How to cut a board at a 45° angle

Test Paper Grade 5 Woodworking 2 options

Among the large number of construction tools there are all sorts of additional devices designed to facilitate the hard work of masters. Those engaged in carpentry are familiar with this somewhat strange name. “”, which refers to a tool-assist for making a cut of a board or any other profiled material

at an angle that is fixed structurally or self-determined. For perfect interior and exterior projections, the angle is usually done in 45°.

Material for sawing at an angle can be different: skirting boards, door and window trims, mouldings, laths, cornices, etc.д. The workbench is fixed firmly to the workbench and the material is sometimes clamped with a clamp. this device is safe and easy to use.

Chisel

The cheapest solution for making cuts at an angle is a simple power drill. It is usually made of plastic or wood, it has slots to make the cut with a saw at an angle of 45 ° or 90 °. There are also saws with many holes for different angles. Use a fine-toothed hacksaw with a wide blade and press the wood you want to cut into the back of the jigsaw. The relatively narrow gouge shown in the picture is suitable for small parts, e.g. to cut wooden strips for picture frames or other small wooden parts.

Example of calculating the slope of the roof in degrees

To understand how to calculate the angle of the roof, it is worth considering the process of calculations on a specific example. For example, the following data will be taken: the crate has a thickness of 2.5 cm, one square meter of roofing weighs 15 kg, as a thermal insulating material used insulation thickness of 10 cm, a square meter has a weight of 10 kg, and to cover used ondulin with a weight of 3 kg per square meter.

Calculation of the slope of the roof is carried out in accordance with the above methodology. Substituting the available data leads to the following expression: (15103)x1.1 = 30.8 kg/sq.м. The value obtained is quite acceptable. the average statistical load on the roof of residential buildings is just under 50 kg / sq. ft.м. In addition, the formula there is a coefficient of 1.1, which slightly increases the actual weight of the roof structure and allows for further replacement of the roof covering on a heavier.

https://www.remontiruemlegko.ru/kak-rabotat-ruchnoj-piloj.html https://sinstrument.ru/brus/kak-raspilit-brus-vdol-svoimi-rukami.html https://morflot.su/otpilit-pod-uglom-45/

How to work with a hand saw

The saw has to be driven, otherwise it will start to “walk”. This should be taken literally. Wood is a living material, and its behavior is unpredictable. Hard annual rings, knots, cracks, high humidity and high resin can make sawing very difficult.

For this reason there is no universal tool that can account for all the vagaries of wood, but there are many different special saws. It is not the material of the saw blade that determines the shape and the order in which the teeth are set, but their intended use. Some saws can only be used in a straight line, others travel better in a circular motion.

When sawing, only the saw moves, the workpiece must be securely clamped. That’s why you need a stable support. E.g., workbench or scaffolding. Workpieces are clamped with a clamp or held in place by hand, and particularly large workpieces are additionally clamped with a knee.

Sawing begins and ends by repeatedly pulling the saw lightly in the opposite direction, that is, laying a “trail”. At the end of the sawing process you have to hold on to the hinge to make sure it doesn’t break off with the hunk of wood.

Sawing. one of the most common processes in the processing of wood. Clean, even sawing is not a problem if you choose the right tool and know how to use it.

In the photo (from top to bottom): a large and small hacksaw; a saw with a “back”; a saw with a narrow blade. On the left side next to it is the clear-cutting saw.

How to bend a corner

There are several basic ways to get out of the metal angle designs with a given shape and profile, namely, to distinguish:

Cold bending metal angle, in turn, is divided into:

- Free bending. this is when the angle is bent without the use of special equipment;

- Bending with a rolling mechanism on a specialized profile bending machine.

The use of cold bending a metal angle, unlike other ways, has certain advantages, namely:

- This is the least expensive method of giving the metal a given shape, and does not require the use of additional equipment for heating, cutting, welding and subsequent processing of the metal;

- The resulting framework is very strong because it eliminates the kind of defects normally associated with heating, cutting and welding;

- finished structures are guaranteed to last longer because the integrity of the metal profile structure is preserved during processing;

- the likelihood of metal corrosion over time is reduced.

