How To Adjust The Carburetor On A Stihl 55 Lawn Mower

Chainsaw carburetor adjustment instructions

Setting up a chainsaw carburetor begins with a preparation procedure. The preparation is based on the following actions:

- Check the air and fuel filter for contamination, and if any, these elements need to be cleaned

- Check the diaphragm for damage

- Serviceability of the needle valve

- No air leaks, which can occur due to leaky oil seals, gaskets and seals

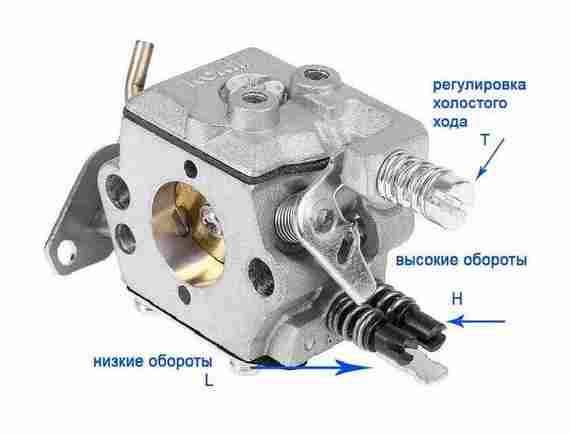

After making sure that the carburetor is in good working order, you can adjust it yourself. It is possible to restore the mechanism to the factory settings, but it is not always necessary to do this. Instructions on how to adjust the carburetor on Stihl, Husqvarna, Makita, Dolmar, Champion, Sadko and others chainsaws are described below. Initially, we find out what each screw in the mechanism is intended for:

- Screw H. main jet, which is responsible for setting the maximum number of tool revolutions

- Screw L. XX jet, which is needed to set low idle speed

- Screw LA or S or T. increasing and decreasing the amount of mixture supplied to the cylinder

Each type of tool of the brands Stihl, Husqvarna, Makita, Dolmar, Partner is accompanied by an instruction, which contains a section that describes this process in detail. It will not hurt if you find the instructions before setting up, and read it before turning the screws.

Preparing for setting up the chainsaw carburetor includes performing the following manipulations:

- Installing a chainsaw with your own hands on a flat surface. It is also recommended to secure the tool so that it does not move when you press the screws with a screwdriver

- Steer the tire away from you

- Provide a safe distance for others, as the carburetor of the chainsaw is adjusted with the engine running

- It is not necessary to remove the carburetor from the unit to adjust it

Chainsaw mechanism customization process:

This is not the end of the regulation process, but the tool can already be tested in action. For beginners and inexperienced sawers, the setup process is recommended to be completed at this point. For a more accurate adjustment of the carburetor of the chainsaw, you need to set the maximum speed. Let’s start setting up the H screw for experienced sawers:

- Determine the enrichment of the mixture by the exhaust. To do this, we develop the revs to the maximum, and look at the nature of the exhaust. The presence of gray smoke and strong vibration of the instrument indicate excessive enrichment of the mixture

- The tachometer (if connected) will show a large number of revolutions. more than stated in the characteristics

- To reduce the maximum speed, you need to move the screw H a few turns counterclockwise

- The maximum speed is checked again, and the process is repeated again if necessary.

You can make sure that the instrument is configured correctly by the following signs:

- The chain does not move when idling

- The engine works like a four-stroke engine

- When you press the throttle stick, the motor responds quickly and revs up

To make the most accurate tuning, you will need to use a wired or wireless tachometer.

On the Stihl 170 and 180 chainsaw, the process of adjusting the chainsaw carburetor looks a little easier, since there is only one screw. A detailed description of the process of regulating the carburetor on the Stihl MS180 chainsaw is presented in the video.

Chainsaw carburetor design

A carburetor is a device in which fuel is mixed with air, and this mixture is supplied to a cylinder for combustion. During combustion, the crankshaft is driven, to which the drive sprocket is connected to drive the saw attachment. the chain. The absence or malfunction of the mechanism in question will lead to the inoperability of the tool, therefore it is important that the device is in good working order and adjusted.

