How To Adjust The Oil Flow Of Your Chainsaw

Chainsaw Chain Oil Adjustment Partner

One of the important chainsaw systems, without which work is impossible, is the forced lubrication system of the chainsaw chain. It’s not a secret for anyone that at the time the saw is operating, the chain friction against the tire of the chainsaw, which causes it to heat up and premature wear. To soften friction, the chain mechanism must be constantly lubricated.

To supply oil for lubricating the chainsaw chain, a special pump is used in the tool, which is dosed, depending on the number of engine revolutions, supplies lubricant to the saw bar.

The system uses oil to lubricate the chainsaw chain, which has increased adhesion properties, this is necessary to evenly distribute the oil around the entire perimeter of the tire and keep it on it even at high chain speeds. Let’s take a closer look at the oil supply system implemented in modern chainsaws.

Depending on the brand of the chainsaw, the details of the lubrication system may differ slightly structurally, but their total number and connection diagram remains unchanged.

The main components of the lubrication system are:

- oil tank located, as a rule, in the crankcase.

- Filter element, installed in the tank.

- The oil line is a small diameter oil-resistant rubber hose.

- The heart of the system is the oil pump.

- Worm gear gear transmission force from engine to pump.

- A chainsaw tire, it can also be considered an element of the lubrication system, since it has special holes for supplying oil, by the way, the chain itself is involved in the transportation of oil and, accordingly, also has some elements designed specifically to provide lubrication.

Chainsaw chain lubrication system. Chain oils

In the course of long-term operation of the chainsaw, some of its elements and assemblies may become unusable. One of the most vulnerable components is the oil pump. In this regard, many owners of saws have a question about how to repair the oil supply on a chainsaw.

The task of the oil pump is to supply lubricant to the chain. this is necessary for its smooth movement along the guide bar. When the oil pump fails, the lubrication of the chain deteriorates, which reduces the efficiency of the chainsaw. In some cases, this leads to the breaking of the chain. To prevent negative moments, it is necessary to repair the oil supply in a timely manner. How to do it?

The pump is driven by the movement of the drive sprocket. During the movement of the chain, oil is fed into a special channel located on the guide bar. At idle (when the drive sprocket does not rotate), the pump does not provide lubrication. this is done to save money.

The speed and volume of lubricant supply to the chain directly depend on the number of sprocket revolutions. In some models of chainsaws, a manual adjustment system is provided using a special screw located on the body of the device. On expensive saw models, the oil supply is automatically adjusted during operation.

When running a chainsaw, there are two types of chain lubrication problems:

- Insufficient oil flow, which can be caused for various reasons. If measures are not taken in time, the quality of work will noticeably deteriorate, and the chain itself may become completely unusable.

- Excessive amount of oil. In this case, after prolonged operation, pools of lubricant may accumulate under the saw. This not only affects the consumption of oil, which will have to be constantly added, but also negatively affects the environment.

Both of these problems need to be addressed as soon as possible after they are discovered. This will extend saw life and reduce lubricant consumption.

If oil is supplied to the chain in excessive quantities, and not only during the operation of the saw, but also at idle speed, manual adjustment should be made (if the design of the pump allows such an opportunity).

This is done with a screw located on the housing close to the guide rail, usually from the bottom or the side. Tightening the screw decreases the oil supply, loosening it. vice versa.

If the adjustment does not help, it is necessary to check the serviceability of the pump, as well as inspect the tire. it is possible that a gap has formed at the point of its connection with the body, through which oil flows past the chain.

Lack of oil can be caused by several reasons, for each of which there is a solution:

- Defective oil pump. As a rule, it consists in an unusable gasket. In order to replace it, it is necessary to carefully disassemble the pump so as not to damage its moving parts. Then a new gasket is installed, after which the pump is assembled and installed in place.

- Broken oil hose. In the event that the pump gasket is intact, or its replacement did not lead to a result, the hose should be checked for leaks. If it is defective, it must be replaced. Otherwise, it will not be superfluous to clean it and secure it with a sealant.

If the reason lies not in a pump breakdown, it is necessary to inspect all conductive holes and channels for blockages, and, if necessary, clean them of foreign objects. This can be done with a jet of compressed air.

