How to cut a circle with a jigsaw on wood. Directly processing process

The master cuts out perfect circles with a jigsaw. How to cut a flat circle, having only a circular saw from the tools, how to cut an even circle from plywood

Any design, whether in your home, or in production, involves working with metal.

Often, during the operation of this material, the question may arise: how to cut a circle in ?

It deserves attention, since the complexity of the work process and the quality of its result directly depends on the choice of the right tool and technology.

Metal is thin, or thick and durable, so a variety of tools are used to cut it.

The choice of materials and cutting technology also depends on what diameter a circle is needed and how even it should be.

The use of a jigsaw

If there is a need for a perfectly even circle, you can use the electric to cut it.

- First, the thickness of the metal is determined and the appropriate saw canvas is selected for an electric lobby.

- Before cutting the circle in the metal with a jigsaw, the circuit circuit is planned on the working plane, which will be cut out.

- Using a drill and a drill (in the diameter of the component from eight to ten millimeters), a hole is cut out from which work will begin.

- The resulting gap is placed in the resulting gap and the cutting continues according to the intended.

Cutting using this tool does not take much time and effort. over, with the help of a jigsaw you can get a circle with perfect edges. But this tool is used only to work with the metal of the minimum or medium thickness (for example, 2. 3 mm).

The use of corner grinders

Corner grinder is used to work with metal of small thickness. A round hole can be formed with this tool, following such step.by.step tips:

- Before cutting the circle in the metal of the corner grinder, marking is carried out so that its contours are clearly visible.

- In the entire length of the scheduled drawing, short segments are cut out with a disk of corner grinder, which will ultimately combine.

- The figure will be more similar to a multi.line than a circle. Therefore, after the end of the cutting, the product is processed and cleaned until the time, until the edges become quite even and smooth. For processing, you can also use an angular grinder. If the circle has a wide. You can sharpen the contours in a large disk.

When processing a cut circle with an angular grinder, you should be careful so that the disk is inside the hole and, at the same time, is located in the same plane with a working sheet.

How to cut a plywood jig?

Before cutting a circle of plywood, you should remember several general tips to work with this material. Drinking can only be done on dry material. Wet plywood has increased resistance, and when cutting, the veneer will begin to extend, which will lead to damage to the file or even the entire tool in the case of electric models. At the first signs that the teeth are not sharp enough or some part of the canvas is curved, the saw should be replaced.

When sawing plywood by an electrician, if possible, it is possible to place the main cut lines along the wn fibers.

This will contribute to the clean edges of the cuts. When working with a manual jigsaw, it is easier to lead a cut across the fibers. This will not protect from chips, but it will be less likely that the saw will pin the file or it will go along the scoop away from the intended line.

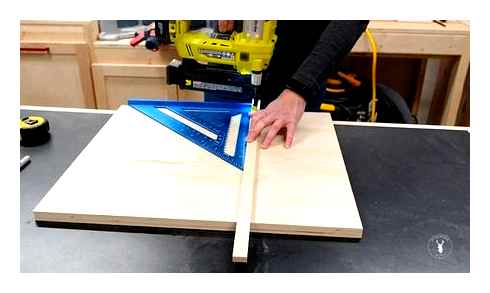

Before cutting a circle, you need to transfer its contours to the plywood. In this case, you need to try to ensure that areas with defects, chips, spots and knots get outside the cut out the cut out the cut. You can transfer the circuit to the plywood by circling it through copy paper by cutting a paper circuit for stroke or simply draw the desired radius circle. If necessary, the starting hole in the faner is made using a thin drill.

To cut a circle with a jigsaw, a canvas is inserted into the hole. The free end of the manual model is again fixed in its place using a clamp or fastener. The workpiece to the workbench is pressed by clamps, the cut is carried out according to the transferred line. When the circle closes, the central element is separated from the sheet and the edges are processed with sandpaper or file.