The design of the chainsaw carburetor consists of the following components:

- Solid aluminum alloy body. The use of aluminum for the manufacture of this mechanism helps to lighten the weight of the tool

- Air supply diffuser located on the side of the mechanism entrance

- Jets. valves that serve to regulate the flow of the mixture

- Sprayer. a device from which the fuel mixture enters the combustion chamber of the cylinder

- Float chamber. a device for creating and maintaining a certain fuel level

A detailed design diagram of the device in question is shown in the photo below.

Chainsaw carburetor tuning is an important step every sawer has to deal with. The chainsaw needs adjustment not only after purchase, but also in the following cases:

- Before running in the tool. How to set up the mechanism for the correct running of the chainsaw is described in detail here

- After the end of the running-in process

- After overhaul of the internal combustion engine

- During the operation of the tool, when malfunctions occur during operation and starting the motor

The mechanism has 3 screws for adjustment (on some Chinese models 2 screws), which are the control panel for the user. It is with the help of these screws that the carburetor of the chainsaw is adjusted independently and quickly. It is possible to adjust an important unit of the tool even in the field without the help of specialists.

Carburetor Air / Fuel Adjustment. When Needed

The first adjustment of the chainsaw carburetor is performed immediately after purchasing a new tool. This is done in order to run the tool motor. To run the internal combustion engine of a chainsaw, you need to limit the maximum speed, which is done using the adjusting screws. As soon as the running-in is completed, which lasts 2-3 tanks of burnt fuel, it is required to re-adjust, but only now in order to establish the maximum speed.

In addition to running-in, chainsaw carburetors are adjusted when:

- Knocking down the settings set after running

- If the internal combustion engine does not start well

- If the engine does not develop speed or when you press the gas, the chainsaw stalls

- Wear of the piston group, but only in this case, adjusting the carburetor of the chainsaw is a temporary measure, since the internal combustion engine needs a major overhaul

- If the engine does not idle

- Unit vibrations

- Carbon deposits on the spark plug

- Increased fuel consumption. This phenomenon can be detected by the excess amount of smoke. If you unscrew the candle, then it will have a black color with carbon deposits.

Many malfunctions during the operation of the gasoline unit arise precisely because of the incorrect setting of the chainsaw carburetor or when they are knocked down. To restore the tool to its previous performance, it will be necessary to adjust the mechanism. Many beginners trust this process to specialists, for which the masters take a lot of money. It’s time to figure out the adjustment, and carry it out on your own, since this process does not require disassembling the mechanism.

How the carburetor on a chainsaw is adjusted. instructions

A chainsaw is a complex unit, the operation of which is based on a two-stroke type internal combustion engine. The internal combustion engine requires the use of a carburetor. This mechanism mixes fuel with air, and this mixture is supplied to the engine cylinder for combustion. The operation of the internal combustion engine largely depends on the carburetor, which needs periodic adjustment. Chainsaw carburetor adjustment can be done by hand, but for this you need to know the instructions, which are described below.

How the chainsaw carburetor works. the principle of operation

The operation of the unit in question, despite its complex design, is simple and understandable even for beginners. The principle of operation is based on the following actions:

- As soon as the engine of the internal combustion engine starts, the air damper opens

- In the area of narrowing of the diffuser 16, the flow of incoming air is accelerated, which is mixed with the gasoline-oil mixture

- The gasoline-oil mixture is fed through the nozzles numbered 15 and 12, and the air, before passing through the damper 7, passes through a filter located in front of the inlet

- The damper 8 is located behind the diffuser, and serves to regulate the supply of the amount of the mixture to the combustion chamber

- Screws 17 and 10 adjust the volume of gasoline that passes through the jets. On the carburetor control panel, these screws are labeled L and H

- The needle valve 11 regulates the volume of the fuel mixture in the float chamber 14. To adjust the position of the needle valve, a diaphragm 13 is installed in the mechanism

- Another membrane 4 is responsible for supplying fuel to the combustion chamber of the cylinder. The position of this membrane depends on the number of revolutions of the internal combustion engine

- A fine filter is used to clean the gasoline-oil mixture

The simple principle of operation of the carburetor ensures the smooth operation of the internal combustion engine. The quality of the setting determines how the tool will behave at idle and during operation. This mechanism has a direct impact on the performance of the entire tool. The service life of the tool depends on the quality of the adjustment.

