How to change the piston on a STIHL 180 chain saw

How to check the ignition coil of a chainsaw with a multimeter?

A special device, a multimeter, can help pinpoint chain saw ignition system failure. It will make it possible to determine whether there is a breakdown of the coil and other elements of the node. The procedure is as follows:

- First, you need to set the multimeter so that the arrow of the device was located at the mark of 200 ohms;

- After that, you need to open the instruction manual of the chainsaw and study the optimal resistance indicated there for the primary winding of the ignition coil. As a rule, this figure ranges from 3 to 5 ohms;

- Next, the primary ignition coil should be connected to the device. If the values of this part of the coil are normal, start checking its secondary winding;

- Again read the manual, and look at the optimal resistance value indicated for the secondary coil. It is worth noting that this part of the element has large indicators, so the multimeter should be adjusted so that its arrow is located near the 20K indicator;

- Then connect the unit to the hole on the spool where the wires are inserted. If the multimeter shows normal values, it means that the coil is completely serviceable. However, if the resistance on the device display is far from the parameters specified by the manufacturer, then the coil will have to be replaced.

It often happens that the coil produces a spark, but the values of its resistance on the primary and secondary windings are far from the parameters specified by the manufacturer. In such cases, you also need to replace the element, because after some time it will become unusable.

STIHL, shtil, MS180, STIHL, STIHL chainsaw / STIHL 180 chainsaw startup video.

As mentioned earlier, the examination of a faulty chain saw must begin with determining the presence of gasoline in the fuel tank, also with finding out the technical condition of the breather.

STIHL chain saw repair in case of fuel system malfunction.

When checking the gas level in the tank the fuel cap should be opened without fail. This should be done even if you are sure that there is gas in the tank.

How often is it impossible to start the machine because there is no fuel in the combustion chamber? The prerequisite for this in most cases is the usual clogging of the breather. a special bypass valve that serves to equalize the pressure in the tank at a gradual flow of gasoline. In that case, the gasoline chain saw repair is reduced to a gentle scouring of the breather normal sewing needle.

Replacing the piston group on the STIHL MS180 chain saw

Here the video we will show you how to, perform piston replacement

STIHL MS180 chain saw piston groups, crankshaft oil seals.

A distinctive feature of the cylinder block on the STIHL MS 100 eighty will be that it has two compression rings, although not in fact all of his main rivals have only one. As the manufacturer says, the installation of a pair of rings, allows you to better stabilize the piston during operation, to enhance its cooling and increase compression in the engine, by introducing this method startup is improved.

Choosing the right piston for your STIHL 180 chain saw

In this article we look at the piston groups from the STIHL 180 chain saw. The STIHL 180 is the most popular chainsaw in the world (like a Kalashnikov assault rifle) and therefore has a very large number of reciprocating. On the zipo76 website.There is a large selection of pistons from different factories in China. We have a long history in tool sales and repair. Only use the best parts for your tool. Warranty on parts and repairs.

Adjusting the carburetor of a chainsaw with their own hands

To adjust the carburetor yourself the owner of a chainsaw will need a Phillips-head or flathead screwdriver. as well as a handheld tachometer.

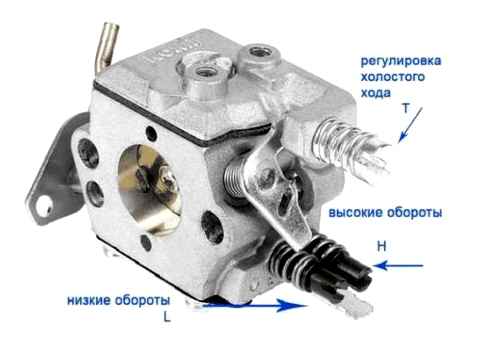

To adjust the carburetor chainsaw. its carburetor has spring-loaded adjusting screws in the basic design.

Depending on the brand of the chain saw manufacturer, the markings on its adjusting screws may vary. Nevertheless, in order to set the carburetor on the chainsaw correctly initially. You can always act according to the same algorithm:

- First the operator must find in the instruction manual of the saw the exact angles of gradual turning of the spring-loaded adjusting screws. Immediately after that, on the used saw with the motor turned off, they must be turned according to the instructions in the manual. If this is not done, the operator risks breaking the engine of the tool;

- Next, the chainsaw used in the household will need to be set firmly on a flat, stable surface. In doing so the guide bar and the chain must always point away from the operator;

- Then start the engine of the saw and let it warm up for at least 10 minutes;

- After that you need to find the correct position of the L screw. To do this, the operator should slowly turn it clockwise and counterclockwise until the engine is quiet and without slack;

- If it starts to turn, find the position of the screw T where the chain stops:

- Then connect the tachometer to the engine cylinder. Then you need to turn the H screw. As soon as the rev counter shows the same value as shown in the instruction manual, you can let go of the revolver.

