How much should the battery of the screwdriver be charged

The main types of screwdriver batteries

Screwdriver batteries: lithium Li-Ion, nickel-cadmium Ni-Cd, nickel-metal hydride Ni-MH.

Manufacturers of screwdrivers use different batteries in the production of their units, which have their own characteristics of operation and, accordingly, charging. In order for the screwdriver to work without interruptions for a long time, it is very important to carefully read the instructions that come with it. It is worth noting that different screwdrivers differ in many parameters, including price, quality and power, therefore all screwdrivers are divided into semi-professional and professional. Accordingly, the batteries that are installed by the manufacturer also differ in price, quality and, most importantly, in charge capacity.

In professional models, which are more expensive, as a rule, batteries with a higher capacity are installed, so they can work without recharging for a much longer period of time. Most professional builders have a spare, pre-charged battery for uninterrupted work, but if the screwdriver is designed for simple housework, it is not necessary to have a second battery, although in some cases an additional screwdriver battery is included with the unit. There are 3 main types of batteries that are most often used in screwdrivers:

- lithium-ion;

- nickel-cadmium;

- nickel metal hydride.

Screwdriver battery connection diagram.

The most widely used today are nickel-cadmium batteries for screwdrivers. This type is distinguished by its rather compact size, relatively low cost and large charge capacity. The main drawback of these batteries is the same “memory effect”, but with proper use and recharging, batteries of this type can be recharged more than 1000 times, although it should be noted that even with proper use, the charge capacity will gradually decrease until it reaches a minimum. Among other things, it should be noted that such a battery contains highly toxic substances, therefore their production is significantly harmful to the environment, which became the reason for their ban in many countries.

Nickel-metal hydride batteries are in second place in terms of frequency of use. Batteries of this type belong to a new generation, as they are completely safe for the environment. This type has a lot of advantages, the main of which is the absence of a “memory effect”. However, it is worth noting that they have a high self-charging current, and these batteries should be stored exclusively in a charged state, and if the screwdriver is not used for a month, it is necessary to discharge the device and recharge it.

Lithium-ion batteries are a relatively new product in the market for these products. They do not have a “memory effect”, therefore, they do not require adherence to recharge cycles to restore the charge capacity. It takes very little time to fully recharge these batteries, and the capacity of these funds is quite high. However, these batteries have disadvantages, including reduced performance in cold weather and a rather high cost.

Features of charging screwdriver batteries

Charger circuit for a screwdriver.

A very important point is the first charging of the screwdriver, since it depends on it whether the full charge capacity will be activated. Each type of battery has its own characteristics of primary charging. The biggest challenge is charging nickel-cadmium options. Their first recharging should be three times so that the entire charge capacity is filled. Thus, after purchase, the unit must be fully charged, then turned on and left to work until it is completely discharged, then you need to put it back on to recharge and discharge again, and so on 3 times.

For the first time, the nickel-metal hydride version should be completely discharged immediately, because, as a rule, when buying such a battery, it has a small charge, after which you need to leave it to fully charge. Recharge batteries of this type only after they have been completely discharged. The full charge-discharge cycle should be considered the first 4-5 times, after which you can additionally recharge the batteries, even if they are not completely discharged.

Screwdriver specification table.

Lithium-ion batteries are more modern, so there are no special requirements for their recharging, since in any case their capacity does not decrease.

During the first and subsequent recharging, it must be borne in mind that the most optimal recharging effect can only be achieved if this process takes place at a temperature of 10 to 30 ° C. Among other things, it should be noted that when charging, some types of batteries may begin to heat up, which can extremely negatively affect the entire battery. Do not allow the entire battery to overheat above 50 ° C. After work, it is best to store the battery separately from the screwdriver, although this is not necessary.

How long does it take to charge screwdrivers?

Battery composition.

Important issues regarding charging screwdriver batteries include the time it takes to fully charge the battery. Many people believe that charging the screwdriver battery is worth until it heats up, but in fact this is a sure way to reduce the charge capacity and performance of the entire unit. It should be said right away that at present there are hundreds of types of screwdrivers and no less number of batteries, so it is very important to familiarize yourself with the instructions that come with a specific unit, because in one case 30 minutes will be enough for charging, while in the other for a full charging will take more than 2 hours.

Many types of batteries have an indication system, that is, there are 2 LEDs on the upper instrument panel, usually red and green. These LEDs let you know exactly when charging is complete. However, even if the indicator is present, it is necessary to disconnect the batteries from the mains in time, since a long stay in the connected state after recharging can damage the battery.

In addition, considering the duration of charging, you need to immediately notice that there are 2 main types of chargers, and it depends on which type is attached in the kit with a screwdriver, how long the charging process will take.

Chargers are divided into impulse and conventional.

As a rule, cheaper semi-professional devices are equipped with conventional chargers. Pulse chargers are more expensive, but at the same time, they allow you to charge the device in less than 1 hour, which is especially important for professional devices.

How and how much to charge the screwdriver battery?

Screwdrivers have long been invariably popular not only among professional builders, but also among ordinary people, because these units are indispensable when you need to screw something or, conversely, untwist it. The versatility of screwdrivers is the main reason for the popularity of these units, both in everyday life and in large construction, but all users of these units have a lot of difficulties when it comes to recharging the batteries with which most models of screwdrivers are equipped.