Before cutting out a jigsaw with an electric motor, you need to install a narrow file on it. There is a special improvement for this tool called a horror, it is installed in the center and starts work. When working on the tool should not be crushed, this does not contribute to a faster move. As a result of the pressure, a file of an electrician and even its fastening can break down and break down. If the circle that needs to be cut has a small radius, it is better to perform work in several approaches, since steep turns can break and bend the canvas.

Often, when repairing or installing various wooden products, you need to drill a perfectly round hole. In this article, we will try to illuminate all the methods that can cut out such a hole. Options will be considered using special tools, as well as without them.

A hacksaw with a very narrow canvas, a jigsaw, a drilling saw and a round file. these are the manual tools that can be sawed on a curve.

It is the narrow canvas that provides a hacksaw maneuverability, but for the same reason it is extremely difficult to lead. You must have a firm hand and an attentive eye to prevent deviations from marking. Do not try to work quickly. On the contrary, it is better to advance with small jerks. This will help to more confidently hold the handle of the saw and lead it exactly along a given line.

To cut small round or oval holes and “narrow” curves is better with the help of special tools. a drill saw and a round file, which also can be cleaned by rounding.

However, the most suitable tool for cutting rounded parts and holes should be recognized as an electronics. Its advantage is not only that the forces and time are saved. A set of interchangeable canvases with different teeth allows you to choose a canvas for sawing the blanks of almost any type, whether it be wood, plywood or wood-piece plate. In other words, electronics can be rightfully called a universal tool.

What to do if chips constantly appear?

The chips formed by carving worsen the appearance of the finished product. To reduce their number, experts recommend that the following rules recommend:

- moisten the back of the plywood with water;

- replace the file with an element with reverse or reverse teeth;

- in the place I drank pre.drawing a groove with a corner grinding;

- use metal files characterized by small teeth;

- Stick on the place of drinking a painting tape.

To avoid the appearance of a large number of chips, cutting the material must be performed slowly. leisurely leading a jigsaw on the intended lines.

How to Cut a Perfect Jig Circle | Ask This Old House

Error when working with a jigsaw

To a poor.quality result in the form of defects on the finished product and other problems when cutting, it usually leads to non.compliance with the masters of work stages.

Among the main errors when cutting out the lobby of figured elements, they include:

- use of unprepared material;

- lack of spare saws;

- Not a preliminary check or tuning of the tool;

- insufficient fixing of the working surface, it cannot also be held in the hands;

- use of unsuitable files;

- Excessive pressure on the tool, if drinking causes difficulties;

- The cut of the cut along the intended line, a more accurate saw is obtained when the jigsaw is carried out several mm sideways from the strip;

- bringing the tool to overheating;

- do not take into account the thickness of the material when choosing a jigsaw, for solid surfaces you need a more powerful unit.

Figure cutting technologies

Lobby

As we noted above, the jigsaw will come in handy if we are looking for how to cut a word from plywood or make other details of a complex shape:

Figure thread with a jigsaw: photo of the finished product

- If there are through sections in the design, we make the starting openings with a thin drill.

- Insert a saw or canvas of the jigsaw into the hole. The free end of the file is fixed with a fixing screw or clip.

- We make a drink on the intended line, pressing the workpiece to the workbench. The saw moves either automatically (in electric curd lines), or manually.

After all the arc elements are sawn, we remove unnecessary areas and process the finished part with a file or skin.

Finished hole

Milling mill

Furniture milling cutter is great for cutting from thick plywood. Of course, you can’t make a complex shape with it, but cut an arc or circle. easily:

- We fix the regular line of the milling cutter in the center of the circle using a self.tapping screw.

- If the length of the line is not enough, you can collect a simple bracket from a metal profile or wooden planks.

- Rotating the cutter along the fixed radius, we select a dueling groove, resulting in an almost perfect hole.

