How to count the links on a chainsaw chain

Chainsaw chain marking

This is the defining feature and depending on the pitch all existing chains are subdivided into five groups 1/4″, 0,325″, 3/8″, 0,404″ and 3/4″ pitch chains.1/4″ (6.35 mm) pitch are small chains used on small, low-powered, one-handled saws.

0.325” (8.25 mm) and 3/8” (9.3 mm) pitch chains are the most common. than 80 % of chainsaws manufactured in the world are fitted with such chains.

0.404” (10.26 mm) and 3/4” (19.05 mm) pitches feature chains with larger links and higher performance. For several decades, they were installed on Russian-made saws, but now they are installed only on powerful felling saws and harvester equipment.

The longer the chain pitch, the larger the chain links and the higher the cutting performance, but the wider the kerf. power is needed to overcome increasing cutting resistance. Smaller pitch chains have other advantages: more teeth per unit length, smoother progression through the kerf and therefore less vibration, and a cleaner cut.

Drive link thickness. During use the chain slides in the guide bar groove and this sliding must be smooth, without catching or excessive “chatter. Shank thickness and groove thickness should be strictly matched to each other, what increases reliability of chain fit and excludes possibility of chain “slipping. All available in five standard sizes:

- 1.1 mm (0.043”) for low power saws

- 1,3 mm (0,050”) for household and semi-professional chains,

- 1.5 mm (0.058”) heavy-duty and high-powered saws,

- 1.6 mm (0.063″) and 2.0 mm (0.080″) professional saws.

The intended use imposes its own requirements on the chains used. For example, when you need to saw hard and dirty wood or in demolition and construction, it is better to use special Picco Duro or Rapid Duro carbide chains with carbide teeth or pads that give them unbeatable strength and durability of use. Some jobs just can’t be done without them.

It is also known that for longitudinal sawing of wood (along the fibers) it is desirable to use special chains. The main difference between longitudinal and crosscutting chains is the cutting angles. For cross-cutting chains they are 25-35 degrees. Longitudinal chains (e.g. STIHL Picco Micro X chains) have sharper angles of 5 to 15 degrees.

The use of chains that do not correspond to their intended use results either in low productivity or increased “aggressiveness”, strong vibration and additional load on the chainsaw engine.

Additional chain features are profile height and cutting depth.

Chains are available in high and low profile depending on the height of the cutting edge above the plane of the guide bar. High profile chains are usually used for professional purposes to get maximum cutting performance. Low profile chains are installed on domestic and amateur class chainsaws, t.к. they are safer because of the increased support area of the cutting links and the reduced thickness of the cuttings.

Depth of cut is the amount of clearance between the top face of the tooth and the kerf to control chip thickness. Most common are 0.025″ (or 0.635 mm) and 0.030″ (or 0.762 mm) clearance patterns and those with up to 0.07″ (or 1.778 mm) clearance, the latter designed for machine felling units.

Length. overall size

New chain size depends on the length of the bar. Tires generally last up to twice as long as chains, but only if they are made from quality materials. to get the right length of chain you need for your tool, you need to measure the size of the guide bar. Usually the length is indicated on the side of the bar, but over time, all markings wear off. You can find out the length of the guide bar by referring to the machine’s data sheet or by measuring it with a ruler.

Measuring the bar length. how to measure correctly

If it is decided to replace the guide bar together with the chain to a larger size, it can be done in exceptional cases, when the power of the chainsaw corresponds. If you install a larger guide bar on your power saw, it will not be able to do the job. The recommended lengths for mounting the guide bar are indicated in the tool’s passport.

Chain lubrication system

Chain and guide bar lubrication quality is of decisive importance for chainsaw reliability and efficiency. In order to keep the chain and bar in good working order the manufacturers equip the machine with a lubrication pump to feed oil to the cutting system through the openings in the chain. the chain itself is responsible for even oil distribution. its shanks, passing through the sprocket, catch the lubricant that spreads over it and the saw bar as a result of the movement of the clothing. Often, to increase lubrication efficiency, special channels are made in the drive links with a cutter or drill, and additional recesses in the connecting links.