Trimming at an angle with a protractor

Angle trimming is done by using a protractor. It is a measuring tool, easy to use and is used for measuring angles or for marking the required angles on parts. Place the protractor on the part, mark the corner and mark it with a pencil. It is not difficult to cut the workpiece to the right angle using this marking.

Using templates

If you do not have a protractor, a jig, or ready-made angles, you will have to look for a suitable template. Of course the template must have the right angle. It is attached to the workpiece and a pencil to mark the workpiece. This is one of the easiest ways to achieve the desired result.

Trimming on site

The walls, floor and ceiling will not always be perfectly flat in practice. Most often they have irregularities. For this reason, there is no need to trim blanks at precise and accurate angles, because they will not fit perfectly anyway.

Instead it is sometimes convenient to trim the same ceiling plinth on the spot. That is, first one baseboard strip is glued, trimmed in the corner, and the second strip is trimmed under it.

Of course, it is hardly possible to cut a perfect billet. However, if there is a small gap in the corner, it can always be sealed with putty or plaster. Nothing special.

How to cut the corner of a skirting board or a baguette without a chisel

When installing baseboards, it is important to properly design the corners. These are often the ones that spoil the overall picture. How to make an angle on the baseboard. external and internal, how and by what to cut. Let’s go over all of this next.

Trimming parts at an angle with a protractor

You can use a protractor to trim the part at an angle. It is a measuring tool that is easy to use and is designed precisely to measure angles or to make necessary marks on certain workpieces. Place the protractor on the part, mark the angle and mark the corner with a pencil. It is very easy to cut a piece at an angle using this template.

Using templates

If you do not have a protractor, a plane or ready-made angles, you will have to look for a suitable template. Of course the template must have the right angle. It is attached to the workpiece and mark the workpiece with a pencil. This is one of the easiest ways to achieve the required result.

Trimming “in place”

The walls, floor and ceiling will not always be perfectly flat in practice. They are often irregular. For this reason, there is no need to trim blanks at clear and precise angles, because they will not fit perfectly anyway.

Instead, it is sometimes convenient to trim the same ceiling plinth on the spot. That is, first glue one baseboard plank, trim it in the corner, and under it trim the second plank.

Of course, you can hardly cut the workpiece perfectly. However, if there is a small gap in the corner, it can always be filled with putty or gypsum plaster. Nothing fancy.

How to cut the corner of the skirting board or baguette without a chisel

When installing baseboards, it is important to properly design the corners. They often spoil the overall picture. How to make a corner on the baseboard. external and internal, how and with what to cut. Let’s discuss all of this further.

Cutting without tools

How to cut the corner of the ceiling plinth without a chisel? It is possible to calculate and cut manually.

It is sufficient to make a good marking on the ceiling, then cut the required angle evenly. The significant disadvantage of this option. the inconvenience of having to hold hands all the strips in the process of measuring. In general, this method is not worse than helping to make the necessary measurements.

When you put the product to the place where it will be mounted, you can immediately take into account all the errors on the walls.

First two blanks are cut at an angle of 90 degrees. Then apply one of the slats, pointing it perpendicularly to the wall. Run a fishing line for a trimmer along the ceiling, outlining the desired contour. Then remove the slat and attach the second. for the reciprocal marking. The intersection point of the straight lines will be the point of trimming. Then the place for the future cut is marked on the slats.

The best knowledge of how to cut ceiling plinths in the corners, experienced carpenters, joiners and builders. Most advise to make cuts at the side and try on the ceiling trims, if necessary. trim in the direction of adjacency details to the surface.

Once the rough joint is made, screw the final finished fillets to the wall. Seams are sealed. the installation of the baseboard is complete.

Skirting board for the ceiling is an excellent means of masking the various irregularities that necessarily arise at the joints of the walls with the ceiling. The result is not only a visually even corner, but also quite aesthetically complete interior.

