How to correctly put a disc on the angle grinder

How to change a disc on an angle grinder

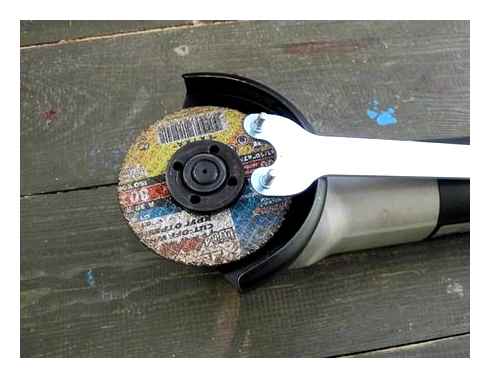

Since the wheels for the angle grinder are consumables, then sooner or later you have to change them. They are attached to the spindle of the angle grinder with a clamping flange (nut) with a thread of M14. To unscrew it, in the package to the angle grinder must go a special horn wrench that has pins on one side.

So, to replace the tool on the angle grinder, follow these steps.

- De-energize unit by pulling out the mains plug.

- Lock the angle grinder spindle with the button on the front of the housing. When the button is pressed, the stopper enters the hole in the disk installed in the gearbox, and fixes the spindle in a fixed position.

- Insert the wrench pins in the holes on the clamping flange.

- Hold the latch with one hand and with the other hand turn the wrench to the left (counterclockwise) until the nut is loosened. Then it can be unscrewed without a wrench and removed from the shaft. In this case the spindle of the angle grinder rotates clockwise. But in what direction to unscrew a nut if at your device rotation of a shaft occurs counter-clockwise? Remember: always unscrew the clamping flange in the opposite direction to the shaft rotation.

- The tool can now be changed by removing the old tool beforehand. If you notice that dirt has accumulated inside the hood, you should remove the bottom flange and use a steel brush to remove dirt from all surfaces.

After performing the above steps, the tool change is considered complete.

Why do some craftsmen put discs on an angle grinder with the picture inside?

Receive one article in your inbox every day that you can read. Join us on and

What do those who put the disc with the picture out say?

Proponents of installing a cutting disc angle grinder picture outward in most cases argue their choice by the fact that only with this method of fixation is visible marking blade: its thickness, as well as the purpose (metal or stone). The second important argument is the presence of metal rings. So many consumables have them only on one side, namely on the side where the picture is. In the opinion of some masters, this already points out that the disk should be put with the picture on the outside.

What do those who put the disk with the image inside say?

Proponents of this method of installation cutting disc angle grinder like to point out that the metal ring on the work surface should adjoin tightly to the metal base of the angle grinder. Allegedly this method significantly improves the grip of the elements and protects the disk from spinning when jammed. Experts with this opinion also point to the fact that even if the disk tears, then extract its remnants will still not be a problem. And therefore, it is worth it to secure the disc more securely.

And what is the right way to do it??

It all depends on the disc. In some cases there is no difference at all. Although, if the angle grinder is used by several people at the same time, the installation of the picture outside may be preferable to increase the safety of the work process, so that a person immediately have the opportunity to see the purpose of the tool.

There are also special grinding discs. In most cases they are mounted with the picture inside, because they cannot be mounted in any other way. In addition, if one specialist works with the angle grinder, then he can safely give preference to the second method of fixing the disk, as this will, to some extent, make the tool safer.

If you want to know even more interesting things, it is worth reading about 5 mistakes in working with the angle grinder. which can end badly.

Measures to avoid jamming

If you take care of safe operation of the angle grinder in advance, you save yourself the trouble of having to take corrective measures. Such measures include:

- Laying cardboard or plastic washers between the disc, flange and spindle head. They don’t allow the tool to jam, but even in the event of a corkscrew, they can be removed/melted down and the item can be easily unscrewed.

- The abrasive wheel must be set correctly. To do this, place the face of the disk on the supporting flange (with the picture facing the gearbox). It must not be in contact with the jam nut. In this case, the washer that prevents jamming is the standard metal ring in the center.

- On the clamping flange to weld an ordinary nut, which allows you to clamp the installed disk with an ordinary wrench.

- Control the tightening torque. Do not use excessive force to install the cutting element. Otherwise it will jam under heavy loads.

What must be used to mount the disc

The operation is quite simple and will not take more than a few minutes, if you choose the right guide. But to carry out this type of work, you must follow the basic rules, and use a special tool.

- A special wrench with which you can unscrew the nut, which presses it to the angle grinder. It comes with the equipment, and in case of loss the key can be bought in a construction store.

- The abrasive itself to replace the old one.

- In some cases a chisel or similar hard object may need to be used. This tool is needed in case the cutting disk was jammed during work. In such a situation, there is nothing left but to crack it to make a replacement. Abrasive residue can get into the gap, so you need to remove them so that the new disc does not interfere with the splinters. In most cases you will not need to use these tools, but it is advisable to have them close at hand.

Having decided on the tools that will be needed for replacement, you can proceed directly to the installation:

- There is a metal ring on top of the abrasive to hold it in place. The ring has two holes and the key has two pins that match the dimensions.

- The key should be put on top, in the holes of the ring, and turn counterclockwise. If the disk has not been changed for a long time, the ring may stick (not move from the operator’s efforts). In this case, the wrench must be extended with any pipe and try again to unscrew the ring.

- Having removed the old abrasive, it is necessary to put a new one in a socket. Put a metal ring on top and screw it clockwise with a wrench. It is advisable to press the key again to check that the abrasive has taken hold.

Important! Do not exert too much force when tightening, otherwise there is a risk of damaging the disc wheel.

How to put a disk on an angle grinder: how to install and remove it? How to unscrew the disk, if it is jammed? Which side should it be installed?

