How to assemble the cutters on a single axle tractor 3 knives

How to assemble the cutters on a single axle tractor

Working the land in modern conditions is much easier than it was half a century ago, for example. Today, there are many options for this. For example, handy power tillers, which due to their compactness, but versatility allow to solve various problems in processing even small plots of land. As a result, they are very popular with farmers and dacha owners, who work in the soil.

The single–axle tractor itself is not of much interest if it is not equipped with the necessary additional equipment. It’s the only way to get the most out of it. In this case, we will figure out how to assemble the cutters on a single–axle tractor with our own hands.

What you need to know making a snowmobile on the basis of a power tiller

Before creating such a snowmobile to solve the problem: what is the purpose of the future machine? For this clarifies the mass of the largest baggage, the desired number of seats, under what criteria the machine will be used. Once you have learned all of the above, when determining the future concept of a snowmobile, begin to consider options for creating machines. After that proceed to the selection of parts and assemblies for the snowmobile. To do this, determine what type and model of engine is best suited.

Choose the box, the type and design of the frame and other elements. Particular attention should be paid to the choice of form of running gear. Also thoroughly calculated characteristics of the design: the size of tires, motor power and snowmobile weight.

After analyzing and comparing the ability to compare your desires, choose a scheme of rover. Prerequisite for completing this step of activity is the scheme and drawing of the snowmobile, a self-made.

For a snowmobile on pneumatic wheels, an engine from a power tiller will do just fine. For this purpose, choose a motor that is most suitable for the conditions of use and power. Another advantage of using motobloc engines, the presence of air or water forced cooling, as the snowmobile does not have the conditions necessary for natural cooling.

READ How to Make an ATV Out of a Hoe-Block

Four-stroke motors have a number of advantages over their two-stroke counterparts. When choosing the type of engine: carburetor or diesel, you must also weigh the pros and cons. After all, both systems contain pros and cons. In comparison with an internal combustion engine, the diesel one is more economical. But in severe frosts, it is hard to start and unstable, without a pre-start heater. Gasoline engines, on the other hand, are even less prone to this.

How to assemble the right cutters on a single axle tractor?

Assembly of the tiller with its own hands should be carried out as correctly as possible. Here it is particularly important to make sure that the active part hits the ground during operation. For this purpose, it is initially recommended to study the drawings, and then already proceed to the manufacture of equipment. The following tools are required to build a cutter:

- Rotor axis of the required length. It can be split into two parts if it is necessary to assemble the cutter from two blocks.

- Short axle.

- Gearbox with locks.

- Left and right knives.

- Bolts, washers, nuts.

Assembly does not take more than an hour, but it is important to install the blades in such a way that they do not interfere with rotation.

Folding knife zt 0630

- The long rotary axis is equipped with knives at an angle of 30 degrees.

- It is necessary to combine four knives on one block by attaching them to the gearboxes.

- Then the correctness of the construction is checked and all fastening elements are tightened.

This construction is very reliable and can withstand sufficiently high loads.

Cutter types

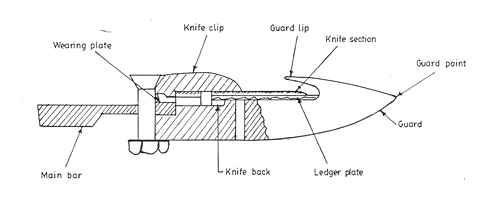

The fixture consists of four bent knives. “petals”. mounted on a shaft. Most of them are directional: when assembling it is necessary to take into account the direction of movement. Blades are usually bent on both sides, except for those located on the edges of the shaft. There are models with all “tines” bent towards the gearbox side only: this prevents crop damage when ripping. But in this case the working width is reduced.

Elements are made of pressed steel. for the lightest machines. and of steel strip, often forged. The latter variant is the strongest. The tiller is usually a separate piece, but there are also models with two tillers mounted on the same shaft.

- Sharpened. the “petal” is easier to penetrate the ground and does not allow adherence to the soil. This means less strain on the engine and lower fuel consumption. On the other hand, the sharp blades cut the roots of the weeds, some of which remain in the ground and sprout again. Sharpened burrs should be used with great care.

- With a semi-circular edge. safer, but in ripping experience more resistance, more often get stuck. This element removes weeds more effectively, as it does not cut, but winds up the root and pulls it out of the soil.

The diameter of the tiller for the cultivator determines the maximum plowing depth. Relative is set by the coulter.

- To the rivets. the element is not disassembled. The difficulty is not so much in storage, as in transportation;

- on bolts. a demountable part. The photo shows a sample.

Welding is not used for the connection. this reduces the strength of the product.