How to cut a decking board from wood-polymer composite

How to cut a board of wood-polymer composite along. Installation of terrace decking

Decking – Decking made of wood-polymer composite, a modern flooring material. Decking is mainly used in the construction of outdoor terraces, which are becoming increasingly popular among owners of country houses. The terrace serves to connect the external environment of the site with the living space of the house. It allows you to be outside the walls of the building in the fresh air, but at the same time spend time with the comfort of home. A patio can be used to connect a pond or hillside to the garden area. Modern building technology makes it relatively easy to extend and heighten terraces, and to integrate them into any complex landscapes. Besides this material is widely used in construction of: verandahs, arbours, piers, jetties, decks. Often decking is used together with decorative fences of wood-polymer composite, as a rule, this is done in arrangement of grounds near swimming pools, children’s playgrounds, garden paths and bridges, patio areas. In general the decking from wood-plastic composite is an ideal variant everywhere if you need a stable, moisture proof, safe and ecological material which combines wood and plastic.The decking is made by extrusion of wood flour 60 % and polymers 40 % under high temperature. The board is dyed completely to the depth of the material and fade naturally over time without losing its primary color, that is, the decking of the wood-polymer composite over time there is a natural stabilization of color, just like in products made of wood. The decking from wood-plastic composite has a number of advantages in comparison with an ordinary wooden board. The products from the wood-polymer composite are not exposed to rotting, shrinkage and shrinkage, resistant to mechanical effect, temperature difference, sharp seasonal changes and increased humidity, which allows to use the material under severe weather conditions. Biopersistence is achieved by using special polymers in the composition of the decking, making it impervious to mold, fungi, bacteria and insects. The decking from wood-polymer composite can be cut, sawn, drilled, screwed with self-tapping screws. For the assembly of the decking we recommend to use the usual joinery tools. High-tech decking has a natural appearance and retains its original geometry, strength properties and smooth coloration for a long time, the material does not create additional maintenance worries for the decking.

Characterized by high hardness: to cut it with ordinary discs for larch, of course, will get, but the process may take a little longer. Normal, familiar to us, wood does not have the same hardness and resilience.

For successful slicing. wood-polymer composite lag. To trim the composite steps and other products the corresponding tool accessories are used.

It should be noted that the wood-polymer composite is processed mechanically approximately the same way as the wood that we are accustomed to. It can be sawn (cut) to the desired length, drilling holes in the board for installation. Some even manage to saw out of the solid wood-polymer composite board unusual figures. But now we are not talking about the masters of their craft.

For working with decking boards and composite planks you will be fine:

- A circular saw for cutting PVC or chipboard,

- Saws with blades with fine teeth,

- Carbide discs,

- Drill,

- Tungsten carbide drill bits,

- Electric screwdriver,

- Screwdriver,

- Level,

- Hammer,

- A tape measure,

- Pencil or construction chalk.

All of the above tools are available to almost everyone who has already built a country house and is now engaged in the improvement of their plot. As mentioned above, the most important thing is to. choose appropriate cutting discs and drills.

When starting the installation work, you first need to cut the beams for the supporting structure. If you are using joists made of wood-polymer composite, as recommended by the manufacturers, all the holes are drilled in advance. Mark the points on the lag where you need to make a mounting hole, use a drill. it is better not to use an electric screwdriver for this purpose, even if it is very powerful: there is a risk of overheating the device or breaking it at all.

Then the beams should be laid and fastened, having previously checked the slope with a construction level. Do not forget that the decking. Especially in open areas, be sure to lay with a slight slope. 1-2 °. Excess moisture will run off the terrace, and puddles will not form on the board.

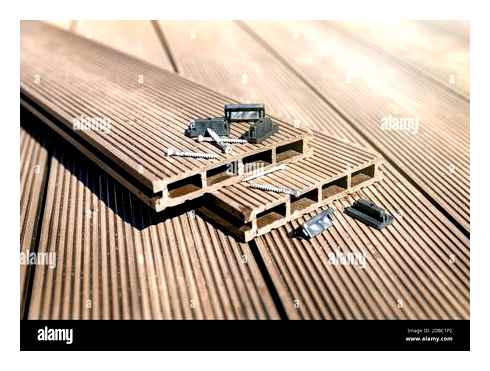

The installation of the decking made of wood-polymer composite is not complicated thanks to the special fasteners. clips. You will need an electric screwdriver to fix the clip with a self-tapping screw in the lag. Remember that the screw is screwed in not to a full stop: too tight fastening can have a negative impact on the “behavior” of the clip and the board during thermal expansion. But also the fastener should not dangle, otherwise the boards will wobble.

Sometimes full-body decking made of wood-polymer composite. bamboo or ipe is mounted to the joists with self-tapping screws directly. In order to facilitate this process, professional installers make holes in boards and planks beforehand. Here is a little trick: the holes should be made with a diameter slightly smaller than the diameter of the screw. So it does not violate the tightness of fastening, and the installation process is faster.

The appearance of decking on modern market of construction materials has made it possible to assemble indoor and outdoor foundation, which by its characteristics is not inferior to any known floor covering. With the seeming simplicity of the installation of decking. not the most simple process. Although if you understand the technology of installation, to understand all the nuances of the processes, even a novice will cope with it. Therefore, in this article we will consider the types of this building material and the technology of its installation.

