How the ignition works on a power tiller. General rules for operating and starting all types of power tillers.The first steps in setting up a power tiller.

Principle of power tiller ignition

EXCELLENT TOOL FOR CRAFTSMEN AND HANDICRAFTS AND ALL FOR THE GARDEN, HOME AND SUMMER COTTAGE LITERALLY FOR FREE THERE ARE REVIEWS.

Many households have power tillers and power tillers, which greatly facilitate the work in the garden. I’ve got one of those, too. It was obtained back in the 90s and served me faithfully all the time, everything was up to his ears, as they say. And I, in turn, tried not to offend him. So we’ve been living with it.

But lately the single-axle tractor suddenly started worse. I had to exert a lot of effort to revive the engine. Started to figure out what’s wrong. The ignition system was suspected. the spark was very weak.

Wandered around the Internet, read a lot of tips and settled on one. So, the cause of a weak spark may be the aging of the magnets attached to the engine flywheel. As they rotate, magnetic field crosses the coils of coils, fixed on the housing, which leads to electric current.

EVERYTHING YOU NEED FOR THIS ARTICLE IS HERE

After learning about the price of a new flywheel, which needed to be replaced, I decided to change the ignition system of my power tiller and make a battery ignition system from the factory transformer one.

I visited an auto junkyard and bought for 300 dollars the ignition coil from VAZ 2101-2107. In the store I took 10 batteries (cell 33), and at home I found 2 m of wires PGVA cross section of 1.5 mm. I grouped the batteries and wrapped them with duct tape. Soldered them together in series, t.е. I got 15 volts on the output wires. I connected the minus wire with the casing of the power tiller, preliminarily cleaned the place of contact, and assembled the electric circuit (see pic.1). rice.)

If you don’t have a suitable switch, you can do without it. It is only necessary to connect the wires by twisting them together during the work of the power tiller.

Then I pumped some gasoline, according to the instruction, wound the starter rope around the flywheel drum, pulled it. and the single-axle tractor started up like a young man. It was last fall, and I had time to plow the whole plot for potatoes. I put my iron friend in the barn in winter. The spring came. took out single axle tractor, checked oil in crankcase, poured petrol, connected wires. and engine started. I planted potatoes with it. That is, the batteries overwintered well.

How to adjust ignition on MB1 and MB2 power tillers?

Perhaps the most common breakdown and cause of ignition failure is spark plug failure. That’s why it’s very important to always have a spare spark plug in your parts arsenal. If you have an engine model DM-1 or DM-1D then select a spark plug from the following range: A-11-1, A-11-0, A-17B, C-12RT. They all have a 12mm thread, which is their specialty. Proven themselves enough spark plugs B8AC from a well-known brand Bosch.

- Unscrew the spark plug.

- Wipe electrodes dry well.

- If there is soot on the plugs it needs to be cleaned.

- Adjust the gap between the electrodes.

- Place the angle piece of the ignition lead on the spark plug.

- Press the spark plug housing against the cylinder head.v

- Doing the previous point, it is worth paying attention to the electrodes looking away from the hole under the plug.

- Spin the crankshaft and see if the spark appears. If there is a powerful and bright spark, then the adjustment is correct.

The gap between the stator and the flywheel’s magnetic shoe plays an important role in the ignition operation. It should be no more and no less than 0.1. 0.15 mm. What to do if you need to adjust the gap:

- Remove the housing from the fan.

- Loosen the stator mounting bolts.

- Insert the dipstick plate, set the gap and screw in the bolts.

- Check the clearance around the flywheel.

Such simple instructions will help you to resume the ignition work and easily identify the cause of its failure with your own hands. If you are confident in your technical knowledge, it is no problem to perform the above steps. In order to avoid breakdowns of your motor-block in the future, you should carry out its regular diagnostics, which will allow you to immediately identify all kinds of malfunctions and cut them off at the first steps.

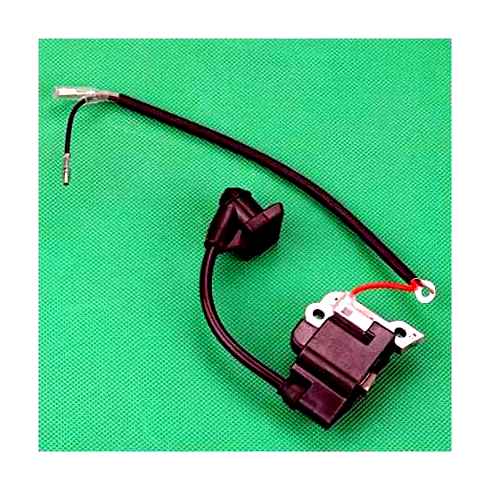

How to check the ignition coil on a power tiller?

