How to change the line for a Husqvarna trimmer

How to properly change your garden trimmer line to steel cable

A trimmer with a weak motor is very often hardly able to cope with a dense lawn, which is already talking about trying to cut real weeds. This state of affairs will not please any owner and even upset with the fact that the acquired device turned out to be absolutely useless on the farm. Once in such a situation, do not be discouraged ahead of time, because you can carry out a simple modernization of the trimmer, which will significantly increase the efficiency of its work.

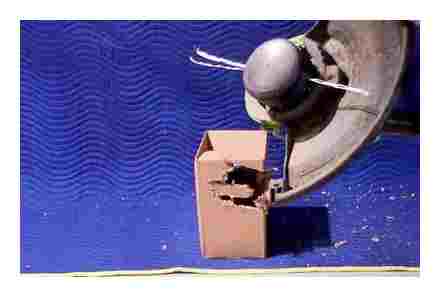

So, to carry out the modernization, you will need nothing at all, namely: a rubber bushing, a trimmer, a set of standard tools and, of course, a steel cable up to 2 mm with thick veins. Installing the cable begins with disassembling the trimmer coil. After that, you need to measure and cut the cable so that it does not hit the trimmer itself during operation. After that, the cable is unbent with pliers and bent in the middle. This is done in such a way that the result is a small loop.

A pre-prepared rubber sleeve is inserted into the resulting loop. It should have a slightly larger inner diameter than the trimmer shaft.

Note: if there is no bushing, in the most extreme case it can be replaced by wrapping the loop with electrical tape. However, it should be understood that such a system will not work for a long time with faith and truth, but soon enough it will have to be repaired, again wrapping with electrical tape. Otherwise the trimmer may become dangerous.!

Now you should tighten the bushing by winding the loose cable back. For reliability, you can fix it with a wire tie. After that, it is threaded into the base of the head, the sleeve is pushed onto the shaft. When all this is done, it remains to close the lid.

As a result: a trimmer equipped with a cable will confidently cut even dense greens, weeds and branches of bushes.

How about an even harsher upgrade, here’s a story on how to swap out line for a saw blade.

Did you like the article? Then support us, press:

What it is?

The trimmer consists of a cutting element, a bar, a motor and a handle with a control mechanism. It is designed for mowing grass in garden areas and for creating the perfect lawn. Thanks to its compactness, the device does the necessary work in places where the lawnmower cannot reach. In addition to grass, the trimmer is designed for mowing tree branches and bushes, as well as creating flower beds. Such equipment is not always used for the lawn, since the length of the grass will have different heights.

Husqvarna petrol cutter. replacing the trimmer head with a metal blade

Specifications

The main technical characteristics of the trimmer are:

- power;

- equipment weight;

- type of power supply (from the network or using a battery);

- engine location (top or bottom);

- type of cutting element;

- rod type.

All this must be taken into account, buy this or that device.

How to correctly replace the line in the mowing head, the reel of the Husqvarna 128R brushcutter

From all of the above, it follows that the manual mowing head for the trimmer is inconvenient. That is why you should choose the automatic type. However, such a trimmer head is not popular with users, since a large amount of fishing line is consumed during operation. Therefore, the optimal view is the semi-automatic.

How to choose the right one?

Before purchasing this equipment, you need to understand for what purpose it will be used. For a large area with a flat lawn, it is better to purchase a light model with low power. If you need to equip a summer cottage, then you need to choose a more powerful model.

Trimmer mowing head

It is a special assembled coil with a cord inside. Its dimensions can be varied. On the inside of the spool, a 15-meter cord should be wound. Its ends are pulled out a certain distance to do the job. When meeting with a solid object, it is destroyed. The trimmer mowing head is available in various designs. It all depends on the type of device. They differ not only in design, but also in the way they are connected. There is also a universal trimmer head that is suitable for different equipment. This became possible due to special adapters.

The trimmer head is classified according to the line feed method:

- Manual. In this case, the name speaks for itself, that is, the line is fed mechanically. To make the cord even longer, you must stop the trimmer and manually pull the ends.

- Semi-automatic. If you want to replace the cord, the trimmer head needs to touch the ground. At the same time, a special button is pressed and the anchor mechanism opens. Further, the lengthening of the cord occurs due to the centrifugal force. No matter how well the electric trimmer we purchased works in a summer cottage or a country house, sooner or later the time will come when we need to remove the trimmer head for. The main feature is that the procedure takes place when the trimmer is on.

