How to clean the oil supply to the chain chain. The main malfunctions of the ignition system of chainsaws

STIHL chain lubricant system

One of the fundamental systems of the chainsaw, work without which is impossible, is the system of forced lubrication of the chain of the chain of the chain. It is not a secret for anyone that at the time of operation of the saw there is a friction of the chain on the tire of the chainsaw, which causes its heating and early wear. To soften friction, the chain mechanism must be lubricated all the time.

IMPORTANT. An experienced electrician leaked a secret to the network how to pay for electricity half as much, a legal way. Read more

Chain lubrication system

To supply oil for lubrication of the chain of the chainsaw, the tool uses a special pump, which is dosed, depending on the number of revolutions of the motor, supplies a lubricant to the saw tire.

The system uses oil for lubrication of the chain of the chainsaw, which has high adhesive characteristics, this is necessary for uniformly dispersing the oil around the entire perimeter of the tire and holding on it even with high revolutions of the chain rotation. Oil flows, the output is located in the place where the chain tension bolt is from here from. Let us see more than the oil supply system implemented in modern chainsaws.

Chain lubrication system

To supply oil for lubrication of the chain of the chainsaw, a special pump is used in the tool, which is dosed, depending on the number of engine speeds, supplies the grease onto the saw tire.

The system uses oil for lubrication of the chain of the chainsaw, which has increased adhesion properties, this is necessary for uniform distribution of oil around the entire perimeter of the tire and holding on it even with high revolutions of rotation of the chain. Let us consider in more detail the oil supply system implemented in modern chainsaws.

The device of the lubrication system

Depending on the brand of the chainsaw, the details of the lubricant can differ a little structurally, but their total number and connection scheme remains unchanged.

The main components of the details of the lubrication system are:

- Oil tank located, as a rule, in the engine crankcase.

- Filtering element, installed in the tank.

- Oil wiring, this is a small diameter hose made of oil.resistant rubber.

- The heart of the system is an oil pump.

- Worm gear gears transmitting force from engine to the pump.

- The tire of the chainsaw, it can also be considered an element of the lubricant system, as it has special openings for oil supply, by the way, the chain itself is involved in the transportation of the oil and, accordingly, also has some elements designed specifically to ensure lubrication.

Field advice

It is not enough to know how to solve problems with a flying or torn chain, because there is always the opportunity to prevent this. Proper care for the saw will help extend the life of the device and its parts. Therefore, it is recommended to observe the advice of specialists:

- Regularly clean the air filter and lubricate it with oil. Periodically, the filter needs to be changed.

- Each time before starting work, you need to check the reliability of the twist of all nuts and bolts. Then there will be no failures during operation in the device.

- You need to lubricate both bearings and asterisk.

- Regularly clean the candles from fuckers.

- Lubricate, tighten and pull the chain in time.

High.quality chainsaws, provided that the proper care and timely repair can last longer.

When moving the saw chain of the chainsaw in the tire pier, a large amount of heat is released due to friction. If the oil does not enter the chain of the chainsaw, it is necessary to stop the work and take all measures to eliminate the malfunction of the lubricant system. The combination of large loads and overheating of the headset is accompanied by its accelerated wear and early failure.

- All the chainsaws and their electric counterparts are equipped with systems of the same type, through which the lubrication of the tire, saw chain and details of its drive is implemented.

- The standard composition of this device includes a reservoir from which the chain oil is supplied to the input of the pump with fixed or adjustable performance.

- Further, the working fluid in a dosed amount enters the duct of the tire, in which the saw chain with the tails of the saw chain is evenly distributed throughout the headset and the working surface of the crown of the leading star.

Read also: Wolfram what is this material

Tires of productive sets of 400 mm long are equipped with a driven star. Periodic lubrication of the bearing is carried out individually, after 6-8 hours of production.

The device of the lubrication system

Depending on the brand of the chainsaw, the details of the lubricant can differ a little structurally, but their total number and connection scheme remains unchanged.

The main components of the details of the lubrication system are:

-

Oil tank located, as a rule, in the engine crankcase.

Advantages of high.class oil pumps

The maintainability of collapsed pumps is sufficient to restore the performance of the unit at home.

