How to change the rotation of an angle grinder. Replace graphite brushes

How to reduce the speed of an angle grinder with your own hands?

Collector motors with series excitation are used in lathes with speed control. They can operate on DC or AC current. This type of motor is easily adjusted by changing the current in the circuit.

Because modern regulators use key-type impulse control, they cool down to an insignificant degree and can be installed even in small tools. To regulate, a potentiometer is used, the knob of which is derived from the handle of the machine.

Why control the speed of the disc?

Different cutting or grinding speeds are required by the physical properties of the materials being worked with. So, high speed with low pressure is required when cutting hard materials that might otherwise crumble or split. Soft materials that are not resistant to heat (thermoplastics, wood), on the contrary, require low speed:

- ceramics: 10000 rpm;

- metal: 8000 rpm;

- hard plastics: 5000. 8000 rpm;

- wood: 3000. 5000 rpm;

- soft plastics: less than 2000 rpm.

All professional tools are equipped with a stabilized speed regulator, but inexpensive household angle grinder, power less than 1200 watts, not always complemented by it. In this article we will talk about how to make such a regulator yourself to reduce the speed.

the angle grinder spins backwards what to do

Usually the disk rotates counterclockwise (if you look from the side of the disk), sparks fly forward, but recently, in a warehouse selling pipes, I saw that the cutter’s disk rotates in the opposite direction, sparks fly under the feet. It has to cut a lot and daily. That’s why the question arose. what’s the right way to do it? Correct for safety when sparks are flying at the worker working with angle grinder, at his feet. Why? When the angle grinder is clamped, it flies forward. No harm done. (Sparks fly, pants burn. does not count). When you turn it over, the sparks go forward. Usually when cutting, the right elbow rests on the right shin. And when clamping, the angle grinder flies over the shin. It is better not to describe the consequences, I think it is clear. At least a month in the hospital. Most professionals cut “on their pants.

How to replace the Bosch grinder carbon brush

That’s exactly right (as you saw)-when sparks fly to the cutter, and the traction of the angle grinder from the cutter, not on it. What you saw, sparks flying at the cutter, it is the right choice of setting the position of the angle grinder, and exactly the setting of the housing, handle and shroud, for the direction of rotation of the shaft does not change. You can change the handle (depending on the model of angle grinder, it can be set in three or two positions at 180 degrees and 180 degrees in increments of 90) You can turn the hood within its adjustment. But not all angle grinders allow you to “twist” the hood as you like. At some it is possible to change gearbox position.

Angle grinder (in common parlance “angle grinder”) is quite dangerous tool, although very effective in many locksmith operations.

Having experience with all popular grinders, from 115-th to 230-th (the diameter of the disk, and thus the power of the unit), I can say that the devices to 150-th disc can still be confidently kept in the case of unpredictable “kickback” then above this diameter, it is very difficult, and fraught with serious injury (!) That’s why you should not tempt fate, and regardless of the power of the unit, and the disc diameter, always direct its rotation away from yourself (if you look at his top) and sparks may fly at the feet, but it’s one hundred percent guarantee that you will hold the angle grinder in the case of bite and ejection.

Again, from personal experience, I can conclude that the arm muscles are much harder to reflexively respond to extension than to flexion (IMHO!) “Ducking” the cutter is less dangerous than rolling on it. In an extreme case, the angle grinder will simply jump out of your hands and rush away from you instead of toward you. Of course you let go of the retainer and it just falls off without hurting you.

Let the sparks fly, but always saw at yourself. That’s what you need a good suit (pants and a suit of thick fabric) From the flying sparks can burn your pants (just that. it’s not terrible) and from the angle grinder flew at you. That can happen!

I have come to this belief solely on my experience, and this experience was not without some “losses. However, it is confirmed by others

I have a small angle grinder DWT, as standard the disk is on the right, rotates counterclockwise, the sparks fly forward. But for me it is absolutely uncomfortable, because I can’t see the product or the wheel.

Turned the gearbox so the disk was visible, but the sparks fly at me. not nice. The question is whether you can somehow make the wheel rotate clockwise? Change the wires from the brushes? And another question, how safe is it. In principle, the discs are light, serious injuries will not cause, except that the eyes will be knocked out if no goggles.