- Automatic. To make the cord elongate, the engine speed is reduced. How to remove the head from the trimmer. Further, when increasing them, the line is fed automatically.

Cutting tool

To make the cutting process easy, you need to choose the right cutting element.

An ordinary trimmer line or knife is often used in its role. When choosing one of the species, it is worth evaluating the type of vegetation. Remove the spool 17 as with and the protective cover from it and from the bosch art 23 trimmer. In accordance with these data, select a cord, a knife of a certain shape. How to replace, remove the mowing head of the electric trimmer head or. An important element is the trimmer head. We will consider its varieties below.

Usually, the diameter, which can be used for mowing young grass, does not exceed 1.6 mm. I have on a similar trimmer how to remove the coil from the trimmer, and meanwhile the vegetable garden is overgrown. The thicker the thread, the more coarse grass it is able to overcome.

There are fishing lines with sharpened edges in the form of an asterisk or a square, this option is more adapted to mowing dry grass precisely due to the existing sharp edges, but its drawback is greater wear and is inferior in strength to a round cord.

Spiral line feed

The feeding of the line in a spiral when casting lures is one of the most common problems in the operation of spinning devices, which is solved in a fairly simple way, because the problem of incorrect operation lies in the clogging of the line guide roller. The essence of repairing a spinning reel when this problem occurs is to clean the line laying mechanism from dirt.

You will need to disassemble the line guide roller, following the recommendations presented in our article in the previous chapters, and remove visible blockages with a brush, followed by washing the parts. Having lubricated the assembly anew, it is sequentially assembled and the device is comfortably operated.

How to replace, remove the mowing head of the BlackDecker GL716 electric trimmer

How to change, remove the mowing head of the BlackDecker GL716 electric trimmer for repair or replacement.

How to disassemble the trimmer coil. Changing the line on the trimmer.

In this video I show how to disassemble the coil from a gasoline trimmer, as well as how to wind it correctly.

Uneven line winding

Uneven winding of the fishing line is characteristic of old devices with a long service life. The problem manifests itself in the form of a tapered front laying of the line during winding, or the same rear winding of the line on the spool. If a taper is formed in the front part, completely remove, remove the washer from the main shaft of the part.

An option for repairing a spinning coil when winding with a cone upwards consists in adding another washer to the shaft, which compensates for the generated production. And in either case, the problem is eliminated in full, allowing you to wind the cord in the original, convenient for casting, originally and constructively laid down by the factory style.

What types of woods are there

A common type of line that fits virtually all types of reel round cords. How to remove the coil on the pgt-800 sbm trimmer. I can not. To ring, but not the same as in the trimmer, the starter and the coil grind, on which. This is an ordinary fishing line, suitable for mowing succulent grass, but it will be much more difficult to mow dead wood with it, and even more so it will not cope with shrubs.

Coil mechanism wedges under load

If the coil mechanism wedges under load, then there is a high probability that the driven or driving gears will need to be replaced. To determine, diagnostics will be required, which consists in disassembling the case and visual inspection of the transmission mechanism with the definition of defective parts. The problem arises from the poor-quality material of the gears and toothed shafts, as well as from the solid life of the inertia gear. Symptoms of a malfunction initially appear as light tapping inside the body, subsequently turning into a limp when the handle is scrolled, and then into its jamming and jamming even at minimal loads. It should be borne in mind that to fix the problem, you will need spare parts that are suitable in terms of parameters.

There are fishing lines with improved aerodynamics with corresponding dents, scales and notches, a similar product makes less noise, but it is used only on petrol cutters, since the exit of such a thread from the reel is difficult, it is used in most cases with discs into which segments are inserted. This video is about how to change the air filter on a Husqvarna trimmer (brushcutter). The disadvantage of such a product is its fragility.

Preparing for replacement

We disassemble the trimmer spool

For clarity, the mowing head (spool) was removed from the brushcutter. To replace the fishing line, you do not need to remove it, everything is done locally. It doesn’t take long.

We disassemble the trimmer spool. it rests on the latches. Remove the cover by pressing on the latches. If you do not have enough effort to do this with your hands, then use a screwdriver.

The spool consists of the following:

- Spring case

- Cover with locking latches

- Button coil

How to Re-Spool Husqvarna weed wacker/string trimmer – FAST & EASY!

The principle of operation is as follows. By pressing the button, the spool presses on the spring and comes out of the locking grooves in the spool cap. Holding in this state, the reel can be twisted, thereby adjusting the length of the line. When the button is released, the body spring returns the coil to its original fixed state.

