How to bore concrete with a hammer drill. Can I drill metal with a hammer drill?

How to combine a regular drill with a rotary tool

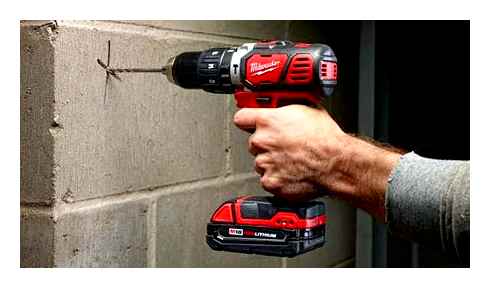

Concrete walls and slabs can be drilled with three types of tools:

The first two tools can often be combined in one housing. This is a more economical option, but requires attention in the selection of drills. for each mode (drilling, impact) you need different devices.

Peorator is able not only to drill, but also to make a powerful impact at high frequency. This allows it to partially replace a jackhammer and to drive through chisels and large excavations in concrete with a special saw. Masonry work is broken up and old tiles can be removed easily.

Drilling with a rotary hammer

When using a peorator it is necessary to follow safety rules and choose drill bits and borings according to the type of the clip on it. It can be of several kinds:

- SDS. has 2 slots and 1 cm shank diameter, working part from 0.5 cm

- SDS plus. has 4 slots and shank diameter of 1 cm, the working part from 0.5 cm shank diameter

- SDS top. has 4 slots and 1 cm shank diameter.4 cm, working part from 1.5 cm

- SDS quick. has 4 grooves and 1 cm shank diameter, working part from 0.5 cm

- SDS max. has 5 slots and a shank diameter of 1.5 cm, working part from 2 cm

Diamond drills must not be used for the impact mode of the torch. Their destruction is inevitable because of their high fragility. The floor saw is ideal for larger work and for drilling through thick supporting walls and foundations.

Drilling with a drill

Drill bits with pobedite or diamond-coated bits can be used. The latter drill bits in medium speed can perfectly drill through ceramic tiles or stone surfaces without splitting them apart. The drill is suitable for a variety of non-scaled jobs at home or apartment repairs. Can only be drilled through walls of small to medium thicknesses.

- When working with both a torch and a drill, protective goggles and a respiratory filter mask are mandatory. Otherwise eye injuries and inhaling fine rock dust are unavoidable.

How to use the tool safely

The peorator may only be operated when wearing personal protective equipment. This includes safety goggles, earplugs, gloves, respirator. The dressing should be without fluttering long-haired parts. Hair must be kept tucked under a headdress. shoes must be dry, comfortable and non-slip, preferably with socks reinforced with metal plates. Noise level of operating tool ranges from 100-110 dB. Noise levels of up to 140 to 150 dB if surfaces resonate (e.g., concrete walls). This noise level can cause systemic or psychological problems. Wear earphones or earplugs.

Reverse

Reverse function allows reversing the chuck’s direction of rotation in different directions.

When drilling in reinforced concrete the hammer often hits and clashes with the reinforcing bar. In order to release it, there is a reversing switch that makes it possible to turn the drill in the opposite direction and continue drilling, bypassing the reinforcement. Usually the reversing button is placed specifically near the machine’s start button.

Reversing mode turns the torch into a screwdriver that can be used to tighten or unscrew screws, nuts and screws of any size and configuration.

Tramming the ground in the greenhouse

The use of an attachment on the peorator for ramming the soil has proved to be a good idea. It is a flat iron plate with which to “trample” the ground site. Used locally in the construction of greenhouses, beds.

Preparing the tool for work

Visually inspect the tool before beginning work. And it is important to check that it is complete. It is worth watching that the body or the cartridge was not damaged. You should also determine the integrity of the cable. No cracks or chips on the surface of the workpiece. All edges must be sharp.

After that, it is recommended to test run the device in idle mode. It is of no small importance to assess the functioning of the buttons and toggle switches, which are used to switch speed modes and change the direction of chuck movement.

Tool must be prepared for work

Drill types

Drills are differentiated by the type of work they allow:

- Conventional. For carpentry work.

- Impact. For hard stone materials. The motor of such a drill imparts reciprocating motion to the chuck simultaneously with the rotary.

- Peorator. The principle of operation is similar to that of an impact drill, but the crushing mechanism is different, and the efficiency is higher.

It should be noted that peorators, despite the more powerful mechanism of work, are not without disadvantages:

- High cost;

- High power consumption;

- Complexity of operation and mechanism;

- Heavy weight;

- Unable to perform precise work;

- Regular tool lubrication and cleaning.

In order to determine what type of drill you need, you need to understand what kinds of work are planned.

