How to Assemble a Champion Spring Trimmer Knob

Rewind carrying from an old vacuum cleaner.

Old used electrical appliances can still be useful in the household. If not in whole, then in separate aggregates. In parts. So to me, the burnt vacuum cleaner fell into the hands, which the neighbor was going to throw out, but was intercepted in time. Indeed, in each device, you can find something you need for yourself. And I decided to extract from it more. Less valuable, disassembled it in parts.

Self-reeling carry from an old vacuum cleaner.

And of course, the most valuable thing in it turned out to be a self-reeling coil with an electric cable.

Having pulled it out and saving, from already unnecessary additional wires and microcircuits, I left only two main wires coming directly to the contacts. As can be seen from the photo, the coil is a ready-made self-reeling design, which only needs to be attached to a rigid case. Since it is made of thin plastic, it was simply necessary to strengthen it. But more on that later.

And for starters, I measured the footage and thickness of the wire that was on the reel. Since the factory version, it was wound only seven meters, for me, the normal carrying should be at least twice as much, so I decided to change the wire.

It turned out to be quite easy to do this, you need to disassemble the coil (which is assembled and held on plastic clips), and change the wire to your own. Well, since I put a wire of a smaller diameter, then according to the footage, it entered twice as much. Although I will not hide, there were fears that the carrying might not be unwound for the entire length, due to the limitations of the reeling spring, but everything works fine.

Also, before assembling the coil, I did not forget to clean the moving contacts, removing dust and layered dirt from them.

It remains only to assemble the carrying case.

To do this, I cut two sidewalls from a thin chipboard to the size of the coil, slightly lengthening one of the sides, this way we got peculiar legs that protect the carrying from tipping over.

Fastened the main (fixed) side of the coil with short screws, directly to one of the sidewalls. Pre-drilled in it, in the center of the hole for the withdrawal of wires.

Fastened the second sidewall so:

He marked the center of the coil and sidewall, and drilled a hole equal to the diameter of the plastic shaft on the coil. He combined both sidewalls together on a coil, then marked out and drilled three holes for the bolts. On the inside of the carrier, bolted, screwed restrictive nuts. With their help, you can easily adjust the width of the distance from one sidewall to the other, thereby achieving easy rotation of the reel drum.

It remains to install the outlet under the withdrawn wires and screw the plug. That’s it. The carrying is ready! So from a broken vacuum cleaner, I was able to benefit and acquire a much needed thing in the household.

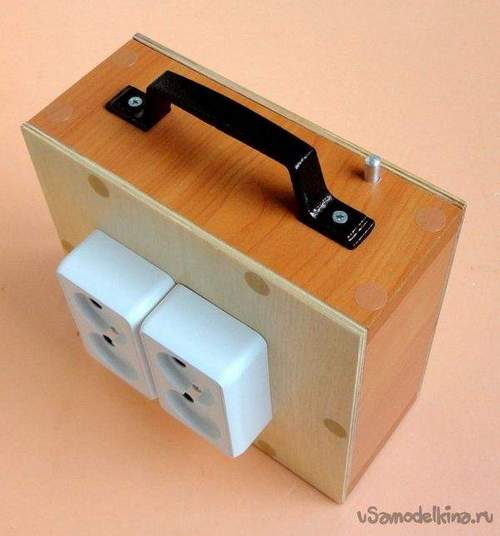

Self-winding extension cord

In this design used:

– Details from the PHILIPS vacuum cleaner.

– Two twin sockets 16A.

– The handle is furniture.

– LDSP 16 mm thick.

– Edge tape.

– Plywood 6mm thick.

– Coupler furniture 5X50mm.

– Screws with a diameter of 3.5mm.

– Fasteners M3, M4.

– Colorless varnish XB-784.

Used coil parts with wire from a vacuum cleaner.

Parts cut out from chipboard with dimensions 210x80x16mm. 2pcs, 168x80x16mm. 2pcs, with holes and a handle. The inner surface of the wire holes and buttons are varnished.

