How to Adjust the Performance of a Chainsaw. Adjusting a STIHL and Partner chain saw carburetor

chainsaw carburetor adjustment tunning | chainsaw Repair മലയാളം

Gasoline saw repair with their own hands: instructions for current malfunctions

A thorough understanding of the actual problems that are fatal or simply negative to the operation. This material is a comprehensive knowledge base on how to repair chain saw breakdowns of varying severity. All malfunctions are presented in the form of detailed announcements referring to the full version of the topic with a comprehensive breakdown of the particular problem. Choose the problem you are interested in and go to the problem page. Learn how to diagnose, read instructions, and repair. In most cases, there is no reason to write off the chainsaw.

A multifaceted, general problem that can be caused by one or a combination of several factors. From simple filter problems to piston failure. complete failure to start is a common problem. If your chainsaw isn’t working and you’re not sure what the problem is, take five minutes to read the following material. “Why the chainsaw won’t start.”.

The article presented at the link is informative and helps to clarify the type of failure. Examine possible symptoms and determine the area of malfunction, then return to this page and select the specific manual that corresponds to your problem. With a complete lack of basic knowledge, the search for the cause can be delayed, but you will enrich your experience with an understanding of the operation of the main nodes of the system.

When a carburetor tune-up is required

New chainsaw is set for the recommended mix. Only a fine-tuning with three screws is required, no need to disassemble the carburetor. Adjustment screw assignment:

- “L” controls the fuel supply at low rpm;

- “H” is needed to regulate maximum fuel flow;

- “T” idle speed regulator.

Because you adjust the carburetor by ear with the engine running, it is important to take safety precautions. The saw must be positioned steadily with the cutters pointing in a direction that is safe for those present.

Before you begin manipulating, you should mark the original position of the screws with paint or marker. The exact values of the carburetor adjustment of the chainsaw for each model are in the instruction manual.

However, more often a carburetor tune-up is required after a tool failure has been corrected. The causes may be:

- Violation of the protective cap and unbalanced screws;

- Engine piston wear, requiring a different mixture for operation;

- Unsatisfactory operation of the carburetor itself.

How to adjust the carburetor on a particular model chainsaw? Carry out the operations sequentially, following the instructions. Here is an algorithm, a general sequence of actions.

Basic tuning is performed only for fuel screws at low and high speeds. Slowly close the choke all the way. Also open both screws gently anticlockwise by 1.5 turns. After that, start the engine and warm it up for 10 minutes.

How to adjust the carburetor on the chainsaw when the engine is on:

- adjust the idle speed with the screw “T” by turning it counterclockwise until the engine stops idling;

- check the speed of revving, in case of slow revving turn the screw L by 1/8 of a turn additionally;

- Set the highest rpm on the tachometer with the H screw;

- check the operation of the carburetor at idle finally.

Adjusting the carburetor on the chainsaw

How to adjust the carburetor on a chainsaw. And so we have three carburetor adjustment screws. Screw H is responsible for the tenor revolution. this is the maximum revolution that the saw develops at maximum power. Screw L is responsible for low rpm, when the saw is idling, at low rpm. Screw T regulates throttle opening, i.e. it is the same throttle valve which is actuated when we press the gas pedal handle.

So, the T in our case is responsible for the amount of air in the combustion chamber. Screw L is responsible for the amount of fuel in the combustion chamber. Screw H is responsible for fuel supply into the combustion chamber at high RPM.

This is a pretty straightforward diagram. Turning the screw clockwise, we open the throttle and provide more air flow into the combustion chamber. And on the reverse, to close, we turn counterclockwise to reduce the amount of air flowing into the combustion chamber.

You can see that at idle when you turn the knob to the right, the throttle opens. Turn the screw to the left, counterclockwise the flap is completely blocked.

How to tune a Partner chain saw

You need a screwdriver for work.

Adjusting the carburetor is self-adjusting if you have a tachometer and know how to work with it. Otherwise, independent work is meaningless, the adjustment of the chainsaw should be entrusted to professionals-mechanics.

Setting the carburetor of a chainsaw is carried out only with one screw, the other two are hidden from the consumer by the manufacturer. Their designation on the body is as follows:

The manufacturer adjusts the operation of the carburetor for optimum performance, leaving the possibility of corrective adjustment of the unit in extreme situations. When using the machine in the recommended temperature and air composition ranges, there is no need to make adjustments.

The L and H screws are used to adjust the operation by using fuel of different quality from the standard. To lower the octane number of gasoline, the screws are turned from left to right. This will increase the rpm. To increase the octane number, a turn from right to left is performed. Low revolutions are set.

Adjustment of the carburetor of the chainsaw Partner or other manufacturers is carried out taking into account the following rules:

- Carry out precise work only when the engine is hot. Minimum working time is 10 minutes.

- The air filter must be clean and unclogged.

- Use the adjusting screw to stop the rotating chain until it has come to a complete stop. Turn the screw from right to left.

- Observe safety instructions. Guide the chain in the opposite direction from yourself. Always keep the saw on a level surface. Do not touch objects with the cutting part.