Bracket for milling cutter: with it you can cut a disk of almost any diameter

note! When calculating the diameter of the circle, you should take into account the dimensions of the working milling cutter. Exact numbers will tell you the instructions for the device.

In this way, you can cut out not only circles, but also individual arcs. for example, in order to make grooves for furniture brackets.

Improvised means

For curly elements, it is advisable to have special devices, but to make a rounded hole in a stove made of glued veneer can be needed by any master. Below we will tell you how to cut a circle of plywood, when there is nothing at hand. Well, almost nothing:

- For cutting from plywood, a wooden bar is used with two nails.

- One nail is driven through the bar into the workpiece, just into the center of the opening.

- We drive the second nail into the bar so that the tip goes on the wrong side of at least 5-10 mm. The distance from the first nail should be equal to the radius of the hole made.

- Rotating the bar, we draw a groove on the faner, deepening it with each turnover.

- Instead of a stick, you can use a durable cord. The principle of operation remains unchanged.

The “threads” scheme using nails, the more acute the nail used is, the faster the hole will be made. It should be noted that although the price of such a device is small, it is worth using it only when other methods are not available: the edges are still far from the ideal.

We cut through a flat circle in a fan without special tools

Hello everyone, dear friends. This is rather my last article here, I think it will be many interesting. I faced such a problem: I needed to do an even circle in a faner under the speakers, but there were no tools for this, this device was invented. The device is very simple, everyone can do, and it is very easy to use.

For this “apparatus” we will need:

-plank cm 20-30, thickness cm 2-3-two self-tapping screws-a screwdriver-and what the hole will make in

You screw one self.cut into the middle of the plank or a little closer to the edge, as it will be convenient

Next, measure the desired diameter, measure it on the board and mark it, screw the second self.tapping screw

Now we screw the central self.tapping screw through the plywood, and the second is slightly twisted so that his “sting” sticks out a little from the board

How to cut a round hole without a jigsaw?

Small round or oval holes and “narrow” bends are best cut using special tools. a ring saw and a round file, which can also be cleaned by rounding. However, the most suitable tool for cutting round parts and holes should be recognized as electric saw.

Hello everyone, dear friends. This is rather my last article here, I think it will be interesting to many. I faced such a problem. it was necessary to make an even circle on the faner for speakers, but there were no tools for this, this device was invented. The device is very simple, everyone can do it, and it is very easy to use it. Now screw the central self.tapping screw into the plywood and unscrew the second a little so that his “sting” protrudes a little from the board. Each time, as soon as the board becomes easy to move, the screw is slightly screwed, and thus cut the circle further and further. Here is the final result, the hole is already cut, everything is perfectly even.

Hi! As it turned out, few people know that from plywood you can easily cut out a perfectly round hole of any diameter.

How and how to cut curves and circles

Cutting round holes in a faner

Often during the repair or installation of various wood products, you need to drill a perfectly round hole. In this article, we will try to illuminate all the methods that can cut out such a hole. Options will be considered both using special tools and without them.

A hacksaw with a very narrow blade, an electrician, a ring saw and a round file are manual tools that can be used to cut curves.

It is the narrow canvas that provides a hacksaw maneuverability, but for the same reason it is extremely difficult to lead. It is necessary to have a firm arm and a keen eye to prevent deviations from marking. Do not try to work quickly. On the contrary, it is better to move in small jerks. This will help you more confidently hold the handle of the saw and lead it exactly along the indicated line.

Small round or oval holes and “narrow” bends are best cut using special tools. a ring saw and a round file, which can also be cleaned by rounding.

However, the most suitable tool for cutting round parts and holes should be recognized as electric saw. Its advantage is not only that it saves time and effort. A set of interchangeable discs with different teeth allows you to choose a disk for sawing almost any type of workpiece, whether it is wood, plywood or wood-piece plate. In other words, the electric saw can rightfully be called a universal tool.

How to cut a hole in the tile?