Parts cut out of plywood with dimensions of 210x200x6mm with holes. Plywood is sanded and varnished.

Assembled body frame. Details are connected by furniture ties 5x50mm.

The back panel of the housing with mounting screws M4 and M3.

Rear panel of the housing with a fixed coil base. The base is fixed with M4 screws.

Coil assembly, wire fastening.

The front panel of the housing with an additional screw clamp for the axis of the coil.

Front panel of the housing with installed base sockets. The base of the outlets is secured with M4 screws.

Installation of the main elements of the device in the housing.

The lock release button is made of an aluminum rod with a diameter of 17.5 mm. The restrictive washer is cut out of the felt-tip pen body and is simply very tightly put on the rod.

Extension cord assembly. The heads of screws and screeds are sealed with self-adhesive furniture plugs.

The length of the fully unwound wire is 9M. Case size (without sockets and handles) 210x200x92mm. The total power of the connected load is up to 2.2 kW.

If you need additional information, write to the post office, I will try to be sure to answer.Feedback, suggestions and comments are very welcome.

Communities ›Оснащение Гаража и Tool› Blog ›Reverse extension.

Good day to all.

Everyone knows what a cat does when he has nothing to do. I, unlike the cat, decided to make something.

A coil with a wire from an old vacuum cleaner caught my eye. The very one on which the cord is automatically wound. Coil with a broken spring, but with working sliding contacts. The length of the wire is 5 meters. And the idea came to me to make the extension cord the other way around, so that the coil would stay in place, and the wire with the socket would be pulled out of it.

Particleboard extension case.

I don’t have a milling cutter, so the groove tortured with a pen. To make it convenient to carry, I screwed on the top of the glamorous handle from the old cabinet.

Here’s a reverse extension cord I got. Use is convenient. Honestly, I do not see any pluses or minuses in it. At least unusual and not like everyone else.

I ask you not to judge strictly, because the device was made not of want, but of great idleness. =)

Thank you all for your attention.

All good and more creative ideas.

Tags: extension cord, carrying.

Comments 25

Cool invented, well done! I bookmarked it myself. I’ve been tormented for a long time with a bunch of “polevik” in the garage, which is constantly confused, and the old vacuum cleaner with the same coil is just lying in the garage.

From a pyloser the whole system will be attached

Do not forget!

When loading a load of more than 300 watts, it is necessary to completely unwind the coil, otherwise the wires remaining on the coil will melt.

Leading to a fuse-fighter-fireman.

Where is the logic? Please explain.

Elementary electrical engineering.)))

Believe and explain it is not easy to believe, and hunting is a dream.

Just take Axiom (a theorem requiring no proof))), completely unwind any extension cord rolled into a coil or just rings, with a decent load on the wires))))

Ps

just at work already 4 extension cords so burned))

Those. In your opinion, a 50-meter extension cable also always needs to be unwound completely? Thank you for your concern, but don’t be crazy.

The 300 watts that you are talking about is no more than 1.5 A. For such a wire, even wound in a coil, this is nonsense.

And how, following elementary electrical engineering, a two-kilowatt vacuum cleaner worked in which this coil used to live. After all, they do not always unwind it completely.

I’m not going to include more than a kilowatt in this carrying.

2 kW in a vacuum cleaner equipped with a coil, it’s funny to listen, do not confuse Chinese cotton with electric…

max 350 watts there the engine is standing, overall power has not been canceled.

Ps

10 meters of wire burn on a coil when a 500 W PCN is turned on

pps

I can take a photo, at work I still have a piece of fused wire)))

Depends on the thickness of the wire.

Those. In your opinion, a 50-meter extension cable also always needs to be unwound completely? Thank you for your concern, but don’t be crazy.

The 300 watts that you are talking about is no more than 1.5 A. For such a wire, even wound in a coil, this is nonsense.

