How to adjust a Chinese chainsaw. Algorithm of actions for adjustment

Carver chainsaw carburetor adjustment

Using a chain saw makes life much easier, even for recreational users and is practically indispensable in some workplaces. But like all comparably complex machines, chain saws need service. Improper or inadequate maintenance can lead to malfunctions and engine problems. One of the most common causes of malfunction is that the carburetor of your chainsaw is set incorrectly, either by shifting the adjusting screws due to vibrations or by trying not to adjust them properly.

Adjustment of chainsaws is required in the following cases:

- The factory settings of your chainsaw‘s carburetor are knocked out;

- The engine starts with a struggle and stops almost instantly;

- debris entering the fuel distributor mechanism due to a malfunctioning air cleaning system;

- the exhaust is too thick, fuel consumption is too high, fuel does not burn completely in the cylinder

- considerable wear of the piston group (in this case carburetor adjustment is a temporary measure).

The carburetor is designed to prepare the fuel mixture for the engine. Engine malfunctions if the proportions in the fuel mixture are too low.

adjusting the carburetor on a chinese chainsaw

The design of the carburetors varies from model to model, but they all work according to the same principle. The air moves quickly through the air duct. The exhaust velocity is regulated by a damper that closes the channel. The fuel fed into the channel through the nozzle mixes with the air, and then the resulting air-fuel mixture enters the engine.

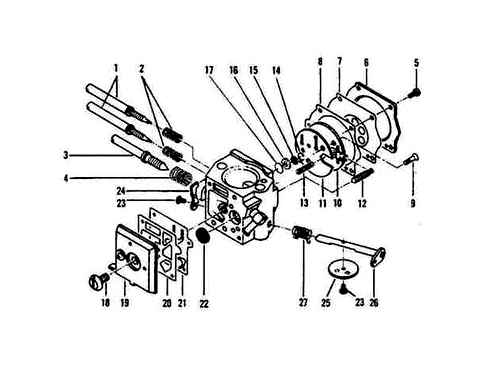

The carburetor always consists of the same set of parts, although it may vary slightly depending on the manufacturer. It consists of the following parts:

- The basis. It is a special tube, which has an external resemblance to an aerodynamic structure. The airflow goes through it. In the middle of the tube in transverse direction there is a flap whose position can be changed. The more it is pushed into the duct, the less air enters the engine.

- Diffuser. It is the narrowed part of the pipe. It is used to increase the velocity of the air flow exactly in the part from which the fuel is supplied.

- Float chamber. The shape of the element is similar to a tank. it is used to continuously maintain the optimum fuel level before entering the channel from which the air is drawn.

- Channels for the fuel intake. The fuel mixture is in the float chamber, from where it goes to the nozzle and then to the atomiser.

For the functioning of the tool to be effective and smooth, the output maximum, and fuel consumption economical, timely adjustment of the chainsaw carburetor is required. The air and fuel filters should be checked for cleanliness before tuning. Most power saws adjust with three screws: high rpm, low rpm, idle speed.

The carburetor adjustment procedure must be done very carefully, because a mistake might have drastic consequences, up to and including engine failure.

The following are indications that the setting is correct:

- The engine accelerates quickly and smoothly;

- The chain remains stationary at idle speed;

- The engine emits a smooth noise, like a four-stroke machine.

The adjustment of the carburetor of the Chinese chainsaw is performed in the same way as with models made by European manufacturers, in fact, the Chinese analogues are copies of famous brand-name tools, but with some changes.

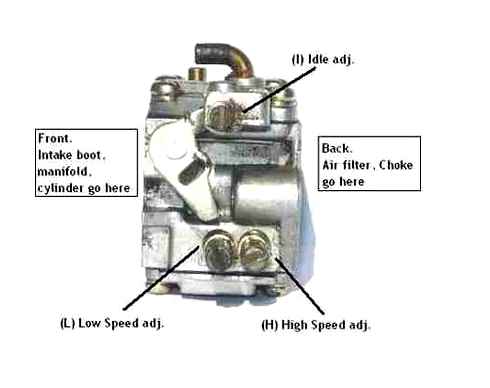

Use the same screws H, L and T. The standard for the carburetors of Chinese chainsaws is the position of the screw L, at which it is loosened compared to the fully clamped state by one and a half turns. For the screw H standard. one turn from the same position. Idle speed adjustment is performed when the engine is warm.

On some models only the idle speed can be adjusted. Nevertheless, the owners of Chinese chainsaws and service employees say about the increased complexity of carburetor adjustment in tools made by Chinese manufacturers. Even experienced technicians can adjust a Chinese chainsaw a little more time than an original tool.

Chainsaw starter motor repair

With frequent chain saw starts, some parts of the starter are constantly subjected to dynamic loads. As a result, the cable may burst, some teeth of the ratchet may get chipped, and the shaft. will rotate at a much slower rate. That’s why revision and even starter motor repair are operations that sometimes need to be done several times a season.