Most often, the test of this important element of the ignition of the motoblock is made with a known working test sample. If during the testing process it turned out that everything started working as it should with the installation of the sample, it means that the original ignition coil of the motorblock is defective.

But not everyone has a sample on hand. If there is none, then it is necessary to try to check the built-in coil in other ways. Before this, it is necessary to rule out any breakdowns that may appear in the start button and high-voltage wiring. In addition, the user should carefully study the wiring diagrams. which indicate the location of the ignition system elements.

- measuring the resistance of the integrated ignition coil. It is worth noting that it is not always used by farm equipment users. First, the operator must know the exact parameters of the resistance created by the regular coil. Secondly, in addition to the inductance coil, the ignition system has semiconductor components required to generate the desired electrical pulse. Problems with all of these elements can only be detected by heating them up. In order to properly check the ignition coil, you will need to disconnect the cap and the original armature wire from it. Knowing the exact parameters of the built-in element resistance, the operator will be able to understand which part of the system is faulty;

- Checking the spark created by means of a special device. it should be connected to the place of the electrical circuit break between the high-voltage wires of the standard coil and the spark plug;

- testing the coil with an integrated spark plug. to do this, unscrew the integrated spark plug and carefully put its body to the cylinder. Then pull the handle of the starter and pay attention to the spark that forms between the factory contacts of the spark plug. It should be noted that this method of checking the existing coil is approximate. the spark plug in this case is not under load, due to which there is no compression in the internal combustion engine cylinder. As a result, the engine flywheel will spin faster.

Medium boys are power tillers || What four-ton brick-breaking machine gets stuck in soft soil.

Each of these methods gives an approximate indication of the condition of the ignition coil. It should be remembered that to find the exact cause of the faulty part is possible with the use of specialized testers, which are available only in specialized workshops.

Checking the efficiency of a magneto

If anyone doesn’t know how to check the ignition coil, they can read the information about spark plugs above. The test method is the same. The main thing that the spark plug, the lug and the high-voltage wire must be in good condition. Put the cap and wire on the spark plug, and bring the lower part (electrode) to the magneto body and rotate the flywheel with your fingers. If there is no spark, then the ignition coil has failed.

Many owners of power tillers wonder which spark plug is better. The best is the spark plug with the shortest path of heat dissipation. The shorter the spark plug for your power tiller, the less it heats up and lasts longer. Poor spark plug performance is indicated by a weak (dim) spark.

How to check the ignition coil on your motoblock?

often than not, this important element of the ignition of a power tiller is checked using a known working test sample. If in the process of testing it turned out that with the installation of the sample everything started working as it should, it means that the regular coil of the motor-block ignition is defective.

However, not everyone has a test sample at hand. If it does not, then you should try to test the built-in coil in other ways. Before that, you need to rule out any breakdowns that might appear in the starter button and high-voltage wiring.

- measuring the resistance of the integrated ignition coil. It is worth noting that it is not always used by users of agricultural machinery. First, the operator must know the exact parameters of the resistance created by the regular coil. Second, in addition to the inductance coil, the ignition system design includes semiconductor components required to generate the desired electrical pulse. Problems with all these elements can be detected only when they are heated. To properly check the ignition coil, remove its cap and original armature wire. Knowing the exact resistance parameters of the built-in element, the operator will be able to understand which part of the system is faulty;

- check the spark created with a special device. it should be connected to the place of the electrical circuit break between the high-voltage wires of the regular coil and spark plug;

- testing of the coil with the built-in spark plug. to do this, unscrew the built-in spark plug and carefully put its body to the cylinder. Then you need to pull the starter handle and pay attention to the spark that is formed between the factory contacts of the spark plug. It should be noted that this method of checking the existing coil is approximate. the plug in this case is not under load, due to which there is no compression in the ICE cylinder. As a result, the standard motor flywheel will spin faster.

Each of these methods gives approximate information about the state of the ignition coil. It should be remembered that you can find the exact cause of the failure of the part using specialized testers, which are available only in specialized workshops.

Oil Change

Also, as for the gearbox, and the motoblock in general, lubricants play a major role in their operation.

The type and density of the machine oil is accurately specified in the instruction manual, which is supplied with the product, but as for the brand of oil, this manual is long outdated.

In addition, to replace the not very wide choice of fuel and lubricants of the time, which was the peak of production of motor blocks “Luch”, came a large number of modern machine oils. Of course, not all are suitable for use, but there are analogues to what is specified in the instructions, and they are largely superior to the recommended.

A good engine oil for tractor “Luch” is not very difficult to choose, any dealer will recommend it. But if you want to buy it yourself, or through an online store, it is best to focus on the brand 10W40. It is desirable to use mineral or semi-synthetic oil.

Full synthetic oil is not suitable for such engine, because due to its inherent fluidity, such oil simply does not retain on the parts sufficiently.