Don’t want to mess with your chainsaw but need oil flow adjustments? Ask for help from our specialists who will diagnose and repair the chainsaw, and, if necessary, will carry out repair work and adjust the lubrication level. Your saw will be like new!

The guarantee of a long service life of the chainsaw can be not so much the power characteristics of the tool, but the proper way of use and compliance with the rules for handling it. This primarily concerns the chain.

Proper care of it will help maintain cutting performance for more than a dozen years.

It implies not only adherence to the technology of working with the tool, you also need to carefully select the oil for the chainsaw chain, which is recommended to be used regularly.

Educational program: chainsaw oil pump

I am starting a column called “Educational program” in which I will talk about the details and units of chainsaws, their design, reasons for failure and about repair methods.

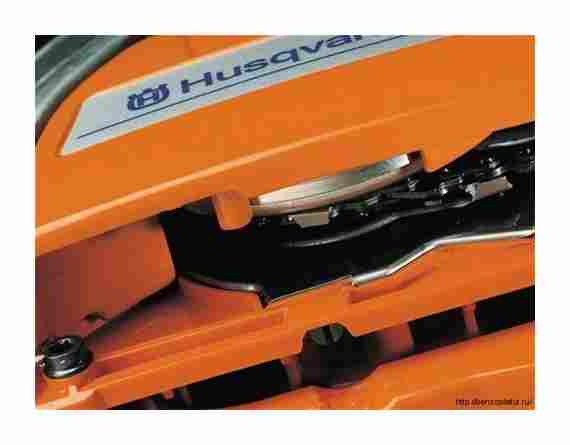

The oil pump opens this heading. The oil pump in the chainsaw is required to lubricate the saw chain during operation. In most cases, a plunger-type oil pump is installed. The oil pump is located under the clutch.

To get to it, you need to remove the clutch (the whole process can be seen in detail in the video. Thanks to the author of the video, Evgeny Kravchenko for a detailed story!).

In the figure, the plunger is very clearly visible, in which there is a groove on the tail. This groove is needed to capture the required portion of oil and feed it through the hose to the guide bar and further to the chain. Rotation of the plunger is given by the sprocket of the clutch drum. accordingly, we get the required amount of oil at any engine speed, since the engine speed and the plunger speed are interconnected.

Plunger Stihl MS 210,230,250

Many chainsaws have the ability to adjust the amount of oil supplied. Adjustment is made by rotating a screw that decreases or increases the amount of oil that is captured by the plunger. The screw is located underneath the pump. (see photo).

Variable oil pump

- The most common reason the chain oil stops flowing is a clogged outlet. In this case, you just need to blow through the channels. Channels can also be clogged on the bus. Also easy to clean.

- Oil leaks during standstill. There are several possible reasons: 1.Cracks in the oil pump housing. 2.Check the integrity of the hoses and their fastening.

- Insufficient chain lubrication. As already mentioned above, on some chainsaws, you can adjust the amount of oil supplied. If there is no such adjustment, then again there are several reasons. Air leaks through cracks in the hoses, pump casing or in the hose attachment points. 2. The coils on the oil pump drive have worn out. In that case, a replacement. This also applies to the plunger.

- High oil consumption. This malfunction may occur due to: 1. Incorrectly installed tire 2. Failure of the oil pump. In fairness, it should be noted that many chainsaws have too much oil consumption for chain lubrication by nature. Its consumption can be reduced by using specialized oils for chain lubrication.

Diagnostics and repair of the oil pump and chainsaw chain lubrication system

Troubleshooting

After it has been determined that oil is not being supplied, further diagnostics is possible only if the oil system is completely removed. Of course, changing the filter helps in some situations, but this is very rare.

Access to the oil pump of some saw models is possible only after complete disassembly, accordingly, without having the skills to repair gasoline tools, it is better to entrust the repair to professionals.

- Broken oil hose. It can sometimes be detected by visual inspection. The problem is solved by replacing the defective part.

- Lack of threads on the oil pump shaft, replacing it will help.

- A defective thread on the pump drive gear is similarly solved by installing a new part.

- No corkscrew of the main shaft (relevant for some models of tools, for example, Homelite). You can fix it by installing instead of the native corkscrew, suitable for the diameter of the studs, cutting it to the required length.

- Blockage in the line.