Which line to choose

Before you stock up on this material for refueling in the trimmer, you need to decide on the choice. After all, the usual so-called round fishing line is far from the only existing species. How to choose the most suitable one? First you need to determine the working conditions.

Selection by type. Round line is the most common. It will fit any coil with rare exceptions. This type of consumable is suitable for cutting fresh, juicy grass. But with the mowing of the so-called dead wood, such a species may no longer cope. It is pointless to mention attempts to mow bushes with this thread.

In addition to the usual type, there are others with sharp edges. Usually they are made with an asterisk or a square. The presence of sharp edges is the main feature and key difference of these threads.

It is thanks to this feature that the threads of these types are able to mow dry weeds. But sharp-cut threads are not without drawbacks, the main of which can be called rapid wear and strength, which is noticeably inferior to the round type.

In addition to the already mentioned types of woods, there are also interesting and common varieties. Especially among them can be noted fishing lines, inside which a metal wire is stretched. Threads of this type are often used in gasoline-powered tools with an engine more powerful than one and a half horsepower.

Metal-cored threads come in both round sections and sharp edges. Regardless of the type of section, such threads are the best suited for overcoming difficult-to-cut plants. Threads of this type can easily mow not only dry grass, but even small bushes.

The wires with a wire inside compare favorably with other types of consumables for their incredible wear resistance. Unfortunately, this feature has a more than noticeable impact on the price of this type. The cost of yarns with a core significantly exceeds the cost of other types.

Coil with one working tendril

The simplest option and uncomplicated sequence of actions:

- The dimensions of the reel and the length of the original factory winding determine the recommended length of the line for winding. 2. 5 m.

- One end of the line is inserted into the fixing technological hole located inside the spool.

- The fishing line is wound on the drum in the opposite direction of the spool rotation on the trimmer product. as a rule, on the inside of the reel, an arrow indicates in which direction the winding is carried out.

- A small section of the line is left free to bring it out. it is fixed in a specialized groove on the inner side of the bobbin, designed to hold the winding when assembling the bobbin into working condition.

- The left end of the line is passed through the hole in the outer part of the reel.

- The bobbin halves are assembled and put on the trimmer bar.

DIY trimmer coil repair: how to remove, disassemble, change the line, assemble and install back

Coil with two working tendrils

In this type of spool, you should determine the number of grooves for winding the line, lying on the inside of the spool:

- one groove. both antennae are wound together in one groove;

- two grooves. each antenna is wound on an individual groove.

For both cases, a line with a length of 2-3 m is taken.In single-groove reels, the line is pulled into a through hole, its ends (antennae) are folded together and aligned, after which they are wound in the opposite direction of rotation of the bobbin on the rod side. inside the arrow usually indicates the correct direction of winding. If there are fixing grooves, the ends of the fishing line are threaded through them or held with the fingers of the free hand, they are threaded into the through hole of the outer half of the bobbin, the spool is closed and attached to the trimmer bar.

The difference in line winding in double-groove spools is that initially a 2-5 m long line segment is folded in half (to determine the middle fold), and the fold loop is inserted into a special groove between the grooves. Both antennae of the fishing line are wound each along its own groove, fixing the antennae and assembling the coil is similar to the above option with one groove.

The first execution of this procedure, perhaps, will seem long and rather laborious, but with time and experience this task will be solved much faster and easier.

The video below will clearly show how to thread the line into the trimmer spool and wind it correctly. this operation is not difficult and with some patience it will certainly be crowned with success:

After the cutting thread has worn out as a result of the work, turn off the scythe and remove the cover on the mowing head. Pull the wood out of the slot by pulling it to the desired length, and reinsert it into the slots. The amount of material wound on a reel is enough for 5-10 work cycles, depending on the model of the device. When you put the cover back in place, carefully look if the grooves where the latches are inserted are not clogged, if they are clogged, then thoroughly clean them.

When the line is worn out, you need to disassemble the mowing head again, remove the spool and rewind the line on it.

The trimmer is the most common machine used for cutting grass and small bushes. This device is distinguished by its simplicity in service, simple operation during operation, and due to its low weight, even women can cope with it. It is no secret that for high-quality performance of work on mowing grass, the correct selection of cutting tools is required. As the latter, special cutting attachments (discs, knives) or trimmer heads with a fishing line inside are used in trimmers. Nozzles and fishing line are consumable tools, but if the knives can be sharpened, then when the line is used up, it must be replaced. In this article, we will tell you in as much detail as possible how to properly replace the fishing line.