Who knows, tell me: I borrowed an angle grinder (Interskol). I insert the wheel, put a gasket under the nut. I tighten the nut like it’s supposed to. I turn it on and the nut immediately begins to unscrew. Especially fast. after I turn off the angle grinder. What’s that got to do with it??

luchnik78 wrote : The nut immediately starts unscrewing. Especially fast. after I turn off the angle grinder. What does it have to do with?

Well, there’s not much to recommend it. Tighten it more or remove the gasket.

How could this happen and how to fix it?

luchnik78 wrote: angle grinder. when rotating the clamping nut unscrewed Why.

I’ve never unscrewed it!I have passed through my hands a lot of grinders, I myself work 125, when rotating the nut should unscrew judging by the thread (I work this way, I am so comfortable), and never unscrewed, you better tighten, or put a new nut!

when the angle grinder brakes, the disc, by inertia, unscrews the nut. Put the spacer under the disc, not under the nut, or remove it altogether.

Maybe it has been serviced and the brushes were accidentally switched and now it is rotating the other way

eatherly wrote : maybe it has been repaired and the brushes were accidentally switched, now it rotates the other way

then the nut would be self-tightening on stopping.

when the angle grinder is braked, the disc, by inertia, unscrews the nut. Put the gasket under the disk and not under the nut, or remove it altogether.

I put a new nut and a new gasket but the effect is the same. I think. maybe the disc really rotates in the other direction. The owner said his disc was jammed and he had to remove the head with the shaft that has the bevel gear. He would clamp it in a vice and use a gas wrench to unscrew the nut. I might have got it wrong. He told me that when you put a new disc, give it a load, and then the nut will not unscrew, but I do not like it. you can forget and hurt yourself

Gearboxes

The possibility to use the same power tool for different materials (metal, stone, wood, plastic, concrete, etc.) makes the angle grinder very popular among users. The size of the nozzles together with the gearbox ensures optimum speeds for safe and efficient operation.

Design, principle of operation and purpose of the angle grinder

The technical name of the angle grinder implies its main purpose. grinding of surfaces of machined materials. However, the versatility and versatility of angle grinders allows, with the help of interchangeable accessories, to perform such technological operations as cutting, scraping, polishing and some other.

How the gearbox is designed, in section, photos and drawings

Minimal gearbox dimensions thanks to bevel gear. Small bevel gear enters into mesh with the big one, and the direction of rotation of the motor rotor shaft is changed by 90°, which reduces the size of the angle grinder in length. Narrow in thickness drive pinion enables maximum flatness of gearbox housing, which ensures operation of angle grinder in hard-to-reach places.

Sectional view of the angle grinder gearbox. Photo source here.

Support units of the rotor and spindle shafts are made with ball bearings, needle and bushings made of antifriction materials, depending on the model of angle grinder, capable of withstanding high axial loads. The housing, in which the driven and idler gear shafts are assembled, protects the bearing assemblies reliably against dust, which is formed during the operation of the angle grinder. Example of gearbox construction shown in the figure below. How to disassemble in order to diagnose and repair can be found in a separate article.

Adjustment

The bevel gearbox of an angle grinder will work without problems with the shafts rotating freely in bearings, which have no backlash. This is achieved by fitting additional shims to the drive and idler shafts to eliminate the clearances left during assembly.

A special feature of the bevel gear is the adjustment of the gearing itself. It is necessary to ensure the alignment of the initial cones of the gears. Thermal play must also be taken into account here to prevent the gear from seizing up due to heat during operation.

This is done by placing metal spacers between the gearbox housing and the gearbox cover. Correctness of adjustment is checked by checking the contact patch.

Practically it is done by the application of the coloring substance, for example, blue paint on the teeth surface and after running in the operating mode it is visually defined the area of the tooth working surface, on which the blue paint is absent. The correct location and dimensions of the contact spot in the image below.

Easy and best way to change carbon in grinder | How to replace the brush set | Angle Grinder Carbon

Depending on the degree of accuracy of the transmission there must be:

In angle grinders, metal spacers are installed between the cover and the gear housing, the number of which corresponds to the correct initial adjustment of the gearing. As the teeth wear, some of the shims are removed to preserve the clearance and normal operation of the transmission, thus ensuring the service life of the angle grinder reducer.