Diagram of the structure of the screwdriver.

The thing is that with incorrect charging, the so-called “memory effect” appears, that is, under certain conditions, the charge capacity may decrease, and in the future the unit will be discharged less completely. As a rule, this effect occurs when a person tries to recharge an incompletely discharged screwdriver battery. Proper charging of screwdriver batteries has a lot of subtleties, so it is very important to consider all aspects of this matter so that the screwdriver retains its functionality and performance for a long time.

Additional tips for charging screwdrivers

If the tool is not planned to be used in the near future, the question immediately arises: is it necessary to recharge it before moving it to storage? In this case, a lot depends on the type of battery. Common nickel-cadmium batteries need to be recharged first. It should be noted right away that if the tool will not be used for a long time, then before starting to use it, it will be necessary to perform at least 3 discharge-recharge cycles of the battery in order to restore its charge capacity.

Nickel-metal hydride units should also be recharged before sending the tool for storage, and if the period of non-use of the tool exceeds 1 month, it is worth recharging the unit for about a day before using it. This will restore the charge capacity. Lithium-ion batteries are considered the most convenient in this regard, as they do not need to be charged before storage.

Types of batteries used to operate the screwdriver

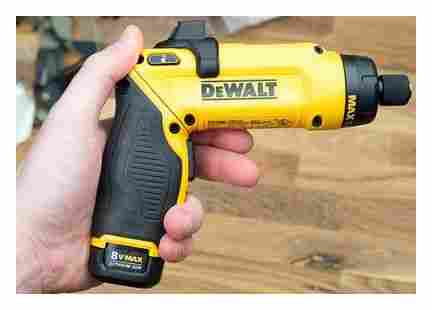

Before purchasing new batteries for the screwdriver, you must carefully study the instructions for the device. The tools required for work can be professional, household and semi-professional. Batteries for them differ from each other in capacity, quality and price.

For certain jobs, certain types of cordless tools are also intended, designed for different loads, therefore, different batteries are needed for them. The higher the power rating of the battery, the longer it can work. For convenience, it is better to have two batteries so that you can recharge the second when working with one. Often a second battery is already included when the instrument is sold.

Various types of batteries can be used for screwdrivers. The most commonly used nickel-cadmium (Ni-Cd) and nickel-metal hydride (Ni-MH), and more recently also lithium-ion (Li-Ion).

The most common of these are nickel-cadmium batteries, which are compact in size, large in capacity and at an affordable price. These batteries can be effectively charged more than a thousand times, depending on their design, purity of materials, operating mode, including correct charging. However, these devices have a so-called memory effect, and if you charge them without waiting for a full discharge, the battery capacity will gradually decrease. In addition, the production of such elements is so toxic that the European Union abandoned it on its territory.

In second place in terms of frequency of use. nickel-metal hydride batteries, representing a new generation of similar devices. From an environmental point of view, both the production and disposal of these batteries are practically safe. The advantages of batteries of this type include the fact that they have less pronounced memory effect, and the disadvantages. high self-discharge current. These batteries must be kept charged and fully recharged when not in use for more than a month.

recently, more powerful lithium-ion batteries have been used for cordless tools. They also do not have such a disadvantage as the memory effect, which requires periodic discharge cycles to restore capacity. However, these batteries do not tolerate low temperatures well, and it is undesirable to work with them in cold weather. Despite their fast charge and high capacity, they are not very popular yet, as their price is quite high.

How long does it take to charge the batteries of the screwdriver?

As a rule, the charging time of the screwdriver battery is indicated in the instructions for the tool. These recommendations should be carefully followed. Often the charger has a special display system to help you understand how the charging process is going. Thanks to this, you can easily determine with how much to charge the battery of the screwdriver. When charging is complete, you need to interrupt it in time so as not to damage the batteries. On average, the charger battery for a screwdriver can recharge from about half an hour to 7 hours. Practice shows that a Ni-Cd battery with a capacity of 1.2 Ah is charged with a current of 250 mA for about seven hours. Charging current is maintained using the mains adapter.

It should be borne in mind that there are two types of battery chargers. conventional and impulse. A standard conventional charger is more often used in a non-professional tool, it charges the battery in about 3-7 hours. Pulse. more suitable for professional mechanisms. Thanks to it, the battery performance can be restored in a maximum of an hour.

Battery charging features

How to properly charge a screwdriver battery so that it lasts as long as possible?

Batteries need to be charged before first use as they discharge during storage. In order for the battery capacity of the screwdriver to become the maximum possible for the nickel-cadmium cell, it is recommended to charge it three times and then discharge it. Thus, since the new battery has incomplete capacity, it must be brought up to full working capacity. After that, the batteries will need to be charged as soon as their capacity becomes minimum. Lithium-ion batteries are easier to use. They do not have a memory effect, so you can not bring them to full discharge and charge when it is convenient.

When charging, you need to take into account the optimal temperature regime of the process. It is better that the ambient temperature is above ten degrees and does not exceed forty. Batteries sometimes get warm during charging, but this should not be the case, as overheating adversely affects their performance, and they need to be cooled. It is undesirable to leave batteries in the charger. Yes, and it is better to store them by disconnecting them from the screwdriver, separately from the tool itself. If the batteries are not used for a long time, they should be recharged once a month.