Trimmer head types

The grass mowing head is a cylindrical body in which a spool (bobbin) is inserted with a fishing line (cord) tucked in it. This design can be installed on both gasoline and electric trimmers. The heads differ in the way of threading and feeding the cord and there are 3 types.

- Automatic. Cord feed is performed after the user reduces engine speed. Although the automatic line feed is convenient if a large amount of work is being done, such bobbins have one drawback. a high thread consumption.

- Semi-automatic. The use of this type of heads does not require the user to perform complex manipulations. The principle of their operation is designed in such a way that the cord lengthens automatically while the apparatus is operating at full speed. It is enough to lightly knock the trimmer head against the ground (this removes the blocking of the cord), and the line is pulled out of the bobbin due to centrifugal force, and then it is cut to the required length with a knife located on the protective cover.

- Manual. To lengthen the cord, the device must be stopped, after which the line is pulled manually.

Based on the above, semi-automatic bobbins are the best option. It should also be borne in mind that trimmer spools are single-string (used only for trimming grass) and two-string, which are used for mowing tall grass and small, thin-stemmed bushes.

Read also: Do-it-yourself cable wiring in the apartment

The cord lengthens spontaneously

There are times when the trimmer user notices a very fast line flow. However, he never hit the ground with a button to lengthen the line. The reason for the fact that the line spontaneously lengthens, being cut on a special knife on the casing of the device, may be the absence of a spring in the mowing head. Often novice users of mowers, trying to load the line into the reel, forget to install the pressure spring in the head, or completely lose it when opening the lid, and in the future, do not even know about its existence.

Also, the line can be lengthened without using a button if the spring is loose. If checking the spring has confirmed this fact, then several washers must be placed under it in order to enhance its clamping properties.

How to remove the spool and replace the line

Trimmer owners, mostly beginners, find themselves in confusion, bordering on panic, when they need to change the cutting tool or line in the reel. Very often, when trying to unscrew the mowing head, users simply render it unusable, not suspecting that it is unscrewing in the opposite direction. To prevent this from happening, if you need to replace the tool, it is recommended that you read the step-by-step instructions below.

- Stop the brushcutter engine or power off the electric trimmer before threading the line into the spool to avoid injury from accidentally starting the cutting tool.

- Unscrew the attachment attached to the gearbox shaft. To do this, the shaft must be fixed by aligning the holes on the washer and on the axle, and inserting a metal rod or screwdriver into them.

- Unscrew the nozzle. You should be aware that the thread on the shaft is left-handed. Therefore, turn the trimmer coil to the right, that is, clockwise.

- Disassemble the mowing head. Most often, the head cover is attached to the clips. To remove it, you will need to sink these latches into the case, squeezing the edges of the cover. If your trimmer has a semi-automatic mowing head with a button on the bottom, then the disassembly of the attachment should be done carefully, since you can lose the spring, which sometimes flies out when the cover is removed.

- Cut off the required amount of line. Usually its length is 5 meters. Use a cord of the same diameter as indicated in the instructions for the tool. It is not recommended to exceed the maximum line diameter as this will result in increased engine load and higher gas mileage.

- Find the midpoint of the line by folding it in half. You will have a loop.

- Special grooves are cut inside the coil (there may be holes). Insert a loop of line into this groove.

- Wind the line around the spool by turning it counterclockwise. It is necessary to fill in the cord as evenly as possible, the turns should lie down without overlap and with good tension. When the winding is finished, leave free ends of the line about 20 cm long and fix them in the grooves on the sides of the reel.

- Assemble the mowing head. Be sure to insert the spring and washer (if equipped) before final assembly of the accessory. Place the spool in the body and thread the ends of the cord through the holes or lugs.

- Put on the cover and secure it with the latches.

- Screw the adapter back onto the gearbox shaft, also securing it with a screwdriver. You will need to twist the trimmer coil to the left (counter-clockwise).

The cord lengthens spontaneously

There are times when the trimmer user notices a very fast line flow. However, he never hit the ground with a button to lengthen the line. The reason for the fact that the line spontaneously lengthens, being cut on a special knife on the casing of the device, may be the absence of a spring in the mowing head. Often novice users of mowers, trying to load the line into the reel, forget to install the pressure spring in the head, or completely lose it when opening the lid, and in the future, do not even know about its existence.