And how, following elementary electrical engineering, a two-kilowatt vacuum cleaner worked in which this coil used to live. After all, they do not always unwind it completely.

I’m not going to include more than a kilowatt in this carrying.

And 50 meter and 150 meter, it is necessary to unwind the whole!

Elementary electrical engineering.)))

Believe and explain it is not easy to believe, and hunting is a dream.

Just take Axiom (a theorem requiring no proof))), completely unwind any extension cord rolled into a coil or just rings, with a decent load on the wires))))

Ps

just at work already 4 extension cords so burned))

Nonsense. Use an extension cord appropriate for the load and do not need to unwind anything.

Where is the logic? Please explain.

You need to unwind completely. Otherwise, with a powerful consumer, an inductance coil will turn out. What will lead to the melting of insulation and short circuit

Yeah. How about an inductor.

From two wires with oncoming winding.

Induction heating is familiar to you such a concept) Of course it is not in its pure form, but the principle is similar. An example from the same opera. Svrshchikov have a habit of winding the cable on his hand at work (for convenience). Very often, with a large current, it reduces the muscles of the arm))) I myself had a case where the coil with an extension cord was not unwound, the insulation was famous for in a solid monolith and, naturally, short circuit

It’s a sign. We have dozens of different coils in our company for heating wheels, gears, axles and more. Only here is the problem. A metal core is required for heating, and the core itself is heated substantially, not a coil (although it also gets, but much less than the core)

And what can heat up at a frequency of 50 Hz?

The device of a transformer is also familiar (in fact, the same induction coils). I used to wind them in my childhood in dozens. When two completely identical windings are wound in parallel, and then connected in the wrong way. When the transformer is working, there is no voltage in them, since there is no induction.

Partly agree with the example of the welder. In the part that such a phenomenon takes place. But attributing it purely to the phenomenon of induction is completely wrong. Permanent magnetic field. Yes, but not induction. For a long time ago, I no longer saw the use of AC MMA welders, with the development of inverters, everyone became constant. But at a direct current, as you know, there can be no induction.

The situation with induction can be true with an extension cord for 3 phases. I can’t judge what is happening there, but for one phase. Not for life, all the stories about induction in a conventional extension cord are bullshit.

But I do not deny such a thing as heating a wire due to the flow of electric current through it. Unfortunately, manufacturers also know this and are actively using it. Hence the myths that the extension cord needs to be unwound.

It is known for certain that a 0.75 sq. Mm wire passes through 10A of current, but only if the wire is pulled in the wind, the same wire rolled by a snake will not last even 5 minutes. And in the performance characteristics there is a reason to write about the maximum permissible current of 10A, but subject to a whole bunch of conditions.

Our labor safety at one time also forced us to completely unwind the extension cords, but then, when we cut a couple of such unwound extension cords, the production managers already howled, and the top management began to listen to the voice of reason. After that they calmed down.

Self-winding extension cord

Good day. I bring to your attention my version of manufacturing a fairly convenient self-reeling extension cord from the parts of a “killed” imported vacuum cleaner.

On the Internet there are many options for similar designs, which used plastic scraps from the body of the vacuum cleaner itself. The idea was to make a completely independent device case from materials and parts that were readily available and at hand.

In this design used:

– Details from the PHILIPS vacuum cleaner.

– Two twin sockets 16A.

– The handle is furniture.

– LDSP 16 mm thick.

– Edge tape.

– Plywood 6mm thick.

– Coupler furniture 5X50mm.

– Screws with a diameter of 3.5mm.

– Fasteners M3, M4.

– Colorless varnish XB-784.

Of the tools used:

– A drill on a rack.

– Jigsaw.

– The grinding machine.

– Iron.

– Screwdriver, wire cutters, etc.

Used coil parts with wire from a vacuum cleaner.

Parts cut out from chipboard with dimensions 210x80x16mm. 2pcs, 168x80x16mm. 2pcs, with holes and a handle. The inner surface of the wire holes and buttons are varnished.