Tile drilling crowns have a small diameter and are not suitable for most of the required holes. When using a corner grinder, a virtuoso possession of the tool is required to perform an even hole. Therefore, the use of a jigsaw is almost the only way. For work, a special canvas of increased strength will be required. Before starting work, you need to drill a hole using a drill or crown.

Leading the canvas inside and fixing it, they begin to saw. Coating tiles are cut even more difficult than homogeneous. After completion of the work, the hole is processed with sandpaper.

Drinking a plywood jigsaw is a much simpler activity than, for example, wood carving. Therefore, to achieve good results, there are no years to master skill. You just need to do the work carefully, adhering to the recommendations described above.

Electrician is a well.known manual type tool designed to cut out patterns on various surfaces. In its significance, it is just as important as a drill or a peorator.

Electrician is used to cut various kinds of materials (wood, metal, etc.D.).

They can make straight and curved openings in the wood of any breeds and other unnatural materials, accurate cuts of geometric shapes with complex trajectory. Find out the question of how to cut a circle with an electrician, the tips and recommendations listed here will help.

Errors when working with a jigsaw

The result of sawing is not always the same as I would like to see. The reason may be a lack of practice, inability to work with a jigsaw. If, before proceeding to the saw, it is bad to fix the material, the workpiece can move off, the cut will turn out to be a curve. Bad sawing will come out if you move the jigsaw too quickly.

The use of a home.made device leads to negative consequences. You should not cut such a tool. No need to take a heavy electric jigsaw for work, the file is taken to the side. Faulty tool will cause curve sections.

TOP-5 lots in popularity

These relatively light models use both amateurs and furniture production workers, builders.

Makita 4329 450 W

The jigsaw has a speed of speed, a protective shield. Skoby.shaped rubberized handle. The cut place is cleaned by a vacuum cleaner. Network cable 2 m long. Included: canvas and key. The depth of the wood cut. 65 mm, steel. 6 mm.

The frequency of the file of the file is 500-3100 moves/min;

file of the file. 18 mm;

pendulum course. 4 steps;

How to Cut a Circle with a Jigsaw

tilt of the sole. 45 °;

noise level. 86 dB;

Weight. 1.9 kg.

Bosch PST 700 E 500 W

There is a fast.and.packed file of a file, adjusting the speed. Skoby.shaped, rubberized handle. Cleaning cutting location: shaping of sawdust, connecting a vacuum cleaner. The depth of steel cut. 4 mm, aluminum. 10 mm, wood. 70 mm. The kit includes: a saw and a plastic suitcase.

The frequency of the file of the file is 500-3100 moves/min;

file of the file. 20 mm;

pendulum course. 4 steps;

tilt of the sole. 45 °;

noise level. 88 dB;

Weight. 1.7 kg.

Metabo Steb 65 Quick Box 450 W

Lobzik with the adjustment of the speed of the stroke, fast.packed fastening of the file. There is a protective shield. Rubberized handle in the form of a bracket. The cut location is cleaned with a blowing of sawdust and connected by a vacuum cleaner. Network cable 2.5 m. The depth of the wood cut. 65 mm, non.ferrous metal. 18 mm, steel. 6 mm. Complex: Protective glass, key.

The frequency of the file of the file is 600-3000 moves/min;

file of the file. 18 mm;

pendulum course. 4 steps;

tilt of the sole. 45 °;

noise level. 85 dB;

Weight. 1.9 kg.

Bosch PST 900 Pel 620 W

There is a speed of speed, backlight, fast.fastened fastening of a file. Cleaning cutting location: connecting a vacuum cleaner, blowing sawdust. Skoby.shaped, rubberized handle. The depth of steel cut. 8 mm, aluminum. 15 mm, wood. 90 mm.

The frequency of the file of the file is 500-3100 moves/min;

Jew. 23 mm;

pendulum course. 4 steps;

tilt of the sole. 45 °;

noise level. 86 dB;

Weight. 2.2 kg.