Gear ratio

angle grinder (angle grinder) Makita GA9010C. 220Volt photo

In the classic sense, the gear ratio of the angle grinder reducer, as in fact, any other mechanical gearbox, is the ratio of revolutions of the drive shaft to the driven shaft revolutions. For most angle grinders, it ranges from 2.5 to 4. The gearbox is a reduction gearing, so that the speed at which the work surface does not overheat quickly, and the torque required for the work is reached.

To a greater extent, the gear ratio of angle grinder reducers depends not on the manufacturer’s model, but on the power of the grinders. Less powerful angle grinders have higher spindle speeds and correspondingly lower gear ratios. For high-powered professional grinders, high torque is important and large spindle speeds are not used for work with large-diameter attachments in order to ensure safety. Here the ratios are closer to the maximum values.

What gearboxes are there: straight, reduction, angle and others

Mechanical reducer is a mechanism that transmits torque and shaft speed required for operation of the driven device from the drive unit. Some types of reducers can change the direction of their rotation.

Gearboxes with coaxial (parallel) shafts are usually the most common with spur gear. They may have different gear ratios and number of conversion steps. Transmission is smooth, virtually lossless, but they can not change the direction of rotation of the shaft.

General safety rules

To reduce the risk of injury when working with a grinder, the tool must be used properly. The following rules for use must be observed:

- Must use personal protective equipment. The operator’s health must be in good condition.

- Before starting work, check that the hood is properly and securely fastened, so that it does not fall out in the process, and sparks do not fly to the operator.

- Use only complete discs without defects (cracks, chips, splits) and strictly for the purpose of treating the specific material.

- A protective screen must be placed between the operator and the grinding wheel, to provide protection if the wheel breaks.

- Before starting work, you must check the condition of the tool at idle for about 1 minute: rotating evenly at maximum speed, no vibration.

- Inspect all attachments before use to determine their suitability for use.

- Protect items that can be ignited by asbestos sparks or ordinary wet cloth: greasy cloth, fuel and lubricants, paper, solvents, ropes.

- Always be sure to fix the working nozzles so they don’t fly off.

- If it is possible to control the rotational speed, set the speed recommended for cutting or sanding the workpiece.

- Saw very carefully through the wood, as a fall on a branch can cause the tool to break from your hands.

- Do not install circular saw nozzles because they are designed for different spindle speeds.

- The tool must be held with both hands.

- Before beginning work, remove everything unnecessary and make sure there are no objects on the cutting plane other than the workpiece.

- Take regular breaks from work.

- If the workpiece is stuck, turn off the tool immediately.

- A stable (balanced) body position must be maintained.

- Power cord Keep away from the rotating part to avoid cutting it and causing a short circuit.

- Only when the grinding wheel has come to a complete standstill may the tool be loosened from the hands.

- When navigating on the job, the mill should be turned off, and this should also be done when the power is off.

- You only need to cut at full speed.

These safety precautions have been developed by the manufacturers of angle grinders as well as by the special organizations (services) concerned with occupational safety.

The person working with the grinder must be adequate and have a balanced psychological state.

Protective equipment in use

When working with an angle grinder, the user must use the following personal protective equipment:

- A medical mask or goggles that cover your eyes from all sides;

- Gloves made of thick fabric or leather;

- Special shoes (all, stable) and work clothes;

- A gas mask that will provide protection against small particles entering the respiratory system when cutting concrete, glass or ceramic tiles, bricks, faora, foam, stone and other dusty materials.

The use of protective equipment is mandatory when working with the grinder. This helps work safer.

The electric sander can be a Destroyer. correctly set the direction of rotation of the motor shaft

Today, for sharpening kitchen knives and scissors, you can use mini-grinders. They do a good job. But for sharpening axes, chisels and other working tools, as well as when performing a number of locksmith operations without the electric sharpener is not a thing to do.

An electric mower head is in demand in any man’s household. Buy it somehow not like a man, because this machine can make their own hands and it will be better than the factory one.

The store price of the machine starts at two thousand reais. With the money saved, you’d better buy your wife some flowers or a present.

Introductory safety briefing for master Samodelkin, who is making an emery machine

For those who do not want to spend money to buy a factory-made emery machine and decided to make it themselves, I advise to watch the movie comedy “Behind the Matches.