The chain saw’s lubrication system works to reduce the damaging effects of friction and, of course, heat. This greatly extends the service life of both the chainrings and the tool as a whole. This is why the lubrication process must be monitored by the operator. If there is no oil film on the sawing line when the chain accelerates, it means that the saw overheats, and the chain itself can get blunt or even break quickly enough.

In order to increase the lubricating effect, world producers produce organic saw oils. They are slightly more expensive, but provide one-quarter less consumption and, when released into the environment, self-degrade within a few hours.

Professionals’ tips for the use and maintenance of saw chains

Experienced experts have formulated several factors that prevent saw chains from fully developing their design life and leading to increased wear:

- insufficient lubrication causes increased friction and overheating of the parts;

- Worn drive pinion;

- Too much chain tension;

- Use of low-quality lubricants not recommended by the manufacturer.

It is recommended to have several interchangeable chains for each saw. This allows you to keep cutting without interrupting the sharpening of blunt tools in the shop. It also makes it possible to choose the most suitable chain for different cutting conditions.

Chainsaw chain pitch. Table

Depending on the pitch, chains are now available in several subtypes:

| № | Rivet spacing | Chain pitch (width in inches) |

| 1 | 6.35 mm | 1/4 |

| 2 | 8,25 mm | 0,325 |

| 3 | 9.3 mm | 3/8 (0,375) |

| 4 | 10.26 mm | 0,404 |

| 5 | 19,05 mm | 3/4 |

As you can see in the table, the chain pitch is given as a normal number (3/4) and a decimal number “0,375”. Such a division was caused by the similarity of decimal values. “0.325” and “0.375”, because the difference of one digit created confusion when selecting the saw. That’s why it was decided at one time to establish two different designations: decimal and regular fractions.

The pitch is stamped in the area of the special sawing depth limiter on each tooth.

Advantages of chains with a large tooth pitch include:

Please note, however, that a wide kerf requires a more powerful motor, which in turn increases the resistance considerably.

The advantages of fine pitch chains are:

advantageous due to the large number of teeth and the small spacing between them.

All known classification of chains is based on peculiarities of their marking depending on pitch, which is designed for specific needs and produced for a specific power of electric equipment. For a better understanding of each pitch type, they should be considered separately.

Main parameters of chains

Chain marking implies the following parameters:

- Pitch:

- “0.325”. the most common and minimum pitch size, which is used in semi-professional and domestic chainsaws with low power. The standard power value for this pitch ranges from “0.325” to “3l.с.”but no more than “3,5 hp.с”. When working with this type of chain the cut is smoother, more comfortable and without “tearing” of the workpiece.

- “0,375” (“3/8”). applied to chainsaws with a power of “4l.с”. This type of chain is used when cutting medium- and small-thickness wood.

The accuracy and quality of the cut depends on the pitch. if it is not important to have a high quality of cut with a chainsaw, accuracy of cut is sometimes very important. For this purpose it is absolutely necessary to take into account the pitch dependence on the wood to be cut in accordance with the markings made in advance.

- Drive link thickness (tails). When a chainsaw works, its chain carries most of the load. With this in mind, another key characteristic of a chainsaw is the thickness of the link elements that fit into the grooves of the bar. This value also indicates the total thickness of the fastening links, which is measured using a normal caliper. The standard thickness values include:

- “1.1 mm” (“0,043”) and “1,3 mm” (“0.05”). used in entry level chain production that is intended for low workloads. Often with these link thicknesses, the pitch length of the chain can be “0.325”, which implies low loads and sparing working conditions. Therefore, they are used in domestic and semi-professional machines;

- “1.5 mm” (“0.058”) is the most common thickness value on the chainsaw and its accessories market. this value is able to provide safe working conditions at a pitch of “3/8”. Chains with a thickness of 1.5mm are not designed for professional level sawing;

- “1.6 mm” (0.063) and “2.0 mm” (0,08). designed for the most demanding tasks. Production of such chains is done with steel of special grades, and increased strength characteristics are incorporated into construction.

the thicker the link and wider the bar groove, the higher the quality of the chainsaw, because it can handle higher loads.