It is better to buy rechargeable batteries at specialized points of sale. Correct use will help increase their service life. During operation, it is undesirable to discharge the elements completely until the engine stops. They will need to be charged as indicated by their markedly reduced performance.

Do I need to charge the batteries before storing?

If the cordless tool is not used for a long time, experts advise you to carefully consider the battery cells.

It is recommended to discharge nickel-cadmium batteries before storage, but not to zero, but to the point where the tool stops working at full capacity. In case of long-term storage, to restore the battery capacity, it is necessary to carry out 3-5 complete cycles of its discharge and charge. During the operation of the tool, it is also advisable to ensure that the battery is not partially discharged before charging, but completely.

Nickel-metal hydride batteries have a higher self-discharge rate than previous cells. They are recommended to be kept charged, and after a long “rest” to charge for about a day. Partial discharge is preferable for this type of battery. Their capacity decreases after 2-3 hundred charge-discharge cycles.

Lithium-ion batteries, which have no memory effect, can be charged at any time, whatever the degree of discharge. These batteries have the lowest self-discharge rate at the highest capacity. It is not recommended to fully discharge them, as this may disable the protective circuit. Power tools with such batteries are equipped with control electronics that disconnect the cell from the load when the temperature or voltage rises. It is recommended that these batteries be kept 50 percent charged. The number of charge-discharge cycles does not affect the capacitive characteristics of the cells, however, their life is limited by time and is about two years.

Tools

Among power tools, both household and professional, the screwdriver is one of the most demanded. With its help, you can not only twist and screw in self-tapping screws, but also drill holes. Mains-powered tools cannot be used always and everywhere, and the cord interferes with work all the time. Cordless screwdrivers are relieved of these disadvantages. With them, you can move freely and not depend on the presence of an outlet in the room.

An important element of every cordless tool is the battery, which allows you to work with it autonomously. This is very convenient, but sooner or later, each owner of such a power tool faces the question of how to charge the battery of a screwdriver.

- Types of batteries used to operate the screwdriver

- Battery charging features

- How long does it take to charge the batteries of the screwdriver?

- Do I need to charge the batteries before storing?

- What to do if the screwdriver battery does not charge?

What to do if the screwdriver battery does not charge?

If the battery of the screwdriver does not charge, perhaps the reason is to look for its deterioration or in the malfunctioning of the charger. However, often the problem lies in the disruption of contact between the battery terminals of the screwdriver and the charger, as they unbend over time. In this case, you can disassemble the charger and bend its terminals.

In addition, after some time of use, both the battery contacts and the charger contacts may oxidize and become dirty. Even minor changes of this kind can prevent the batteries from charging properly. This usually translates into a significant reduction in both the charging time and the operating time of the cordless power tool itself. To prevent this from happening, you need to periodically wipe the contacts of the battery, the charger for the battery of the screwdriver and the tool.

Unfortunately, battery cell performance degrades over time. So, with improper use of nickel-cadmium batteries, most often used in household screwdriver models, they quickly lose capacity. Experts sometimes advise to “overclock” such batteries. The battery pack is disassembled and problematic items are identified. After that, they need to be charged. What current to charge the screwdriver battery in this case? Experts recommend that you first charge such elements with a higher current than it should be, then discharge them and charge them again, but with a small current. If the electrolyte has not yet evaporated in Ni-Cd batteries, this “therapy” may help bring them back to life.

In addition, you can restore one battery pack from two that have partially lost their capacity by selecting from them and soldering together whole “banks”. After that, to equalize the charge, it is required to fully charge and discharge the recovered unit several times.

Also, the reason is that the battery does not charge, it may be in the temperature sensor.

What to do if the battery won’t charge or hold a charge

In this case, there are few options: either the cause of the malfunction lies in the charger, or the screwdriver itself “jams”. Also, the battery pack may eventually exhaust its resource and need to be replaced. In order to find out the reason, it is necessary to carefully inspect both the instrument itself and its battery together with the charger.

Often the reason for poor battery charging is that the contact between the screwdriver and its charger looses due to the extension of the terminals. To fix this problem, it will be enough just to disassemble the charger and carefully bend its terminals back.

Do not forget about such a frequent problem as the oxidation of the metal parts of the battery itself and the charger. The constant ingress of construction dust and dirt also contributes to a weak flow of charge current from the charger to the battery: the tools are charged worse. It is important not to forget to take care of all components of the instrument in order to prevent deterioration of its performance by wiping the metal contacts and cleaning them from dirt.

If the battery itself runs out, you can try to “swing” it, as is usually done in the case of nickel-cadmium cells. If this does not help, you will either have to change the battery pack completely, or carry out a partial replacement of its elements.

About screwdriver battery repair →

Usually any screwdriver comes with two identical batteries. If one of them fails, if desired, you can assemble one working battery from two, in case the capacity has become less in both. After one working unit is assembled from two blocks, you need to remember to equalize the capacity indicators of the cells by “pumping” the battery with several “charge-discharge” cycles for 3-4 hours.

You can also try to “invigorate” the batteries separately. To do this, the weakest of them should be charged with high currents, after which the battery should be assembled back and charged in normal mode. This method sometimes works with nickel-cadmium batteries. “Point” recharging with high currents should last no more than 3-5 seconds, while it is advisable not to allow strong overheating of the element in order to avoid its destruction.