Gear drives of budget chainsaw pumps for the most part polymer. Advanced in terms of technical equipment, company models with adjustable performance are equipped with drive mechanisms made of non.ferrous metals. The cost of such systems is compensated by economical, up to 50% of the flow of working fluid.

The peculiarity of independent search and elimination of malfunctions

A full.fledged independent repair of the lubrication of the chain chain under all equal conditions requires knowledge of the interaction of all elements of the system, the presence of tools and locksmith skills.

The restoration of the working parameters of many chainsaws provides for partial or complete dismantling of component equipment. To carry out complex repair work, it is better to use the capabilities and technical potential of service workshops.

Parts with torn threads and damaged with slotted compounds, as well as non.graceful constructions that are equipped with a lubrication system for popular chainsaws of STIHL 180 and other models of the same type are subject to replacement.

If, with the tank of the tank, the oil does not enter the design of the headset, the reason should be sought in the pump itself. Dismantling and disassembling the mechanism will help identify faulty parts and eliminate the malfunction for their replacement.

In modern chainsaws, a reliable supply of lubrication for the chain is organized, with violations in the operation of which, it is not worth exploiting a chainsaw in order to avoid further breakdowns. It is better to eliminate the lubrication system malfunctions by contacting a service center or to an experience that has experience in the repair of a specialist, this guarantees the quality of the final result.

Why does the oil do not enter the chain of the chainsaw?

If the oil does not enter the chain of the chainsaw in the process, you need to find the cause of the problem. In fact, there can be many reasons affecting this process. You should disassemble the chainsaw and identify the main problem. The likely prerequisites of this process will be described below.

A prerequisite for the lack of oil supply to the chain during the operation of the chainsaw can be several reasons and to detect them, you need to disassemble the chainsaw.

Possible reasons for the non.allowance of fuel

Oil on the chain may not enter only if there are 2 breakdowns. They include:

The main reason for the breakdown is the air leak. This can happen due to the depressurization of the oil hose during the use of the chainsaw. In this case, it is necessary to remove the hose from the hole. You need to do this in the place where it is connected to the card. Then the hose sits on the sealant and is installed in the usual position. If this did not help, most likely elasticity was lost. For further operation of the chainsaws, it is advisable to replace the hose.

The second reason is the breakdown of the oil pump drive. In the common people, this part is called the worm. When the drive is out of order, the oil will cease to be supplied to the chain. The oil pump drive is a round plastic ring, inside which grooves are located. The constant use of the chainsaw leads to the wear of the internal parts, as a result of which the metallic hook located inside the drive occurs. After this breakdown, the oil ceases to enter the chain.

You can eliminate problems yourself or under the guidance of specialists.

Oil supply adjustment to the Partner chain chain

How to repair oil supply to the chainsaw

In the process of prolonged work of the chain saw, some of its elements and components can become unsuitable. One of the most vulnerable components is an oil pump. In this regard, many owners of saws have the question of how to repair a supply of oil on a chainsaw.

The task of the oil pump. apply grease to the chain. This is necessary for its smooth movement along the guide. When the oil pump is destroyed, the lubrication of the chain worsens, and therefore the effectiveness of the chainsaw is reduced. In some cases, this leads to a rupture of the chain. To prevent negative aspects, it is necessary to repair oil supply in a timely manner. How to do it?

The principle of operation and the device of the pump

Oil pumps can be made of metal and plastic. They are also divided into two types that differ in their design:

The pump is activated by the drive of the leading star. When the chain moves, the oil is supplied to a special channel located on the guide. At idle (when the leading star does not rotate) the pump does not provide a lubricant supply. This is done to save.

The speed and volume of the lubrication of the lubricant into the circuit directly depend on the number of revolutions of the asterisk. Some models of the chainsaws include a manual adjustment system with a special screw located on the device case. On expensive models, the oil supply is automatically regulated during operation.

The main problems with the supply of oil

During the operation of a chain saw, two types of problems are possible when applying lubrication to the chain:

Partner chainsaw does not open the oil on the chain.

In this video, we will examine in detail the power pump Partner chainsaw, find out why Partner is not a chainsaw.

How to adjust the oil supply to the chainsaw

Someone can use my first channel:.

- Insufficient oil consumption, which can be caused for various reasons. If measures are not taken on time, the quality of work will noticeably deteriorate, and the scheme itself can become completely useless.