- Depth of cut is a distinctive feature of manufactured chains and is characterized by the profile height of the cutting teeth. Measured by the space between the stops and the top cutting edge. Both high profile (0,762mm) and low profile (0,635mm) types of chains are available on the market.

The higher the profile height, the higher the material entry (depth) and the cutting speed

High-profile chains are fitted to chainsaws with higher engine power. Profile height information is usually written in the manual of the machine.

Profile influences the vibrations that can cause wear on the tool drive or problems holding the tool in your hand. In doing so, the higher the cutting parts, the greater will be the degree of vibration.

Household chainsaws are equipped with a low profile. semi-professional machines can have a combination of chain types. However, in most cases, the principle is adhered to:

Chains with a high pitch have a low profile and chainsaws with “0,325” pitch have a high profile

Such variations increase the cutting speed not by the pitch, but by changing the depth or height of the profile. Although in the professional tools Accent makes to increase the pitch, explaining it by the fact that the chainsaw becomes more manageable.

- Cutting tooth geometry. the profile can be of two basic types:

- chipper (popularly called “sickle”). has a sickle shape and is characterized by high performance. Easier to sharpen during use and does not require precise sharpening angles. Disadvantage: risk of high loads and deterioration of cutting performance;

- Cheziel (commonly known as a “seven”). its cutting surface is straight and shaped like the number “7”. Used in chainsaw pitch “0.404” or “3/8” on professional saws. The main disadvantage of cheesel links is the difficulty in sharpening the cutting elements and the sensitivity to dirt.

- Number of cutting teeth. defined as the ratio of the number of teeth to the number of guides in the bar. Good-made chainsaws should have a combination of two guide links in the cutting part of the tool.

- Type of link sharpening. depends on the type of work to be done. Classic types of chainsaws are mostly used for cross-cutting and are rarely used for longitudinal sawing. Taking into account the resistance of the tree in both cases, the chains may use a different angle of link placement. On building shelves now it is possible to meet chains with following types of cutting links:

- longitudinal chain type. it is supposed to cut wood along its fibers. cutting angle reaches 5-15 degrees.

- transversal type. the cut is transverse. Cutting angle in chains is 25-35 degrees.

- Chain length. depends on the parameters and technical characteristics of the chainsaw itself: power, dimensions, etc. If the chain has standard or standardized tension, the length of the chain is most often given in the data sheet.

- Link order. the order of the links can be different:

- Standard. for each cutting link in the chain there are two driving links;

- with a semi-step. every third link in the chain is replaced by a so-called connecting link;

- with a gap. at the location of each second link for cutting, a connecting.

Description of chainsaw Ural 2T Electron

Country-producer of all models and modifications of Ural chainsaws. Russia, factories where these tools are made: Uralmash, Uralstal. Power of the chainsaw 2-T Electron is 3680 W or 5 horsepower. It belongs to the class of professional tools used in harsh weather conditions. Can be used for continuous operation without shutting off.

The legendary “5 horsepower” of gasoline saw Ural Electron is known to all fans of machinery and owners of various tools. On the basis of this engine it is possible to create homemade household units, such as a snow blower.

Scope of application of the 2T Electron: cutting of large trees, felling, creation of blanks from fallen trees, longitudinal and cross cutting of wood in furniture and construction industry. Ural 2T Electron chainsaw can be used even in severe frost or snowfall.

Ural 2-T Electron chainsaw package:

- tire and chain;

- chain tensioning device;

- handles;

- gearbox, starter, motor;

- gas tank;

- instruction manual;

- cardboard packaging.

(up to 3 thousand hryvnia).

It is possible to buy a used model at a cheaper price, but the exact price depends on the condition and equipment of the tool.

Why is the tabular form of presentation the best??

The first parameter is caused by many factors and is usually in the range of 30-45 cm, although there are exceptions.