Replacing the cord

When pulling it there is a constant rubbing of the cable on the starter housing

To replace it disassemble the housing of the assembly, carefully lift the ratchet drum to prevent the return spring from slipping out of its sockets. It is better to do such work by two people: an assistant fixes the spring while the cable is being replaced

After fixing the cable in the handle and in the grooves of the drum, the cable is wound on the roller and the housing is assembled.

Repair of the spring

If the starter spring material was bad quality, the spring breaks (usually at the place of its connection to the drum, where it forms a loop). Do not replace the spring in this case. It is enough to carefully clean its surface from dirt and traces of grease, carefully grind the place of destruction, then temper the spring at 600 650°C (steel spring should turn crimson). The spring should be cooled slowly and at 100 150 ºC you can already carefully wrap its end in the form of a limiting lug on the inner surface of the drum (steel will get the necessary plasticity) and put into place. The elastic properties of the spring will not change.

Situations in which adjustment is necessary

New chain saws are shipped from the manufacturer with the carburetors already set. This is called standard adjustment. But for normal running-in process it is necessary to decrease the maximum engine speed, adjust the carburetor. After the running-in period, the chainsaw needs fine-tuning for maximum engine performance.

If there is too much fuel in the mixture, the engine parts are poorly lubricated and premature wear occurs. Also, a low-quality mixture can cause the engine to seize due to overheating (this is one of the reasons why the chain saw

This is what a jammed, overheated piston looks like on a disassembled chainsaw with an improperly tuned carburetor.

Adjustment is needed in the case when the engine does not hold idle, stalls or does not develop full power. Carburetor tuning should be done with clean air and fuel filters. We also recommend reading an interesting article detailing the main reasons why a chainsaw

Chinese chainsaw carburetor. adjustment, repair and features

Most chain saws of different brands available today in the Russian market are made in China. Even well-known European manufacturers have their own production technologies, but in China. Chainsaws assembled in the EU and the USA can only be found at brand-name centers. Therefore, when talking about carburetors on Chinese chainsaws, it is assumed that they are installed on most chain saws.

The most optimal designs of carburetors for chain saws are developed by the world’s leading manufacturers. German STIHL, Japanese Walbro and others. These best designs are hard to beat. That’s why most Chinese manufacturers copy the best models.

Today there are a lot of Chinese carburetors for chainsaws on sale.

Some are nameless, from an unknown manufacturer and do not even have markings. They are offered simply for a particular model of chainsaw. For example, a carburetor for chain saw STIHL MS 361.

Others have brand names of well-known brands.

Others have their own catchy names. in the Russian transcription of King-Cong, Technopark, Reset, and others.

Process Description

If the chainsaw carburetor is not adjusted, and it is not possible to start the chainsaw, then the adjustment begins by setting the screws (L) and (H) in the position of the standard setting. These are 1/5 turn of the screws until they are fully torqued. After that, it is necessary to start the engine, let it run for a while and warm up. The next step is to adjust the low speed mode. Optimal operation of the engine at “low” can be achieved by adjusting the screw (L) and idle (T). To do this, first turn the screw (L) to obtain the maximum engine speed, and then release it by 1/4, and use the screw (T) to bring the idle speed to normal.

After adjusting the work at “low”, the traction and maximum engine revolutions are adjusted. To do this, turn the screw (H) slowly and check the revolutions according to the electronic tachometer.

do not allow the engine to exceed the maximum rpm stated by the manufacturer.

An important step is to check the saw on all modes of operation after its adjustment, for this you need to let the chainsaw cool down, then start it according to the algorithm of starting a cold tool. If the saw starts normally and runs smoothly at idle, you should check how it saws. If in the process of checking revealed shortcomings in the power of the chainsaw, it is necessary to repeat the adjustment of the screw (H) by unscrewing it and checking the thrust in the work.

loss of traction at maximum rpm as recommended by the manufacturer is an indication of worn cylinder heads or poor fuel quality.

How a chainsaw carburetor works. principle of operation

The work of the unit in question, despite its complex design, is simple and understandable even for beginners. The operating principle is based on the following actions:

THEY SAID THE CHINESE CHAINSAW WOULD DIE AFTER 3 YEARS. OVER 3 YEARS OF USE & STILL RUNNING STRONG!

