How to check the ignition coil on a trimmer

Selecting by model

By passing substitution ignition coil, shows a method of how to simply make a slot at home criteria.

The insidiousness of such a failure is that the diagnosis of the following methods does not give a 100 percent confidence in the performance of the ignition coil. Such an apparent failure when the spark seems to be, but it is not quite right, is often misleading and forced to write off difficulties with the ignition coil on a faulty carburetor. The usual action in such cases is to increase the fuel supply. It turns out that such a spark can ignite an enriched mixture, but not a proper one. But the introduction of enriched consistency leads to severe wear of the cylinder-piston group and muffler. module, coil ignition of brushcutter (lawnmower) How to set the ignition on the trimmer ECHO srm 22 ges. Therefore, in such disputable situations, check again both the carburetor and the ignition coil.

How to Check the Lawnmower’s Ignition Coil

It is not uncommon to encounter situations where tool users come in with faulty ignition. It often turn out to be really defective, but often the ignition coil has nothing to do with the instrument failure. Here are the actions to check the ignition coil condition.

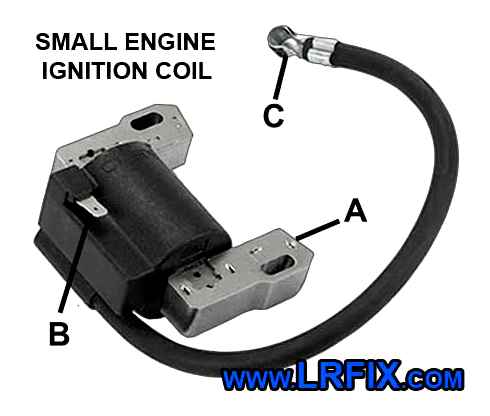

Assessment of the current state of the coil.

Before you tackle the ignition coil, it’s worth checking that the entire circuit is in good working order. Follow up:

- visually inspect for cracks and visible defects on the coil body

- contamination of current-conducting parts and assemblies

- Functionability and isolation of high-voltage wires, contacts of wires, reliability of their fastening, absence of rust in the fastening points

- check the condition of the spark plug cap: it is often torn from the high-voltage wire and tried to return it by “improvised” means. Remember: Any “snot” in this area will reduce the quality of the electronic arc of the candle

- check if the spark plug is working properly. The quality of our gasoline does not let the spark plug “live long”

- Check that the spark switch is working. Especially with Chinese saws and trimmers.

The meaning of these actions is to exclude all elements of the chain, except the coil, from the list of likely defects. If everything is OK move on.

Why you need a good spark.

The quality of the spark is determined by its ability to ignite a properly formed air-fuel mixture under working conditions. A weak spark in a high-pressure, high-temperature combustion chamber cannot do that. The ignition is delayed or does not happen at all. There is a bulge in the motor, the engine does not gain speed, there is vibration, detonation, in the starter can appear effect of “cranking”.

Checking the ignition coil of a power tiller. How to check the ignition coil.

In this video, you’ll learn how to check the ignition coil (ignition module), used on motor blocks.

How to check the ignition coil

How to correctly check the ignition coil, you need a multimeter, the manual to your equipment and a pair of hands.

The insidiousness of such a breakdown is that the diagnosis of the following methods does not give 100 percent confidence in the performance of the ignition coil. How to check the ignition coil Honda? Tumbler system how to check the coil. Such an apparent failure when the spark seems to be, but it is not quite right, often misleading and forced to write off the problem with the ignition coil on a faulty carburetor. The usual actions in such cases. is an increase in fuel supply. It turns out that such a spark can ignite an enriched mixture, but not a proper one. But using an enriched mixture leads to fast wear of the cylinder-piston group and the muffler. Therefore, in such disputed situations, check both the carburetor and the ignition coil once again.

Checking the ignition coil.

In order to rule out possible wiring and button failures, it is possible to disconnect the control wires from the ignition coil for the duration of the test.

- Measuring coil resistance. This method is not always applicable: first, it is necessary to know the parameters of the coil winding resistances. Secondly, in addition to the inductor coil, the ignition contains semiconductor elements to form the desired high-voltage pulse. So if you try to test the magneto through the high-voltage wire and the minus wire, you will either get a “Breakage in Circuit” reading or a huge resistance. If the circuit is still testing, this is most likely a sign of malfunction.

- Using a device that checks for the presence of a spark. It is installed in the gap between the spark plugs and the ignition coil high-voltage wire. The device is expensive and is used mainly in serious service centers.