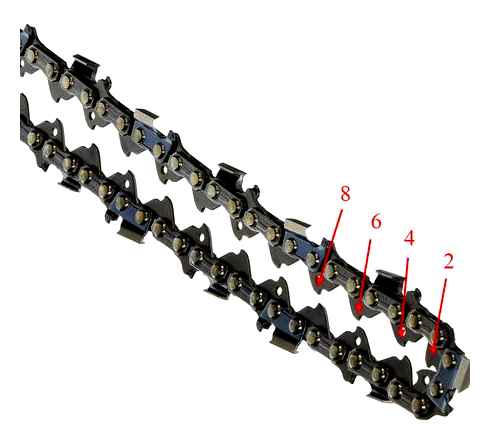

Chain pitch is the distance measured between 3 nearby rivets.

You can measure the thickness of the drive links or the height of the bar groove with a normal caliper. It is usually within the range of 1.1 to 2.0 mm.

The total amount of cutting links is also taken into account when selecting a chain.

Roller Driving Chains

Drive roller chains are designed for power mechanical gears of various machines and mechanisms. Of all the drive chains, these are the most common. There are three basic standards, which regulate the parameters of the drive roller chains. GOST 13568-97, adopted in Russia; ISO/R 606, British standard, adopted in European countries, and ANSI B29.1M as adopted in USA. This type of chains can be manufactured as collapsible, straight or curved plate circuits, and with different types of anti-corrosion coatings. Roller chain dimensions have full analogues among American and British standards.

Normative documents: GOST 13568-97 Drive roller and sleeve chains. International standards: ISO/R 606, ANSI B29.1М.

Four-row drive roller chains GOST 13568-97 (4PR)

Name of the driven roller chain 4PP Chain pitch Chain diameter Chain roller Width between inner plates Chain roller diameter Chain roller width Inner plate width Chain breaking load Weight per metre ISO 606 ANSI B29.1M P d1 b1 d2 Lc h2 g mm kN/kgs kg/m

| 4PR-19,05-128 | 12A-4 | 60-4 | 19,05 | 11,91 | 12,7 | 5,94 | 101,9 | 18,2 | 128/12800 | 5,75 |

| 4PR-19,05-155 | – | – | 19,05 | 11,91 | 12,7 | 5,94 | 101,9 | 18,2 | 155/15500 | 6,80 |

| 4PR-25,4-228 | 16A-4 | 80-4 | 25,40 | 15,88 | 15,88 | 7,92 | 129,9 | 24,2 | 228/22800 | 10,90 |

| 4PR-31,75-355 | 20A-4 | 100-4 | 31,75 | 19,05 | 19,05 | 9,53 | 157,5 | 30,2 | 355/35500 | 14,70 |

| 4PR-38.1-508 | 24A-4 | 120-4 | 38,10 | 22,23 | 25,4 | 11,1 | 197,1 | 36,2 | 508/50800 | 22,00 |

| 4PR-50.8-900 | 32A-4 | 160-4 | 50,80 | 28,58 | 31,75 | 14,27 | 252,3 | 48,3 | 900/90000 | 38,00 |

An example of an identification number of the chain: 4PR-50,8-900 4. chain row GOST 13568-97 PR. drive roller 50,8. chain pitch in mm 900. breaking load in kN

An example of component designation: C-4PR. 50,8. 900. connecting link to the chain P-4PR. 50,8. 900. connecting link to the chain P2-4PR. 50,8. 900. double link to the chain

READ How to dilute gasoline for Partner chainsaw

SashaMoto.ru

Motorcycle and bicycle reviews, useful articles on repair and operation

Link Sequence

- Standard. 2 leading links 1 cutting link;

- With semi-strip. 2 links 1 connecting;

- With a gap. there is one extra link between each cutter.

Chain length

Chain length refers to the number of links it consists of. The parameters of your chain must be indicated in the documents attached to the construction equipment.

READ Best Blades for Saw Blades

Main parameters of chains

The marking of the chain implies the following features:

- Pitch:

- “0,325”. the most common and smallest pitch size, which is used in semi-professional and domestic chainsaws with low power. Standard power value for this pitch ranges from “0,325” to “3l.с.”, but no higher than “3.5L.с”. When working with this type of chain is cut more smoothly, comfortably, without “torn” products.

- “0,375” (“3/8”)-applied to chainsaws with “4 hp.с”. This chain is used when sawing medium- and small-thickness wood.