- As soon as the internal combustion engine is started, the air damper is opened

- in the area of the narrowing of the nozzle 16 the incoming air stream is accelerated and mixed with the petrol-oil mixture

- Gasoline-oil mixture is fed through nozzles number 15 and 12, and the air, before passing through the flap 7, passes through the filter placed in front of the inlet

- Damping flap 8 is located behind the diffuser and controls the amount of mixture in the combustion chamber

- Screws 17 and 10 is adjusted the amount of gasoline, which passes through the nozzles. On the control panel of the carburetor, these screws are marked L and H

- The needle valve 11 regulates the volume of the fuel mixture in the float chamber 14. To adjust the needle valve position a diaphragm 13 is fitted in the mechanism

- Another diaphragm 4 is responsible for the fuel supply in the cylinder combustion chamber. The position of this diaphragm depends on the number of rpm

- A fine filter is used to clean the gasoline-oil mixture

The carburetor’s simple operating principle keeps the engine running smoothly. The quality of tuning influences the way the machine behaves when idling and during operation. The mechanism under consideration has a direct impact on the performance of the entire tool. Adjustment quality influences the service life of the tool.

How to adjust chainsaw carburetor correctly

A chainsaw is a technically complex machine that requires maintenance from time to time. Cleaning, filter replacement, and of course adjusting your chainsaw’s carburetor will help it last as long as it should. In this article we will consider the issue of carburetor adjustment. How and why it is done.

About carburetor adjustment (My own experience)

My chainsaw is a Chinese 5200 type.Adjustment of the carburetor of Chinese chainsaws, is done with the screw T, the screw L and the screw H. This is how they are conventionally labeled. The location of these screws on the left side, under the cover. The T screw is on top. L and H screws are near and under the T screw. The L screw is the one on the left and the H screw is the one on the right.For me, finding the L and H screws caused some difficulty. But removing the air filter cover, installed right with a screwdriver, where exactly they are. The “T” screw is used to adjust the idle speed of the chain saw. After “starting” and after “warming up” the engine. If idle rpm is too high, the “T” screw turns counterclockwise. If rpm is too low and the saw stops. screw is turned clockwise. One indication of high RPM is that the chain keeps turning when idling. Then to stop it, turn the screw counterclockwise. With the screw of the nozzle “L” is regulated. low engine speed, by the way again at idle. The more you tighten the “H” screw, the more you increase high rpm and correspondingly chain speed when you press the gas pedal button. /The gasoline supply is reduced and the oxygen supply is enriched./ Professionals advise not to overdo the high revs and tighten the “H” screw! The preferred order of adjustment is L screw first, then H, finally T.Basically, the adjustment is made with the working engine, but from my experience I can say that it is possible to do it with a non-working engine.By design, Chinese chainsaws are copies of the Japanese Zenoah g4500 / g5200, only they are made in different factories.♜♜♜

No matter how much experience a technician has, and no matter how confident he is, sometimes he needs to consult someone. Communicating on the Internet has long been commonplace for us. A variety of web users, whether a professional or a knowledgeable amateur, can put up tips (simple helpful hints on various topics) that can be usefully applied to your home.

The WORST Thing About The CHINESE CHAINSAW!!!!

What are the advantages of using the resources of the forum?

- A constant stream of interesting information about new construction ideas.

- Simple and useful tips for construction.

- Opportunity to communicate with interesting people, experienced craftsmen.

- Recommendations on the choice of tools or materials.

- Also a nice plus is the lack of advertising, because users are the same customers as you are.

All the latest construction news are placed in our forum, because our specialists always keep abreast of construction events. Here you’ll find useful information for the operation of the room, equipment and so on. Many people find it useful to do more for the house with their own hands, because it is useful for health, profitable economically, and provides some moral comfort. And there is a logical question: “How to do it yourself??” You can get answers by browsing our website. It is after visiting this forum that you will feel completely all the pros. On this Internet resource you will find information for the arrangement of the cottage with their own hands. But many of those recommendations can also be taken into account in the arrangement of the apartment. Household projects of varying sizes require tools. For general consultation of site visitors an overview of the tools is created, where the information is presented simply and accessible.

Troubleshooting

As a conclusion, let us describe the typical malfunctions associated with improper adjustment of the carburetor and ways to fix them:

- The engine does not start or starts and then shuts down after a few seconds. It is obvious that the cause is improper adjustment of the mixture quality at low rpm, it is too poor. If the carburetor is serviceable, you need to slightly enrich the mixture, turning the screw L for 1/2 turn, and then end the setting of the screw T.

- The engine under load substantially loses power. In this case, the carburetor gives out too rich mixture at high revs. Screw H should be tightened by 1/8 of a turn, if the motor load is still not sufficiently supported, but progress is noticeable. tighten a little more.

- The engine sings at full throttle without any load. Mixture at high rpm is too lean, rpm is too high.

- Engine stalls if you accelerate after idling. Mixture is too weak or too rich, the condition of the spark plug is an accurate indicator.

Pay attention that the carburetor settings can go astray because of the strong vibration. For this reason, a successfully adjusted setting should be memorized by counting the turns and position of each adjusting screw. If you have determined the best type of gasoline and oil ratio, keep a small portion of that mixture to check in case of malfunction whether the malfunction is due to fuel quality and improper adjustment, or whether the cause is faulty chainsaw.