How to adjust the carburetor on a Chinese instrument

Let’s figure out how to properly adjust the carburetor on a Chinese chainsaw of different brands. The setup principle is similar to that described in the material above. First you need to inspect the tool, and identify the presence of adjusting screws. Usually the T screw is on the top and the L and H screws are below. Access to these screws does not always require you to remove the protective cover or shroud.

If the Chinese chainsaw has a different number of screws, then based on their number, you need to make the appropriate adjustment. The device and principle of operation of all chainsaws of different brands and manufacturers is approximately the same, therefore, there will be no problems with adjustment.

It’s always easy to do any job, even a new one, if there are instructions, so don’t be afraid to tackle the setup. Even if you do something wrong, then by contacting a specialist, he will definitely point out your mistakes. If you have any difficulties with adjusting the chainsaw carburetor, then describe them in the comments. Experts, masters and just amateurs, together with the founder of the portal, will help you understand this issue.

How to properly adjust

Before you start adjusting the carburetor trimmer, do the following:

- flush the engine;

- replace or clean the spark plug;

- change to a new one or clean the air filter (it is recommended to wash it in warm, soapy water, wring it out and let it dry well).

It is also necessary to install a cord of a suitable diameter in the trimmer coil or install knives. this is done so that during the tuning process the engine has at least some kind of load. After installing the cutting tool and starting the gasoline engine, let it warm up for 10 minutes.

If at idle speed of the engine you notice that the cutting tool rotates, then it is necessary to reduce the engine speed. This is done using the lower idle speed control, often marked with the letter “T”. The illustration below shows the placement of the adjusters on a Husqvarna trimmer.

But, for example, on the Stihl trimmer, this screw may be marked “LA”.

So, turn the idle speed control to the left until the trimmer head comes to a complete stop.

To adjust the carburetor, 3 regulators (screws) are used.

- The right L regulator adjusts the enrichment level of the combustible mixture at low revs. It needs to be regulated first. Achieve maximum idle speed. This is done with the L knob by turning it left and right. After finding the point of maximum speed, return the regulator half a turn to the left (counter-clockwise).

- The lower T (LA) adjuster is used to adjust the idle speed. Turning it to the left, the engine speed will begin to decrease, and when turning the regulator to the right, the speed will increase.

- The left regulator H is responsible for enriching the fuel mixture at high speeds. The enrichment setting completes the carburetor adjustment. Also, using this regulator, you can adjust the maximum speed, fuel consumption and engine power.

Important! If the engine is allowed to run at full speed for more than 10 seconds, then it may fail.

To eliminate this nuisance, adjustment will be required. With the engine running, give full throttle, then turn the “H” regulator to the right until the speed starts to decrease. After that, the regulator “H” must be slowly scrolled to the left until you hear the uneven operation of the engine. Then you should turn the knob “H” to the right until you hear the smooth operation of the motor.

After performing the above steps, the carburetor setting can be considered complete. After correct adjustment, the engine should confidently pick up speed, a little quarter at maximum speed, and when idling, the cutting tool should not turn. This manual is suitable for adjusting carburettors on Huter, Patriot and other lawn mowers.

There are also carburetors without a screw, which is responsible for enriching the combustible mixture at low speeds. That is, they have only 2 adjusting screws: an idle speed regulator and a fuel mixture quality regulator at high speeds. How to tune this type of carburetor can be found in this video.