Proper charging of the screwdriver: how to do it better

There are some simple rules on how to charge a screwdriver battery so that the tool uses its entire possible resource.

If your screwdriver contains lithium-ion batteries, it is not necessary to carry out such a “pumping”, because the “memory effect” is not peculiar to them: these are more modern batteries.

It is necessary to charge the battery at a favorable ambient temperature. The best temperature indicators at which the screwdriver battery should be charged is not lower than 10 ° С and not higher than 40 ° С. During charging, do not leave the battery unattended for a long time to avoid overheating and overcharging. Although, if the standard charging of the tool is equipped with an indicator for monitoring the entire process, the device will automatically “finish” it when it is needed.

It is not recommended to leave the battery pack in the charger for a long time. And if the screwdriver is not used as often, it is better to remove the batteries from it and store it separately from it. In the case when the batteries lie without use for a long time, make sure that they are in a charged state, carrying them “recharge” once a month for 25-30 minutes.

As you know, the cordless power supply of the screwdriver is either nickel-cadmium or lithium-ion. Ni Cd batteries can be stored in any state of charge. Their main advantage is that they are not afraid of deep discharges. In order for them to work well after a long break, they should be “pumped” as usual three or four times. The “pumping” time, on average, is 3-4 hours, during which you can work with the screwdriver in normal mode. It is advisable during the operation of the screwdriver to control that the Ni Cd battery is not partially discharged, but completely. This will help her not to accumulate the same “memory effect”.

If the rechargeable power supply of your instrument is equipped with lithium-ion, rather than nickel-cadmium, batteries, their main “plus” is that they have no “memory effect”. However, it is recommended to monitor their charge level more carefully. If the screwdriver with lithium batteries is not used for some time, they need to be recharged periodically. They just do not like deep discharge. If lithium batteries are deeply discharged, the safety controller inside the battery pack will operate. To prevent this from happening, make sure that the batteries are charged at least 50 percent.

Read about which batteries are better for a screwdriver here →

How long does it take to charge the battery of the screwdriver

Each power tool is always accompanied by an instruction manual, which indicates exactly how long it takes to charge the screwdriver’s battery. As already mentioned, the vast majority of modern chargers have charge level indicators, which makes them much easier to use. When the indicator lights up green, or in another color, indicating that the charging time of the screwdriver battery is coming to an end, you need to disconnect the battery in time.

The average time it takes for the battery to fully charge is 7 hours. And if the battery just needs to be recharged, it can be left on charge for 30 minutes. Although, in the case of Ni Cd batteries with a “memory effect”, frequent and short recharges are not recommended.

There are several types of screwdriver chargers, depending on their area of application. Ordinary charger, as a rule, is included in the package of household power tools. The battery charging time with it varies from three to seven hours. There are also powerful pulse-type chargers that come with professional tools. How much to charge the battery of a screwdriver with such a device? “Impulses” can fully charge the battery within an hour, which is their indisputable advantage. However, the cost of such a tool, of course, is much higher.

How much should the battery of the screwdriver be charged

When buying such a versatile and necessary tool as a screwdriver, its owners may have different questions during operation. Since any power tool of this type is equipped with a battery pack that allows you to work autonomously with it, it is important to know how to properly charge the battery and the optimal charging time for the screwdriver battery. In addition, there are a number of practical recommendations for its use, which can always be useful.

So, the most common questions that arise for those who are just starting to use a screwdriver:

- how to properly charge a screwdriver battery;

- what to do if the battery does not hold charging, does not charge at all;

- how to charge a screwdriver without a standard charger;

- and, of course, what is the optimal battery charging time.

Non-standard methods of charging the screwdriver battery

It also happens that the “native” charger from the power tool is either lost or fails, and getting the same one is very problematic. Many people ask if it is possible to properly charge the battery by connecting it to some other power source.

Of course, this can be done. And such charging methods will not do any harm to the battery if you are well acquainted with the characteristics of the tool itself and any other charger that can serve as an alternative source of power for the battery.

In order to choose a suitable alternative charger for your screwdriver, you need to know the indicators of its voltage and capacity. They are usually indicated on the outer casing of the instrument. You should also pay attention to the polarity. It can be different, depending on the manufacturer. This is very important for the correct connection of the battery to the charger.

Which charger is suitable is determined as follows. For example, we have an 18-volt screwdriver with a 2 Ah battery capacity. This means that the charger must be capable of delivering the same voltage, and 200 milliamperes per hour will suffice. since a full charge of such a battery takes a long time. It is better to use a charger with the ability to adjust the amperage, charging the battery for 6-7 hours.

Small crocodiles can be used to supply current to the battery. And so that the contact is good, they can be additionally secured using metal wires.

If possible, try charging the screwdriver battery with a car charger. It is important to remember that the voltage in this case should be set to the minimum. Determine what polarity the battery and the car charger have (as already mentioned, it can be different). Then connect the terminals from the car charger directly to the battery. Sometimes, for optimal contact, you also have to use additional “fasteners” in the form of clips or flexible metal plates.

After such simple manipulations, all that remains is to plug the device into the network and closely monitor the charging process. For a start, 15-20 minutes may be enough, and when heat transfer increases in a charged battery of a screwdriver, the charger should be disconnected.