It should be noted that when using special nozzles instead of a drill, the electric drill will perform other operations. The main ones are: grinding, polishing and milling work, sharpening, screwing in self-tapping screws, kneading.

What is fraught with a disturbance in the wiring during drilling

Drilling through walls is dangerous and demanding work. Carelessness can result in failure of the torch, necessitating re-routing of the electrical cord. If the cable or cable sheath is partially damaged, the circuit breaker always trips. The most unfortunate consequences of careless attitude to drilling walls: electric shock, fire, injury when falling down.

Even if you know how to drill correctly, you may encounter a problem when the drill bit gets stuck in the wall. The most common cause is getting the nozzle between the stone and the iron fittings. This can happen if the drill bit penetrates too deeply into the wall. Do not pull the trigger further and loosen the tool. The tool can break and is not always easy to retrieve. Worst of all, the torch will burn out. If the drill is stuck in the wall, the chuck is released from it. A thin drill bit is inserted into the tool and a piece of concrete is gently drilled out near the stuck nozzle. There’s no need to get on it. Gradually, taking your time, it will be possible to hollow out chunks of concrete and pebbles around the stuck nozzle. After that, the drill can be taken out of the wall.

You can use adhesive tape and a bag to minimise dust when working

How to use the torch in different modes

Many people wonder how to properly work with a gnawing tool. There are a number of modes of operation of the device, which should be selected taking into account your tasks. If you study the instructions carefully, even a girl or child can cope with the device.

Drilling

How to properly drill with a drill bit? To start work, the drill must be switched to drilling mode without impact. The lever should be set in front of the marking of the drill. Little physical effort is required for drilling.

Notice! To prevent the chuck from breaking, the tool comes with a locking function. It is used to work with wood or metal.

The tool is suitable for drilling

Impact drilling

To use this mode, the switch must be in the “hammer drill” position. This mode helps to make holes in concrete and brick. The device performs progressive and rotary movements.

Punching

Many people wonder how to bore concrete with a tiltrotator. To do this, you need to put the switch beside the stop switch. The tool will not rotate in this mode. It can be used to crush building structures, pierce chinks, and perform chipping work.

When drilling into hard surfaces, it is important to hold the device firmly. It is recommended to use special tools. spades, trowels, chisels, chisels.

Reverse

This feature helps change the direction of movement of the tool. Low-cost devices use electrical reverse. Professional appliances use a gearbox. This alternative is considered more reliable. But such tools are much more expensive.

Important! Reverse is used if the drill is jammed in a large hole. It can be used to easily release the drill bit.

Additional tool features

Some gorator models have additional modes. One of the most common causes of shock hazard situations is that the bit rotates. This mode is required for efficient drilling. The chisel rotates by a specific degree in this position. This is done with every stroke.

How to change and regulate modes of the torch

You should only change modes when you stop using the tool. These do not require the tool to be disconnected from the mains. It is important to verify that the switch is in the proper position.

Concrete drilling machine. Only repair with their own hands in the apartment: photos, videos, instructions

Types of tools for drilling through walls

During major repairs or redevelopment we always face the question of laying wiring, pipes, cabling, relocation of switches and outlets. All these works are connected with wall drilling. Let’s try to find out what kind of work is it, what it needs and what kind of tool is needed for ditching walls.

Why do you need to drill a wall?

So, slotting is gouging grooves in the walls and ceiling for laying electrical wiring, piping systems. To lay and hide electrical, antenna or telephone wires and cables, we also use slotting.When installing air conditioning, the wall also needs to be drilled.

If you need to hide the existing wiring, we make a channel (stroba) in the thickness of the plaster or concrete, put there wires or cables and putty.We stroeblyuyut walls and when it is necessary to mount the internal models of electrical outlets or switches.

These models are built into the inside of the wall, so you need to cut a round hole that corresponds to the size of the switch or socket.

Choice of tools depending on the wall

Driving through is done with special tools, the choice of which depends on the material of the wall in which you want to make a channel. Angle grinder, floor saw, chisel and hammer are used for this. Chisels on concrete walls can be made with an angle grinder, a rotary sander, a chisel and a chisel gun.

A panel wall is treated in the same way as a concrete wall. But you can not do diagonal drilling. The maximum depth of the channel should not reach the reinforcing frame in order not to damage the construction. If the depth of the channel reaches the armature, then it is better to make an additional layer of plaster or level the surface with plasterboard. We make grooves in a brick wall with the help of a stubbing cutter.

SECRET to drilling through concrete for tapcons (so simple so effective)

This manual angle grinder, which we use when piercing hard concrete walls, when you need to pierce a lot of long grooves for the wires. Then mount a special disc for concrete work, for example a diamond disc.