Do-it-yourself lawn mowers carburetor adjustment

Lawn mowers, like all gas powered garden tools, are not difficult to maintain. It is possible and necessary to repair, configure yourself. For example, adjusting the carburetor of a lawn mower with your own hands is a matter of five minutes.

A lawn mower carburetor is a unit in the power system. In it, like any carburetors, there is a process of mixing air and fuel (gasoline) for further supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, for which they regulate the carburetor.

Fuel pump problems

A common malfunction that “pursues” the fuel pump is the deformation of the pump membrane. For this reason, it does not fit properly and the pump passages are not sealed.

The reasons for membrane deformation can be the following:

- long work of the trimmer;

- use of unsuitable fuel;

- ingress of gases into the impulse channel.

As a result, diaphragm damage reduces pump performance and, as a result:

- depletion of the combustible mixture occurs;

- difficulty starting the engine;

- there are interruptions in the operation of the motor;

- the piston is damaged.

Also, the above-described consequences for the motor can cause clogging of the pump cavity on the impulse side. In this case, dirt enters the membrane through the impulse channel.

To remove the blockage, you will have to disassemble the carburetor and clean the membrane.

Phased operation of the device:

- Air supply to a tube with an air baffle (damper). The baffle regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and the nozzle tube with a constriction. A float chamber adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with a constriction it is already low. Due to the pressure drop, the fuel penetrates through the jet.

- The acceleration of the air flow facilitates the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the required proportion or density is formed.

- The air / fuel mixture enters the engine cylinder through the fuel pipe.

The level of air density in the system depends on the area of the open air damper. The wider the throttle is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a lawn mower is about creating an optimal fuel mixture through correct air supply.

Damper wear

The throttle and choke valves are mainly subject to wear due to the presence of abrasive particles in the air. Defective dampers look like they have been sandblasted.

As a result of valve wear, engine performance decreases, malfunctions appear in its operation, piston rings, piston and cylinder coating wear out.

Intake Adjuster Lever Problem

This problem can occur if the adjusting arm is not properly installed or if it bends before installing. As a result, the contact surface takes the wrong position, which disrupts the additional fuel supply.

When to adjust

Carburetor adjustment is necessary in the following cases:

- the new engine was run-in (4-5 liters of fuel mixture was used);

- the composition of the fuel has changed (brand of oil and gasoline);

- the weather has changed (it became hot, cold);

- air rarefaction has changed (for mountainous regions);

- after long-term storage;

- the load on the engine has increased (after changing the tool, etc.);

- due to vibration, the adjustment screws spontaneously unscrewed;

- fuel consumption has increased, the carburetor overflows fuel;

- carbon deposits quickly appear on the spark plug electrodes (while the fuel mixture is prepared correctly);

- the engine starts and immediately stalls or gains momentum poorly;

- gasoline does not enter the cylinder;

- large amount of exhaust gases.

Deformation of the control diaphragm

The membrane can undergo deformation during prolonged operation of the unit and when using aggressive fuels.

Failure of normal adjustment due to a defect leads to:

- damage to the piston;

- difficulties when starting;

- depletion of fuel;

- improper engine operation.

Adjusting and repairing the carburetor lawn mowers

The trimmer is not a complex household appliance, therefore most of its breakdowns are mechanical in nature and are quite successfully eliminated by hand. Even if the engine fails for serious reasons. damage to the piston ring, for example, repairs are reduced to replacing a part.

But even with a relatively simple design, such a part of the device as a carburetor needs adjustment.

Signs of imbalance

Debugging the carburetor must be done during the manufacture of the device. As a rule, the owners will find out about the need to adjust the fuel supply with their own hands only after serious enough breakdowns, in the process of correcting which, the module was removed and, for example, cleaned.

Signs of a configuration failure are the following:

- starts, but the engine immediately stalls. since the engine can only work when a certain amount of gasoline is supplied, with too “lean” fuel, that is, blocking the supply channel, the engine will stop;

- too high fuel consumption, a lot of exhaust gases. the result of incomplete combustion of the mixture. In this case, on the contrary, there is too much fuel and the mixture is too dense.