- Excessive amount of oil. In this case, after long work under the saw, you can collect puddles from fat. This not only affects oil consumption, which will need to be constantly poured, but also negatively affects the environment.

Both of these problems must be eliminated as soon as possible after their detection. This will extend the service life of the saw and reduce the consumption of lubricant fluid.

Correction of problems

If the oil enters the chain in excess amounts, not only during the saw, but also at idle, it is necessary to perform manual setting (if the pump design provides this possibility). This is done using a screw, which is located on the case near the guide, usually from below or from the side. Tightening the screw, the oil supply is reduced, and the weakening. vice versa. If adjustment does not help, it is necessary to check the performance of the pump, as well as inspect the tire. Perhaps, at the place of its connection with the body, a gap is formed through which the oil flows past the circuit.

The lack of oil can be caused by several reasons, for each of which there is a solution:

- A malfunction of the oil pump. As a rule, it consists of unsuitable masonry. To replace it, you must carefully disassemble the pump so as not to damage its moving parts. Then a new gasket is installed, after which the pump is mounted and installed in place.

- Damage to the oil wire hose. If the pumping of the pump is in order, or its replacement has not led to the result, check the tightness of the hose. If it is faulty, it must be replaced. Otherwise, it will not be superfluous to clean it and fix it with a sealant.

If the reason is not related to the failure of the pump, it is necessary to check all the conductive holes and channels for blocking and, if necessary, clean them of extraneous objects. It can be done by a stream of compressed air.

Do not want to contact a chainsaw, but you need to adjust the flow of oil? Seek for help to our specialists who will diagnose and repair the chain saw, and if necessary. adjust and adjust the lubrication level. Your saw will be the same new!

General concept of the lubrication system of the chain of the chain

To understand how important the choice of chain oil for the chainsaw is, we will consider the principle of operation of the lubricant itself on the example of the STIHL 180. This model is chosen as one of the most common modifications of the chainsaw from Stihl.

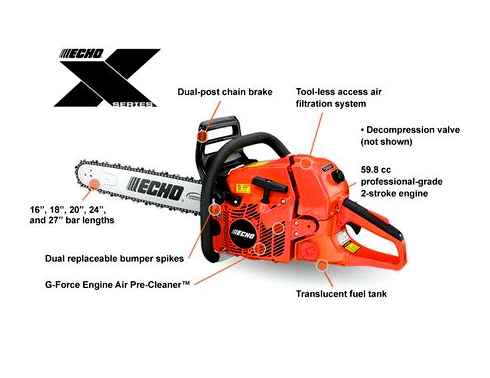

The STIHL chain of the chain of the chain 180 consists of several main parts:

- expansion tank;

- tubes of the supply of lubricants from the tank to the pump;

- oil pump;

- channels for supplying lubrication to the tire (on some saws, the intensity of oil rolling into the tire can be adjusted);

- channels inside the tire for the distribution of lubricant over the entire working surface of the saw headset.

The intensity of the lubricant supply for the chain of the chain of the Stihl 180 chainships in the general case is not manually regulated. You can adjust the oil supply to the chain of the chainsaw in some other models (for example, at Husqvarna saws).

And in this saw there is a simple rule: the higher the engine speed, the more intensively the pump rotor rotates and in a larger amount the lubricant fluid comes to the saw.

subtle settings without the use of the methods that are not provided for by the instructions for the operation of the methods are absent.

Oil is poured into a special tank with each refueling fuel. The designers worked out this chainsaw in such a way that after the production of fuel in the expansion tank, oil should still remain in a small amount. That is, with proper operation, the likelihood is excluded that the chainsaws will work on dry.

The lubricant system works as follows. The crankshaft through kinematic connection drives the rotary oil pump of the simplest structure.

The oil pump creates discharge and sucks grease from the tank. Then he drives it under pressure into the tire system system. Oil enters the driven teeth of the chain and spreads throughout the headset. The chain, the working surface of the tire and its front needle bearing are lubricated.

Field advice

It is not enough to know how to solve problems with a flying or torn chain, because there is always the opportunity to prevent this. Proper care for the saw will help extend the life of the device and its parts. Therefore, it is recommended to observe the advice of specialists:

- Regularly clean the air filter and lubricate it with oil. Periodically, the filter needs to be changed.