This disc is usually thick enough to get the desired size of the indentation.If the width of the channel should be greater, then make two channels in parallel at a distance of not less than 5 mm, and then peoratorom squeeze out the gap.

Expand the hole by disk movement of the angle grinder perpendicular to its plane can not: the machine is not designed for this, and it is very dangerous.

Making stroebe, we use heavy tools, the power of which exceeds 500 watts, and quality disks on concrete. Working with such a tool, do not forget about the rules of safety. Work carefully, holding the machine firmly in your hands.

HAMMER DRILL VS. REGULAR DRILLWhat’s The Difference?!! (Do You NEED a Hammer Drill?!)

You shouldn’t drop the tool. Although it will turn off, but the disc rotation will not stop immediately, and the surface of the floor or even feet can be damaged. Screw on the nut securing the blade firmly so the cutter does not fly out while working. It also happens, and it is extremely dangerous. Drilling with an angle grinder is ideal. The only disadvantage of this tool is a large amount of dust.

Peorator

We use this tool if we want to make a mortise in the concrete. Insert the “spatula” while working with the peorator. This is an attachment whose shape allows you to hollow out a narrow and elongated hole that corresponds to the shape of the groove.

Do not forget that the blade during the actual cutting cannot be placed across the marks, because pieces of the wall material can break off. If you want to make a recess for the socket, use the “bayonet” attachment in addition to the “shovel. Use the bayonet to mark the hole and use the spade to make it wider.

Performing perforating walls with the perforator we can use another method. We put the auger with diameter of 6 to 10 mm into the drill and set the impact drill mode. We drill holes along the channel at a distance of 10 mm, then we insert the blade, set the rebound mode and proploblyvayut intervals between the holes. Proceed in the same way, making the landing places for sockets or switches.

To get the hole of desired depth, on the drill (at the required distance from the tip of the drill) wind electrical tape, which will mark the desired depth.It must be said that the channels, punctured by the pen, may be uneven, and they will have to be processed additionally.

To make perforator fast and easy shrovelling walls, you need special skills, so using this tool, you must be careful and cautious. The piezoelectricator makes a lot of noise when it is in operation.

This tool is designed specifically for piercing any wall and is considered the best tool for piercing grooves. With the use of a strobor cutter we make hollows for electrical wiring, water supply or heating systems. It works on the same principle as the angle grinder, but differs from it.

There is not one, but several diamond discs in the stitching cutter, the distance between them can be adjusted. It is also possible to adjust the depth of the stubbing. The tool is equipped with a dust collector, which directs the waste into a vacuum cleaner or removes it to the side.

Starting to make channels and holes, be sure to check the thickness of the walls. If the wall is thin, consider the load and do studding closer to the ceiling or floor to the wall itself they were a little. If the wall is more than 10 cm thick, we cut the furrows at the shortest distance, saving time and effort. In addition, do not forget to check whether there is electrical wiring in the area.

Chisel and hammer

The cheapest, but also the most time-consuming option. We use these hand tools, if we need to make not long channels in plastered walls. Chiseling concrete or brick by hand is impractical.

How to work without dust

Often the peorator has to drill into walls and ceilings, in which case dust is inevitably spread throughout the room. To avoid this, savvy builders have come up with several devices:

- Plastic cup. You have to make a hole in the center of the bottom, and then put the cup on the drill or drill bit. During work, all dust that forms will fly directly into the cup. When the drill stops, it can be easily emptied into a trash can or thrown away. This method is suitable for a drill that is at least 10 cm long. For shorter nozzles, you’ll have to cut the cup.

- Glued package. Before drilling the holes, it is necessary to glue a bag with a hole made in it to the wall. Once you start drilling, your partner can connect a construction vacuum cleaner to it, so that it can remove all the debris.

- Paper envelope. It is necessary to take a piece of paper and bend it vertically almost in half so that a free strip is left at the top. Then the sides of the sheet is bent vertically to form an envelope. The resulting construction is glued to the wall under the intended hole. During drilling, all the debris flies there.

In the store you can buy special plastic bags for collecting dust. They are put on the drill, after which the debris along the grooves of the drill is collected inside.

Where to buy a peorator

So, knowing how to use the peorator in different modes of operation, you can proceed to the stage of selecting the appropriate tool. You will not have any problems with the choice, as described in detail how to choose the right peorator for the home.

You can buy the tool, referring to the online store Cylinder. In the catalog site presents models from different manufacturers. Guided by personal experience, reviews, as well as technical parameters, you can choose a good peorator, and learn to use it correctly.