An important point in fixing the ceiling plinth is to measure and cut it correctly.

So, let’s look at how you can cut a ceiling plinth.

To begin with, let’s define what a ceiling plinth is, and what it can be made of.

For the manufacture of ceiling plinth strips different material is used. It can be quite flexible polyurethane, wood, polystyrene foam, PVC.

The most durable, stable and flexible are considered polyurethane skirting boards. By the way, it is worth noting that this element of the decor has its own name. the fillet. Because it can be confused with moldings that are attached to the flat surface of the walls or ceiling.

How to protect the saw from damage

Any saw (especially its cutting edge) must not come into contact with other tools during storage. Such an environment can cause the saw to break down in next to no time.

If you do not have a sheath for your saw it is easy to protect the cutters from damage. You make a cut in a piece of hose of the necessary length, and then you put the hose on the saw blade. The best thing for this purpose is a rigid hose covered with a cloth on the inside. It is held tightly by the saw blade even after repeated use.

If you are sawing longitudinally, it is better to buy a circular saw. Doing it with a hand saw is a hassle. This is the first, and the second: the information that can be gleaned from the texts in the frame is incomprehensible to the beginner, and useless to the professional.

A different saw for every workpiece

A hacksaw is fast, but the wide tooth pitch leaves a rough cut in soft material. On the other hand, it would be difficult to saw a thick beam with a coping saw. In short, material and tool must fit together. Only then can you count on quality work and getting an even, defect-free piece. Here’s a quick guide to what kind of wood should be sawn with which saw.

The saw has to be driven, otherwise it will start to “walk”. This should be taken literally. Wood is a living material and its behavior is unpredictable. Hard annual rings, knots, cracks, high humidity and high resin content can make sawing extremely difficult.

For this reason there is no universal tool that can take into account all the vagaries of wood, but there are many different special saws. It is not the material of the saw blade that determines the shape and the order in which the teeth are set, but the saw’s purpose. Some tools can only cut in a straight line, but others cut more circularly.

When sawing only the saw moves, the workpiece should be firmly secured. That’s why you need a firm support. For example, a workbench or trestles. The workpiece is secured with a clamp or held by hand, and especially large workpieces are additionally secured with a knee.

Sawing begins and ends with repeated light pulling of the saw in the opposite direction, that is, a “trace” is laid. At the end of sawing it is necessary to hold firmly the remainder, so that it does not break off along with a piece of main wood.

Sawing is one of the most common processes when working with wood. A clean, even cut. no problem if you choose the right tool and know how to use it.

In the photo (from top to bottom): large and small hacksaw; hacksaw with back; saw with narrow blade. On the left side there is a saw for the finish sawing.

Ceilings

Ceiling skirting does not only a decorative function, visually separating the walls from the ceiling, but can also hide the connection of different materials finishing the ceiling and walls. Not every interior design involves the introduction of the plinth, but in most cases, the view of the room seems incomplete without it. There is nothing complicated about fixing this element. Fillet. Almost all types of skirting boards are attached by glue. But the question of how to correctly cut a ceiling plinth in the corners of the premises, can confuse many. After all, even in the most ordinary room, there are interior corners, where the plinths of the ceiling plinth should be exactly and perfectly docked. And in a more complex room configuration for you will also have to dock the skirting boards, making an outside corner. In this article, we will look at different options on how to cut the ceiling plinth with and without tools at hand.

At first it is necessary to understand how to cut a ceiling plinth, the answer is depending on the material from which the fillet is made. Now we sell PVC, polystyrene foam, polyurethane and wood ceiling skirting boards.

PVC ceiling skirting. The cheapest. They simply vmjatayutsya and creases that are unrealistic to repair, because the product must be thrown away. They also have the disadvantage of being electrostatic. Ability to attract dust. You can cut them with a sharp construction knife or hacksaw.

Skirting with ceiling foam is also cheap. This material is very fragile, it simply crumbles when processing, so you need a sharp knife or hacksaw for metal to cut the styrofoam, without making a very pressing force.