Besides the fun you also get a lot of valuable information on the need to obey the rules of safety.

According to the plot of the film, there were no matches in a Finnish house. And the master of the house, played by Yevgeny Leonov, set off on a long adventure filled with adventures.

My wife and another woman stayed at home. They got tired of being cold and began to look for a way out of the situation. They decided to make a fire with the help of a hand-grinding lathe. And with such speed began to twist the handle that the stone was torn from its supports and, spinning, began to rush around the house. It made a lot of destructive troubles in the economy, but it did not kill anyone well.

Hence, the homebuilder needs to remember the first 2 rules:

- The speed of the stone in the grinding machine should not be too high. It is not recommended to use a rotating motor with speed over 1,5 thousand rpm. At higher speeds, the probability of breaking the sharpening stone and the unfortunate consequences for this reason increases.

- The power of an electric motor for a homemade sharpening machine should not exceed 0.4 kW.

Home-made electric grinder. the steps of making

A single-phase motor may be taken from an old washing machine. The 12-ohm resistance winding is the working winding, and the 30-ohm resistance winding is the starting winding. Do not change the circuit. To connect a 3-phase motor to a 220 V household electrical outlet, use a circuit with a starting capacitor.

- The first thing to order at the turner or make yourself from pieces of pipe flange with a clamping nut, matching the inner diameter under the shaft of the engine.

- We organize the workplace, fasten the motor, connect it, check in which direction its shaft rotates, counterclockwise or clockwise.

- If the flange clamping nut turns clockwise, and the motor shaft turns counterclockwise, nothing needs to be changed. If the directions of rotation are the same, you need to change the wiring diagram so that the directions of rotation do not coincide.

Clockwise clamping nut, the wheel rotates counterclockwise and vice versa

The safety guards are not marked on the picture. Always take time to install them.

To avoid the “Beyond matches” situation, do not allow: 1) the shaft and flange jaw nut to be turned in the same direction. 2) they hit the stone. 3) motor shaft speeds over 1500 rpm. Home-made electric grinder

The variant shown in fig. 1 is more suitable for electric grinders with less massive stones, the variant two for big-diameter emery stones.

BAR 15 Mar 2012

Sparks on themselves:

Igor Kozlov : If you cut with sparks from yourself, ALL splinters from under the guard will fly in your direction. I saw some video clips from Bosch, where the discs were specially filed and turned on remotely in a chamber with a cloth over it for clarity. When shooting “sparks at yourself” all splinters flew forward from under the guard and only a small fraction of the splinters flew down and toward the body of the angle grinder. I found this video about eight years ago after I hit myself in the leg with a disk. I was sawing then “like everyone else” with sparks from myself.

Alexander Grebenkov : When clamping, sometimes the disk breaks off and spins in the opposite direction to the direction of the sparks. If you are not a kamikaze, the sparks should fly to you, the specials will protect you from them. clothes and shoes, and nothing will protect you from a disk flying at you. The disc, rotating at high speed, cuts clothes and shoes on its way.

Andrei Sysoev : When cutting metal, sparks should fly at you. Because when you clamp the disk angle grinder will vomit forward, in the opposite direction from you.

osminin.aleck : the sparks should fly at you. It is necessary to saw from yourself. The machine itself crawls on the metal and cuts even its own weight

Eugene Kuznetsov: To work with the reverse rotation (the spark from himself) have to move back, which is not very from the standpoint of safety. Personally saw how the drive when clamped in the metal, torn from the angle grinder and it flew forward, but not to the employee (thanks to the correct rotation forward)

Andrey Novikov: If your hands are from one place then of course the clothes burn, but I’m in an ordinary overalls (not spark-plug, like “Spring-N” from the B-C) cut up probably hundreds of kilometers of rebar, but nothing burned, although I cut, with very rare exceptions, sparks “on themselves.

READ How to Choose the Right Angle Grinder

Sergey Kalnin : Those who do not retrain to work “sparks on itself” do not take on work. You can put a new gearbox on your grinder every week, when you’re sawing away from yourself. Sparks all over the shop, by evening half of the workers at the eye. If you hold the angle grinder firmly and do not let it hit the body with the disk, the disk will break for sure and will fly into the neighbor’s head. Welders aren’t always sober, they come in with a bad head. If the angle grinder

jerk it forward or sideways, you can lean it on the workbench or the floor without letting it out of your hands. If the angle grinder jerked at the body, it often breaks out of hand, and if not break it will fly head or ass on the “stake”, the workpiece.