Parts cut out of plywood with dimensions of 210x200x6mm with holes. Plywood is sanded and varnished.

Assembled body frame. Details are connected by furniture ties 5x50mm.

The back panel of the housing with mounting screws M4 and M3.

Rear panel of the housing with a fixed coil base. The base is fixed with M4 screws.

Coil assembly, wire fastening.

The front panel of the housing with an additional screw clamp for the axis of the coil.

Front panel of the housing with installed base sockets. The base of the outlets is secured with M4 screws.

Installation of the main elements of the device in the housing.

The lock release button is made of an aluminum rod with a diameter of 17.5 mm. The restrictive washer is cut out of the felt-tip pen body and is simply very tightly put on the rod.

Extension cord assembly. The heads of screws and screeds are sealed with self-adhesive furniture plugs.

The length of the fully unwound wire is 9M. Case size (without sockets and handles) 210x200x92mm. The total power of the connected load is up to 2.2 kW.

If you need additional information, write to the post office, I will try to be sure to answer.Feedback, suggestions and comments are very welcome.

August 2019

Stanislav Shurupkin.

Email: st-shur@mail.Rusource

Be the first to comment

Leave a comment Cancel reply

You must be logged in to post a comment.

Wire for extension cord: which to choose for carrying, self-winding for a lawn mower, which is needed for a trimmer. What a garden consists of

Electric lawn mowers are good for everyone: they are lightweight, mobile, relatively inexpensive, productive and environmentally friendly.

The only big drawback of such devices is the dependence on the electric network, which causes many inconveniences when it is necessary to process a spacious lawn in the absence of a sufficient number of connection points (sockets).

You can solve the problem with an extension cord. After reading the information below, you will learn how the extension for a lawn mower works, get recommendations for choosing a suitable device and its subsequent operation.

Principle of operation

The principle of operation of an extension cord for a lawn mower for an end user is not much different from the mechanism of action of an ordinary network carry: the device is plugged into an outlet, transferred to the required distance (unwinds to the desired length), where the device is connected to it, in this case, a lawn mower.

According to their structural design, extensions for lawn mowers are classified into products “in the bay” and “on the coil”. The second option is the most popular and preferred.

In its turn, reel extension cords are also classified into 2 groups. Representatives of the first category have the form of a coiled extension cable, one end of which is equipped with a molded outlet. Directly, the coil and plug are located at the other end, which is located at the point of connection to a stationary outlet.

Such a design is very convenient to use. The user does not need to carry the coil itself, it is enough to simply unwind the wire. Thanks to the features of the case, the unwinding and reeling of the cable are quick and effortless.

The second type of reel extension is noticeably different from the model discussed above: here the coil is equipped with several sockets, allowing you to simultaneously connect more than one device.

For the manufacture of coils, metal and plastic can be used. The first option is more preferable and is characterized by improved indicators of durability and resistance to adverse external influences.

For use in combination with electric lawn mowers AL-KO, Gardena, Stig, Bosch Rotak 32, Stihl, Makita, Champion, reel extension cords of the first group are best suited, as in accordance with safety precautions, taking the coil far from a stationary outlet is strongly discouraged.

Along with this, models made in a waterproof housing are available for sale. If possible use just such an extension cord for a lawn mower.

How to choose an extension cord

When choosing an extension cord designed for use in combination with an electric lawn mower for grass, you need to pay attention to a number of significant parameters and characteristics.

Firstly, choose the optimal extension cable length. At this point, focus on the size of your site. Additionally, add a couple of meters “in reserve”.

Too get carried away in this regard is also not worth it. With each additional meter, the cost of the extension cord increases significantly.

To determine the approximate extension cord length, you can use the following diagram.

Given: rectangular section 20×30, i.E. Standard 6 acres.