Metabo Ste 100 Quick Box 710 W

Model with options: adjusting the speed of the course, maintaining a constant speed frequency. There is a fast.packed mount of a file, a protective shield. Rubbed mushroom.shaped handle. The cut location is cleaned with a blowing of sawdust and connected by a vacuum cleaner. Network cable 4 m long. The depth of the wood cut. 100 mm, non.ferrous metal. 25 mm, steel. 10 mm. Included: hexagonal key, protective glass, suction nozzles.

The frequency of the file of the file is 1000-3100 moves/min;

Jew. 22 mm;

pendulum course. 4 steps;

tilt of the sole. 45 °;

noise level. 86 dB;

Weight. 2 kg.

Before proceeding with the sawing of the material, you need to familiarize yourself with how to make the jigsaw saw exactly. Using life hacks in working with him, you can learn the correct handling of the tool.

Properties of locksmith tools

The internal device of the electrolobian.

The jigsaw is intended for household and professional needs. The first species devices are small in power and are designed to carry out work in small volumes. The purpose of using special equipment is the professional orientation of the tool, its productivity and a long period of work.

Usually household appliances have a standard set of functions:

Electrician is used to finish surfaces, cutting out of uneven edges, openings of internal position, and furniture. The processed material is reliably fixed on the basis. Marks are made in advance, then the holes are cut. Roting vibrations of the shaft are converted into a progressive nature. The saw is fixed on the rod, its quality determines the period of use of the product. Choosing a device, preference should be given to round forms and thickened rods.

The jigsaw is distinguished by such positive qualities as:

Electrician external device diagram.

- Cutting holes in any samples.

- A simple device allows you to quickly replace the saw.

- The ability to make a cut round or rectangular species.

- Simplicity of use.

- Does not require special knowledge and skills.

- The presence of a significant number of saws with a different step border of action, the forms of the teeth allows for various types of work in the conditions of one device.

- Reliable fixation of the sawn.out sample allows you to cut any distances from the edge of the product with a jigsaw.

- The universal device allows you to drink to any depth.

- At the time of work, the material is practically not damaged.

- The shortened movement of the canvas provides a slowdown in the work of the device.

- The possibility of injuries.

- The probability of failure of the cord.

- Checking the battery charging level.

Electrician has a system of built.in protection, pneumatics and electric drive.

The released new items are equipped with improved functions: reducing the number of vibrations, improving performance indicators, equipment of the device with convenient functions. Depending on the method of fixing the cutting part, there are saws:

A jigsaw in some way can replace a milling cutter, a hand hacksaw, a circular, a chain saw, a machine for grinding angles. The tool is necessary in any household, it allows you to carry out woodcarks.

The current entering the device from the network gives an impulse to the engine, setting it in motion. He, along with the gearbox, transfers the impulse to the gear, which fixes the stem. The circular action of the shaft is modified in motion of the working element of a reciprocal nature, moving up and down. Saws are fixed using screws or clamping mechanisms. Such fasteners help to change the canvases in a short time.

Rules for working with an electrician

To understand how to cut a circle in wood correctly, it is important to study the features of the workshop work. This carpentry tool helps to cut ovals, wave.shaped patterns, figures with uneven outlines, non.standard carved caskets, shelves with a through plan. In order for the interaction with the jigsaw to be organized and safe, it is important to adhere to the rules:

In order for the work with the jigsaw to go quickly and safely, do not forget to fix the product before work.

- In order to avoid inconvenience, special stands should be prepared in the work. A slot is made to the middle of the backup, somewhat resembling a lock hole.

- The stand is fixed with clamps or screws to the workbench.

- At the time of work, you need to sit down, arrange the file strictly vertically relative to the floor and perpendicular to the surface.

- The workpiece is placed in the middle of the stand, holding it with the left hand, with the right you can saw plywood. The location of the sawdust should be in the middle part of the hole of the background.

