How to convert a milling cutter on a tiller

how to assemble a milling cutter for a tiller with your own hands

Cutters. How to assemble correctly? Tiller Hopper 900MQ

Seductive blowing. DPS SHOCKED!

LARGE, MEDIUM or SMALL BITE CHALLENGE !

Tiller cutters

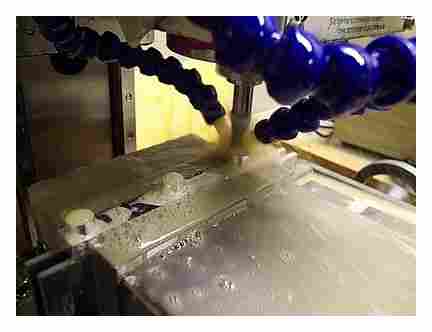

Equipment such as a milling cutter is essential for any tiller, as it can be used to carry out most of the work related to soil cultivation. Basically, the rotary tiller comes with the unit, but in cases where you need to change the width and depth of processing, you should purchase the equipment separately.

Additional cutters allow you to increase the functionality of the tiller and simplify the work with it. Experts recommend having several pairs of cutters in your arsenal.

Milling cutter assembly for FM 643, FM 653

HOW IT IS CORRECT TO ASSEMBLE THE LEFT MILL ON Tiller CENTAVR MB 2013B-3

assembly milling cutter # assembly left milling cutter # milling cutter THIS IS NOT ADVERTISING SHARE YOUR EXPERIENCE.

Things from Aliexpress that make you crazy / Crazy Things from Aliexpress Contest

What is a cutter and how to assemble it?

Before figuring out how to assemble a cutter, it must be said that this is one of the most important parts in a tiller. This attachment must always be fully operational. An important point. when assembling, remember that the sharpened part of the blades should cut into the ground.

To assemble the cutter on the tiller, you need to know that it is attached to the axis of the output shaft. To fix it, the summer resident will need a stopper. And since it can be very difficult to carry out all the actions on your own, it would also be good to stock up on tragus beforehand (their ideal size is 50 cm).

Milling cutter

At this stage, we will talk exactly about how to assemble the cutter. Since their designs are completely different, the assembly method will be different. However, the principle will still remain.

The blades of the cutter must be inserted into special slots and fastened with bolts. This is where it is important to place the correct cutting edge of the petal. it should stand in the direction of travel and stick its sharp end into the ground. Some manufacturers on the blades themselves give a hint how to screw them (R. on the right side, L. on the left).

The additional section is attached to the main one with a pin.

The limiting disc is connected to the rest of the structure with a bolt.

How to assemble cutters on a tiller

tiller

For convenience, the tiller should be leaned against a hard surface (tilt angle is approximately 45). Tragus is placed under the handle for stability of the structure. Now you need to remove the wheel. Only now can you start assembling the cutter itself and installing it on the tiller.

Assembling the tiller cutter

Tiller cutters are the main attachment, therefore, it is important that they are always ready for work. In this material on the correct assembly of the cutter for the tiller and their installation, we will see the video and the diagram. This scheme is suitable for most tillers such as Neva. Bison, Salute, etc.

Milling cutter assembly diagram for tiller

The diagram itself explains everything, but it is important to remember that the cutting part of the cutters must be installed in the direction of travel.

Assembly and installation video:

Watch the video

This article will be useful to those summer residents who want to try to assemble a milling cutter for a tiller. over, this can be done without the involvement of outside help.

How to assemble cutters for tiller and cultivator?

All videos by this user: Man’s Building.

Views: 799

Instructions on how to assemble cutters on a tiller and cultivator

This channel will be useful to those who are engaged in construction professionally or are just starting out, those who have a summer cottage and everyone who does not sit idle!

Surely in your free time you like to relax in nature? And even with a fishing rod!

How to remake a tiller

Many owners want to improve the tiller to increase comfort during work. The most common modifications are adapters and trailers. This upgrade allows you to expand the functionality of the tiller, because the adapter allows you not only to transport various goods, but also to use the tiller as a vehicle.