Ceiling skirting boards made of extruded polystyrene is somewhat more expensive than polystyrene, they are dense and more difficult to cut. But they are the least crumbly, which makes them easier and more comfortable to work with. Cut with a construction knife and a metal saw.

Polymer ceiling plinths are now the most expensive. They are strong, flexible and water-resistant, can be easily cut with a construction knife, and will not disintegrate. The disadvantage of baseboards made of polyurethane is their dependence on the configuration of the temperature. For example, over a gas stove, a polyurethane skirting board will routinely warp and slightly crack. If you try to process or cut such a skirting, it can bend or deform in other ways.

Wood ceiling skirting boards. These are dense toms that can only be cut with a hacksaw, preferably with small, dense teeth. You can also use fabric for metal.

Before we proceed to the enumeration of methods, how to correctly cut the ceiling plinth, I would like to note that there is a possibility not to cut the plinth with great accuracy. Commercially available special corner pieces into which the edges of the baseboard are inserted. In this case, rather cut the skirting strip at an angle of ninety °, and the corner element will hide all the shortcomings. But this method is not always used, because the size of the corner parts is slightly larger than the skirting boards themselves, so the corners in the room will stand out against the background. Occasionally it can look three-dimensional. But, if the design of the room allows the use of corner pieces for ceiling plinths, it makes sense to use them. The following instructions will be helpful to those who nevertheless decide to accurately cut the baseboard at this angle.

How to trim a ceiling plinth with a jigsaw template

Something resembling a box can be made, using the necessary corners of the cut on paper, cardboard or wood. Draw two parallel mowing strips, find the center, and then set the necessary angles using a protractor. The advantage of this method is that you will be able to set aside at least any angle, including more than ninety degrees. Naturally, before you cut the angles ceiling skirting boards

, should first be checkedcorner between walls with a corner and measure with a protractor.

The technique of cutting the ceiling plinth with a painted box is exactly the same as the introduction of the box itself. We press the baseboard to one of the parallel lines, then set the hacksaw to a suitable angle, which is already marked, and cut.

How to cut the corner of a ceiling plinth with a wire cutter

Drawer for mitre. This is a common carpentry tool that allows you to cut the workpiece at the desired angle. In most cases, this is a tray of plastic, wood or metal with vertical slots for cutting at an angle of ninety ° and 40 5 °. There are more complicated mitre box designs. For cutting at an angle of 90, sixty and 40 5 °. For more professional work using a box with a swivel mechanism, where the saw can be fixed at any angle to the workpiece.

How to cut a skirting board with a box. Inner corner:

- We put a skirting board on the ceiling, measure the required length.

- Then we install the Baseboard strip in the box, so that the position coincides with the position of the baseboard on the ceiling.

- The baseboard strip must be pressed against the far wall of the box.

- With your left hand hold the baseboard.

- We choose a position of the hacksaw where the angle is 40 5 degrees, and the handle of the hacksaw is very close to the left hand.

- Cut the workpiece without exerting too much pressure on the saw.

- Subsequent step. Trimming the slope of the baseboard. We also set it on the far wall of the box.

- Press and hold with your right hand.

- We choose a position for the hacksaw when the angle is 40 5 degrees and the handle of the hacksaw is close to your right hand.

- Cut the baseboard.

Next, connect the cut skirting boards and check the accuracy of the cut. They also tell you to start cutting from the front of the baseboard to complete the inside corner, so you can get a clearer orientation. After cutting the wood baseboards, it is likely to have to be corrected with a rathole.

How to cut a skirting board with a miter saw. The outside angle:

- In order not to make a mistake with the size, it is better to start with the marking of the inner corner, and then cut the outer corner. In an unpleasant situation, it is likely that the boards may not be long enough.

- You need to attach the bar to the ceiling and find the dimensions.

- Place the Baseboard strip and press it against the closest wall.

- Hold it with your left hand and choose a hacksaw position at an angle of 40 5 degrees with the handle close to your left hand.