Can be removed by blowing with compressed air or mechanically using a wire of suitable diameter.

In view of the fact that the Stihl MS 180 is one of the most common models of chainsaws, I would like to dwell on one inherent only malfunction and describe a way to eliminate it without replacing parts.

Quite often, on the Stihl MS 180 chainsaw, there is a depressurization of the oil line in the place where the oil line from the tank is installed in the saw body. The malfunction can be determined by the characteristic grease smudges on the bottom of the tool.

To eliminate the malfunction, it is necessary to remove the chainsaw handle, remove the hose from the bore, clean and degrease. After all these manipulations, apply sealant to the seat of the hose and install it in the body of the chainsaw.

You can learn more about troubleshooting and full diagnostics of the Stihl chainsaw lubrication system by watching a video that shows step by step the process of disassembling and repairing the lubrication system.

All Stihl Chainsaw Common Oil Leaks and How a Chain Bar Oil System Works How to Check 017 018 MS170

How to install the chain

A long service life of the device is possible not only if the components for it are carefully selected, the installation of the chain on the chainsaw must also be correct. In addition, the chain may need to be replaced sooner or later. In this case, it is necessary to think about safety, in particular, to carry out work in special protective gloves. To “put on” the saw, you need to perform the actions in the following sequence:

- Prepare the surface for work. You can place the chain correctly on a table or other comfortable and level surface. Additionally, the surface can be covered with a rug.

- The wing nut on the body must be unscrewed, and then removed the sprocket cover.

- The latter must be turned to the right until it stops. After that, gradually put the chain on top of the bar, while it is better to start work from its top. It is advisable to follow the correct direction of the chain at each step.

- Turn the chain so that the bar is on top of it. At this stage, the bit on the top of the tire should be facing forward, not to the side. This indicates that the direction of movement is correct, and the location is accurate.

- Put the tire on the sprocket.

- After that, put the chain sprocket cover on the engine block, turn the wing nut until it stops, but you do not need to tighten the sprocket cover completely.

- Unscrew the clamping screw, for which it is necessary to turn it in the direction of the top of the bar, while the chain links must fall into the corresponding grooves.

- Tighten the wing nut until it engages.

- Check the part for sagging and overtightening, tighten or loosen if necessary.

If the chain flies from the chainsaw or it breaks, this means that the device has some kind of malfunction, under normal conditions it should not do this. There are three reasons why the chain fails:

- Bus problems. They lead to a loosening of the tension, which can lead to the chain breaking. This problem most often occurs in the groove between the outer plate on the chain guard and the inner plate on the motor housing. The casing with the tire is fixed with a bolt, which can loosen during the operation of the chainsaw, as a result of which the tire begins to move or vibrate. To solve this problem, it is necessary to find and lower the chain brake, for which the tension screw, which is located next to the tire, must be turned until it is fully tensioned.

- The chain has stretched out. Sagging may indicate a malfunction of the chainsaw mechanism. During operation, the metal is deformed, which means it can become 0.5-1 cm longer. In this case, it is recommended to replace or shorten the chain.

- Drive sprocket is loose. To fix it, you need to remove the protective cover of the engine and spark plugs, and then pull out the air filter. The candle itself must also be unscrewed, after which a special stopper must be installed in its place, fixing the piston. Turn the fastening disc clockwise until the piston stops in the extreme upper position. A thick rope folded several times can act as a stopper. After locking the piston, tighten the drive sprocket. Assemble the chainsaw, installing all parts in the reverse order.

See »TOP-2 models of Japanese chainsaws of the Hitachi trademark (Hitachi)

Most problems can be solved by repairing. Only in exceptional cases will you have to change it.

In modern chainsaws, a reliable supply of lubricant for the chain is organized, in case of malfunctioning of which, it is not worth operating the chainsaw in order to avoid further breakdowns. It is better to eliminate malfunctions of the lubrication system by contacting a service center or an experienced repair specialist, this guarantees the quality of the final result.

How to choose a chain

The study of their typology will help to choose a chain. Important differentiation criteria are:

- Tooth pitch. This parameter is measured in inches. The most common sizes are 0.325, 0.375 and 0.404. Each of them is selected depending on the assigned tasks. The smaller the specified parameter, the lower the productivity will be, which means that you will not need to put much effort. Therefore, it is necessary to purchase a chain whose power would correspond to a chainsaw.