Improving the tiller will allow you to create a whole mini-tractor. Adapters and trailers can have their own steering, which is much more convenient than using a tiller steering wheel. There are many step-by-step photo tutorials and videos showing how to create a trailer. One of the most important elements of such a device is the frame, which is made of a channel or pipes. Wheels can be taken from any car, ideally wheels from an ATV. Bridges can be taken from VAZ 21-09, they must be shortened. The steering column can be taken from the same vehicle. The driver’s seat will allow you to work with maximum comfort.

In addition, a mini-excavator can be made from a tiller, for the creation of which a hydraulic system is required. Such an excavator is very convenient for construction on a personal plot, because it is compact and can drive where heavy equipment cannot.

How to improve a tiller with your own hands: revision and modernization

Often, alteration of a tiller is carried out in cases where the operational characteristics of the unit, functionality and ease of operation cease to satisfy the owner of the equipment. In some cases, individual craftsmen carry out tuning of the tiller to realize their visual fantasies or to impress others. Today, almost every private house and summer cottage has a tiller or a motor-cultivator. However, the capabilities of this technique are limited. To expand the functionality of tillers, you can contact a specialized workshop, but the cost of such a conversion can be very high. There are several ways to do it yourself inexpensive and practical tiller upgrade.

Increase in speed and cross-country ability

These questions are relevant for those who have to work on hard and wet ground, on ups and downs. Even the most advanced models can slip, forcing the operator to put extra effort in pushing the machine forward. Many are not satisfied with the speed of the unit when towing equipment or transporting various goods.

There are several ways to solve these problems:

How to Convert a Manual Mill to CNC

-

Increase the diameter of the wheels. Most of the tillers are equipped with wheels with a diameter of 25-30 cm. If you put wheels 45-50 cm from an old small car, then the speed of the unit will double. But, you should not make a racing car out of a tiller, since this device does not have high strength and good stability. You can accelerate to 25-30 km / h only on a flat road without sharp turns.

There are many opportunities for a radical transformation of even a small domestically produced tiller. This technique can be transformed into any agricultural implement and off-road vehicle.

Do-it-yourself Tiller Cascade modernization

Most of the upgrades of tillers are aimed at improving important characteristics, for example, performance, cross-country ability, expanding functionality. Upgrading the tiller Cascade will help improve certain characteristics or correct shortcomings.

Engine replacement may become necessary to improve performance. Lifan engines have proven themselves for their quality and long service life, and in addition, they are excellent for the Cascade tiller. It is important to take into account that if a motor of an imported manufacturer is purchased, the rotation of the shaft may differ (clockwise), while domestic tillers are adapted to engines in which the shaft rotates counterclockwise. The problem is easily solved. just move the tiller pulley to the other side.

Larger wheels can be fitted to improve flotation and stability. Pneumatic wheels show themselves well. Also, instead of wheels, you can install lugs, which are easy to purchase from the manufacturer or create with your own hands.

External tuning of the unit

Structurally, light, medium and heavy tillers practically do not differ. They consist of a power plant, chassis and controls. The operator resembles an ancient plowman, holding the machine handles with both hands. However, it is not protected from sunlight, rain, snow and heat from the engine. There is no need to spend additional funds to create additional comfort. Everything you need is at hand. External retrofitting of the tiller involves the installation of a removable or permanent awning, an additional protective casing or a hood above the power plant.

To work you will need:

- roulette;

- building level;

- Angle Grinder;

- welding machine;

- electric drill;

- set of wrenches;

- steel or aluminum corner 30 x 30 mm;

- paint brush;

- acrylic paint;

- tarpaulin or cellular polycarbonate;

- flexible plastic.

External revision of the tiller is carried out in the following sequence:

- Drawing up drawings. It is necessary to accurately calculate all dimensions of the frame, provide options for its attachment to the frame and handles.

- Marking, sawing out blanks for awning, casing, fenders and hood.

- Welding the frame from the corner. Drilling mounting holes, cleaning metal from rust, oil and dirt. Painting of the manufactured structure.

- Fitting the frame to the frame. Basting and making holes in it. Fastening the frame with bolts and nuts, checking the reliability of all connections.

- Installation of plastic covers and awnings on frames.