The carburetor for lawn mowers Stihl, Makita, Husqvarna and others is adjusted using the adjusting screws. Sometimes the reason for the malfunction is a violation of fixation. due to vibration or damage to the protective cap. Such a breakdown can be detected by simply trying to turn the screw slightly: if the fixation is not rigid, it is worth checking the setting.

Principle of operation

A carburetor is a power system module in which liquid fuel and air are mixed before being fed into the engine cylinders. Mixing and feeding are adjusted accordingly depending on the tool and its mode of operation.

The carburetor device for lawn mowers is the same for almost all cases. It belongs to the category of float devices. The latter provide stable parameters of ready-made mixtures.

The principle of the module is as follows.

- Air enters the body of the air damper tube. The latter increases or decreases the air flow depending on its position.

- In the area where the hole for the gasoline supply is formed, the tube has a narrowing. a diffuser. Here the flow rate increases.

- Fuel from the float chamber is fed through the nozzle into the tube. The float level determines the amount of fuel supplied. Since the pressure in the chamber is normal, and in the tube it is low due to the greater rarefaction of the air, gasoline is sucked in through the nozzle.

- The accelerated air flow picks up the fuel and atomizes it, forming an air-fuel mixture of the desired density.

- The mixture is sucked into the cylinder through the pipeline.

The more open the air damper in the tube, the higher the density of the air flow, and, therefore, more fuel enters the cylinder. Setting up the carburetor of lawn mowers is reduced to setting such a ratio of flaps at which the density of the fuel mixture becomes optimal.

DIY lawn mowers carburetor adjustment

Setting up the module does not apply to repair and replacement of spare parts is not required. In this case, the lawn mowers carburetor repair kit will not be needed.

Three screws are provided for debugging:

- L. is regulated first, since it is responsible for supplying fuel at low speeds;

- H. he is responsible for the supply of gasoline at high speeds, as well as for fuel consumption and temperature;

- T. it is used to debug idle.

There are options, as a rule, this is the carburetor of a Chinese lawn mower, when only one screw remains on the body for debugging. for adjusting the idle speed. This does not mean that the module is configured automatically. it means that it will be difficult to carry out even such a type of repair as debugging. In the photo. adjusting the carburetor of a Chinese lawn mower.

- The module is configured only when the engine is warm: for this, the device is pre-switched on for 10 minutes. If the mowing head rotates while idling, then the debugging is started immediately: turn the screw T counterclockwise until the rotation stops.

- Adjustment begins with screw L. The screw is turned to the right and left until it is found such a position at which idle speed does not become maximum.

- Then the screw is turned ¼ turn counterclockwise. This will be his working position.

- Idling must be adjusted by turning counterclockwise to increase the number of revolutions and clockwise to decrease it. Its debugging consists in achieving such a mode in which a sufficient number of revolutions are made before the start of rotation of the mowing head. In this case, the engine must work stably at different positions.

- The position of screw L is determined last. at maximum speed, the trimmer should not work for more than 10 seconds. The throttle opens, the screw turns clockwise, very slowly, until a decrease in the number of revolutions is audible.

- Then, also slowly, the screw rotates counterclockwise until the motor starts to malfunction. Then the screw is turned back clockwise until the engine starts working normally again.

If there is a tanometer, and if the recommended rpm values are indicated in the product passport, the correction can be made more accurate, focusing not on hearing, but on the readings of the device.

The adjustment of the carburetor of the lawn mowers in the video was carried out by ear.

8 comments on the entry “Adjustment and repair of the carburetor lawn mowers”

-

Dmitry Pavlovich 07/04/2016

Please clarify. In the adjustment section p. 5, screw L. error? Should you read screw A? Thank you.

prompt the initial position of the screws H L LA

SHOW START POSITION

prompt the initial position of the screws H L LA

Thank you very much for the video about the accelerator and I don’t know, but the defect is very important and creates a huge problem that almost everyone is silent about. BRAVO….