- Using the spark plug. Unscrew the spark plug and put its housing on the cylinder. Pull the starter and observe the spark between its contacts. How to check the ignition coil on a trimmer yourself, video. Into the coils. This method is approximate and does not tell the whole story about the condition of the ignition coil, as the spark plug is not “under pressure” and the flywheel will spin faster because of the lack of compression in the engine (spark plug turned out)

- The “barbaric” way. It is used at your own risk in hopeless situations.

- Remove the cap from the spark plug and put a nail in it. Be careful not to damage the inside of the cap. It then put it back on the spark plug and operate. How to check the ignition coil on a trimmer yourself, there are no cracks in trimmers. It is better to bite off the head of the nail. Otherwise it might be difficult to get it out.

- place the nail 6-7 mm from the cylinder.

- start the engine, i.e. do the usual thing you do when starting an instrument. This will make the ignition system work. Note that the spark plug should be screwed into the spark plug hole.

- look at the presence and color of the spark. ideally the spark is strong and bright blue. Anything else is a sign of malfunction.

- important points:

string trimmer weed eater coil test & replace

the spark plug must not be unscrewed: lack of compression will result in faster rotation of the flywheel, which will not correspond to the real operating conditions

if there are electronic nodes in ignition system, such method can put them out of order

the distance between the nail and the cylinder simulates the compression and dielectric properties of the fuel mixture. The distance of 6-7mm is approximate and may vary on different models.

Philosophy of the method: there should be a big gap between the nail and the cylinder, the spark should be strong and bright blue

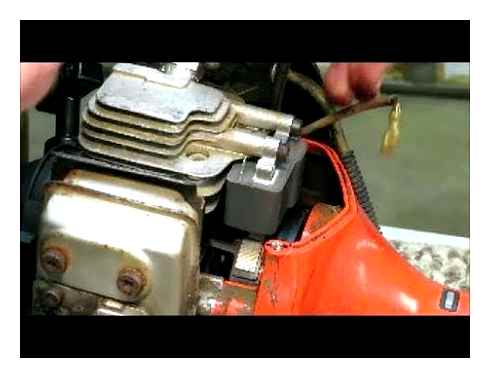

Tuning the ignition system.

Most modern chain saws and trimmers do not require you to adjust the ignition timing. This angle is determined by the position of the special groove on the flywheel for keying to the crankshaft and the magnets installed on the same flywheel.

It is only necessary to correctly set the gap between the flywheel and the ignition coil. Depending on the tool model, the gap may be different. It is usually 0.2-0.4mm. Since the flywheel is round, a regular automotive feeler gauge will not do. It would be technically correct to set the gap using a special template. But it is not always possible to buy it. Buying such an inexpensive gauge for a one time use is unwise. A strip from a plastic water bottle can be used instead of the company template. Cut the strip out of the bottle where there is no embossing. Next, the actions for setting the zazahor are about the same for both chainsaws and trimmers:

- Loosen the ignition bolts.

- Suspend the magnets on the flywheel to the ignition coil

- Press a bottle plate between the flywheel and coil and tighten the mounting bolts.

- Remove the stripe

- Rotate the flywheel 360 degrees several times, making sure that it does not cling anywhere to the coil.

All. How to check the ignition coil for performance and troubleshooting? How to test the ignition coil with a tester. The gap between the coil and the flywheel is set.

Repair of the ignition coil is impossible and impractical. Below is a list of ignition coils, which can be purchased on our site

How to Check the Ignition Coil for Proper Operation?

The minimum life of the coil, which creates the spark discharge on the electrodes of the plug, is 100 thousand. km mileage, although on most cars the element works much longer. Usually problems in the machine’s sparking system are caused by other parts of the circuit. But there are situations when it is necessary to check the health of the ignition coil, in order to identify faults by method of elimination. It is proposed to consider the principle of operation of the transformer and ways of diagnostics in the garage conditions.

Measuring the winding parameters

To measure the resistance of the primary winding with a multimeter, you need to switch it to ohmmeter mode and set the lowest limit of measurement (how to use a multimeter). After that the probes of the device should be short-circuited and, if the design of the device allows it, it is necessary to expose zero of the ohmmeter. If the construction of the device does not allow it, memorize the readings and then subtract them from the measurement results. To measure the resistance of the secondary coil on the meter, the measurement limit is set to 100 kOhm, zero is set or the reading is memorized with the probes closed.

If you measure the resistance of the primary winding of individual coils, the probes should be connected to the contacts of the low voltage connector numbered 1 and 3 (extreme). for common. to the two low voltage terminals (B and C or and.).