There is an option for mounting the instrument panel on the handle. So the unit will look solid and representative. The operator additionally gets the opportunity to monitor the state of the power plant, know the speed of the machine and the distance traveled. When reworking the tiller from the outside, it is necessary to pay attention to the fact that air freely penetrates to the motor, cooling it qualitatively.

Power plant tuning

Its power and equipment performance depend on the stability of the engine. It is very expensive and unpromising to upgrade a regular motor. But, there are several ways to make the engine work more efficiently.

This requires:

- Install a quality spark plug. Regularly clean it from carbon deposits, periodically check the gap. At the first sign of a decrease in power, replace the plug.

- Use the best strips on all joints. This allows you to maintain the desired pressure in the unit, prevents a decrease in power and the formation of smoke during operation.

- Fill the engine with the best oil up to the upper mark. It should be remembered that when the unit is tilted, oil outflows from rubbing parts.

- Check the quality of fuel before filling the tank. It is advisable to let it settle for a while so that the water sinks to the bottom of the container. The tank itself must be cleaned and wiped dry every 2-3 days.

- Install an additional radiator. To do this, steel plates are welded to the engine housing, which will effectively remove excess heat.

A radical solution is to replace the power plant with a more powerful and perfect one. Today, Japanese, Chinese and European engines are available for high performance and reliability. It is possible that the frame will have to be redone for a new power plant.

Manufacturing of additional devices

Tillers go on sale assembled and with a minimum set. To carry out the entire volume of agricultural work, the plow and cutter are clearly not enough. A factory kit for reworking a tiller can cost more than the unit itself. You can make various attachments and attachments from scrap materials using the tools that are in every pantry of a country house and summer cottage.

It is worth considering some options for making additional equipment with your own hands:

- Redesigned rake for collecting cut grass, debris, twigs and fallen leaves. If you do this work manually, then it will take a lot of time and effort. Trailed equipment will allow you to clean large areas in a few minutes. For work, you will need a wide strip of sheet iron and several meters of reinforcement with a cross section of 8-12 mm. The reinforcement should be cut into 10 cm long pieces and welded to the plate in several rows and at intervals of 3-4 cm. Long rods are welded to the plate to attach to the tiller frame. The trailed rake can be equipped with rollers for improved maneuverability and smooth running.

- Blade for cleaning snow. Most units work much more efficiently in the cold, as they do not overheat. Snow removal can be mechanized in winter. The moldboard is made of two pieces of channel welded together. This makes it possible to obtain a cutting height of up to 40 cm. The blade width is selected according to the power and weight of the unit in the range of 40-80 cm. The blade is rigidly bolted to the front of the machine. Initially, it can be mobile or stationary.

With a creative approach, you can make a hiller, harrows and a potato digger that are not inferior in quality to factory counterparts.

We make a wood splitter

Among other things, a log splitter can be made from a tiller. To do this, you need to carve a cone on a special machine, as well as a thread. After that, the already finished cone must be mounted on a shaft that has suitable bearings. Then, on the end of the shaft, you need to install a flange, as well as an asterisk. It can be taken from a motorcycle wheel.

The cone can be fixed to the shaft with a bolt. After that, a spacer made of pipes, as well as a pair of nuts, must be installed between the motor and the shaft itself. This will help tighten the chain. In order to make supports for the shaft, you can take supports from the Zhiguli. The motor must be taken from the tiller. With this redesigned structure, you can easily cope with the splitting of firewood.

Excavator

As a result of the alteration, such a technique will turn out to be quite compact and convenient. However, to cope with this work, you first need to make drawings. All work with drawings must be done in great detail. this will greatly facilitate further work. After that, you can deal with the design itself. First you need to make a frame, you can use a channel. After that, you need to attach the beam (up to 11 meters) to the frame. Springs and springs are not needed. For a simpler option, you can use a homemade axle on which the wheels are mounted. The result is a chassis. Further, using a special machine, it is necessary to grind out all the mechanisms that are needed for movement, as well as brackets and mounts for hydraulic cylinders.

When all the parts are purchased, you can start assembling. Then it is necessary to connect the power take-off shaft of the tiller, as well as the oil pump through the cardan. After that, you need to connect all hydraulics with high pressure hoses. Further. the finished structure must be painted, as well as all the details must be lubricated, after which it must be tried in work.