The accuracy and quality of the cut depends on the pitch. When it is not important to achieve the highest quality when working with a chainsaw from time to time the accuracy of the cut is of particular importance. To do this, it is essential to consider the dependence of the pitch on cutting the wood according to the markings made beforehand.

Pitch and its dimensions

The pitch is the intermediate distance between 3 rivets that are placed side by side. For correct calculation of chain pitch it is necessary to determine the distance between the axes of three rivets placed near each other. In formula form, this consists of the following:

Where, L is the value of the pitch, which in chain saws characterizes the degree of distance between the 2 teeth in relation to a loved one;

S. value of the space between the last 2 rivets of the three.

The pitch value is also equal to the distance between the 2 adjoining shanks.

The friction between the teeth is greater, the deeper they will go into the material to be sawn

By increasing the pitch it is possible to increase the chainsaw performance. But, in a similar case, the degree of force applied to embody rotation of the drive sprocket changes. The higher the pitch of the chain, the more power the engine can use and the more physical effort it takes to pull it when cutting materials.

Properties of wear-resistant chains of general and special purpose

There are professional and consumer products on sale, the difference is in the type of material used in the manufacture and some other things. An example is the model that is designed to work with concrete, the hardness of which is quite high.

Recently, wear-resistant models made of special alloys are increasingly preferred. They can withstand prolonged exposure and overheating, but special tools are required for sharpening. Working with frozen wood cuts product life by about 2-3 times no matter what materials are used.

Chain pitch for chainsaws

Chainsaw chain pitch is one of the main features of the product. This is the distance between the three elements next to each other. In order to calculate the chain pitch, you need to use the formula L=S/2. In this case:

Now let’s break down the advantages of large and small pitch chains. Let’s start with the big one.

Such a chain helps the saw to penetrate deeper into the material, which means that the saw performs better overall.

It is worth mentioning, however, that large steps require a powerful motor and considerable physical strength.

- A chain with a small tooth spacing vibrates much less;

- The work is done more smoothly and easily;

- The amount of cutting is increased.

In the home, chain saws with a fine cut of about 0.324 mm are used more often, as they work more smoothly, which guarantees greater safety. Professional applications mean chain saws with a chain pitch of 0.404 mm.

Chain pitch. Table

Depending on the pitch, chains are now available in several subtypes:

As you can see from the table, the pitch of the chain is marked as an ordinary number (3/4) and as a decimal number. “0.375”. Similar division is caused by the similarity of decimal values. “0,325” and “0,375”, because the difference of one digit created a mess when selecting the saw. Therefore, at one time it was decided to establish 2 different designations: decimal and ordinary fractions.

The pitch is stamped in the area of each tooth with a special sawing depth limiter.

Among the advantages of chains with a large pitch can be attributed:

Keep in mind that a bigger kerf requires a more robust motor, which in turn increases the resistance.

The advantages of chains with small steps are:

This is achieved by the large number of teeth and the small spacing between them.

All the popular systematization of circuits is based on the features of their marking, depending on the pitch, which is designed for certain needs and is made for a certain power of electrical equipment. For the best comprehension of each type of step, they must be seen separately.

READ How to Change the Bars on a Husqvarna 137 Chainsaw

How to make correct rivets with an electric drill?

Fear not: you do not need to buy a machine tool. Use an ordinary drill. The whole process of making rivets with an electric drill and an ordinary file is described as follows. From a nail, the diameter of which is equal to the diameter of the inside of the rivets (check it with a caliper), cut out a workpiece. a piece of about 7 cm long. This workpiece is secured in the head of the electric drill. The drill itself must also be securely clamped.

On a wooden bar is fixed two notches, the distance between which will be equal to the width of the inside of the rivet. You may not be able to do it quickly, but you must be absolutely accurate. It only remains to organize an even flow of the bar on the workpiece. How to shorten chainsaw chain with your hands. We recommend to use a piece of board, one end of which we fix to the stationary part of the workbench with a wide door hinge, and on the second end of the board we fix a bar with flats.