Recently, it has become very popular to replace batteries in a screwdriver from cadmium to lithium, especially among professional craftsmen who use a screwdriver regularly. Battery charging time in this case will also depend on the type of charger. If you have a regular “regular” charger, the battery can be charged from 3 to 7 hours. And if it is possible to purchase a modern impulse charger, a little over an hour will be enough to bring the battery into working condition.

How many hours to charge a serviced battery?

How long does it take to charge a 60 Ah battery? For standard 60 Ah batteries, the normal current is 6A. It is possible to calculate the value using the following formula: the current strength should be 10% of the total capacity. How long the recharging process will take depends largely on a number of factors. In most cases, 12-14 hours is sufficient. The state of the electrolyte should be monitored. If it boils, it means that the battery is “full” to the eyeballs.

Some owners increase the amperage in an attempt to speed up the process. Indeed, things will go faster, but this method significantly worsens the condition of the lead plates. As a result, the battery will run out of its resource prematurely. The negative impact of the increased current concerns primarily batteries with lead plates. It is also necessary to take care of the voltage level, if it is below the nominal value, there will be no charge. The voltage from the charger should be in the region of 13-14V, this is how much the car generator gives out.

How to use the calculator

To find out how long it takes to charge your battery, you do not need to go into the details of all processes and calculation formulas, just use this calculator.

For online calculation, you must fill in all three fields:

- In the “Nominal capacity” field, enter the capacity of the rechargeable car battery.

- In the “Degree of discharge” field, you can enter both the percentage calculated from the table and the voltage measured with a voltmeter.

- In the “Charging current” cell, you need to indicate with what current you plan to charge the battery from the charger.

By pressing the “Calculate” button, get the required time to fully charge the car battery.

Calculator Questions,

and also leave ideas in the comments

Preparing the battery for the recharging process

One of the main reasons for the decrease in battery capacity is the critically low temperature. It is important to take care of the charge level of one of the most important elements in the engine starting system even on the eve of the first frost. You do not need to try to invent your own device to restore the battery charge level, thereby exposing your safety and those around you. The right decision would be to purchase special equipment for safe long-term operation. The first step in the recharging process is to organize the workspace.

The following requirements are put forward for the room in which the car battery is installed:

- It must be equipped with ventilation to quickly remove toxic fumes.

- There should be no voltage surges or surges in the power grid.

- Availability of the necessary fire-fighting equipment.

When a room that meets all the criteria and requirements is found, you can proceed to the stage of preparing the battery itself. Contacts should be thoroughly cleaned from dirt and oxidation. Then it is recommended to walk on the surface of the device with a soft cloth moistened with ammonia. Also, do not forget about the organization of high-quality lighting. At this stage, the stage of preparing the battery for recharging can be considered completed.

Online calculation of battery charging time. Calculator for calculating how much you need to charge a car battery with a charger

Charging is required not only for a completely dead battery (it is not desirable to bring it to this), but also for a battery in operation. Only now the recharge time will be different for them. This is often 8 to 12 hours. Our online calculator will help you calculate how much you need to charge a car battery using direct current.

The first charge of a new (uncharged) battery can last for a relatively long time: 25-50 hours (depending on the state of the battery). How long a used battery will take to charge depends on its discharge rate, operating time and condition. A highly discharged battery may take 14-16 hours or more.

As a rule, the state of charge of the battery is judged by the density of its electrolyte. The density of a fully charged battery should be 1.26-1.28 g / cm³, voltage is not less than 12.5 V. Everything will depend on what density of electrolyte was originally set in the new battery in your region of residence, it can be as high as 12.7 So 12.9V. The lower the density, the more it is discharged. A decrease in density by 0.01 g / cm3 in comparison with the nominal means that the battery has been discharged by about 6-8%. The degree of charge must be determined by the bank with the lowest density.

| one hundred | 1,277 | 0 | 12.73 | Not necessary |

| 90 | 1,258 | ten | 12.62 | 2 |

| 80 | 1,238 | 20 | 12.50 | four |

| 70 | 1.217 | thirty | 12.37 | 6 |

| 60 | 1.195 | 40 | 12.24 | 8 |

| fifty | 1.172 | fifty | 12.10 | ten |

| 40 | 1.148 | 60 | 11.96 | thirteen |

| thirty | 1.124 | 70 | 11.81 | 16 |

| 20 | 1.098 | 80 | 11.66 | 20 |

| ten | 1.073 | 90 | 11.51 | 24 |

| 0 | 1.06 | one hundred | 11.4 | Sulfation |

A lead-acid battery that is more than 50% discharged in summer and only more than 25% in winter must be removed and recharged. Also, additional charging is required for the battery, the density in the banks of which differs by more than 0.02 g / cm³.

The optimal charging current of the storage battery is considered to be a current equal to 0.05 of its capacity (equalizing charge). So for a battery with a capacity of 55 Am / h, this value is 2.75 A, and for 60 Ah, it is already 3 amperes. The purpose of this method is to ensure complete restoration of active masses in all battery plates.

Equalizing charge is able to neutralize the effects of deep discharges. Recommended for elimination of sulfation of electrodes caused by long-term operation of the battery with a charge of less than 70%.