Motorized towing vehicle

Sometimes, when buying a factory motorized towing vehicle, you have to face many disadvantages. Therefore, most often they are made by hand. They are strong enough if you use a tiller for this. This design will do its job perfectly, and will also save fuel. In addition, it will be possible to attach compartments to such a structure in order to fold the necessary tools.

What materials may be needed?

To remake a tiller, you need simple tools as well as blueprints. Only when everything you need is at hand, you can start work on the alteration.

Tools you need:

- a set of keys, as well as drills;

- electric drill;

- welding machine;

- Angle Grinder;

- different elements for fasteners;

- screwdriwer set.

How to properly design a mini tractor?

Breaking a tiller into a mini-tractor is carried out in several stages. First you need to tackle the frame. It is made of durable metal, which is cut into pieces of the required length, and then welded together. When the frame is ready, you can start assembling the undercarriage.

If the motor is placed in the front, then the width for the wheels can be left the same as in the chiller. In order to attach the wheels to the back, you need an additional axle. It is made of the required length, an ordinary piece of pipe is suitable for this, the main thing is that the width fits. Bushings and bearings must be installed at the ends of the pipe. Then you can install wheels on them.

If the motor is decided to be located at the back, then the width of the wheels must be increased, otherwise the minitractor will not have the necessary balancing. So, you need to remove its wheels from the tiller, after which you need to make the bridge a little wider.

To operate the mini tractor, you can take the handles from the tiller. However, this will make the converted tractor look like a motorcycle, and it will be a little awkward to drive. For convenience, it is better to install a regular steering column.

The driver’s seat can be made from a sled frame that needs to be welded. In addition, one must not forget to put the headlights, as well as the dimensions. After the complete assembly of the minitractor, it is imperative to lubricate all the parts, as well as run it in.

From all this it follows that almost every person, even a little familiar with the technique, can convert a tiller into a mini tractor.

How can you make an ATV and a tricycle?

If we talk about an ATV, then it is important to know that this is a fairly powerful four-wheeled motorcycle. It has a high speed, and you can drive such a unit anywhere. One of the most important parts in it is the motor. That is why ATVs and tricycles, converted from tilers, have shown themselves perfectly. For this, you can use any model, however, motors from the “Neva” are best suited.

In order to make such devices with your own hands, you do not need to redo the tiller especially. The only thing you need to get or do yourself is the drawings. After that, you can proceed to the alteration itself.

The work can be divided into several stages:

- first you need to expand the wheels;

- further. you need to install more powerful wheels;

- after that, you should deal with the frame.

After that, you can start altering the frame. For an ATV or tricycle, you can take a frame from a bike or motorcycle. If it is not there, then any cuttings from water pipes may do. You can attach such a frame with two pins, using a pivot hinge for this.

Then you can start installing the wheels. First, you need to determine which disks you can use. Discs taken from a car will work best. It is necessary to take rubber with a low profile so that it fits more tightly to the discs themselves.

By altering the tiller in this way, as a result, you can get a wonderful device that can move on any road, and the costs will be quite small.

Motobur

Many fishermen no longer want to go fishing with a conventional drill, so some of them decide to convert the tiller, which is not needed in winter, into an ice ax. You will not need to apply special efforts for this. You just need to rearrange the wheels of the “Zhiguli”, as well as make a nozzle to set the drill in motion. Then you can safely go fishing. In the summer, the tiller will be used again for its intended purpose.

Tips for making a karakat

To assemble a homemade karakat, first you need to decide which technique you can take the frame from. A frame taken from a Ural motorcycle is perfect. Next, you need to make a suspension, as well as a rear-wheel drive. Then you need to use a corner to connect the steering column, side members and a special bracket.

After that, you can start attaching the wheels. You can take rubber from cars such as “Ural” or “KamAZ”. The last is the motor from the tiller, as well as all additional systems. it is necessary to connect the brakes and clutch, as well as to take care of the gas emission system.

After assembly, it is imperative to test the made karakat. With the help of such a homemade all-terrain vehicle, you can easily drive even to swampy places.