We find the square of the diagonal of the site, summing up the squares of its sides. Next, you need to extract the root from the obtained value to get the length of the diagonal. In the case of this site, it will be 36.06 m.

The nearest standard extension cable length. 40 m. We buy such a product. The stock will be used to compensate for turns, bends, etc. Rounding the calculated length to the smaller side is possible only if stationary outlets are installed at different angles of the structure located on the site.

Secondly, you need to determine the appropriate cross-section of the carrying wire. To do this, you need to know the power of the lawn mower (indicated in the product passport or on the housing). The power of simple electric trimers is usually not more than 2 kW, wheeled lawnmowers. Up to 4 kW.

In the case of trimmers, the recommended cable sections will be as follows:

- For a device with a power of not more than 1.5 kW. 0.75 mm;

- 1.5-2 kW. 1 mm;

- 2 kW and more. 1.5 mm.

The cross-section of the extension cable intended for use in combination with a lawn mower with a power of more than 2.5 kW should be at least 1.5 mm.

Thirdly, need to solve issues with the features of the grounding extension cord. If grounding is necessary (and its presence is highly recommended), buy a product that has a “3” in its marking. As an example, we can consider the model of the KG extension 3×1.5 mm from the popular Atlas brand.

In this case, “KG” indicates the brand of wire, and the number “3” indicates that the extension cable consists of three cores, one of which is directly a grounding wire.

Features of the extension cord in the.

Fourth, you need to choose the appropriate design extension. As noted, such products can be performed on a coil or in a bay. The first option is most preferred. The second is used mainly on an industrial scale and allows you to connect more powerful equipment.

Fifthly, it is necessary to take into account a number of general recommendations for choosing an extension cord for a lawn mower:

- The extension cord must be equipped with one rubber outlet. The presence of two or more outlets will create difficulties when connecting an electric lawn mower and cause inconvenience during operation.

- Extenders are best suited for use in combination with lawn mowers, the cord of which is colored orange. Such a coloring is simply more clearly visible on the ground, so that the probability of accidental cable damage and the occurrence of related problems is minimized.

- Due to the fact that lawn care is carried out mainly in the warm season, it is preferable to choose an extension cord with a PVA wire for use in combination with an electric lawn mower.

- If the extension cord will be used not only in combination with a lawn mower, but also to perform various tasks in the cold season, give preference to models with wires KG.

User’s manual

If you wish, you can permanently fix the extension cord before use. For this the coil design is equipped with two mounting holes.

The purchase of a chainsaw is a rather difficult matter, because it is not easy for even a professional to decide among the many variations of offers. The Carver chainsaw is quality, reliability at an affordable price.

There is no longer such a stylish and attractive tractor as the MAZ-541, which “lived” only at the airport, and the number of MAZ produced by this model is only 3 pieces. By clicking on the link you will learn a lot of interesting things about this special airfield tractor.

With the help of a cultivator, it is possible to plant various crops in the soil with ease and high speed, as well as carry out various other procedures. Here you can find the Patriot cultivator.

Install the reel in a suitable place, mark the locations of the future fasteners through the holes, drill the recesses and fix the extension drum with bolts or other suitable fasteners.

To turn on the extension cord, you must connect its plug to a stationary power outlet. The automatic coil has a function of automatic expansion-folding. Unwind the cable to the desired length. After each half-turn of the cord, its fixation is ensured.

To roll the cable after use, pull it to secure it, then slowly roll the wire.

Automatic coils are characterized by high traction. Avoid uncontrolled cable folding. Hold its end and slowly guide the movement of the automatic coil.

Coils of modern garden extension cords are equipped with mechanisms that provide protection against overheating during operation. As a rule, the color display is the same in different models. So, if the LED glows red, this indicates that the overheat protection is in the on state.

When the aforementioned protective system is activated, the lamp goes out. In this situation, the user must disconnect the extension cord from the network. After a few minutes (when the extension cord cools down), you can try turning the device on again.