- Each time before starting work, you need to check the reliability of the twist of all nuts and bolts. Then there will be no failures during operation in the device.

- You need to lubricate both bearings and asterisk.

- Regularly clean the candles from fuckers.

- Lubricate, tighten and pull the chain in time.

High.quality chainsaws, provided that the proper care and timely repair can last longer.

When moving the saw chain of the chainsaw in the tire pier, a large amount of heat is released due to friction. If the oil does not enter the chain of the chainsaw, it is necessary to stop the work and take all measures to eliminate the malfunction of the lubricant system. The combination of large loads and overheating of the headset is accompanied by its accelerated wear and early failure.

- All the chainsaws and their electric counterparts are equipped with systems of the same type, through which the lubrication of the tire, saw chain and details of its drive is implemented.

- The standard composition of this device includes a reservoir from which the chain oil is supplied to the input of the pump with fixed or adjustable performance.

- Further, the working fluid in a dosed amount enters the duct of the tire, in which the saw chain with the tails of the saw chain is evenly distributed throughout the headset and the working surface of the crown of the leading star.

Tires of productive sets of 400 mm long are equipped with a driven star. Periodic lubrication of the bearing is carried out individually, after 6-8 hours of production.

Signs of malfunction of the lubricant system

The correct selection of consumables and impeccable operation of the system contributes to full lubrication, efficient cooling of sawing equipment and the full development of its resource.

External signs that the chain on the chainsaw is not lubricated. First of all, this is:

- constant level of oil in the tank;

- increasing the load on the engine;

- accelerated wear of cutting edges of saw links;

- characteristic smell of overheated wood.

How to Lubricate the Chain on the EGO Power Chain Saw

In the simplest version, the cause of oil starvation may be clogging with sawdust of oil wire channels. This drawback is characteristic of budget sets that do not have convenient access to problem areas.

Principle of operation

The main node of the system is the pump. The principle of its work is as follows. With an increase in engine speed, the gear installed on the main shaft, through the worm gear, the pump shaft drives in motion. In turn, the rotation of the shaft creates a certain pressure in the oil line, which makes the oil move along it towards the tire.

The end of the oil channel is located at the place of contact of the tire with the tool card, where there is a longitudinal groove on which its oil channel gets when installing the tire.

The groove is necessary to ensure the supply of oil to the tire, regardless of the degree of tension of the chain of the chainships. Simply put, no matter what position the tire is at the time of operation, the oil will fall through the groove through the groove.

Then a chain is included in the lubricant process, on the links of which, depending on the model of the circuit, there is either a groove or a hole through which the oil is accelerated over the entire bus. With an increase in engine speed, the oil supply speed also increases.

Some models of the chainsaws are equipped with pumps, which additionally have the adjustment of the bandwidth, and if necessary, the amount of oil supplied by the lubrication system can be increased or reduced.

This function is satisfied with convenient, t. to. allows you to save and not spend excess oil.

Lubricant malfunctions and how they are eliminated

The main malfunctions of the oil supply system on the chainsaw can be divided into two main types, these are general malfunctions inherent in all chainsaws and individual, which may vary depending on the type of pump and worm transmission installed on a specific model. Let’s start understanding the faults in order.

The work of the chainsaw, if the lubrication of the chain of the chainsaw is not carried out, is prohibited. This adversely affects the tire, the leading star and the chain, and can also result in serious repair costs.

Ryobi chainsaw oiler not working

Signs of malfunction of the lubricant system, checking its performance

- The chain of the chainsaws is dry and has a pale tint without shine.

- The circuit is relatively quickly stretched.

- The tire is very hot and can even partially melt paint.

- The tank oil is practically not reduced.

- The effectiveness of the cut on a sharp chain has decreased

All these signs indicate that the lubricant proceeds with violations. In order to check the supply of oil with a lubricant system, it is necessary to remove the side tire of the chainsaw and start it. Next, you need to slightly increase the speed observing the end of the oil line. If the oil comes, most likely its amount is not enough for normal lubrication and you need to clean or replace the filter and, if possible, adjust the feed. In the case when it does not act, the problem is more serious and requires further diagnosis.