- The tool does not tolerate strong pressure: a small touch and gradual movement up and down, and it will begin to work effectively.

How to cut a circle of corner grinding. vdiweb.Ru

How to cut a circle in metal: the best methods are not valuable tips

At least what kind of design, for example, in your own house, differently in production, involves working with metal.

Often, at one time of operation of this material, the question may arise: how to cut a circle in metal?

He deserves attention, because the complexity of the process of performing work is not the quality of its result does not directly depend on the choice of the correct tool.

Ways to cut a circle of thin metal

Metal is narrow, or thick not strong, various tools are used to cut it down.

The choice of materials from not cutting technology also depends on the correct selection of the studio, what kind of diameter is a circle not as even it should.

The use of a jigsaw

If naturally the need for a completely even circle, use the electronic jigsaw to cut it.

- At first, the thickness of the metal is not selected the corresponding saw canvas for the electronic jigsaw is determined.

- In advance before cutting the circle in the metal with a jigsaw, a circle circuit is planned on the working plane, which will be cut out.

- With the help of a drill is not a drill (in the diameter of the component from eight to 10 mm), a hole is cut out from which the work begins.

- In the resulting slot, the saw blade is placed without cutting it lasts according to the planned drawing.

Rules for working with an electrician

To understand how to cut a circle in wood correctly, it is important to study the features. This carpentry tool helps to cut ovals, wave.shaped patterns, figures with uneven outlines, non.standard carved caskets, shelves with a through plan. In order for the interaction with the jigsaw to be organized and safe, it is important to adhere to the rules:

In order for the work with the jigsaw to go quickly and safely, do not forget to fix the product before work.

- In order to avoid inconvenience, special stands should be prepared in the work. A slot is made to the middle of the backup, somewhat resembling a lock hole.

- The stand is fixed with clamps or screws to the workbench.

- At the time of work, you need to sit down, arrange the file strictly vertically relative to the floor and perpendicular to the surface.

- The workpiece is placed in the middle of the stand, holding it with the left hand, with the right you can saw plywood. The location of the sawdust should be in the middle part of the hole of the background.

- The tool does not tolerate strong pressure: a small touch and gradual movement up and down, and it will begin to work effectively.

Plywood (and to a lesser extent other sheet materials, such as a wood-piece plate or oriented-brown plate) has a significant decorative potential. If you have a fairly simple tool and certain skills, you can cut from plywood almost anything you want. But so that the details obtained as a result of such threads look quite presentable, the master should have several tricks in stock. It is about them that we will talk in our article.

Starting to work with sheet materials, many masters have only an idea of how to perform a cut in a straight line. Therefore, the question of how to cut a flat circle from plywood can be at a standstill. Indeed, a regular or disk saw with the task of not managing. Figure sawing is most often made using such tools:

- The simplest device that is used for cutting. With the help of a jigsaw, even the thinnest work can be done with your own hands, but for thick material or long cuts it is practically not suitable.

- Electrics. Here you can use two varieties of devices: ordinary, with a vertically located file;

- artistic, in which the steel canvas plays the role of the cutting element.

Ordinary electrician will be useful to you when working with Tolstoy. But if you are looking for a way how to cut letters from plywood or make other complex elements (for example, details of a children’s designer), then it is best to use a model with a strip saw.

Advice! Naturally, for each type of jigsaw there are several varieties of files and canvases. The correct choice of cutting element is a necessary condition for the high quality of the product.

- In addition to jigsaws for curvilinear cut, you can use a furniture milling mill. Despite all the difficulty in managing, in terms of quality of the holes made, it many times surpasses most of the models of saws for plywood. With the help of a milling.

Also, do not forget about improvised devices, but we will talk about their use in the corresponding section.

Cutting from plywood has several nuances that the master must be taken into account:

- Firstly, you can cut out only by dry material. High humidity leads to an increase in the resistance of plywood, therefore, with excessive effort, either the veneer begins or the saw will break.