To measure the secondary resistance of a common single-output coil, the ohmmeter probes should be connected to the high voltage output and to terminal or B. to perform the same measurement on a common coil with two high-voltage outputs, the ohmmeter probes should be connected to both high-voltage outputs.

To measure the secondary resistance of an individual coil, connect the ohmmeter probe to the high voltage output and the center pin of the connector.

Why test the resistance. Checking the resistance of the windings allows you to detect an interwinding short circuit or wire breakage. In case of an inter-turn short circuit, the winding resistance will be slightly lower than that of a good winding. If a winding is open, the device will display infinitely high resistance.

Resistance of the windings of some models

- B 114 B (for ZIL 431410, GAZ 3102): primary. 0.38 Ohm, secondary. 19.9 kOhm;

- B116-01 (for GAZ 31029): primary. 0.65 Ohm, secondary. 18.7 kOhm;

- 3705 (for Tavria): primary. 0.38 ohms, secondary. 4.3 kOhms;

- 3705 (for Oka): primary. 0.49 Ohm, secondary. 6 kOhm;

- 3705 (made in Bulgaria for VAZ 2108): primary. 0.43 Ohm, secondary. 5.25 kOhm;

- 2108-37050-10 (made in Italy for VAZ 2108): primary. 0.65 Ohm, secondary. 18.7 kOhm;

- B 115V (for Moskvich): primary. 2.3 Ohm, secondary. 6.3 kOhm;

The above data is not an average. They were received by “Za Rulem” editorial staff when measuring winding resistance of serviceable copies of some models.

How to check the ignition coil

The ignition coil is designed to create a high voltage from a low voltage. The design of an ordinary ignition coil is similar to that of a transformer. It consists of an iron core (magnetic wire), primary winding, secondary winding and electrical connections.

Magnet wire is designed to amplify the magnetic field. A thin secondary winding is wound on this steel core. It is made of insulated copper wire with a thickness of 0.05-0.1 mm, wound up to 50,000 times.

The primary winding is made of 0.6-0.9 mm thick copper wire and wound over the secondary winding.

The primary winding resistance is 0.2-3.0 ohms, the secondary one is 5-20 kOhms. The ratio of the primary winding turns to the secondary winding (transformation ratio) is 1:100.

The technical design may vary depending on the application of the ignition coil. In the case of a conventional cylindrical coil, the electrical connections are designated as terminal 7 (primary winding lead), terminal 11 (primary/secondary winding lead), and terminal 9 (high voltage contact).

The primary winding is connected to the secondary winding at pin 11. This scheme is used to simplify coil production. The current in the primary winding, is switched on and off by a chopper (trambler) or a control unit (ECU). The amount of current is determined by the coil resistance and the voltage applied to terminal 7.

The very rapid change in current caused by the ECU (tramler) changes the magnetic field in the coil and induces a voltage pulse which is converted into a high-voltage secondary winding voltage. It goes through the ignition cable to the spark gap in the spark plug and ignites the fuel/air mixture in the engine.

The magnitude of the induced high voltage depends on the rate of change of the magnetic field, the number of windings of the secondary coil and the strength of the magnetic field.

The opening induction voltage of the primary coil ranges from 300 to 400 V. the high voltage on the secondary coil can be up to 40 kV, depending on the ignition coil.

About the chainsaw and its malfunction

A chainsaw is not such a complicated setup in and of itself. But it’s important to have some basic knowledge to find and fix any defects.

Modern electronics have evolved so much that they have revolutionized the world of tools. Today’s saws are lightweight and powerful at the same time, with electronic ignition systems.

chainsaw ignition system

Not so long ago, saw ignition systems were cam. This carried with it a host of disadvantages: heavy, complicated, expensive and more. And the most important disadvantage of the archaic ignition system is the difficulty of starting. Some saw model systems could not produce enough spark at all to flash at crankshaft speed.

Modern systems are almost failsafe. The saw models are lightweight and rugged, the coil is more professional and lasts almost without fail. However, problems do occur, but in most cases they can be corrected by your own efforts.

Let’s look at the main types of chainsaw malfunctions related to the flywheel and ignition system.

As a rule, the most common ailment of modern chainsaws, involves a lack of supply spark. This also depends directly on the gap (clearance) between the cylinder and the flywheel.

Chainsaw spark problem

Common installation failures are always related to the internal combustion engine. Problems occur in the fuel ignition system, the fuel intake module, in the internal elements of the engine itself.

As for other components of the chainsaw, malfunctions there are usually due to failures of the brake mechanism, poor lubrication, etc.д.

If the starting difficulties are related to the engine, these symptoms are most often observed:

As always, experts recommend identifying fault factors by the method of exclusion. In other words, it is necessary to go through the chain, diagnosing each node, each link.