- The thickness of the tail, the leading link, which means the choice of a product for different tires. The 1.1 mm shank is only present on small saw chains. The most popular size is 1.3 mm. Such a model can even be present on semi-professional devices.

- The depth of the cut and the height of the profile. The performance of the device depends on this parameter. It is always possible to increase the value by cutting down the stops near each cutter. There are two choices: 0.025 “(0.635 mm) and 0.03” (0.762 mm). The high profile chain type makes the chainsaw aggressive and vaping. Keeping a balance between high productivity and low vibration will help the product with a small ponytail.

- Chain length, bar and number of teeth. The choice of this parameter directly depends on the power characteristics of the chainsaw. over, the best saws are not always characterized by an increased number of teeth and tire size.

- Types of cutting links. Types of chains for this characteristic: chisel and chipper. The first option is the most optimal because of the straight working surface, which allows you to evenly cut into the wood. It is difficult to sharpen such links, and if even very small deviations from the upper corners are present, the performance of the chain will be reduced. Chippers have the worst cutting characteristics, but are more resistant to any kind of dirt and are easier to sharpen.

- A sequence of links. The model with one cutting link and two tails is popular. But non-standard options are also possible: with a half-admission. only one connecting link is inserted between every second pair of working teeth, with an allowance. the link is installed between all adjacent teeth. This allows for cost savings. But at the same time, aggressiveness and productivity decrease, and wear increases, including chainsaws.

- The method of cutting the material. Products with a rip and cross cut allow you to guide the tire along and across the fibers, depending on the need. They differ in the angle of sharpening of the cutting links.

How to adjust the oil supply to the chainsaw chain

How to set the maximum speed of the chainsaw?

To change the maximum speed, you need to interact with screw H. If you tighten the screw, the speed will become higher, and if you unscrew it, it will be lower. As a rule, the highest permissible engine speed ranges from 11500-15000 per minute. If you try to work with an even higher number, the ignition problem will begin. In this case, loosen the screw slightly.

Carburetor device

A carburetor is a mechanism that is responsible for preparing a mixture of fuel and air, which is then fed into the engine cylinder. Most chainsaws have very similar carburetors, so they are set up in the same way.

The main structural details of the chainsaw carburetor:

- Aluminium case. Aluminum is chosen as a material for its low weight. Chainsaws are a tool that must always be held in hand and carried, therefore, reducing the weight of the tool is a very important task facing the manufacturer.

- Diffuser and air damper, which are located at the carburetor inlet.

- Jets. valves that provide the dosage of fuel that is supplied to the carburetor.

- Sprayer, which is responsible for injecting fuel into the chamber.

- Fuel chamber.

Acceleration check

If you press the gas button of the chainsaw, the engine should increase the number of revolutions. This should happen quickly enough. If the tool is gaining speed slowly, loosen screw L a little, no more than 1/8 of a turn.

When the adjustment is completed, you need to re-check the operation of the chainsaw at idle. the engine should work properly, and the chain should remain stationary. If the engine runs unstable or the chain moves, you need to repeat the adjustment, omitting the basic setting step.

How does a carburetor work?

- When the engine is started, the air damper is opened in the carburetor.

- The movement of the piston reduces the pressure in the air valve. This causes air to flow into the diffuser. The exact amount depends on the position of the air damper.

- Fuel enters the float chamber. The jets regulate the speed at which this happens.

- Gasoline and air mix with each other in the diffuser to form a fuel-air mixture. She goes to the cylinder. The mixture can be lean (a lot of air, little gasoline) or rich (little air, a lot of gasoline). The amount of the mixture entering the engine is directly proportional to its power and speed.

All processes occurring in the engine are not cyclical, but a constant basis.

How to properly adjust the chainsaw carburetor

The vast majority of gasoline saw carburetor models have three adjustment screws:

- idle speed (T);

- low speed (L);

- high speed (N).

Setting the required parameters is done by rotating these screws.

Use an electronic tachometer to fine tune the carburetor. It will allow you to easily determine the engine speed of the chainsaw.

Chainsaw carburetor adjustment

Chainsaws are a very popular gardening tool. They have gained great popularity among gardeners and those who care for the territory in the local area. Chainsaws are not complete without construction or repairs. Chainsaws are even more important in the lumberjack profession.