Maybe all the same tachometer is a rpm meter, and not a tonometer blood pressure meter

and I have L, H, LA, it’s LA instead of T?

The video shows some kind of tightness, so you need to be able to chew snot.

Idle speed adjustment

We start adjusting low speed. The screw limits the return movement of the throttle lever. by turning it, we increase the idle speed, unscrewing it, we decrease it. Adjust so that the engine runs confidently at low revs and even a little accelerated (for better starting), but so that the line reel or knife does not rotate, and there is a sufficient reserve of revolutions before they start spinning. If the engine starts poorly, increase the idle speed even more.

Spring may interfere

My first attempt to adjust the carburetor of the lawn mowers did not work, as the spring of the screw for adjusting the fuel mixture interfered with. The factory spring turned out to be too thick in the compressed state and did not make it possible to reduce the fuel supply to the required level. I had to pick up another spring and continue adjusting after replacing it.

Fuel mixture adjusting screw with spring

In the photo above the factory spring, below the adjusting screw with the matched spring. I am writing about this because I’m not sure if this is an isolated case, and someone else may face the same situation.

lawn mower or trimmer

A trimmer is a broader concept than a lawn mower (lawn mower), as it can also be electric. A petrol trimmer and a lawn mower are one and the same.

stihl bg55 blower carburetor adjustment

Some authors claim that the trimmer is a weaker tool than a more powerful lawn mower, which can be used for mowing shrubs. Personally, I have a tool with a maximum power of 1.7 kW and capable, as stated in the instructions, to mow small shrubs up to 10 mm thick. The user’s manual is called “Petrol trimmer.”.

From personal experience

Maximum speed limitation

After adjusting the fuel mixture and low speed, check how the lawn mower engine will run at maximum speed. If necessary, limit the maximum speed to the required level using the hollow screw. Loosen the fixing nut and screw in the screw to decrease the maximum speed or turn to increase it. Tighten the nut after adjustment. Setting the maximum RPM is necessary to protect the trimmer motor from overheating and to be able to use the start key lock to reduce right hand fatigue.

In the future, it may be necessary to readjust the trimmer carburetor. For example, if the engine starts to rev poorly when running at full load, loosen the screw another quarter turn. If starting is difficult, increase idle speed. Both weather conditions and the quality of the fuel mixture can affect the operation of lawn mowers. Vibration can cause the adjusting screws themselves to turn.

Carburetor adjustment

Flush the air filter before adjusting the carburetor. It is recommended to rinse it after every 10 hours of operation. After that, you can start adjusting. The photo shows the PRORAB-8406 petrol trimmer carburetor as an example. The numbers indicate the adjusting screws that we will use.

PRORAB-8406 petrol trimmer carburetor adjusting screws

The purpose of the adjusting screws:

- Fuel mixture adjustment screw.

- Idle adjustment screw.

- Maximum speed limiting screw.

Start a lawn mower and wait for it to warm up.

Fuel supply adjustment

Begin to tighten the fuel mixture adjustment screw slowly until the engine starts to stall or stalls if you do not have time to catch the moment. After that, unscrew the screw a quarter of a turn if the engine did not stall, or half a turn if it stalled. Start the stalled engine. Check by opening the throttle as the engine picks up speed. Continue to unscrew the screw a quarter of a turn until the engine starts to accelerate steadily during gas blowing. This will be the moment of the most economical stable engine operation. For the PRORAB-8406 petrol trimmer, the adjusting screws are turned clockwise, unscrewed. against, for some other brands the lawn mower can be the other way around.

Do-it-yourself lawn mowers carburetor adjustment

A lawn mower carburetor is a unit in the power system. In it, like any carburetors, there is a process of mixing air and fuel (gasoline) for further supply to the engine cylinders.

In this process, the main thing is the correct proportion of fuel and air, for which they regulate the carburetor.

The main problems and malfunctions of the carburetor.

Mesh filter. There are often only two problems with this element:

- Blockage.

- Breaking.

