How to Check the Stator And Rotor Angle Grinder

The use of an angle grinder in everyday life is widespread, and due to the difficult operating conditions of frequent use, the failure of the device is a frequent case. Tool repair most often consists in diagnosing failed nodes and replacing them or carrying out restoration measures. If mechanical breakdowns and increased gear generation are easily visually detected, then to check the anchor and stator of an angle grinder, specialized knowledge, skills and technical devices are needed.

Damage to the electrical part of the angle grinder

Breakdowns in the failure of the electrical part of the angle grinder can be divided into only two categories:

- Mechanical rupture of current conductors, which can be detected in the lead wires, power buttons and contact points of the working windings. To determine the absence of breaks, the electrician “multimeter” is used in the resistance measurement mode or an ohmmeter. All electrical sections are checked separately: supply to the electric motor, connections on the contacts of the stator and rotor windings.

- Electrical breakdown of working coils, which can be detected by darkening of conductors, or can be visually hidden. In any case, the tester will have to check the anchor and stator for an angle grinder for the absence of short-circuited turns, which may not always be effective, and a specialized device will be needed for accurate diagnosis.

Checking the performance of the stator

How to check the stator angle grinder with improvised means:

- The stator can have two main failures. A break in the conductor or the occurrence of short-circuited turns. At the same time, testing by a tester in the resistance measurement mode of up to 200 Ohms is able to show only the absence of breaks with average resistance indices, which should not differ between phase windings.

- The absence of breaks in the stator windings can be determined by any low-voltage probe: a pair of wires, a battery, a light bulb. But there is no way to detect the presence of a short circuit in the circuit in this way, therefore, experienced electricians test it experimentally: voltage is applied to the phase coils, and a metal ball is placed in the center between the poles of the windings, which, under normal windings, will “search” for the point of electromagnetic balance. The rotation of the ball indicates the absence of short circuit in the coils, the offset from the center is a short circuit in the conductors on the opposite side.

Attention. This method is unsafe due to the use of high voltage and unpredictable movement of the metal ball.

- It is safe and accurate to check the stator angle grinder only with a professional tool.

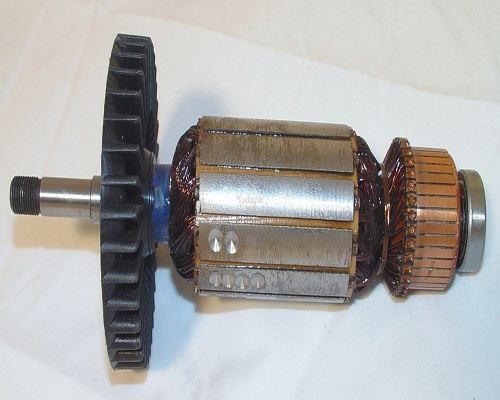

Checking the performance of the anchor angle grinder

An anchor angle grinder is stronger than the rest of the nodes subjected to various electromagnetic, mechanical and thermal influences, therefore it is precisely the rotor that most often causes the tool to fail.

How to check the anchor for an angle grinder with improvised tools:

- An anchor breakdown involves two types of faults: a break in the conductors on the lamella contacts, a short inter-turn short circuit in one or several windings. An electric tester in the resistance measurement mode up to 200 Ohm makes it possible to detect breaks and complete shorting of the winding (it will show an immensely low resistance), and in the resistance measurement mode of about 1 MΩ, the reliability of the electrical insulation of the windings of the working coils to the metal rotor case is checked.

- The absence of a pronounced short circuit in the armature windings does not completely disable the tool, but there is an increased heating of the engine, a decrease in its speed, which will eventually lead to a complete engine failure. Therefore, for any repair of the tool, it is absolutely necessary to ring the anchor of the angle grinder not only with a tester, but also check with a specialized device that detects even minor short circuits.

Repair or replacement of electrical components angle grinder

When repairing a power tool, it is necessary to clearly understand how to correctly check the anchor and stator of an angle grinder:

- The tester allows you to measure the resistance of the windings and detect breakages in the conductors, therefore, even compliance with the table readings of the measurements does not guarantee the operability of the device, but only indicates severe mechanical breakdowns.

- Checking the short-circuited turns in the coils is carried out by professional or home-made devices that measure the changes in the inductance of each working winding, because Short circuit reduces the level of EMF.

- When repairing a tool, it is often found that externally all the windings are intact, but they have short circuits. The operation of such a tool is unsafe, so the question arises of the need to rewind the stator, rotor or replace the “broken” bridle.

- Practice shows that recovery measures (rewinding) even in a repair shop does not guarantee long-term reliable operation of the device, therefore it is recommended not to risk it, but immediately install spare parts from the manufacturer.