Ignition module

Chainsaw NC failure is the most common reason why the tool’s engine won’t start. In most cases, it’s best to start troubleshooting here.

Chainsaw ignition module

- The first is to carefully check the spark plug, carefully removing the armor wire from the head and unscrewing the spark plug from its socket with a special wrench;

- The second is to check the spark plug by jerking the starter with the spark plug wire cap on;

- checking the gap. the main topic of our article (more details below).

So, a faulty spark plug will clearly be evidenced by its soggy. Wet spark device for ignition of the fuel-air mixture indicates that there is an excessive amount of fuel in the system, the carburetor is incorrectly set or there are problems in the NW.

Check the spark plug only after drying it out. Т.е., it is necessary to clean it well with a napkin, dry the internal combustion engine, plug the feeder, and then start the starter a couple of times, to get out the excess combustible mixture.

Then the spark device is put back in place and everything is checked again.

Black soot on the spark plug

In general, the spark gauge can tell you a lot about the whole ignition system. If black soot is observed on the spark plug, it indicates a disturbance in the communications of the gasoline mixture. Here either the petrol to oil ratio is wrong or the carburettor needs to be readjusted. In some cases, this also happens due to poor-quality oil.

The dirty spark plug is cleaned of black carbon deposits with a needle or other sharp object. Then the cleaning with sandpaper (null) of the electrode, until a metallic sheen appears. The sparking device is put back in place, everything is checked again.

Next step: checking the spark gauge. The spark plug skirt is brought to the cylinder and the starter fires. If there is a bluish spark at a distance of 2-3 mm, everything is normal. A spark gap of 0.5-1 mm is already considered as a malfunction. There may be no spark at all, and this is also a big problem. It may be a broken wire.

And here we come to the subject of our article. The clearance between the ignition and the flywheel magneto can be the reason for the chainsaw not starting. This very gap should be within 0.2 mm. Checking is very simple: a special gasket is placed between the flywheel and the reel. If it fits well, not too loose and tight, then the gap is normal.

The saw’s flywheel itself is round, and checking the clearance with an ordinary feeler gauge is impossible. It would be more qualified to set the clearance with a special pattern, but it is not always possible to obtain it. And not everyone can afford to buy an expensive template for a single use.

Gap between magneto and flywheel

However, instead of the foreign pattern, you can use a cut out strip from a 1-2 liter plastic container from under the juice.

Tip. It is advisable to cut the plastic strip where there are no embossed irregularities.

Why the grass trimmer won’t start: finding the causes and correcting them

Owners of dacha plots and owners of country houses cannot do without the help of various equipment. In summer and autumn, the lawn area is saved by the grass trimmer. a simple technique that allows you to quickly mow the lawn, remove weeds, get rid of small bushes. However, it also often surprises its owners: at the most critical moment the lawnmower can not gain momentum, or does not turn on at all in the work. To eliminate the problem as quickly as possible, owners need to know why the grass trimmer does not start. First it is necessary to understand what can lead to such a malfunction, accurately identify the culprit, and then eliminate the obstacle by your own efforts.

The ignition system of a modern chainsaw

Modern chainsaws are becoming easier and more efficient, they require virtually no maintenance and expensive repairs. Improved ignition coils became durable, their life compared to the old contact systems increased tenfold. The main function of this unit is to ignite the fuel inside the cylinder at the right time.

The magneto is a particular kind of alternator that generates alternating current. When working properly, it generates and delivers its energy to the candle.

The magneto device includes an inductance ignition coil. A winding is wound on a coil and a magnet is attached to the flywheel. The flywheel turns together with the engine crankshaft during operation. At a certain point, the contacts inside the system develop and a spark is produced.

To avoid overheating in the case of a sudden burst of energy, the device has a built-in capacitor.

There is also an ignition system with a non-contact magneto, regulated by a control coil. This part is completed by a thyristor and a diode that help regulate the energy process and facilitate the start of the saw regardless of the climatic conditions.

Description of how the ignition system of a modern chainsaw works. The basic elements are highlighted in red: spark plug, BB lead, coil, magnetos on the magnetometer.

For problem-free, fuel-efficient sawing, check and adjust the play between the handwheel and coil periodically. Check the ignition coil clearance recommendations according to the manufacturer’s brand.

| Brand | Recommended clearance, mm |

| Partner | 0,2 |

| STIHL | 0,2 |

| Ryobi | 0,2 |

| Zubr | 0,2 |

As we can see, one common value for the ignition coil clearance is relevant for all in-demand brands.