SERGEI YEFREMOV : A few years ago I was cutting a 63 angle, sparks from myself. I got trapped and knocked to the ground so hard that I was knocked down. Fell down. I’ve been walking around the apartment with a stick for three days. ♪ So let the sparks fly, not the tool ♪.

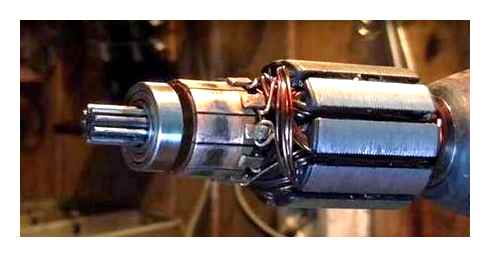

Functions performed by angle grinder components

The collector is a pad on the armature, on which all the power and control cables are led. The task of the manifold is to conduct the signals passing through the windings to the motor and the control unit. Collector when removing the cover of the housing is immediately striking by the presence of polished plates, which have large dimensions.

Electric brushes in the construction of the device serve to transfer the electric current to the collector from the power cable. During operation, if the brushes are in normal technical condition, an even glow is visible through the housing vents. If the glow is not observed when the device is turned on or has a pulsating character, it is a sign of problems with this electrical component of the device.

Operations that can be performed with the grinder

The shredder is a multifunctional tool. The driving mechanism in it is an electric motor, which through the reducer sends motion to the shaft with a removable nozzle installed on it. General view of the device shown in the photo below.

There are models on the market, differing in power and design:

Angle grinder (grinder) FT-1318

Professional large grinding machine 230 mm Stern AG230B

Powerful devices are powered from three-phase voltage of 380 V, and household devices are powered from single-phase 220 V. There are also low-power battery models.

Angle grinder (angle grinder) can be made of different materials as follows basic types of work:

The angle grinder is designed to work with such materials:

Grinding machines are widely used in both domestic and industrial applications. This is due to their wide functionality because of the following factors:

- A good choice of different attachments from different materials perform different operations;

- Can be fixed using special fasteners;

- The presence on some models of additional handles and several speed modes.

In this case keep in mind that only special blades are used for each material.

Safety or how to properly operate the mill

Before starting the work process, you must prepare the grinder: select and install the wheel. The motor power of the angle grinder requires a certain wheel size. The smaller the diameter of the wheel, the higher its speed, and vice versa, the larger the wheel, the less it can work. Incorrect use can lead to rapid wear of the tool, deformation of the nozzle and other undesirable consequences.

Deformed nozzles are not suitable for use. You must get rid of the wheels with cracks, potholes and other abnormalities from the normal shape. After successfully locking the wheel, the grinder is checked in standby mode. You need to connect the tool to the mains and run it at maximum speed for one minute. If you do not hear any unnecessary vibrations or sounds, and the protective cover does not touch the disc, the tool is ready to work.

READ How to Make Guides for an angle grinder

It is also necessary to prepare the person who will operate the grinder. The angle grinder has a protective cover that is designed to protect against sparks and debris from the disc in case it explodes. But the cover will not provide complete protection from injury. Therefore, you must carry:

There are also a few things to keep in mind:

- Do not leave jewelry (such as a bracelet or watch) on your body that can be wrapped around a circle;

- You can’t work when you’re tired or sick, toxic or intoxicated AL-KO;

- Do not use wooden saws for the grinder;

- Cannot be in the cutting plane;

- Do not let go of the tool from your hands until it stops spinning completely;

- Do not touch the equipment until it has cooled down after work;

- Flammable objects: rags, ropes, fuel, solvents, etc.Д.;

- Do not forget to keep the first aid kit nearby.

The fastening of the workpieces is an important aspect of a properly functioning grinder. Everything that is cut and machined must be firmly secured. The only exceptions are the parts that guarantee with their weight the real estate (stones, plates, etc.). Д.). The part can be clamped in a vice or used with a wrench to hold a pipe or other workpiece with an adjustable wrench, for example. A properly positioned piece should not have sagging in the area of the cutout.