There is a method of checking the oil supply without removing the tire. To do this, it is necessary to direct the end of the tire to the side, for example, a freshly sawn chock from the cut side and maximize the speed, while you need to try to keep the end of the tire at a distance of not more than 10 cm from the chock. If oil spots begin to appear on its surface, then the oil is supplied.

Search for a malfunction

After it was determined that the oil is not supplied, further diagnosis is possible only if you completely remove the oil system. Of course, in some situations the filter replacement helps, but it is very rare.

Access to the oil pump of some models drank, it is possible only after complete disassembly, respectively, having no skills in repairing a benzo tool, it is better to entrust the repair to professionals.

The most common malfunctions

- Oil hose cliff. It can sometimes be found during visual inspection. The problem is solved by the replacement of a faulty part.

- Lack of thread on the shaft of an oil pump, its replacement will help.

- Defective thread on the lead gear of the pump is similarly solved by the installation of a new part.

- The absence of a main shaft rogue (relevant for some tools of tools, for example, Homelite). You can fix it instead of a native corkscrew, suitable for the diameter of the carnation, cutting it to the required length.

- Zoror in the highway. Can be removed by purging with compressed air or mechanically, using a wire of a suitable diameter.

- Blocking the filter element.

- The STIHL MS 180 tool, whose pump is unlimited, it often clogs. You can try to rinse in pure gasoline if it does not help replace.

- In Chinese chainsaws (gypsies), very often cuts the grooves on the main gear through which the effort from the star is transmitted to it.

Individual malfunction of the STIHL MS 180 lubricant system

Due to the fact that the Stihl MS 180 is one of the most common models of chainsaws, I would like to dwell on one malfunction inherent only to it and describe the method of elimination without replacing details.

Quite often on the Stihl MS 180 chainsaw, depressurization of the oil line is observed in the place where the oil pipeline coming from the tank is installed in the saw case. You can determine the malfunction by characteristic lubricant leaks on the bottom of the tool.

To eliminate the malfunction, it is necessary to remove the chainsaw handle, remove the hose from the landing hole, clean and degrease. After all these manipulations, apply a sealant to the hose and install a chainsaw in the housing.

You can find out more about eliminating the malfunction and complete diagnosis of the STIHL chainsaw system by watching a video in which the process of disassembling and repair of the lubrication system is stepped step by step.

Adjustment of oil supply to the chain of the chain of the stihl chain

Certainly who the owner of the chainsaw knows what no small and high.quality oil is of no small importance. And, everyone dreams, it is not necessary to say what is really, that this is a typical “vitality” of this device for the production of real and effective work

Today there are an unlimited number of oils and, as the proverb, the choice is very sophisticated.

But, often, not every owner of electrical engineering of such a kind knows what oil needs to grate for his own steel friend, so that the work of the chainsaw is not only easy, and productive. Therefore, below will be considered a question regarding the correct choice of the manufacturer of STIHL. Also, what it is to help the chainsaw at one time of its specific activity, and not harm. What will be needed, let’s get.

Let’s talk about the installation of oil supply directly to the chain

Mainly the hunt to put Accent on the fact that what remains to do our client of the chainsaw of the manufacturer of STIHL own quite small sizes, but, nevertheless, they are very massive. These features attract future buyers of such technology to models of this company. In addition, you can easily and simply create various manipulations with this device regarding work with wood breed (see. how to cut down a tree).

Adjustment of the oil supply of the chainsaw STIHL 180.

Stihl chainsaws also have a high level of cutting ability. over, this technique is equipped with the latest accessories (see.Nazadka for the chainsaw angular grinding) is additional due to which they contribute to convenience and ease of work. But actually let’s talk directly about the device itself, which the manufacturer has equipped with his chainsaws. So, the system of direct chain lubrication of the Stihl chainsaw consists of:

It is worth noting that the direct oil feed through the operation of the pump has a special adjustment. An important fact is that the chain is lubricated throughout the work of the chainsaw. It is for this reason that this part serves its owner for a rather long time.

Undoubtedly, in the process of work, the chain should be systematically lubricated, so the oil for its direct lubrication should come to its surface continuously. Since this is the whole direct design of the tool.