Check the perpendicularity of the location of files and workpiece. and you can begin work. Start the power drill and lower the jigsaws smoothly. They will make grooves on the workpiece. It is not advisable to make rivets in one go, as you should not overheat the metal, but it is necessary to control the thickness of the workpiece on the part you have turned. Too thin a part of the rivet can also damage you, so you need to achieve maximum accuracy. If you can do it right, all you have to do is cut the rivet and use it to connect the chain links.

It is better to cut the rivet by hand, without using an angle grinder. Do not forget that when cutting metal at high tool speeds, there will be a significant increase in the temperature of the material, which is very undesirable. The finished rivet is in no way inferior to the factory product in quality, so the restored chain will last a long time. There are almost no negative aspects of using a homemade rivet. The main thing is that when installing the rivets, you do not forget to align the side parts of the links (you had to bend them when separating the chain). Even a slight protrusion of these elements from the design norm will lead to premature wear of the drive sprocket.

It is recommended to make several rivets at once in the way described earlier. How to rivet the chain on the motorcycle and instructions

It’s not just a matter of stocking up on such essential items (although this is also important). It is more important to choose the most suitable size from the number of pieces: any deviation from the norm will make the chain vulnerable to high loads

Reconditioned chains are not recommended for hardwoods.

How to remove rivets?

A chainsaw chain is difficult to unbolt. The rivets are made of quality steel and are geometrically shaped to prevent the rivets from simply being knocked out of the link. The inside of the rivet has a larger radius. This thickening is where the link turns, and the outer parts of the rivets have only a connecting function, so it’s easy enough to fix them securely on the outside of the chain. To remove a rivet: the chain is clamped in a vice and the protruding part is ground down. Care should be taken not to damage the side links when turning.

Do not use an angle grinder, because the parts will heat up very quickly and this will change the physical properties of the metal. It’s best to use a file or file to grind it. Grinding is done on both sides of the link. And now the rivets can be knocked out of the chain with the help of a bead, slightly bending back the sides of the links.

The chain is unhooked. Don’t throw a rivet away when you remove it from a chain. You might not be able to find a suitable replacement. Sawmakers don’t expect you to repair the chain yourself, so they don’t make such rivets on the market.

It’s also more profitable for retailers to sell chains in their finished versions than small parts for repairs. For these reasons, a suitable rivet with the right geometry will be very difficult to find. It’s even harder to make at home, so you’ll have to use an old rivet.

As you may have guessed, the chainsaw chain has to be stripped twice. Don’t forget to count the number and spacing of guide lugs on the inside of the chain to match the chain saw’s drive sprocket. If you are shortening the original chain, this is not necessary. And if it’s a chain from another chainsaw model, you need to measure and calculate it very carefully. A variation in chain pitch, however small, from the specs given in the design will cause the chain to stretch out again in no time (at best) or to break the chain sprocket of the chainsaw. The tire will be finished as well since the sprocket will overheat quickly.

Number of Chain Links in a Chainsaw

Knowing these three factors makes it easy to find a chain for your saw, pole pruner or harvester head.

chain pitch

The chain pitch is usually expressed in inches and is calculated this way: measure the distance between the nearest chain drive links, or the distance between the three nearest chain rivets (from the center of the rivet), divide by 2 and converted to inches (1 inch = 25.4 mm).

The pitch of the chain should always coincide with the pitch of the saw’s drive sprocket and the bar sprocket.

- Chain with pitch 0,25″ aka 1/4″. Spacing between three rivets (drive links) 12.7 mm ÷ 2 = 6.35 mm translate to inches (÷ 25.4) in inches is 0.25″ (often referred to as 1/4″).

- A chain with a pitch of 0.325″. The distance between the three rivets (drive links) is 16.5 mm ÷ 2 = 8.25 mm which translates to inches (÷ 25.4) which is 0.325″.

- Chain with pitch 0,375″ aka 3/8″. Translate three rivets 19 mm ÷ 2 = 9.5 mm into inches (÷ 25.4) which is 0.375″ (common definition is 3/8″ to avoid confusion with 0.325″).

