How to change nozzle on your drill. Proper handling prolongs life

How to Change Nozzle on Drill

This operation is common and sharp, yet necessary to observe certain rules. The step-by-step annotation will keep you safe while putting the drill in drill.

- Unplug the tool.

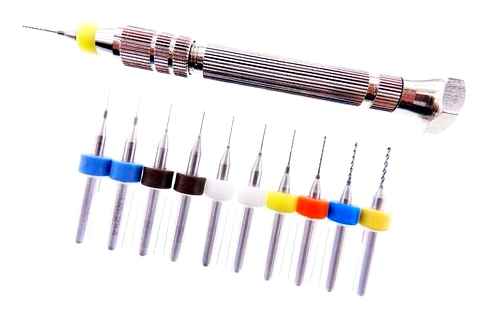

- Then choose the drill bit suitable for your needs, taking into account the type of work, the material in which the hole will be made, and the compatibility of the drill bit with the drill.

- Insert the drill bit into the chuck with the shank end pointing inward (“shank”).

- Then the chuck has to be fixed, taking into account the type of chuck. If the main one, then fasten with a special wrench with teeth, if a quick-clamp, then fasten with your hands.

- After the drill is in place, make sure it does not wobble in the chuck and there is no free play.

- Then you can get to work.

It should be noted that the choice of drill bits depends on your electric drill. There are different models with different technical equipment and abilities. Some drills cannot be used for metal work, for example. Others. allow the possibility of installing drill bits in a cross section of 0.8 to 10 mm or 1.5 to 13 mm. It is not recommended to take cheap drills made of bad metal, it is better to overpay and make sure that the tool works properly and for a long time.

Where else the drill can be used

The scope of application of the rotary drill is not limited to concrete or stone work. This all-rounder can be used wherever impact technology is needed.

Resharpening the drill by yourself

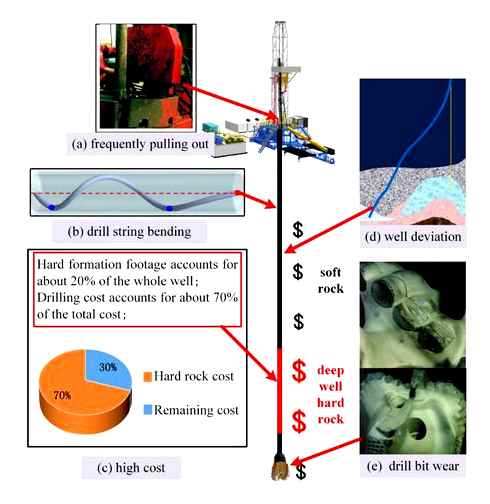

When a carbide-tipped drill bit (auger) is used, it wears out from knocks and friction. in all cases the bit wear life is not yet complete before the bit breaks. In particular, it is noticeable on the tool of a huge cross section. It leads to lower productivity and extra costs for consumables. That is why it makes sense to sharpen augers without the help of others. To do this, you need to use a sharpening machine (emery machine).

READ The brushes on the angle grinder are burning, what’s the reason?

5 Tips to Prolong the Lifespan of Your Drill

at independent sharpening of auger principally to keep the unique angles made at the factory. Their values: 30 degrees. front edge, 60 degrees. back edge. For more precise sharpening, an angle piece is made to fix the auger in the right position when sharpening.

How to change a drill bit in a Makita drill

How to replace a drill bit in a Makita drill? The question is not complicated, but it requires proper attention, because if the drill is not fixed correctly, then problems can arise: a broken or uneven hole, the possibility of falling out of the tool causing injury, as well as other troubles. First let’s look at how to insert the drill bit into the drill chuck.

For the drill to work correctly, the drill bit has to be inserted into the power drill chuck with the shank. Most drills are equipped with a cam-type chuck. These parts have a cylindrical body. A ring or sleeve rotates on their surface, and cams are placed inside the cylinder, which come together when the ring rotates clockwise, compressing the drill bit in the process. Clockwise rotation moves the jaws away from each other, thus relaxing the drill bit. This allows it to be replaced or removed. To make it easier to insert the drill bit, the cams should be loosened to a certain extent. The operating principle of cams makes it possible to fix drill bits of any diameter. Normal household drills are available with a standard range of drill diameters. 0.8-10 millimeters, some models may have an interval of 1.5-13 millimeters.

There are two ways of clamping: quick clamping and key clamping. In the first option, the rotation of the sleeve is done manually. Drills with this clamp often use locking elements that limit the clamping force. In the second version, the adjusting sleeve moves due to the presence of a wrench. On the side of the chuck there is a hole where the wrench with teeth is inserted. Sometimes there are several such holes (up to three), each of them must be loosened by turning the key counterclockwise once or twice. Then start turning the cartridge counterclockwise, thereby increasing the diameter of the nozzle hole. Now insert the drill bit and clamp first the chuck and then the sockets.