Although the so-called forced charge is often used and a different ratio is taken. 10% of the capacity. That is, a standard 55Ah car battery is charged with a current of 2.75-5.5A, and for a 60Ah battery, the charging current is set in the range from 3A to 6A. But, you need to know that the lower the charging current, the deeper the charge, although it takes more time. The situation is exactly the same with the supplied voltage. the more the faster, but it should not fall below 13.8 and exceed 14.5V). The charging voltage is raised to 16.0-16.5V only when charging a maintenance-free battery.

Supply current above 1/10 of its capacity is harmful, but below 1/20 will be useless when charging.

It should be definitely noted that today there are several methods for recharging the battery:

- At constant current;

- With constant voltage;

- Combination in automatic mode (we will not consider it, since in this case a time calculator is not needed).

Stages of discharging a car battery

How the battery should be prepared for charging

Preparation for the charging procedure is a must for any battery, whether new or used. Preparing a new battery consists in filling its cans with electrolyte having the required density. For a battery that has been in operation, everything is somewhat more complicated. Initially, its contacts are thoroughly cleaned from traces of oxidation and dirt. Then the entire area of the battery is cleaned with a soft rag, which must be moistened with either a soda solution or ammonia. And this is where all the preparation ends.

True, this statement is only true for maintenance-free batteries. The serviced battery additionally needs a thorough cleaning of the top cover and the plugs screwed into place. The presence of plugs prevents dirt elements from entering the battery during the cleaning process, which will inevitably lead to battery failure. The plugs can only be unscrewed after completion of work.

At the next stage, the compliance of the electrolyte level with the norms and the indicators of its density are checked. If necessary, the level is brought to the recommended level by adding distilled water or an electrolyte of appropriate density. At the end of this operation, the plugs do not need to be replaced, allowing the battery to “breathe”. If this is not done, then the possibility of an explosion of the battery due to the accumulation of evolved gases in it during charging is not excluded. In addition, the absence of covers will allow you to control the temperature of the electrolyte to prevent overheating and boiling.

The charger is connected to the terminals of the prepared battery with strict observance of the polarity, which cannot be confused in any case. The connection sequence is as follows:

- We connect the charger wires to the battery terminals.

- We turn on the charger to the network.

At the end of the charging process, the actions are performed in the reverse order and in no case otherwise. This is done to prevent the possibility of ignition of a mixture of oxygen with hydrogen from a spark, which may occur at the moment of connecting or disconnecting an active charger. Hydrogen is released as a result of chemical reactions in battery banks.

Battery charging time at constant current

The formula for calculating the charging current is: I = Qk, where Q is the battery capacity, and k is a certain coefficient from the nominal (its ideal value is in the range of 0.04. 0.06, and the optimal value is up to 0.1). Based on this recommendation, the calculation of the time it takes for a fully loaded battery looks like this: T = Q / I. Substituting your values, you will see that it takes a lot of time, but since often not a full charge is required, but only the restoration of the lost capacity, then this figure will be two or one and a half times less.

For a rough estimate of the required time for charging a car battery with a constant current, you first need to determine the degree of battery discharge (in percent), then determine the lost capacity (in Ah), and then, choosing the value of the charging current, calculate the full charge time. The formula for calculating how long to charge the car battery looks like this:

The multiplication of this ratio by 2 times is necessary due to the fact that the efficiency of the process is 40-50%, the rest is spent on heating, as well as the associated electrochemical processes.

The use of the calculation formula must necessarily be accompanied by control over the progress of the charging process, especially at its completion, so as not to miss the onset of violent boiling.

When within an hour at the battery terminals, when charging, the voltage stops increasing. the battery is 100% charged.

The value of the final voltage depends on: the value of the charging current, temperature, internal resistance of the battery, the presence of impurities in the electrolyte and on the composition of the alloy of the grids.

Charging the maintenance-free battery

Recently, maintenance-free battery models are gaining popularity. As a rule, devices with a luminous indicator are used to charge such batteries. It is impossible to trace the charge level, the case of a maintenance-free battery is absolutely sealed, it will not be possible to detect the boiling of the electrolyte and the evaporation of gases. It is quite logical that you need a charger that automatically controls the level of the supplied voltage.

Such a device is capable of supplying voltage from 13.8 to 14.5V. At the initial level, the battery can absorb amperage ranging from 50% to 60% of the nominal values. Thus, for a 60 Ah model in the first hour of charging, a current of 36A is suitable. In the second hour, the battery charge rate drops to 20%. In the third hour, these indicators fall to 7-8%. This is a completely automatic process that does not require human control. It will take about 10 hours to restore 100% charge level of a 60 Ah battery using such a device for a battery.

Constant voltage charging time

This option is gaining more and more popularity. this principle is implemented on many Chinese devices, where there are practically no VOLTAGE and AMPERAGE indicators, but only luminous “dots” or a scale that signals the charge. Such a device is designed specifically for maintenance-free batteries, because you cannot watch the boiling of the electrolyte and the release of gas from it, because everything is hermetically sealed. Therefore, the first option is not entirely good. The voltage and “amperage” are automatically regulated here.

SO: The voltage can float in the range from 13.8 to 14.5V, the higher the voltage, the faster the charge goes.