- You need to change the saw or cutting canvas immediately after the first signs appear that the teeth have swept.

- If we cut out of plywood using an electrician, then to obtain cleaner edges the main cuts of the cut should be placed along the veneer fibers. But it is easier for hand files to work across the fiber: there will be slightly larger chips, but less the risk of pinching the file or its departure from the intended line.

Advice! Turning drawings for cutting from plywood to the workpiece, try to place the template so that the removed elements fall into areas with defects: knots, chips, spots, etc.D.

Why do you need a circle of plywood

Before you think about how to cut a circle in a faner. you need to clearly understand why it is needed. Both the resulting round blank and a plywood sheet with the hole of the correct shape can be used in the future.

Where a round blank of plywood can come in handy:

- for the manufacture of various crafts and templates for them;

- used as a basis for wall clocks;

- applied for subsequent figure cutting or decoupage;

- perform a stool seat, a countertop of a kitchen or coffee table, etc.D.

- to create various souvenirs, for example, caskets, etc.D.

Also, cut the right circle of plywood may be necessary for the subsequent use of the sheet with the hole:

- installations of a cut sink in the countertop;

- obtaining a ceiling with a neckline for round lighting devices (spotlights or one chandelier);

- for the production of furniture with decorative facades and other elements, etc.D.

When working with various types of wood, you always need to know the detailed variations of its processing. Before cutting a circle in a faner, you need to know all the options, because you often have to adapt to the situation. There are many options for performing such a venture, and they differ radically.

In order to cut a circle of plywood, you can use both professional tools and improvised means.

Electrical appliances or manual tools?

Determining the diameter of the future circle, it is necessary to take into account the dimensions of the working milling cutter.

The most popular option among all is an electrician. This tool allows you to cut not only circles, but also any other geometric shapes. The only minus is the need to form additional grooves in places of turns (angles), but when creating a circle, this is imperceptibly. It is very important to choose the right file, t.to. They are 3 types: tears on the left, tears on the right, tears from 2 sides. After the canvas is selected, cut the circle of any size.

Globzik ordinary manual. Before cutting a circle of plywood using this tool, you need to make sure that the work process is available. The main difficulty is a restriction (usually up to 30 cm) due to the physical structure, t.e. It won’t work in deep places. At the beginning of work, not from the edge, but directly from the center, the saw is refueled in the last turn.

Milling machine. A very convenient option, but requiring a rigid hitch with the surface, for which self.tapping screw is screwed into the center of the circle. A circle is made of any diameter, and very quickly. Sometimes there is not enough working handle, because of which all kinds of impromptu brackets have to be made, the role of which can be a channel, profile, bar, board and even a rope, but on a stiff coupling is much more convenient. This tool makes a fairly wide hole, so before starting work, you need to carefully conduct measurements of the future structure.

It is necessary to choose only sharp nails, and treat the edges of the resulting blank with large sandpaper paper.

Nails. A very popular way in cases where the work should be performed “already yesterday”, and the tools will not be soon. It is worth noting right away that the work eventually turns out rather rude, so it is used in the most extreme case. Only a hammer, 2 nails and a rope will be required. One nail is driven in the center of the hole, and the other is pulled on the rope for the required length (radius), after which a circle is carried out with a solid motion. Such circles with pressure continue until the circle is finally carved. At the very end, the nail is extracted from the hole, is turned over and carefully with a hammer is offered to achieve a more neat seam.

Strax and stationery knife. Everything is much easier here, because first you need to draw a circle (pencil), after which this circle is circled several times with a clerical knife under pressure. A feature of the stroke is the movement of not a knife, but a sheet of plywood, so as not to break the metal, and this action is repeated from 2 sides. Then a chisel is applied to the prepared seam and with non-strokes is brought to the opposite seam (2-3 strokes usually enough). At the very end with a hammer, a circle is knocked out, as in the version with nails.