To change the drill bit, you have to pull it out first. Let’s look at how to remove the drill bit from the drill. The process is fairly straightforward, but you must be careful because you might damage the drill or chuck.

- First you need to turn off the equipment.

- The drill bit must be carefully taken out of the chuck with the special wrenches. Note which chuck is installed. If it is keyed, the key itself must be placed in the hole designed for it. Then the wrench is turned counterclockwise until the clamps separate. Next, the drill can be easily pulled out and a new one can be installed in its place.

- If a quick-action chuck is used, the socket must be rotated with the wrenches until the drill comes out (it is required to apply force, the drill must be clamped in the hand). Slap the chuck with the palm of your hand. If the drill bit has not been clamped too tightly, it will come off easily after such a movement.

If the drill is jammed, use force to remove the drill. Be careful when doing this as it can damage the tool. The work is done in the following way:

- First the equipment must be turned off.

- Then gently tap the chuck with a hammer to avoid damaging it. Place a board between the hammer and the chuck.

- Knock on the chuck until the drill bit shank comes out.

If the electric drill works only with metal chucks, then to pull out the jammed drill, you will need two gas wrenches. They are needed to clamp the sleeve, then the chuck must be rotated counterclockwise. This method can also be used with a plastic chuck, but there is a risk that it will be damaged. If all else fails, remove the chuck from the tool.

The drill blade may remain in the material being worked on. You can tell when the drill is stuck by the characteristic noise. If this happens, switch off the machine immediately and then unclamp the chuck.

The drill bit may not come out. In this case, take a new chuck, then carefully chisel away a small section near the stuck element with the drill. “Injured” equipment is extracted quite easily, for this purpose it needs to be rocked slightly. If none of the measures help, then contact the service center. It is not possible to apply too much force, because the equipment could break.

Replace the drill in a Makita drill is not that difficult, even if it jams during operation, you only need to choose the right models and chucks. It is enough to do the job once, so that you can do it later without mistakes.

Disadvantages

Owners of “Interskol” tools still notice disadvantages of the drills.

- These include, for example, the weak integrated lighting of the work area in some models of this company. Many note the insufficient length of electrical wires, which is not always convenient when working in large spaces.

- It happens that the speed is not immediately switched, but it probably depends on a particular model and its serviceability.

- Some types of drills are equipped with sufficiently wide ventilation holes through which debris and production waste can enter.

Of course, it is important to remember that all the shortcomings are associated with the conditions in which the tool works, with its serviceability.

To avoid trouble, you need to be careful when buying, get acquainted with the drill in the store and ask the consultant questions.

In any case, the diversity of opinions converges in one. the products of the brand “Interskol” have a lot of advantages, because of which you can not notice the small disadvantages at all.

As mentioned above, the Russian company offers a fairly wide range of drills. Your attention can attract low-speed drill, whose speed is 650 revolutions per minute or tools with high torque. It is possible to choose a suitable drill for you among electric and pneumatic models. It is possible to buy low-speed tools or those designed for simpler, more standard jobs.

Let’s take the “Interskol” range of products as an example of some products.

Impact

The most popular among impact drills are almost all proposed models, because each of them has its own characteristics, and the buyer chooses the product based on their own needs.

- The model DU-13/780ER is one of the best. Power up to 780 W, enough for large-scale construction work. It’s convenient to have an extra handle, which is important when working with very hard surfaces. The diameter of the suitable drill reaches 13 millimeters, and the speed is 2700 revolutions per minute. At a weight of 2.2 kilograms it is comfortable enough for long-term work.

- And here the DU-16/1000ER model can be produced with the label “Professional”, because its power reaches 1000 watts, and the drilling diameter reaches 16 millimeters. The main advantages are the metal gear case, which ensures safety, the additional handle is kept on an aluminum mount, the presence of a speed switch, and quite smooth adjustment of the speed, which, of course, is convenient at work.

Impactless

In the category “impact-free drill” the most favorable in terms of price stands model D-10/300ER. it is adapted for work with drills of small diameters, suitable for working with thermoplastic materials, and its small volume and low weight affect the result of the process only positively.

Perhaps the most expensive and truly professional in this category can be called a model D-16/1050P2.

Its. however, and the qualities of this drill can be considered the best. The most powerful motor undoubtedly ensures high productivity for a long time. Metal gear housing made of light alloy allows you to work in harsh enough conditions. 16 mm key chuck. ideal for large tooling.

