cannot be adjusted to angles that are as steep as the non-sliding saws. This is because the rails used for sliding interfere with the side to side motion.

Blades You Can Use With a Miter Saw

Whether you use a single or a dual miter saw, the quality of your work still depends on the right type of blade for the job. Miter saws are versatile woodworking tools that you can use with a variety of circular saw blades. Here are some of your best saw blade options to use with a miter saw:

- Crosscut blade: Miter saws are meant for crosscutting, which is why your miter saw needs a good crosscut blade. For best crosscutting results, choose a blade with a high tooth count, so you can achieve smoother cuts.

- Combination blade: If you use a variety of materials besides lumber, then a combination blade is a good option. Combination blades allow you to achieve smooth cuts in materials other than lumber.

When selecting your saw blade for your miter saw, be sure to choose high-quality blades that are built to last longer and perform better.

Choose Luxite Saw Blades for Superior Woodworking

Whether you’re a professional craftsman or carpenter or you’re new to hobby woodworking, choose Luxite woodworking blades for high-quality woodworking results. We offer superior carbide-tipped circular saw blades that are made to last, giving you a better return on your investment.

For more information on Luxite saws, reach out to our representatives today. Call us at 1-800-654-7297 or contact us online.