- Cut the billet.

- Set the striker to the closest wall, hold it with your right hand.

- Set the hacksaw at an angle of 40 5 degrees, with the handle close to the right hand.

- Cut the billet and connect the corner.

The way to connect the casing without trimming

Plinths today often do not trim at an angle to then join together, but make the junction at right angles. This method of connecting the platband does not require any special trimming, which is very convenient. In addition, this method looks more modern and attractive.

If it is still necessary to cut at an angle this or that part, it is worth stocking up on a wire cutter. the simplest device, which looks like a small box. The chisel has slots that are designed for a saw or a long, sharp knife. Of course, these slots are made in such a way that they form an even and precise angle of 45 degrees.

However, the cross cutter can have several notches at the same time, at different angles. This is convenient, since with a single device, you can cut any part at different angles.

There are commercially available adjustable chairs. Slots in such a chair can be adjusted, allowing the master to set exactly the angle that is required at the moment. In particular, it’s quite easy to move the slots in such a chair to a 45 degree position.

Now it is possible to cut the workpiece elementary. Put a molding, a platband or a baseboard in the chair, and then insert a saw into the slots and elementary cut off the surplus. The resulting angle is a perfect 45 degrees.

What to do if you don’t have a power drill bit?? Very easy. It is necessary to make a template on which it will not be difficult to transfer the necessary markings on the workpieces. As a template, you can choose thick cardboard or something else that will be appropriate in this case.

Trimming “on the spot”

The walls, floor and ceiling aren’t always going to be perfectly straight in practice. Most often they have irregularities. For this reason, there is no need to trim blanks at precise and accurate angles, because they will not fit perfectly anyway.

Instead, it is sometimes convenient to trim the same ceiling plinth on the spot. That is, first glue one baseboard plank, trim it in the corner, and under it trim the second plank.

Of course, it is hardly possible to perfectly cut the workpiece. However, if there is a small gap in the corner, it can always be sealed with putty or gypsum plaster. Nothing fancy.

How to cut the corner of a baseboard or baguette without a chisel

A architrave is an overlay frame inherent in a door or window opening. This is a decorative detail, made in the form of shaped slats. There are also carved platbands, their difference is that they are made of wood and are often decorated with abundant carvings. The role of the frame is not only decorative, it allows you to eliminate so unwanted blowing in the area of the gap between the wall and window or door frame, by overlapping.

5 degree template. 45 degree angle pattern

Often a home handyman has to make a measurement or marking at a certain angle in a hurry, and either an angle piece or protractor is not at hand. In this case he will be saved by some simple rules.

If you have an urgent need to make a right angle, and you do not have a protractor, you can use any printout. The angle of the piece of paper is a very precise right angle (90 degrees).). Cutting (punching) machines in printing houses are set up very precisely. Otherwise the initial roll of paper will begin to cut crookedly and tangentially. That is why you can be sure that it is a right angle.

And if you do not even have a printed edition or need to build a corner on the ground, for example when marking the foundation or a sheet of plywood with uneven edges? In this case the rule of the golden (or Egyptian) triangle will help us.

A golden (or Egyptian, or Pythagorean) triangle is a triangle with sides that relate to each other as 5:4:3. According to the Pythagoras theorem, in a right triangle, the square of the hypotenuse is equal to the sum of the squares of the cathetuses. Т.е. 5×5 = 4×4 3×3. 25=169 and it’s undeniable.

Therefore, to build a right angle, it is enough to draw a straight line for the trimmer on the workpiece with a length of 5 (10,15,20 and t.д. divisible by 5 cm). And then, from the edges of this line begin to measure off on one side 4 (8,12,16 and t.e is a multiple of 4 cm) and the other is 3 (6,9,12,15, etc.д. multiple of 3 cm) distances. The arcs have a radius of 4 and 3 cm. Where these arcs intersect each other is the right angle (90 degrees).