Cutting-off wheels do not have a programmed direction of rotation. That is why it does not matter which way they will be installed. But as already mentioned above, the installation of the disk face outward, facilitates the process of changing it (on the abrasive side to unscrew the nut is much harder). In addition, this installation provides several other advantages.

Ensuring smooth installation on the shaft

The metal ring increases the support area. So when the saw blade is mounted on the shaft and begins to be tightened with the nut, the pressure is evenly distributed. This guarantees a straight fit of the cutting disc and reduces the chance of damage due to misalignment.

Comfortable insertion of the blade

Installing the abrasive wheel face outward provides another advantage. you can always visually see exactly which attachment (metal or stone) is installed at the moment on the angle grinder. They are not interchangeable and a mistake can have serious consequences. For example, when trying to use a cutting disk on metal to cut through the concrete, it is possible to destroy it and injure the master by the resulting pieces. Therefore, the installation of an abrasive wheel with the label facing outward will provide not only convenience but also safety of work.

Prescription instructions

In the instructions of many angle grinders, e.g. the Metabo WP 850, it is clearly stated that “the metal flange of the wheels for abrasive cutting should be against the supporting flange”. Manufacturers make these recommendations for a good reason, as they ensure safe handling of the tool, and reduce the risk of serious injury to the machine operator.

Advantages of mounting the blade with the ring on the angle grinder

There is no exact direction to follow when mounting a wheel on the grinder. But, as already described above, if you put the cutter “face” outward, the removal process will be easier because the abrasive side is harder to catch on the surface.

There are a few other advantages that are helpful to know about.

Guaranteed smooth installation on the shaft

The metal ring mounted on the disc increases the support area, and therefore the pressure when tightening becomes uniform. This way the disc will be as evenly seated on the desired surface as possible. The possibility of misalignment is eliminated. This directly affects not only the smoothness of the cut, but also the safety of the user. the abrasive will not fly to pieces if the angle grinder does not cling.

Ease of installation

Another advantage of installing the disk face outward. the user will always be able to see which attachment is installed on the angle grinder. To work with stone or metal you need to use different discs, and if you make a mistake, you can get serious injuries due to the breakage of the cutting part.

For example, if you use a disc for metal cutting in concrete, the abrasive simply can not withstand the load and break into pieces in different directions. Therefore, the installation option under consideration is not only convenient, but also safe.

Instructions

On some models of grinders, for example Metabo, it is specified that the metal flange of the abrasive should be adjacent to the supported flange of the angle grinder. It is not for nothing that manufacturers recommend mounting the disc in this way, because they expect safety when working with the tool.

Important! Incorrect installation is life-threatening.

How to mount the disc correctly on an angle grinder?

The disc of the “angle grinder” (angle grinder) is one of its main working parts. It is the disc that determines the use of the tool. With it, this machine can be used to cut, grind or polish various materials. Discs, depending on their purpose, differ from each other: from abrasive grit. for metal, steel cutters and circular saws. for woodworking, with diamond coating. for stone and tile, all kinds of brushes, brushes and emery wheels. for polishing different surfaces.

The disc of “angle grinder” is a consumable material, you can not save on it in the process of work. The disk gradually rubs off (burns out) and it is necessary to change it. When planning the work, it is necessary to be prepared for this and it is better to stock up in advance on several replaceable discs.

Which side is suitable for installation

In order to determine which side to mount the disk, you need to consider several basic factors.

- Pay attention to the label. If the angle grinder works from itself, namely, turns away from the operator, in this case it is necessary to install the disc with the label inside. If it rotates in the opposite direction, the label must also be set outwards.

- Can be mounted without paying attention to the label. But then you can expect the most unpredictable results, such as the usual failure of the disk and angle grinder. At the same time, experts say that such negligence can lead to the fact that the angle grinder simply jams, and in this case it is not necessary to talk about safety.

To determine which way the angle grinder should twist, you need to refer to the safety information here. Concrete in particular must be cut against itself.

In this case, the sparks will fly from the side, namely from the controlling. In general, cutting materials in the direction away from yourself is not safe, because in the case of jamming, the angle grinder with a disc will fly exactly to the one who drives it. This is something to keep in mind.

Picture up or down: how to correctly place the disk on the angle grinder

Receive one of the most read articles in your inbox once a day. Join us on and

If you look into the operating manual of the angle grinder, then there the handyman will not be able to find any clear answer to the question of what exactly side you need to put the disk on the angle grinder. picture up or down. Given how many discussions cause this fact, one might wonder why such an important thing was not spelled out in the main technical document for the users of the tool?

The answer is actually quite trivial. The manuals do not write anything about how the disc of the angle grinder should be set, because it makes no difference. If the design of the disc allows it to be mounted in both ways, then you can do it any way you like. The disk mounting option does not have a significant effect on safety or performance. For the same reason, there is no information about “correct” angle grinder disc installation in either GOST or TU, or in foreign EN.

Manufacturers of discs for angle grinder claim that the structure of the abrasive wheel is uniform and equal in performance and composition. And different companies give different advice about how they think it is best to put the discs. This advice varies depending on what logic guides the craftsman. Most often it is advised to put the disc so that the worker can always and easily see what exactly the angle grinder is “armed” right now. At the same time, the companies add that there are no strict norms and recommendations on the proper installation of the disc.

How to change the disc on an angle grinder?

Put the picture outward manufacturers recommend even for the reason that the paint pattern allows for additional protection of the tool from the clamping nut, thus acting as a protective gasket. However, it does not affect the working qualities of the tool in any way.

And here is an interesting video from our channel:

In continuation of the topic read about 5 things you should understand about the cordless angle grinder (what they will not tell in the store).