Make fine adjustments in the following sequence with the screws: L. H. T. Use the L screw to find the maximum number of revolutions by turning it from left to right or in the opposite direction, until the maximum is reached. You will need a tachometer or a good ear for this process to detect the revolving speed limit by its sound. The engine will break down if you mis-point the regulator H. The cost of repair will cost more than half of the total cost of the chainsaw.

With the use of a tachometer and absolute confidence in determining the limit revolutions by the sound of the motor, the adjustment is brought to completion. Use regulator L to set the maximum or close to the maximum RPM. Use the same regulator back to the right by a quarter turn of the screw. do the same with the knob H: turn it a quarter turn of the thumbwheel from right to left on the warmed up engine. You can tell by the sound. motor turns at maximum, like a four-stroke machine. At a rich mixture appears squeal, which is removed by the screw, the average value of the sound of the running engine is selected.

Adjusts the idle speed. Screw T rotates counterclockwise until chain stops. If you can’t adjust the idle speed yourself, you need to call a master. Working on an out-of-tune chainsaw leads to personal injury.

How to adjust the chainsaw, the video covers this process in detail:

How to remove the carburetor?

How a chainsaw carburetor works. principle of operation

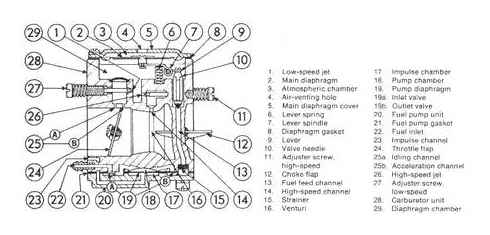

The work of the unit under consideration, despite its complex design, is simple and understandable even for beginners. The principle of operation is based on the following steps:

- As soon as the internal combustion engine is started, the air damper is opened

- In the area of the narrowing of the diffuser 16 there is an acceleration of the flow of incoming air, which is mixed with the gasoline-oil mixture

- The gasoline-oil mixture is fed through nozzles number 15 and 12, and the air, before passing through the slide 7, passes through the filter placed in front of the inlet

- The choke 8 is located behind the diffuser and serves to regulate the amount of mixture in the combustion chamber

- Screws 17 and 10 are used to adjust the volume of gasoline that passes through the jets. On the carburetor control panel, these screws are marked L and H

- The needle valve 11 controls the volume of the fuel mixture in the float chamber 14. To adjust the position of the needle valve, a diaphragm 13 is installed in the mechanism

- Another diaphragm 4 is responsible for supplying fuel into the cylinder combustion chamber. The position of this diaphragm depends on the number of revolutions of the internal combustion engine

- A fine oil filter is used to clean the gasoline-oil mixture

The simple principle of operation of the carburettor ensures smooth operation of the engine. The quality of the adjustment affects the no-load tap-changer’s behaviour when idling and in operation. The mechanism in question has a direct influence on the performance of the entire tool. Adjustment quality affects tool life.

When adjustment is necessary

As already mentioned, the new chain saw already has a standard fuel setting. But for proper running-in recommended to limit the maximum engine speed, and this is done with the help of adjustment screws located on the carburetor body. It is also necessary to fine-tune the fuel mixture after the running-in period.

In addition, you will have to adjust the carburetor in the following cases:

- due to heavy vibration the factory settings have been disrupted;

- the engine does not start up well and immediately stops working;

- ICE starts, but the revs do not develop, and it stops;

- the piston group is worn out. in this case, the adjustment of the carburetor of a chainsaw is possible as a temporary measure;

- the engine does not function at idle speed;

- increased gasoline consumption, which causes the machine to produce a lot of smoke, soiling the muffler and spark plugs with carbon deposits, reducing engine power.

Setting the carburetor of the chainsaw Partner 350

It is inherent in many models of tools to have design differences, even within the same brand. In terms of carburetor adjustment features, some Partner saws are similar to the Husqvarna, in terms of the unique shape of the screw heads. To adjust a chainsaw with a similar device, you will need a special screwdriver with small slits. The need for such a tool is typical for newer tools, newer than 2015 production. Older models have the classic flat tip.

The adjustment process itself is absolutely standard and is described in detail above, in the instructions on Chinese chainsaws, and briefly, on Husqvarna. If the fuel distribution is specifically knocked down and the engine does not start, you can return to the basic settings by tightening the screws L and H to the limit and then unscrewing 1 turn. Learn more about how to adjust the carburetor on a Partner chainsaw from the following guide. The author carries out the adjustment on the example of the old model 350.

Adjusting the carburetor of a Chinese chainsaw

Virtually all Chinese chainsaws have the same adjustments as their brand-name counterparts. The same L, H, and T screws are present. Sometimes there are saws in which only the idle stroke is to be adjusted. However, not every chainsaw has a carburetor that can be adjusted without problems, as owners and service workers say. Even the experienced repairers of some models may take a considerable amount of time before they get an acceptable result.

Standard for “Chinese” carburetors is the position of the L screw, when it is 1.5 turns loose from the fully clamped position. For the H screw. one turn from the same state. In many videos, the L screw is called the mixture quality adjustment, and the H screw is called the mixture quantity adjustment. Idle speed is adjusted in the same way as described above, with the engine warmed up.