During the operation of the device from the groove groove, the oil begins to exit directly and is immediately absorbed by sawdust.

That is why the process of lubrication of the chain area is carried out automatically. But it is worth noting that there are models that have the so.called “dosage” of oil, which should be supplied directly to the chain. And naturally models, the price category of which is quite low, are located only by a manual pump directly through the impact of the drive, which is located on the handle.

Choose the right oil

After you purchased the device, you immediately got a question: what kind of oil to fill in the stihl chainsaw? If you care for correctly for equipment intended for work in the construction and garden sphere, then you can largely increase the level of activity of the direct operation of the device itself not to face breakdowns of various nature.

It is worth noting that the most important factors of the direct performance of the device are to use the correct lubricant and fuel. Although the main problems of the owners of this technique take place with the choice of oil for their “favorites”. In this paragraph, you can find out how to select a lubricant specifically for Stihl chainsaws.

Chain lubrication

In other cases, it is quite possible to replace the oil lubrication of the chain with any other except for the development. However, there is another nuance Often, users have a question.“Why is the oil consumption for lubricating the chain more than the fuel mixture? After all, their consumption is interconnected?»Here it is worth considering that the manufacturers of chainsaws consider the oil consumption for lubrication of the chain, filling their branded. And the consumption of any other can differ both in the smaller and in the larger way.

On many chainsaws, starting from semi.professional, there is the possibility of setting up oil consumption for lubrication of the chain. This is done by adjusting the performance of the oil pump.

If such adjustment is not provided, then the settings are originally from the manufacturer. How to check whether the oil consumption for lubrication of the chain on your chainsaw? It is necessary to start the saw, give gas and bring to the board, log or other surface that is horizontally. From the working chain, particles of oil for lubrication of the chain should fly and leave a thin, even oil trace.

When to use a special oil for lubrication of the chain

The use of special oils for lubrication of the chain will be justified in the following cases:

- You have a new chainsaw at warranty and to save it, you must use the oils recommended by the manufacturer of the chainsaw. Otherwise, if it fails, for example, the oil pump will not be carried out under the warranty. This is especially true for expensive professional chainsaws.

- You respect the environment and prefer not to pollute it once again. In this case, oils with the prefix “bio” are suitable.

- When working at critical temperatures.

Consider several types of oils from different manufacturers and sort them by the price category, environmental friendliness and volume of containers.

Brands of oil lubrication chains

- Oil for lubrication of the chain nanothek standard. Suitable for working at temperatures up to. 20 degrees.

- Adhesive oil nanothek premium. For work at.30 degrees.

- Oil for lubrication of the chain from the well.known manufacturer of machines and equipment. Enkor. Capacity 1 liter.

- And the last in this category oil from Champion. Capacity 1 liter.

Brandenous oils intended for use on the recommendations of the manufacturer.

- Makita oil

- Makita Biotop oil.

- Adhesive oil husqvarna bio.

- Lubric oil for the OREGON 1 liter circuit.

- STIHL BIO Plus oil.

- Oil STIHL 1 liter

Oils packaged in containers large volumes allow you to save when buying. Relevant for enterprises having a large amount of work.

Often the most optimal choice for oil lubrication and tire will be the simplest oil of the M-8 or M-10 brand. Its characteristics quite satisfy the necessary goals.

At low temperatures, it is necessary to pour oil with a low temperature of thickening, otherwise it is possible to fail the pump for oil supply.

Your assistant should be the operating instruction. If you have lost it, you can contact the dealer of the company, which you use, will provide you with electronic instructions.

So, before each inclusion of a gasoline chain saw, be sure to make sure that the chain is working, whether its teeth are sharpened, whether it is stretched well (not sagging, but not too tightly stretched, it can be slightly pulled away from the canvas).

You can sharpen the chain using a special machine or file with a special template (depending on which step to the tooth of the chain, there are different templates).

Each time after use, the chainsaw must be cleaned: a chain, a tire, an air filter, a case, cooler ribs, cracks and other grooves are cleaned of sawdust. After using the saw, we turn the tire so that it wear out evenly, lubricate the star (if there are grooves for lubrication in the front of the saw).

With prolonged storage, be sure to drain fuel and oil! The chain and tire form an electrochemical pair, because they rust together, they need to be stored separately.