Assembly of STIHL MS180

In this video we will show you how to, to carry out replacement of piston on chain saw STIHL MS180, crankshaft oil seals.

When the piston in the cylinder is locked, you can unscrew the flywheel nut. The thread in the flywheel nut is standard, so it should be turned to the left. After loosening the nut it is not necessary to remove it completely, just unscrew it until its upper edge is flush with the tip of the shaft, then a soft metal punch is placed on the nut and a sharp blow is made on it. The flywheel is thereby released from the shaft at high impact, and can easily be removed without any tools.

Which Makita jigsaw is the best to choose?

The engine is held in place by four screws on the bottom of the STIHL 180. To remove them, unscrew them, and then carefully remove the engine from the seat and the rubber nozzle carburetor.

To disassemble the engine undo the 4 crankcase screws and remove the crankcase and allow the crankshaft to be removed, complete with oil seals, bearings and piston rings.

Removal of bearings and oil seals usually does not require additional tools, but if the bearings were pressed on a shaft with force, then a special puller is needed for disassembly.

To remove the piston from the connecting rod you need to remove the snap ring from its seat with a thin screwdriver, then from the opposite side press the piston pin, and then the piston is removed to the side.

The specific disassembly of the STIHL 180, begins with the removal of the handle, which is attached to the body of the chainsaw using 3 rubber shock absorbers. To remove, it is necessary to remove the plastic plugs from the inner cavity of the shock absorbers, then using a strong screwdriver, press out first the upper shock absorber, later the one closest to the rear handle.

To block the crankshaft from turning, you must unscrew the plug and through the candle hole to install a piston stopper, if it does not exist, use an old starter cord from the starter, with the knots tied there and immersed in the cylinder through the candle hole.

Stihl MS 180c Cylinder and Piston Replacement Diagnosis and Repair

No more running

STIHL 180″ chain saw, faults and repairs which you can identify and repair with your own hands, sometimes simply will not start. This problem can occur by accident. You must first open the fuel filler cap and close it again. Ventilation of the combustion chamber should be carried out in the following step.

It is recommended to take out the plugs and dry them well. This is sometimes enough to start the machine and operate it properly. If the problem persists, there’s another reason. The breather plug affects the fuel supply. If it’s clogged, there’s a vacuum in the fuel tank and it won’t work. The breather can be repaired very easily. For that, it’s cleaned with a needle.

Disassembling a STIHL 180 chain saw

Good day to you all!For a long time I did not write anything in the blog, I was busy (work and dacha (house in the country) and also decided to dismantle the barn and build a bathhouse), but here’s the occasion. STIHL chainsaw was sawing and stalled Truth is because I forgot to fill it up, but I’m not looking for easy ways. I opened the air filter look, and there’s dirt and after cleaning saw did not start Thought that maybe the carburetor got. need to dismantle Well, thought that the tank is full I also tightened the chain and oil to the chain refueled.

I’m getting a little off-topic. Let’s take it apart. Before removing the side cover from the ignition switch, we remove the covers from the fuel tank and the oil tank.

Remove the ignition coil by removing a couple of bolts.

Next comes the removal of the air intake and carburetor

Then remove the fuel tank hose was removed during the dismantling of the carburetor.Next, you should remove the shaft (I’ll call it a shaft on and off chain saw (since I do not know the correct name)) from one side up, then pull the other end to the side.

After you should remove the muffler, also unscrewing the two nuts, I forgot to take a photo.

You can already proceed to the dismantling of handles that hold the whole structure, and this requires a screwdriver to remove the three plugs

And we begin to remove the clutch, but to do this, we need to remove the stopper (I’ll call it a drum with a chain sprocket) do not know the correct name.

In order to continue to remove the clutch need to remove the nut, and to do this, you need to lock the crankshaft.I did the following. Unscrewed the plug and in this hole shoved a string with knots pre-torque the rotor and looked into the hole removed from the muffler that the piston has stood in the bottom dead center

We’ve covered the main causes and malfunctions of the STIHL mc 180 chain saw that require the replacement of the cylinder head. But, as a rule, in each specific case, the causes may overlap, and for proper repair, a comprehensive approach to solving the problem is needed. Putting a new piston on the saw does not always solve the problem. It is absolutely necessary to eliminate the causes of the malfunction and the tool will serve for a long time without problems and the need for repair.