Any chainsaw requires proper care, maintenance and adjustment before operation. Overloading the tool can shorten its life and damage the tool.

Today we will talk about that part of the chainsaw mechanism, the task of which is to prepare the fuel before it is fed into the engine cylinder. This function is performed by the chainsaw carburetor. It will depend on him how well the chainsaw works and how much fuel it spends during operation. If you see that the petrol chain saw is not working properly, the carburetor may need to be adjusted.

In what cases is it necessary to adjust the carburetor of the chainsaw?

Here is a list of the most common cases in which you need to adjust the carburetor of a chainsaw:

- The engine starts, but the chainsaw stalls, or it cannot be started at all. Too much air in the fuel chamber may be the cause.

- Increased fuel consumption. It can occur due to excessive saturation of the mixture that enters the engine with fuel. For the engine to work well, the mixture must be of good quality.

- The bolts in the carburetor have lost their hold due to a damaged carburetor housing.

- Debris entering the carburetor. This can happen if the filter is damaged or poor quality fuel is used. You will need to completely disassemble the carburetor, flush it and re-adjust.

- Engine idling poorly or not delivering full power.

Important! If the engine is not performing well due to a worn piston, carburetor tuning will not work. In addition, along with the adjustment, it is advisable to clean the carburetor of debris. this will increase the efficiency of the procedure.

Idle speed adjustment

First of all, you need to find the position in which the idle speed will be highest by turning screw L. When you find this position using the tachometer, you need to turn the low speed screw (L) a quarter (1/4) counterclockwise. The chainsaw chain can rotate during this process. If this happens, loosen the idle screw (T) counterclockwise until the chain stops moving completely.

Chainsaw chain lubrication

Regardless of the type of chainsaw and the frequency of its use, caring for the saw and its spare parts is mandatory, because if you do not monitor the condition of the tool, it will very soon become unusable. Chainsaw chain lubrication, sharpening teeth, refueling the saw, checking the tightening of nuts and candles. this is the key to the long and correct functioning of your tool.

During long-term operation of the chainsaw, its chain may become dull, and the sawing will be significantly complicated. Therefore, it is necessary to periodically sharpen and lubricate the chain on chainsaws. Chainsaw chain lubrication is carried out with a special oil (although you can also use automobile oil). When the fuel mixture is completely used up, it is important that a small amount of chain oil remains. Separately, I want to say about Oregon chainsaw chains. these chains are very durable. The long service life of these chains is achieved by features such as automatic lubrication. This is why Oregon chainsaw chains last long and function well.

Troubleshooting

If oil is supplied to the chain in excessive quantities, and not only during saw operation, but also at idle speed, manual adjustment should be made (if the pump design allows this). This is done with a screw located on the housing close to the guide rail, usually from the bottom or the side. By tightening the screw, the oil supply is reduced, by loosening it vice versa. If the adjustment does not help, it is necessary to check the serviceability of the pump, as well as inspect the tire. it is possible that a gap has formed at the point of its connection with the body, through which oil flows past the chain.

Lack of oil can be caused by several reasons, for each of which there is a solution:

- Defective oil pump. As a rule, it consists in an unusable gasket. In order to replace it, it is necessary to carefully disassemble the pump so as not to damage its moving parts. Then a new gasket is installed, after which the pump is assembled and installed in place.

- Broken oil hose. In the event that the pump gasket is intact, or its replacement did not lead to a result, the hose should be checked for leaks. If it is defective, it must be replaced. Otherwise, it will not be superfluous to clean it and secure it with a sealant.

If the reason lies not in a pump breakdown, it is necessary to inspect all conductive holes and channels for blockages, and, if necessary, clean them of foreign objects. This can be done with a jet of compressed air.

Don’t want to mess with your chainsaw but need oil flow adjustments? Ask for help from our specialists who will diagnose and repair the chainsaw, and, if necessary, will carry out repair work and adjust the lubrication level. Your saw will be like new!

Back to the list

Most modern oil pumps for chain chainsaws are arranged in the same way: in the body (photo 1, pos. 1) there is a cylinder (photo 1, pos. 2), into which a plunger (photo 1, pos. 3) is inserted, making rotational-translational movements in it.