Also, the line can be lengthened without using a button if the spring is loose. If checking the spring has confirmed this fact, then several washers must be placed under it in order to enhance its clamping properties.

Line does not lengthen automatically

If the line does not lengthen when you lightly hit the trimmer button on the ground, then the reasons for this may be the following.

Option 1. a bite has occurred, i.e. clamping the cord between turns. This problem usually occurs if the user has been winding the line on the reel unevenly, with intersecting turns, or winding it with insufficient tension. In the latter case, when the mowing head rotates at high speeds under the influence of centrifugal force, the cord begins to tighten, as a result of which inter-turn clamping of the fishing line is possible. To fix the problem, you will have to disassemble the coil on the trimmer and rewind the cord correctly, that is, in even turns with good tension.

Option 2. too short ends protrude from the head. The line may not come out when hitting the ground if the ends sticking out of the head are not long enough (short). In this case, the centrifugal force is not enough to stretch the line. Therefore, it is required to stop the unit (turn off the engine or disconnect the electric trimmer from the mains) and pull the line manually, after pressing the button.

Option 3. the line is brazed inside the mowing head. This causes the coil to lock and not spin when the button is pressed. Basically, this happens for several reasons: poor quality of the cord, overheating of the coil during prolonged operation of the unit, hitting the line against hard objects.

- In the first case, third-party cord can be made of low-quality and low-melting materials that cannot withstand mechanical and thermal stress. Therefore, you should give preference to “branded” lines.

- But, if you nevertheless purchased a fishing line of unknown quality, and it is often soldered during operation, then you can follow the example of some users who, after filling the cord into the reel, wet it with either silicone grease (from a can) or mineral oil. This procedure greatly reduces the likelihood of soldering the turns of the fishing line together.

- Also, the line can be soldered if it hits a hard object (stone, fence, dry branch, etc.) during mowing. As a result, it stretches slightly and is pulled back into the head at high speed. From friction, the cord heats up, and its turns stick together. The only thing that can be done to eliminate this malfunction is to open the trimmer spool and rewind the line.

Installing Trimmer Line – Husqvarna Trimmer

Major coil malfunctions

Users of electric trimmers and petrol cutters often face a problem with a semi-automatic cutterhead. Coil malfunctions can be as follows:

- the line does not lengthen automatically;

- the cord spontaneously comes out of the reel.

Trimmer coil device

Trimmer mowing heads come in a variety of designs, both simple and complex. The figure below shows a disassembled semi-automatic trimmer head from a Husqvarna brushcutter.

This type of head is present in the complete set of most mowers and electric trimmers, such as Stihl (Calm), Patriot (Patriot), Champion (Champion), Bosch (Bosch), Huter (Hooter) and others. The device of the mowing head is quite simple. It includes the following details:

- mowing head base;

- button for semi-automatic cord feed;

- bobbin (spool) into which the line is tucked;

- spring;

- eyes. through them the line comes out;

- trimmer head cover;

- line (cord).

There are also simpler trim heads shown in the following photo.

All these attachments do not allow you to change the length of the line in a semi-automatic mode (after pressing a button). If the cord breaks, you have to stop the mower and change it manually.

DIY trimmer coil repair

The trimmer, whether petrol or electric, is the only solution for mowing grass in hard-to-reach places that a wheeled lawnmower cannot handle. As a cutting tool in trimmers, metal knives or special fishing line are used, which is tucked into the trimmer coil. But, unfortunately, trimmer heads become unusable over time during operation. Some malfunctions can be eliminated by hand, and some require a complete replacement of the mowing head.

Is it possible to make a coil for a trimmer with your own hands

- Take a piece of plywood or PCB and draw a circle about 14 cm in diameter on it.

- Cut the disc with a jigsaw or metal hacksaw.

- Drill a hole in the center of the disc that matches the diameter of the gearbox shaft. Do not forget to put a washer on it before installing the disc on the shaft.

- Small corners can be screwed on the edges of the disc or 1-2 holes can be made on opposite sides. They will serve for refueling the fishing line in them.

- Several screws can be screwed into the plywood to secure the line.

This homemade mowing head is secured to the shaft with a nut. It will not work to tighten or unscrew the nut without fixing the shaft. To replace the cord, it will be enough to loosen the screws, insert a piece of line of the required length and press it again.

Also, the mowing attachment for attaching the fishing line to it can be made of metal sheet. How to do this can be understood from the following video.