The reason for that is a peculiarity of greasing mechanisms, with the help of splashing. The oil in the engine must be changed after every 25-30 hours of work, change the gear oil is needed less often, after 50 hours.

Also, it is very important that during the oil change the single axle tractor stands strictly horizontally, without tilting. otherwise you can simply underfill it in the right amount. To find out what is the volume of oil in the gearbox of a “Luch” motoblock, just look at the instruction manual.

In a completely dry tank you need to fill two liters of oil, but when you change it, only one and a half.

How Risky Driveing it is to Carry a Power Tiller With Heavy Load of Tree || โหลดไถนาไฟฟ้า_Part_J

For gearbox, in principle, fit any gear oil, but the owners recommend TM-4 80W-85. It is relatively inexpensive and mineral, which fully meets the requirements for the performance characteristics of the oil for the gearbox of this motoblock.

Magneto for power tiller. testing at home

Magneto on a single axle tractor is a structurally complex element, which is in constant contact with high-voltage wiring and interacts with electricity. Because of the operation of a power tiller in wet weather, accidental bumps and power failures, this part gradually fails. Checking it for serviceability is simple enough, but the operator will have to act at his own risk, as the only way to test the part in the field will be very dangerous for the entire ignition system.

To check the magneto of the motoblock, you will need:

- Remove the spark plug carefully and put a small nail in its place. The latter should be clean, with no signs of corrosion;

- The nail must be installed 7 mm away from the cylinder wall of the power unit’s standard cylinder;

- Start the engine of the agricultural machine;

- Check if there is a spark when you start the motor. It should be painted bright blue and clearly distinguishable. If it is not, it means that the magneto is out of order.

If the magneto is broken it must be replaced. This can be done with your own hands by removing the faulty part and installing a new one.

How to check the ignition coil on a power tiller?

The power tiller‘s ignition coil creates a spark that ignites the fuel. The scheme presented allows to get acquainted with the principle of its formation. The ignition can be contactless (first photo) or contact (second photo) depending on the operating principle.

Initially, the coil is inspected. There may be cracks, dents and other damages of mechanical type. If the coil structure is intact, you need to look for another cause of the malfunction.

The following problems may arise:

- Measured coil resistance data. In this case it is necessary to have an idea of the key parameters at which this resistance occurs;

- a spark detector is used. The cost of such a device is quite high;

- The spark plug is used. It is unscrewed and applied to the cylinder. Next, the starter rope should be yanked and the spark should be traced.

The above methods are worth using if it is not possible to ask for qualified help. During work, it is important to ensure that there is no electric shock.

To perform the repair is quite possible with your own hands, following simple tips. To facilitate the work, you can view a video instruction.

For power tillers of such brands as Neva, Ural, Agro, Zubr, Salyut, Mole, Kaskad, MTZ and Honda, the adjustment procedure is completely identical.

Improvement of ignition in the motoblock mole with his own hands

Nowadays, any kind of equipment is available in land stores, but many farms use tillers and power tillers from the stagnation times.

Other owners have been using their mole harvesters for 20 years and all of a sudden they had a breakdown. the electronic ignition unit MB-1 failed.

The main disadvantage of the electronic block MB-1 is its miniaturization and circuitry,

Although there is a proven option with light motorcycles and mopeds. the alternator coil, the electronic filling and the ignition coil are separate units and there are no problems in the ignition system.

And in the MB-1 and the coil winding of the generator is very thin wire and the ignition coil is small, and the main thing. the electronic part of the circuit is in the engine crankcase and heats up to 80 degrees. And the thyristor KU202H used in the circuit is designed for 75 degrees. That’s why the constant malfunctions. The same thyristors were used in ignition circuits operated on light motorcycles and on mopeds and worked reliably. The thin winding wire of the alternator coil does not allow it to produce more current and install a 1 uF storage capacitor.

Try to separate these ignition elements. Here’s an example of how an acquaintance from the forum improved the ignition unit.

Further narration will be led from his person:. Ignition coil. automobile, with multiple reserves and a spark twice as powerful as the former one.

Found a car ignition coil. In the case of burnt-out commutator is mounted electronic circuit.

I mounted the ignition coil on the handlebar plate of my power harvester.

From native MB-1 unit was left the alternator coil and the sensor coil, in place of the native ignition coil installed the second alternator coil,

just have to fit it in.

The motorcycle has a flywheel with four magnets, one of them inverted, so as not to make a fuss with the winding phrases. each generator coil with its own diode bridge.

After all modifications. multiple ignition reliability. Thyristor T 122-25-8 military style, diode bridge at a thousand volts, eternal ignition coil.

In the diagram on the right is the connection of the generator coils. Connected at points A B in the left diagram.

Thyristor. 10 amps and 800 volts. I put. T 122-25-8. 25A 800V.