Reel Extension for Lawn Mowers do not need specialized maintenance. It is enough to clean them periodically. The automatic coil must not be energized during cleaning. To comply with this rule, unplug the extension cord from the stationary outlet.

The outside of the extension cord is cleaned with an ordinary dry and clean rag. Check that moisture does not enter the extension coil design.

During operation of the extension cord, observe basic safety precautions and precautions:

- Do not disassemble the extension cord;

- Do not use the product in rainy weather;

- Do not use extension cord in places with excessive humidity;

- Do not allow moisture to enter the extension cord structure;

- Do not use the extension cord in places with high dust, vibration, etc.;

- Do not short the terminals of the sockets;

- Do not let children use an extension cord;

- Do not plug appliances into the extension cord. The total power of which exceeds the maximum allowable for this device.

Now you know what an extension for a lawn mower is, how to choose it and use it correctly. Follow the recommendations and everything will be in the best possible way.

Nozzle for the vacuum cleaner “1000 hobochotok”

Overview of the nozzle for a vacuum cleaner, which allows you to vacuum hard-to-reach places, leaving small things in place. In fact, there are not 1000 hobots, but only 30, but nevertheless, this is a very interesting little thing. Under the cut a lot of photos and some text.

I came to Ukraine in 22 days in a nondescript package. Content: Proboscis: On the back side:

- August 27, 2018, 22:03

- Posted by: Topcat

- Views: 9252

Therefore, holes occupy 29% of the assembly area.

Air flow is 70% less, so the vacuum cleaner may overheat

It can’t, but it will overheat. Absolutely stupid, and moreover, harmful nonsense, worsening the operation of the vacuum cleaner

- Serge_petrov

- August 28, 2018 00:41

It can’t, but it will overheat. Absolutely stupid, and moreover, harmful nonsense, worsening the operation of the vacuum cleaner

- Goblintsht

- August 28, 2018 09:28

- Serge_petrov

- August 28, 2018 12:01

Yes, even the photo in the review shows that the dust is not all gone

- Serge_petrov

- August 28, 2018, 14:41

- Serge_petrov

- August 28, 2018 17:47

If you are going to blow, then why do you need pre-cleaning?

Would use a vacuum cleaner while blowing to remove dust

Dust stands in an apartment

- Serge_petrov

- August 28, 2018, 19:17

Didn’t you try to leave the apartment?

- Serge_petrov

- August 28, 2018, 20:32

- Serge_petrov

- August 28, 2018, 21:58

The garbage bag in the vacuum cleaner is also completely stupid and harmful nonsense,

Also completely stupid and harmful nonsense

- Jonsons272

- August 27, 2018, 22:48

No matter how I tried to combine the nozzles, nothing worked. The best option without using adhesive tape and electrical tape was 1 Philips hose pushed deep into the adapter:

The adapter for the vacuum cleaner with a high probability will have to cut and file, or use tape or electrical tape.

The nozzle reached the Moscow region for exactly a month. The branded box with color printing was packed in a regular bag, and therefore the edges of the box were badly wrinkled, but inside everything turned out to be intact. The nozzle with tubes has an outer diameter of 30.5 mm to 31.2 mm (slight taper), the tubes are inserted on friction, without hot-melt adhesive, so all holes are present :)Adapters have an external diameter for connection to a cone, the first (with a long cone) from 34.2 mm to 36.5 mm (cone length 55 mm) and the opposite end has an internal diameter of 34.7 mm., And the second (with slots) the cone has a shorter length (25mm) and the diameter of the first cone is from 34.9mm to 35.2mm, the second is almost no cone (part with slots) from 37.6mm to 37.9mm and on the opposite side the inner diameter is 34.2mm.

The nozzle enters the adapters with a tight fit on both sides: So before you buy measure your Measure your vacuum cleaners so you don’t use the blue tape.P.S. The previous review was exactly a month ago:mysku.ru/blog/china-stores/64212.html