In order to find out the cause of the breakdown, the fuel filter cap is unscrewed to remove the strainer. If dirt just accumulates on it, then flushing in gasoline or blowing will help.

If there is visible damage to the mesh filter, it is imperative to install a new one. There may also be damage to the fuel supply pipe (during repair, they practice checking this element).

Blowing out carburetor parts with compressed air is an acceptable and convenient repair practice.

The throttle body, the places where the carburetor parts are bundled, the inlet or outlet pipe. all of these parts are susceptible to depressurization. You can check for sure in a primitive way. smear the problem area with soapy foam.

Lawn mowers carburetor device

The basis of the carburetor for lawn mowers is an aluminum body. It contains a diffuser (hole with inner contours). Air is blown through this hole. The flow rate of oxygen (air) depends on the section (orifice) of the diffuser.

The diffuser is equipped with fuel channels. Fuel is drawn in from them using the air flow.

Outside the carburetor is installed:

- fuel pump;

- jet system;

- a system for adjusting the mixture of fuel and air;

The principle of the carburetor lawn mowers

The throttle valve determines the amount of air to be supplied, and the engine power directly depends on this.

Fuel is sucked into the carburetor system by a pump (its membrane). Then it passes through the choke in the carburetor. The fluid then flows through the pump inlet and outlet valves. Filtered by the grid. Moves through the needle valve into the diaphragm chamber.

Phased operation of the device:

- Air supply to a tube with an air baffle (damper). The baffle regulates the intensity of the air flow.

- The fuel supply system is necessarily narrowed by a diffuser to increase the flow rate.

- Gasoline through the float chamber and the nozzle tube with a constriction. A float chamber adjusts the temporary volume of gasoline. In the float chamber, the pressure level is neutral, and in the tube with a constriction it is already low. Due to the pressure drop, the fuel penetrates through the jet.

- The acceleration of the air flow facilitates the transfer of fuel (gasoline) and its atomization. As a result, an air-fuel mixture of the required proportion or density is formed.

- The air / fuel mixture enters the engine cylinder through the fuel pipe.

The level of air density in the system depends on the area of the open air damper. The wider the throttle is open, the greater the fuel consumption and power.

Simply put, adjusting the carburetor on a lawn mower is about creating an optimal fuel mixture through correct air supply.

How to adjust the carburetor on a lawn mower

Before adjustment, you must thoroughly clean the filters according to the maintenance in the instructions.

Further adjustment of the carburetor of the lawn mowers with their own hands is carried out with the adjusting screws. There are three of them:

- right;

- left;

- lower.

Right (L). adjust the fuel mixture for low rpm.

You need to find the maximum idle speed. To do this, slowly unscrew the screw (L) to the right and left.

To adjust, turn the screw a quarter of a turn, be sure to counterclockwise.

Lower (T). responsible for adjusting the engine at idle.

- clockwise. increase;

- counterclockwise. decrease.

For the correct adjustment of the idle speed, it is characteristic:

- stable operation of a cold engine;

- not overestimated speed of a hot engine;

- a large reserve of turns for the trimmer head;

- stable operation of the engine when changing position (sharp lifting or lowering of the knife).

Left (H). mixture adjustment at high rpm. (The screw is adjusted last).

The left screw (H) determines the overall adjustment of maximum speed, engine power, temperature and gasoline consumption.

The carburetor setting for lawn mowers with the last screw is done as follows:

- Open the throttle to full, while at the same time give full throttle. Turn the screw clockwise until the speed drops (in this case, orientate by ear).

- Turn the screw counterclockwise as slowly as possible until the engine runs unevenly.

- Then turn back just a little, barely hearing a stable, even operation.

- For a more visual use of skills, it is more convenient to consider the work of an experienced user:

Interestingly, from the point of view of the author of the video, the setting (its correctness) is determined by the color of the candle, and not only by the speed and stability of the engine.

Correct adjustment of the carburetor with your own hands in this case. combustion of the fuel mixture without residue, the color of the candle should be light brown.