These angles are commonly used in the construction of rectangular frames. The material from which the frame (baguette) is made is sawn at an angle of 45 degrees and joined. If you do not have a plane or protractor at hand, you can get a template angle of 45 degrees as follows. It is necessary to take a sheet of writing paper or any printed matter and bend it so that the line for the bending trimmer passed exactly through the corner, and the edges of the bent sheet coincided. The resulting angle and will be equal to 45 degrees.

House lamp made of wood with their own hands

A 60-degree angle is needed to construct equilateral triangles. For example, you need to saw such triangles for decorative work or accurately set the power slope. Angle of 30 degrees is rarely used in its pure form. However, with its help (and with the help of an angle of 90 degrees) build a corner of 120 degrees. And it is an angle necessary for the construction of equilateral hexagons, a figure very popular among carpenters.

To build a very accurate pattern of these angles at any time you need to remember the constant (number) 173. They result from the ratio of the sines and cosines of these angles.

Take a sheet of paper from any publication. Its angle is exactly 90 degrees. From the corner on one side measure 100 mm (10 cm).), and the other is 173 mm (17.3 cm). Connect these points. So we received a template, which has one corner of 90 degrees, one of 30 degrees and one of 60 degrees. You can check with a protractor. everything is accurate!

Remember this number. 173, and you can always build 30 and 60 degree angles.

When marking workpieces or drawings on the parts besides the corners themselves it is very important to note their proportions. This is especially important when making rectangular details or for example when marking foundations, cutting large sheets of material. Incorrect drawing or marking brings a lot of unnecessary work or a lot of waste later on.

Unfortunately, even very precise marking tools, even professional ones, always have a certain margin of error.

Meanwhile, there is a very simple method of determining the rectangularity of the part or construction. The diagonals of a rectangle are exactly equal! So, after the construction it is necessary to measure the lengths of the diagonals of the rectangle. If they are equal, all is well, it really is a rectangle. And if not. you built a parallelogram or rhombus. In this case it is necessary to “play” a little with adjacent sides that would achieve exact (for this case) equality of diagonals of the marked rectangle.

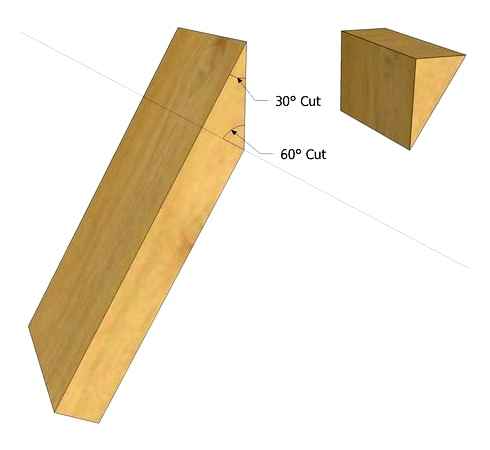

5 degree angles. How to saw at a 45 degree angle

During domestic renovation work you might need to saw materials at a 45 degree angle. Usually this is done to join two parts “in the whisker”, that is, the corner of 90 degrees (frames, skirting boards, door trims, etc.). To be happy with the result of your work, it is important to fit the adjacent parts of the blanks absolutely precisely. Make it without a special device. a plane. is extremely difficult, especially for the novice craftsman.

Prepare an angular template that will help you easily make an accurate cut of the workpiece of wood at an angle of 45 degrees. This device is a profile in the form of an inverted letter “U”, on its sides are made through slots for a hacksaw. Usually they are made in 45, 60 and 90 degree angles. complex crosscutters are additionally equipped with any fixed slots, or have a pivoting design. it allows you to set the saw in the optimum position.

Buy a ready-made carpentry tool from a building supply store with a wooden, metal or plastic tray. For the beginner this is the best option. If desired, you can make a simple crosscut saw with your own hands from three boards or plywood strips (thickness. about 1,5-2 cm).

Drill a few holes in the walls of the future jigsaw, glue the ends of the jigsaw and assemble the box (tray) of the jigsaw. Secure the corner template with screws. The walls of the tool should lie strictly parallel one to the other; the bottom and each sidewall make clear perpendiculars.