- A chain with a pitch of 0.404″. Translate to inches (÷ 25.4) the distance between three rivets 20.5 mm ÷ 2 = 10.25 mm in inches is 0.404″.

- Chain with 3/4″ pitch. The distance between three rivets 38.1 mm ÷ 2 = 19.05 mm converted to inches (÷ 25.4) in inches is 0.75″ (designated as 3/4″).

Thickness

The thickness of the chain is the thickness of the drive link (can be measured with a caliper). This dimension must always match the thickness of the guide bar groove.

There are a total of 6 sizes for electric and gasoline-powered saws and harvesters that determine the drive link length:

The third main parameter when selecting a chain: Length of chain (number of drive links).

Chain length is determined by counting the number of drive (inner) chain links. Important:

- The cutting links do not determine the chain length (don’t count them).

- the length of the guide bar does not determine the exact length of the chain (for example, a 16″ (40 cm) chain may have a 55, or 56, or 57 link chain, depending on the chain tensioning mechanism of your particular model of saw).

- you cannot use a chain of about 55-57 links, but only a certain size recommended by the sawmill manufacturer.

What bar length does my chainsaw have??

The length of the cutting part of the bar differs from its total length. The length of the bar is usually considered the length of the cut (the working part), which is the distance from the front of the saw to the rounded tip of the bar nose. It is rounded to the nearest inch or centimeter. An inch is ” equals 2.54 cm.

For example, the cutting length for the STIHL MS180 chain saw is 40 cm. 40 cm ÷ 2.54 = 15.7 inches. Rounded up, that’s 16″ (inches).

For the STIHL MS180 chain saw, the Oregon 160SDEA074 is a 16″ (40 cm) bar.

Number of Links in a Chainsaw Chain

In some situations chainsaw owners can get a little confused about all the markings on the chainsaw chain markings. This can lead to unfortunate purchases. You can buy a chainsaw chain in a hardware store. Number of chain links. Chainsaws are often determined by only a few basic criteria, one of which is the chain pitch. This helps to identify future possibilities of the tool, in particular its cutting speed, and the standard should correspond to the power level of the motor. How chains are marked? Let’s try to figure it out!

Pitch and its dimensions

The pitch is the intermediate distance between three rivets placed side by side. To correctly calculate the chain pitch, measure the distance between the axes of the three rivets that are close to each other. The type of formula is as follows:

Where L is the pitch which, in chainsaws, is the distance between the two teeth relative to each other;

S is the space between the two outermost of the three rivets.

The pitch a may also be equal to the distance between two adjacent shanks.

The larger the distance between the teeth, the deeper they will move into the material to be sawn off

By increasing the chain pitch you can increase the chainsaw’s performance. However, in such a case, the degree of force applied to perform the rotation of the drive sprocket changes. The higher the pitch of the chain, the greater the motor power can be, not just the physical effort required to pull it through when sawing materials.

chain pitch. Table

Based on the pitch, chains today are divided into several subtypes:

As you can see from the table, the chain pitch is marked as a regular number (3/4) not decimal. “0.375”. Number of links of a small chainsaw with a bar length of 14 saws in a given chain. This division was caused by the similarity of the decimal values. “0.325” not “0.375”, because the difference of one digit created confusion when selecting a saw. That is why at one time it was decided to have two different designations: a decimal and not a fraction.

The pitch is stamped in the area of the throat stop on each tooth.

Among the advantages of chains with a large pitch can be included:

However, it should be noted that a wide kerf requires the use of a more powerful motor, which consequently significantly increases the resistance.

The advantages of small pitch chains are:

Achieved by most of the teeth not the smallest spacing in them.

All known chain classification is based on the peculiarities of their marking based on the pitch, which is designed for specific needs and not produced for a specific power of the electric equipment. For a better understanding of each type of pitch, they should be considered separately.

Key features of chains

The marking of a chain implies the following parameters:

- Pitch:

- “0.325” is the most common non-minimum pitch size used in semi-professional non-household chainsaws with low power. The standard power value for such a pitch ranges in time from “0.325” to “3l.с.”3.5l”, alas no higher than “3.5l.с”. During the work with this type of chain, the sawing goes more smoothly, comfortably, without “rips” of processed products.