Cordless

Cordless impact drill electric screwdriver DAU-10/18L2 is excellent for many types of construction work. The impact mode ensures the successful process of drilling hard surfaces, the Li-ion battery allows the drill to stay charged for a long time, the model has a high power capacity, and there is also a LED backlight of the working area, which is very convenient But it is completely justified.

Manufacturers have also provided a cheaper option from the same category, for example, a cordless drill-electric screwdriver DA-10/12M2 (2 akc). There is a good carrying case with optimal positioning of the tool, and the battery charger with a convenient charging indicator, and the backlight, which is directed exactly where you need it.

The features of this model are perfect for any job and are fully consistent with the cost. Ideal for beginners.

Mixer drill

In this category, the model D-16/850ER can probably be called the most popular. It has a powerful electric motor that ensures a long working process, the metal housing will help the drill to remain in proper condition for a long time.

Troubleshooting

In situations where the drill is used only for narrow purposes and occasionally, users tend to send it for repair at the first problems that arise. But in most cases it is sufficient to know how to avoid unusual situations that arise. To fix minor malfunctions, you need to know how to change the drill, whether it can be done without a wrench, and how to act when it gets stuck.

Drill replacement

To carry out this procedure, you must first remove the old drill bit in the manner described above, and then put the new. Drills with quick-change chucks often have problems because the drill bit is jammed and the sleeve can’t be unscrewed. In this case, you can use a piece of cloth, which will give more grip on the coupling, and try to unscrew. If this method does not help, then you need to tightly fix the hand on the drill and tangentially in the direction of the unwinding hit the chuck with the palm of the other hand, continuing to fix the tool.

Keyless drill bit removal

Key chucks have the definite advantage that the drill bit retention is very powerful, but there is a disadvantage that the wrench must be handy. If you don’t have a wrench on hand, it’s relatively easy to remedy this defect. It will be necessary to find an object that can fix the chuck from one side. It can be a nail, a Phillips screwdriver, a screw, an allen key of the right size. To the second half you need to apply force with your hands and try to unscrew. so there is an opportunity to pull out the drill without a wrench. But if you can’t do it by hand, you can use a vice or a big gas wrench of a suitable size.

The drill bit is stuck

There are situations in which the drill cannot be removed after the work is completed. Neither unscrewing the sleeves by hand if the chuck is a quick-action chuck, nor the wrench if the chuck is a key chuck, helps. You tried turning the drill on and using reverse to try to get the object, but it didn’t work. We fixed the drill firmly and tried to undo the chuck by tangential strokes, but it did not bring the desired result either. Then it’s time to turn to more massive equipment.

There are not many ways to remove the drill bit from the drill:

- Vise and gas wrench. The method involves the use of two gas wrenches or one wrench and a vise. You need to clamp one half firmly and try to move the other half with a wrench.

- Vise and hammer. One half is fixed in a vice and the other half is moved by tangential blows of a hammer from the dead point. It is possible to solve the problem with vibration and impact.

If the methods above do not work, you can unscrew the chuck together with the drill bit completely, clamp it in a vise and, by picking up a screwdriver or some metal rod of the right diameter, knock the drill bit out of the chuck.

See the following video on how to properly fasten the drill bit in the drill.

How to operate the nozzles

There are different chucks in electric screwdrivers. Let’s see how to change the bit in all types.

-

quick-action chuck. Available as single clutch and double clutch. Most commonly installed. To unclamp the jaws and remove the old bit, turn the front sleeve counterclockwise. Insert a new bit and screw the socket back on;

You have to hold the head to remove the bit

Design and features of the toothed chuck

The classic drill chuck refers to clamping devices of the collet or cam type. Not only can various tools with a round shank be clamped in them, but also cylindrical workpieces for their further processing. The main design elements of jaw chucks are:

- cylindrical shape body;

- Adjustment ring or sleeve rotating on the outer surface of the housing;

- cam mechanism or collet, installed in the inner part of the body of the device.

Design of a cam (toothed-ring) key chuck

In turn, the collet mechanism, made of hardened steel, consists of three identical jaws that move together simultaneously by rotating the adjustment ring or the sleeve, thus reliably clamping the tool shank. In the early mechanical drill chucks, the collet was moved by the rotation of the adjustment wheel, today an adjustment sleeve is used for this purpose.

Drill chucks are fitted on the shaft of the equipment in use, with one hand and the tool to be used for machining is inserted into the other hand. Jaw chucks are mainly used for clamping the following tools in them:

The cam chuck of a drill is designed to clamp tools with a cylindrical or hexagonal shank

Types of chucks on drills, screwdrivers

Hand drills and screwdrivers are often used for drilling operations. Drill bits that have a cylindrical shank are used when working with them. The tapered part of the drill bit is clamped with a collet mechanism.

