How Much Oil To Pour Into A Hammer

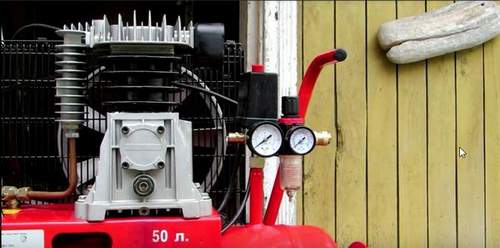

In the process of operating a piston oil compressor, the need periodically arises for “topping up” or changing the oil. This article will discuss how to do this correctly in practice, step by step. The process itself is quite simple, but in practice there may be some questions that we will try to answer. First of all, it should be noted that in piston oil compressors, a special oil is used, with its specification (characteristics), which meets the recommendations for the operation of the compressor. The main indicators of oil quality are: viscosity, acidity, water-soluble acids and alkalis, oxidizability, water and solids content, flash point. We will not go into the specifics of these values, since previously these points were already covered in one of the articles. We only note the fact that the oil you buy for reciprocating compressors should contain an index of 100 (oil viscosity 100 mm 2 / s at 40 ºC.), letter abbreviations may be various VDL, ISO VG, VСL P PD etc. Only such oil can be used for reciprocating oil compressors. It can be mineral, synthetic, semi-synthetic in its composition and contain in its basis various additives that prevent foaming and the formation of carbon deposits. Therefore, if you add a little, then in no case should you mix different oils, since they can contain various additives that can conflict with each other and have a negative effect on the operation of a piston compressor. Thus, if you decide to add oil, then you should certainly know the brand of oil that was previously used. If you do not know this, then it is recommended to drain the old and completely fill in new oil.

So, what are the rules and procedures for changing oil in reciprocating oil compressors? We will analyze these points in order. A complete oil change is recommended. After the first 50 hours in direct drive compressors, and after the first 100 hours in belt driven compressors. Further, it is recommended to change the oil every 300 hours of operation. You can also make a decision to change the oil based on visual observations of it: if the color of the oil changes (whitening. The presence of water, darkening. Severe overheating), it is also recommended to immediately replace it.

To replace the oil in a piston oil compressor, it is recommended that you follow these steps:

1. Turn off the compressor (press the button on the pressostat or move the lever to the “Off” position or to the “ABOUT” or “Off”, depending on the execution. After that, the electric motor will stop and pressure will be released from the discharge air duct and the piston block. Next, you need to reduce the pressure in the receiver to atmospheric. Finally, turn off the input switch or disconnect the power plug from the compressor.

2. Next, you need to wait until the oil in the compressor cools down after operation to a temperature of 50-80C.

3. After, unscrew the filler plug located on the piston block at the top of the crankcase.

4. Loosen the drain plug located at the bottom of the crankcase.

5. Find an old, unnecessary container to collect the used oil to the drain hole, completely unscrew the drain plug and drain the oil.

6. Screw in the drain plug.

7. Fill the oil inlet with new oil intended for reciprocating compressors to the required level.

8. The oil level in the crankcase of the piston unit must be within the red mark of the sight glass.

The filling volume of oil for different models of compressors can be different go from 0.3 liters and above. For reciprocating compressors with a belt drive, on average it is 0.5-0.9 liters.

9. Next, screw in the filler plug.

Everything, all the necessary procedures have been completed, now, you can again turn on the compressor in the network and start working. When you turn on, you can hear that the piston unit began to work a little quieter and more measured. So, the oil change was good for him and was carried out in a timely manner.