The cylinder in the lower part has two holes (in photo 1, pos. 4, only one of them is visible): through one oil it is sucked in, into the second it is pushed out.

The plunger is a steel rod, on one side it has a milling groove. a flat, and on the other a plastic or steel gear. As the plunger rotates, the flat alternately opens and closes the inlet and outlet of the cylinder. On a forward motion upward, the flat first opens the inlet (while closing the outlet) and creates a slight pressure drop. As a result, a portion of the oil is sucked into the cylinder. Then, pivoting, the plunger moves downward, opening the outlet with a flat (while closing the inlet) and pushing oil out of the cylinder. This is how it is fed to the tire in small portions. High cycle rates create a constant and continuous flow of lubricant.

There are two types of oil pumps in use: variable flow and fixed flow. In the first case, the plunger gears have an oblique tooth, and the translational upward movements are provided by an additionally installed spring. The oil flow is controlled by changing the stroke length of the plunger in the cylinder. An example is an oil pump for Chinese saws with an engine capacity of 45-52 cc

In the case of an unregulated oil pump, there is an oblique closed groove on the plunger, against which the fixed stop of the body abuts. Rotation causes the groove to slide along the stop, and since it is oblique, this movement causes the plunger to move forward and backward. With this scheme, it is impossible to limit the stroke of the plunger and the oil is supplied in constant quantities. Example. the oil pump of the Husqvarna chainsaw 137, 142

The torque from the engine to the plunger is transmitted through a special drive, which also has a gear. the counterpart of the gear on the plunger.

Chainsaw chain lubrication

I want to use the TAD 17 chain on the Stihl 250 chainsaw. In winter it is very thick. will not the oil pump be worse from this, will it fail from overload? And if you can. what is the principle, in the pump, supplying oil to the chain?

The oil pump, which is put on 180. 250 Calms, is generally practically unkillable. it has a brass cylinder. Even working off eats twice as long as aluminum.

And the principle of operation is very simple. It is a pity, there is no illustration, and I have not seen it anywhere. In words. two parts, a cylinder and a plunger rotating in it. The plunger has a milled flat at the end. When rotating, the plunger moves slightly back and forth.

Two holes are made in the cylinder opposite each other. When the flat of the plunger comes to the intake hole, it is slightly pulled out of the cylinder. a vacuum is created and a little oil is sucked in.

When the flat turns to the discharge port, the plunger is pushed into the cylinder. pressure is created, oil flows through the channel to the tire. As you can see, in principle, you cannot damage the pump as much as you like with thick oil. it just won’t go, and that’s it.

_

Is it normal if oil leaks out of the reservoir when the chainsaw is idle? Those. if you have to cut a little, then pour a little? Otherwise, during the inactivity of the saw, oil flows out of the tank completely.

Not. It is not normal. The problem is either with the oil pump or with the reservoir itself. In general, oil and fuel consumption is usually 1 to 1.

_

How to lubricate the leading sprocket of a tire on a chainsaw? For example, is Mobil or Jcb hydraulic lubricant suitable? What do you think?

they smear the asterisks on all tires (except for the Shtilev ones), if you do not smear it, then the bearing may crumble, and then the tire will end, but about the Shtilev tires. on the one hand, this is kind of a plus, and on the other, I saw the Shtilev almost new tires with burned out bearings.

_

The chainsaw drives the chain lubrication oil. At idle it pours very slowly, you give it gas. it pours in a stream. For five minutes of work, all the oil is poured out.

Does not react to the position of the adjusting screw. Also, a little (0.5-1 mm), the sprocket, which rotates the chain, is loose. Who faced such a thing?

It is necessary to remove the asterisk and sort out the oil pump, and check the hoses for breaks. The leading sprocket must have a slight backlash. It should not be rigid, the vibrations will go to the crankshaft.

_

The holes coincide when I put it, maybe when the chain is tightened, the hole moves off because of this, oil does not get on the chain, but the chains, you can use one, how to blunt, remove, put a new one, sharpen the old, etc. in a cycle of three chains, do it for now the tire has not worn off?

The oval hole for lubrication on the body of the chainsaw is made in such a way that, in any position of the bar within the range of adjustment by the chain tensioner, the alignment of the lubrication holes on the bar and the body does not disappear.