So in the first hour, the battery can absorb from 50 to 60% of the nominal capacity. That is, if it is 60A, then 60X60% = 36A

In the second hour. the voltage drops, and the charge occurs more slowly, about 15. 20%

The third hour is even lower, about 7. 8%

Fourth. almost full capacity at 90. 96%.

The next hours are not really needed, the current strength can “drop” to 0.2A, charging up to 100% will take almost the same 10 hours.

This option is convenient in that you do not need to “steam” and configure the device. it will do everything for you.

DETAILED VIDEO. WATCHING NECESSARILY!

Two battery structures

This is also an important line, the whole point is that you need to charge each of the types in different ways, more precisely, prepare for the charging process. SO:

The first type is the so-called maintenance-free batteries. They have an electrolyte inside and it is, as it were, “sealed” inside, that is, it cannot evaporate. If it turns into steam, it further condenses on the walls and re-precipitates into the main electrolyte. This is the most problem-free type. No need to clog your head with replenishment level, density, etc.

The second type. (which is a thing of the past). serviced. It does not have a sealed case, so the electrolyte (or rather the water from it) can evaporate, thereby lowering the level. This option is one of the most problematic, you need to be able to care for and charge it! For example, if the level is lowered, charging should not be performed! Need the right preparation.

We will talk about it further.

How long does it take to charge the car battery? We will analyze options ranging from 55, 60 ending with 90, 100 Ah

In winter, topics related to car batteries are especially relevant (after all, a cold start can quickly discharge it). Many people change old batteries (just handing them over to buyers), buy new ones (the main thing is to choose the correct polarity). however, most try to recharge them and use them further. Fortunately, modern batteries run for a long time (about 4. 5 years), but this period can be much reduced! If you apply the wrong current and calculate the wrong charging time, the battery can quickly fail. Therefore, today, detailed information. how long does it take to charge your battery.

ARTICLES

- How the battery works

- Two battery structures

- Battery preparation

- DC charging time

- Constant voltage charging time

- So all the same, how long is the battery 55, 60, 75. 100 Ah?

I would like to make a reservation right away. we will charge the car battery at home with a special charger, at an approximate temperature of 25 degrees Celsius, this is important, because if the temperature exceeds 35 degrees, then it is better not to start the process (here is the dependence of the temperature of the electrolyte and the ambient air)! The thing is that the electrolyte has a different density at different temperatures (by the way, you can see how much of it is in different batteries). However, I propose to remember the principles of charge and discharge.

Battery preparation

Before charging the battery, you need to properly prepare it, because if you remove it, then you need to check everything at once. As I wrote above, it will be about the serviced battery.

- First you need to remove all condensate, oxide and dirt from the surface and contacts. To do this, we simply take an ordinary rag, moisten it in a solution of ordinary soda and wipe the upper part. the contacts. Thus, we achieve cleanliness. this is important! After all, if your battery has twist-off covers on top, then dirt can get into them during dismantling. which is highly undesirable! After all, it can be the cause of battery failure, simply by shorting the banks.

- You can unscrew the covers. We check the electrolyte level, if it is extremely low. it does not cover the plates, then it is necessary. ALWAYS, add distilled water. Otherwise, you will simply “kill” your battery. Lead plates will heat up and crumble.

- Ideally, you need to measure the density of the electrolyte. Let me remind you for a working, normal battery, it is. 1.26. 1.30 g / cm3.

After the preparatory work, you can proceed to charging. However, it is worth noting. that it can be of two options. using direct current and using constant voltage, the time can vary greatly from these parameters. Unless, of course, you have a universal charger, there you have a minimum of settings.

So all the same, how long is the battery 55, 60, 75. 100 Ah?

Guys, as you understood, everything is quite individual, which device you use. You also need to understand. completely discharge or not.

If you exaggerate and imagine a complete discharge of any of the batteries. THEN:

In the case of a current strength of 10% of the nominal. 10 hours, until fully charged.

In the case of “regulated” voltage. 4. 5 hours, up to 90. 95% (which is quite enough) and again 8. 10 hours until full charge.

As you understood this at the maximum discharge, if you have a partial one, then the time is much corrected.

That’s all, I think the information was useful for you. Read our AUTOBLOG.

(165 votes, average: 3.96 out of 5)

DC charging time

I don’t think it’s worth explaining. that you connect the negative terminal of the battery to the minus of the “charger” with a plus in the same way. Many adhere to this particular option, because the “Amperage” which we supply to the battery is a very important parameter. in no case should it be exceeded, and if it is greatly underestimated, the battery will take a long time to charge.

I also want to warn you. that the voltage should be higher than the nominal. that is, we get about 13.8. 14V from the charger, about the same amount is given by a car generator. Only then will the charge go, if the voltage is less than 12 (and even more so 11V), then nothing will happen, but most likely it will further aggravate the discharge.

SO: The optimal voltage is considered to be 10% of the total battery capacity, that is, if you have 75 Ah, then you need to charge with a current of 7.5A.

Thus. if your battery is completely discharged (voltage less than 11.7V), then it should be charged in 10 hours! However, the time may be shortened from the discharge level.

In the version with serviced batteries, it is quite easy to determine this. as soon as bubbles go from the surface of the electrolyte in the cans, this means that the charge is completely completed.