The drill bit shank for screwdrivers or drills with cylindrical and prismatic shapes is held in place by the jaws of the chuck. Usually the mechanism has three cams and is therefore called a three cam.

To understand how to insert the drill bit into the drill, it is necessary to establish the type of chuck installed.

There are two most common types of chucks for drills and screwdrivers:

Key gear chuck

Key chucks allow the drill to be clamped with a suitable wrench. The wrench is a rod with a lever with a small toothed wheel mounted on the rod. A hole is made in the chuck for fixing the wrench shaft and a circular toothed bit corresponding to the profile of the wrench.

To clamp or unclamp the jaws, you must enter the pin in the slot, put the gear on the teeth of the drill bit and rotate the wrench in the appropriate direction.

Usually all wrenches are identical and fit different tools, but there are exceptions. For example, some of the more expensive brands make a kind of wrench with individual dimensions and profile.

In any case, it is very easy to lose the wrench because of its small size, and without it it will be very difficult to insert and remove the drill bit. That’s why many craftsmen tie the wrench to the handle of the tool.

Quick-action chuck

Drills and screwdrivers with quick-change chucks are handy because they let you change drill bits without using a wrench. The drill bit can be clamped and loosened in the jaws of the chuck by hand. The drill bit is simply inserted into the open jaws and then the sleeve of the chuck is rotated by hand in the appropriate direction to tighten.

There are one-coupling and two-coupling chucks.

To clamp the two socket chuck, you should hold the socket closest to the body of the tool with one hand, while you rotate the other.

With a single socket chuck, all operations are done with just one hand. Knowing these intricacies of chucks, you should understand how to insert the drill into an electric screwdriver.

How to remove and change the chuck on the drill

In electric drills, a special device called a chuck is used to reliably securely hold drills. In domestic drills, cam chucks are most commonly used. With heavy use, they can fail and need to be replaced or repaired. Problems often occur during these operations. In this article, the master plumber will tell you how to remove and change the chuck on the drill.

The chuck serves as the seat, holding the main working element of the drill, electric screwdriver, or rotary tool. It can be not only a drill, but also a concrete drill for tools with an impact function, a special attachment in the form of a cross or flat screwdriver. There are special nozzles for the drill, designed for grinding, deburring of various surfaces. They are mounted on a rounded or multi-faceted pin, which is also mounted in the chuck.

Drill chucks differ in design and method of installation on the tool and are divided into three types:

How to Replace a Spigot | Ask This Old House

Tapered chuckWas invented as early as 1864 by American engineer Stephen Morse, who also developed and proposed the use of a spiral drill. The feature of such a chuck is that the clamping of the working element is due to the mating of the two shaft surfaces and a separate part with a planting hole. The shaft surfaces and the drill fitting hole have equal taper sizes, with angles ranging from 1°25’43” to 1°30’26”.The angle is adjusted by turning the base of the mechanism, depending on the thickness of the element to be installed.Toothed-ring design

A more common type of chuck on hand-held power tools for home use. The principle of the device of such a chuck is simple. at the end of the pin coming out of the drill, a thread is cut, and the chuck is screwed on it like a nut.

The drill bit is held in the chuck by three tapered blades in the center of the chuck in the collet. When the nut on the collet is turned with a special wrench, the blades come together and clamp the shank of a drill or other work item such as a mixer whisk, screwdriver bit, impact chisel, tap.Quick-clamp chuck

It is considered the most convenient variant. This is the latest technological modification of this device. It is used in almost all modern models of well-known drill manufacturers.Working cutting or other element is also fixed by special petals, only for their clamping does not require a key. The locking paddles are clamped by hand. by turning the adjusting sleeve, which is knurled for easy scrolling.To prevent the sleeve from unscrewing during tool operation, in its base is an additional blocker.How to remove a chuckSince all types of drill chucks have their own design features, their disassembly involves different actions. Special tools will also be needed.It is possible to dismantle and improvised or interchangeable means, but the first disassembly is not recommended to experiment, as you can damage the tool.In general, the procedure is not very complicated and can be done manually at home.Tapered cartridgeThe Morse method of attaching the cartridge is one of the most reliable, yet involves no complicated manipulation. The design perfectly withstands the forces along the axis in both conventional drills and tools with an impact function. This is why it is so widespread in manufacturing plants.The chuck can be removed in several ways.It is necessary to hit with a hammer from below on the cartridge body. The main thing is that the blow should be directed along the axis in the direction of the seat of the cutting element. the drill bit.