Mark a 45-degree angle with a pencil, add more groove lines if necessary. Use a protractor to keep your calculations straight.

The most responsible thing. the cuts. It is recommended to make them with the same hacksaw that will later be used to make cuts in the finished jigsaw. Start sawing without strong pressure on the working tool, hold its blade. Saw one side first, then the opposite side.

Start processing the lumber. Fasten the jig to a workbench or work table with a screw clamp (clamps to hold parts in place) or with screws. Then make a mark for the future sawing on the lath (board, baseboard) and put the workpiece into the box. Press it firmly against one of the side walls of the template, aligning the marks with a slit angle of 45 degrees.

Insert the hacksaw into the grooves of the jigsaw and cut the wood. The saw’s work will be limited to fixed kerfs, and you will make a smooth and precise cut.

When sawing the baseboards, make sure that the corners of the room are really right. If the walls are very uneven, the angle of cut on the workpieces should be corrected. Measure the joints of the interior walls with an angle gauge and divide the result in half (baseboard joint “in the whisker”). To make an accurate cut, it is recommended to make grooves with a given angle in a homemade jigsaw. Another option is a store turntable that lets you change the angle from 0 to 180 degrees in steps of about 15 degrees.

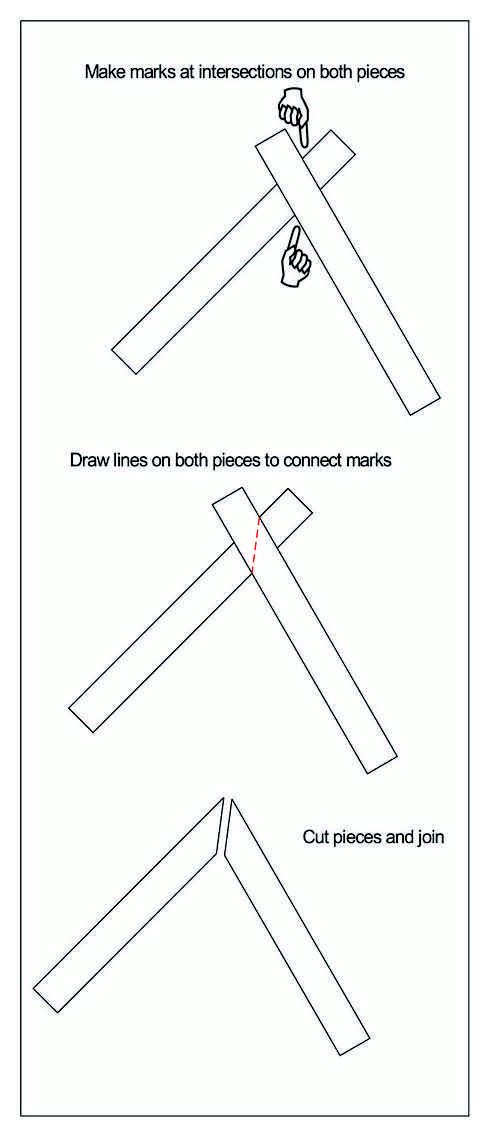

Sawing

Measure the angle of cut, for example with a mallet. If two pieces of wood are at right angles to each other, the angle is 90°. In this case, each of the two angles at which you need to make the cut is 45°. Using the crosscut saw you can make a 45° angle cut to the left or right. For better appearance, make sure that the same sides of the workpiece will be visible from the inside and outside of the completed joint. If you have learned how to make oblique cuts, you can also make a straight joint with a beveled edge to join two pieces of wood to increase length. In doing so, two strips or two baseboards will be neatly joined together.

Variable cutting angles

If you use different cutting angles, you can make the connection at the desired angle. For non-standard angles you can make a neat joint by measuring the required angle of cut with an adjustable mallet or a contour template. Set the mallet to exactly half that angle, and make corresponding marks on each workpiece. After that, place the small square on the same corner, and you can make a neat joint.