- “0,375” (“3/8”). is applied to chain saws with power of “4l.с”. Such chain is used when sawing wood of medium to small thickness.

The pitch has an impact on the accuracy and quality of cut. When it is not important to achieve a good cut while working with a chainsaw, the accuracy of the cut is of utmost importance. That is why in the world to buy a chain for a small chainsaw. Chains with the number of links. For this purpose it is necessarily necessary to take into account the dependence of the pitch on the timber cut in accordance with the markings made beforehand.

Chains for chainsaws, their types and sizes

chainsaws, their types and sizes. Here’s a video we’ll talk about not look at the nets, find out their types, sizes, so.

- Thickness of leading links (tails). When a chainsaw is in action, its chain carries most of the load. With this in mind, another main characteristic of a chainsaw is the thickness of the link elements that go into the grooves of the bar. it also determines the overall thickness of the connecting links, which is measured using a common caliper. The standard link thicknesses include:

- “1.1 mm” (“0.043”) and “1.3 mm” (“0,05”). are used in the production of entry-level chains, designed for small amounts of work. Often with these link thicknesses, the pitch length of the chain is “0.325”, which implies low loads and non-sensitive working conditions. That’s why they are used in domestic not semi-professional machines;

- “1.5 mm” (“0,058”). the most common thickness value in the chainsaw trade. The number of chainsaw chain links should be counted from the products in the chainsaw category. This value is able to ensure safe operation with a pitch of “3/8”. Chains with “1,5mm” thickness are not designed for sawing professionals;

- “1.6 mm” (0,063) and “2,0 mm” (0.08). designed for the most demanding applications. The metal for these chains is steel of special grades and is designed for strength characteristics.

READ STIHL 180 chainsaw No fuel feed

the larger the link thickness and the wider the bar groove, the higher the quality of the chain saw is considered, because it can withstand higher loads.

- Depth of cut is a peculiarity of the chains produced, it is not characterized by the height of profile of cutting teeth. It is measured as oil by the gap between the stops, not by the top cutting edge. In the current market there are usually both high profile (0,762 mm) and not low profile (0,635 mm) kinds of chainsaw products.

There are a lot of chainsaw chain models on sale now. For starters you need to know the right size for your chainsaw so you don’t make a mistake when buying. The second step is to install it correctly on the chainsaw. This process is somewhat time-consuming, but if you know how to put and adjust the chain on the saw bar yourself, the good owner shouldn’t have any problems. We have tried to describe in detail the process of installation of the sawblade on a chain-saw.

We hope that after reading this article you will have succeeded the first time. But in order to minimize problems with the chainsaw and the chain in the future, don’t forget the 3 basic rules:

- If the chain is worn and sagging. replace it with a new one;

- If there is vibration and a bad cut when sawing, watch the chain tension on the chainsaw;

- Never use chain saws that are defective or repaired by dubious specialists. your health and the health of those around you are much more important than saving a little money on a new and reliable chain.

Necessary tools and appliances for tightening a chain on a chainsaw

In order to do the tensioning correctly, you will need knowledge of some simple mechanisms and simple tools. On STIHL chain saws, tensioning is simple with the integrated chain tensioner. This method is as simple as possible and is very quick to tighten. To tension or adjust the slack in the chain, the manufacturer recommends to do

- Using a wing nut, unscrew the sprocket cover;

- turn the adjusting wheel to determine the required chain length, tightening the chain to the required degree;

- close the sprocket cover again and the chain is firmly fixed on the bar.

If it is impossible to tighten the chainsaw chain with the built-in mechanism, use the following tools (using the Sparky electric saw as an example):

- an angle grinder with a metal disc;

- hex wrench, 5 mm diameter;

- piece of wire;

- A piece of wood or a piece of wood splinter;

- flat screwdriver.

After de-energizing the electric saw unscrew the screws with an allen key, remove the housing cover, unscrew the tensioning screw with a screwdriver and remove the stem nut. The side of the screw that is adjacent to the body of the saw is ground with a disk. The saw is then reassembled in the reverse order. The brush is required to clean the housing from sawdust.