Ideally, a set of chains, when used on the saw one by one in a cyclic fashion, and the bar should fail at the same time. There are two lubrication options. Well, I mean. through what the oil is supplied.

Most tires have a separate hole for supplying lubricant to the chain, and these larger ones are used for tensioning. And some (and quite a few) do not have a separate lubrication hole.

And a free pull hole is used for lubrication. In this case, it will necessarily communicate with the tire groove. You can check with a wire. This is neither good nor bad, this is a feature.

So. in the second case, quite large oil losses are possible if the sprocket cover does not fit tightly. Then it just goes right through (unlike tires with a separate hole), and drips down.

_

After a minute of running the chainsaw at idle speed, I pressed a little on the gas several times, the oil to lubricate the chain began to flow very strongly on the chain, which already formed a pool of oil under the saw. Where is the chain oil adjustment screw? And how to make this adjustment correctly?

Your model does not have regulation of the oil supply to the chain, oil is supplied automatically. Carefully inspect and thoroughly clean the oil suction holes on the bar, carefully install the bar and chain. In theory, it should help.

If a puddle of oil forms under the saw, then the most likely is an untidy tire or a skewed clutch cover, as a result of which there is a gap between the outlet of the oil pump and the lubrication hole of the tire, into which the oil goes.

_

Tell us more about the oil pumps installed in chainsaws.

Very rarely, non-plunger pumps are used on modern chain saws (and electric ones as well).

Chainsaw chain lubrication

The only point that depends on the user is to make sure that the oil tank is not empty during operation. If this happens and the oil supply stops, the chain will acquire a bluish tint, which will indicate that it has overheated and has become unusable.

Major problems with oil supply

When running a chainsaw, there are two types of chain lubrication problems:

- Insufficient oil flow, which can be caused for various reasons. If measures are not taken in time, the quality of work will noticeably deteriorate, and the chain itself may become completely unusable.

- Excess oil.

Saw chain lubrication

The lubrication of the saw chain and bar is very important. The design of the chain saws includes a pump that supplies oil from the reservoir to the cutting system through special holes. Further, the saw chain itself distributes it. The grease is captured by the shanks and distributed throughout the entire bar and chain. For additional retention of lubricant in the chainsaw, special holes are drilled in the shanks or channels are milled. Also, in the chain lubrication system for chainsaws, connecting links are often involved, in which additional grooves are made for lubrication. Sufficient lubrication reduces friction and heating, thereby not only increasing the service life of each saw element, but also reducing the level of saw chain elongation. Therefore, it is in the interests of every saw owner to monitor the chain lubrication process so that in the event of a breakdown you do not have to look for new chains for chainsaws.

The lubrication process is quite simple: as the saw chain accelerates, small oil droplets form an oil trail on any light-colored surface if the end of the bar touches it. If there is no trace, there is no lubricant and you need to check the presence of oil, clean the groove of the tire, adjust the saw pump, etc.

And one more thing: in modern saws, it is allowed to install chains and bars of different lengths, but before using a new headset, you need to make sure that the oil pump installed in the saw can handle it.

In the course of long-term operation of the chainsaw, some of its elements and assemblies may become unusable. One of the most vulnerable components is the oil pump. In this regard, many owners of saws have a question about how to repair the oil supply on a chainsaw.

The task of the oil pump is to supply lubricant to the chain. this is necessary for its smooth movement along the guide bar. When the oil pump fails, the lubrication of the chain deteriorates, which reduces the efficiency of the chainsaw. In some cases, this leads to the breaking of the chain. To prevent negative moments, it is necessary to repair the oil supply in a timely manner. How to do it?

The principle of operation and the device of the pump

Oil pumps can be made of metal and plastic. They are also divided into two types, which differ in their design:

The pump is driven by the movement of the drive sprocket. During the movement of the chain, oil is fed into a special channel located on the guide bar. At idle (when the drive sprocket does not rotate), the pump does not provide lubrication. this is done to save money.

The speed and volume of lubricant supply to the chain directly depend on the number of sprocket revolutions. In some models of chainsaws, a manual adjustment system is provided using a special screw located on the body of the device. On expensive saw models, the oil supply is automatically adjusted during operation.