On my own behalf, I want to add. in ancient times (20 years ago), my father very often charged the battery at home, especially in winter. He set the 60Ah option to a current of 2A and left it overnight, thus. the battery took the right amount of energy. from this small current. It should be noted that the discharge was not deep then. Therefore, if you just want to “feed” your battery, for example, the voltage on the contacts is exactly 12V, put it on a current of 1. 2A for the night!

However, now there is another method that also requires a minimum of human intervention.

How the battery works

In order to charge it, you need to understand how it works. no, now I will not decompose it into various components, everyone already knows that inside there are lead plates in a special solution of sulfuric acid. We need to understand. what is, for example. 55 Ampere hours and 12 Volts.

- Amperes and Hours. Battery capacity is measured in Ampere-hours. That is, if your battery (rechargeable battery) is 60 Ah, then it can give 60 Amperes for one hour. Accordingly, if the load drops, for example, to 30A, then it can give already two hours and so on. I think this is understandable.

- Voltage. it is generally accepted that the voltage is 12 volts, although this is not entirely correct. The normal value of the working option is 12.6. 12.7V (there are options with a larger one), this is a fully charged 100% option.

If the voltage is 12V, then it can be stated that the battery discharge is about 40-50%, but you can drive with such indicators. If your car is in good working order and the generator gives a normal “charge”, then the voltage will quickly recover. I would also like to note that the indicator of 11.5. 11.6V indicates a “deep discharge”, it is very “unpleasant” for the battery. The process of “sulfation” of the lead plates inside begins, which simply reduces the capacity of the battery. it can be so much that the car simply does not start.

That is, we understand that the normal indicators are 12.7V (charged), it is with this voltage that 60 Amperes will be given within an hour, and then it will drop to 11.6V (discharged). Then charging and re-use.

How Long Does It Take To Charge Your Vape Battery

Similar news

How do I charge an AGM battery? In car and charger.

Desulfation of the battery. DIY works, restore.

How to remove the battery from the car. Knowledge needed video version

What to do if the screwdriver battery does not charge

Cordless screwdrivers are more convenient to use than cordless ones. They are distinguished by their mobility, independence from the presence of an outlet “at hand”, the length of the cord. The only drawback is that you need to monitor the charge level for timely recharging. But not all types of batteries allow you to do this, and at the most inopportune moment the screwdriver stops working. And unfortunately, there comes a time when the battery stops charging.

Battery types

There are three types of tool batteries:

- Nickel Cadmium (NI-Cd). The older generation, which is still equipped with household screwdrivers. Affordable price, good ratio of size and capacity (rather compact), keep a charge in an inoperative state for a long time. The disadvantage is the memory effect. If recharged without a full discharge, then “information” about an incomplete volume is accumulated, it interferes with giving a charge until the real resource is exhausted.

- Nickel metal hydride (Ni-Mh). Improved analogue of nickel-cadmium batteries with cleaner production technology. Although the memory effect is present, it is weaker. The main disadvantage is that they are quickly discharged during storage.

- Lithium-ion. The most advanced type, which is gradually replacing other types in the segment of professional / semi-professional electric hand tools. High capacity, almost complete absence of “memory”, durability, low self-discharge in storage mode. The only drawback is the high cost compared to other analogues.

Important! The price of a 2 Ah nickel-cadmium can is approximately twice the price of a lithium-ion can.

Why the screwdriver battery does not charge. causes and elimination

The reasons for the absence or low level of charge, as well as ways to eliminate the malfunction, are different:

- There is no contact between the terminals of the charger and the battery. This is a consequence of the fact that the memory plates are bent. Gently fold back the plates, returning to working condition.

- Oxidation of terminals or dirt adhering to them. Contacts are cleaned and wiped with alcohol.

- Failure of one of the “cans”. Disassemble the battery pack housing by removing the cover (unscrew the screws or remove the latches). Call each jar with a tester for voltage or discharge current. With tension it is easier. it is either there or not, but this method does not always work. The discharge current is measured at a load resistor. in a faulty can, it is an order of magnitude lower than in a working one. After diagnostics, the faulty jar is separated from the serviceable ones, and a new one is installed in its place, exactly of the same type, and with the same polarity orientation relative to the rest of the elements.

Important! The most difficult part of changing a can is soldering the cans into a battery. At the plant, spot welding is used, and for DIY repairs, a soldering iron is often used. During operation, it is important not to overheat the battery, you need to work quickly.

There is another reason for the lack of charge, but it is characteristic only for nickel-cadmium batteries. the memory effect has worked, and the battery does not charge, although its resource has not yet been exhausted. In order not to bring it to this, it is important to carry out the charging correctly.

How to charge the battery correctly

When buying a new tool with a nickel-cadmium or nickel-metal hydride battery, the battery is fully discharged and charged (pumped over) three times before use. When using a screwdriver, the battery is not charged until it is completely discharged. Then the pumping is repeated periodically as a preventive measure.

Important! To avoid downtime, you need to have a spare battery.

When the full charge is reached, the Ni-Mh and Ni-Cd batteries are disconnected from the network (for lithium-ion batteries, this is done by the controller). During a long break in work, the battery is removed and stored separately from the screwdriver.

With careful handling, following the manufacturer’s instructions, the battery will work for a long time and will not require early replacement. And minor repairs can be done by hand.

Useful video reviews of smartphones and other gadgets on our Youtube channel