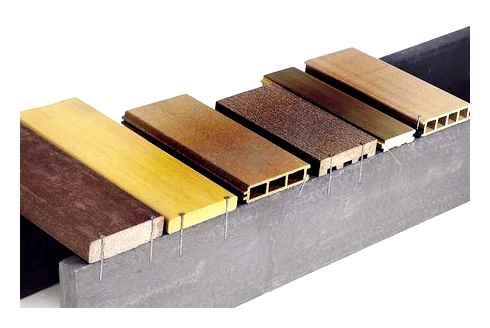

Decking, also known as decking, is the slats of certain sizes. They are made of two raw materials.

Solid wood

Various sorts of wood are used for this: traditional and exotic. Processing of boards. two kinds: smooth (called planken), corrugated (called corduroy). The sizes of the decking. a wide variety, where the length varies between 1.5-4 m, width 100-200 mm, thickness 20-30 mm.

The technology of installation of decking

Let’s proceed directly to the dismantling of the installation of the decking. Like all construction processes it is divided into two main stages: preparation and material laying with fastening to the base.

Preparation

The preparation includes construction of reliable and even base. There are several variants, but more often the decking is installed on a concrete base. It should not only be flat and solid, but also dry. If the decking is built on the ground, in this case, too, you need to take care of the strength of the base under the laid beams. Concrete products can be used for this: paving slabs, blocks, and so on, which can be laid under the terrace.

Regarding the preparation of tools. The following steps are required for mounting the decking:

Attention! If the building from the decking is collected in the open air, you need to take care that the concrete base has a slight slope to drainage of atmospheric precipitation. If you’re assembling on the ground, you should make some grooves 3 cm wide and 2 cm deep under the flooring.

Planning

An important stage that affects the appearance of the flooring and its reliability. What you need to pay attention to:

- The spacing between the beams: 40 cm for hollow planks, 50 cm for solid planks.

- The gap between the parts of the flooring: 1-3 mm for indoor use, 4 mm for outdoor.

- If the decking is laid diagonally, the distance between the beams is reduced: at an angle of 45° in the range of 25-30 cm, at an angle of 30°. 15-20 cm.

Let’s proceed directly to the construction of decking on the terrace from the decking. Consider the installation of boards from the wood-polymer composite, because this process requires certain skills and the use of special fasteners.

What is a decking

the name suggests that this material is used to form a floor on outdoor terraces. But country house owners, architects and landscape designers have not stopped it. The material was in fact so strong, durable and reliable that it was used almost everywhere it could be. Namely: cover for garden paths, playgrounds, lots near swimming pools, piers on lakes and rivers and so on.

The reason for the appearance of decking was the short life of the flooring of outdoor verandas and terraces, which were built from conventional wooden planks, even additionally treated. Under the stresses of nature, wood quickly failed. Therefore, developers had to look for a material that would be all of the above loads could withstand throughout its lifetime. And this material was invented. It is a composite based on sawdust and polymer.

The wood-polymer composite perfectly copes not only with the sun’s rays, atmospheric precipitation, temperature and humidity fluctuations, but also easily withstands quite serious mechanical loads. That’s why the garden paths made of wood-polymer composite last for decades.

Now about the distinctive features of decking.

- Usually terrace construction is built in combination with supporting elements. Here too, the thickness of the subfloor plays an important role. The thicker it is, the greater the distance between the beams or joists, which reduces the cost of construction as a whole. That’s why the decking made of wood-polymer composite is produced with a thickness of 50 mm. That is the best size.

- As this material is used outdoors, a gap is left between the elements during installation so that water can pass through it. That’s why you won’t find a tongue and groove joint in a plank design. It has only grooves, used for concealed fixing.

- On both sides of the board are made longitudinal grooves 1-2 mm deep. On the front side they have an anti-slip function. On the reverse side with their help to relieve stresses that appear with changes in humidity and temperature. But there are models with a flat face.

And one more thing. This material was invented in America, and it is there that it is called decking. This is the same name used in Europe. In Russia it has not caught on, but the terrace board has proven to be a familiar name to Russians.

The quality of decking

Today manufacturers offer several varieties of wood-polymer composite material. They differ from each other in the proportions of the components added. It should be noted that as a wood filler can be used wood flour or sawdust. If the first is used and its volume of wood-polymer composite more than 45%, then such material can not be attributed to the “moisture-resistant”. Flour absorbs moisture, which makes the boards start to swell. But there is such a variety on the market. It is cheap, and it is better to use it indoors. Some designers use this type of decking for walls and ceilings.

Composite, which contains sawdust, the ideal modification. It is durable, with high wear resistance characteristics. These boards are used on outdoor terraces, squares and walkways.

Either polyvinyl chloride (PVC) or polyethylene is added as a polymer. The first substance gives boards more technical characteristics, but the finished product is more expensive. The second is easier to produce. In terms of technical and operational qualities, it is worse than the first, but it is almost two times cheaper.

There is another criterion to consider when choosing decking for paths on the site. It is a solid board or hollow board. The first is more expensive, but with high strength characteristics and carrying capacity. For paths in the garden it is not necessary. Here perfectly cope with the duties of the second option.

According to the method of installation, this material is divided into seamless and seamless. In the first case, to secure the use of metal or plastic klyaymmera, in the second. self-tapping screws with round head.

Choosing boards made of wood-polymer composite, you should additionally pay attention to the number of ribs and the thickness of the walls. The more these two parameters, the more durable the product.

Wooden decking

It should be noted that in the category of “decking boards” can be attributed material made of wood. Such boards are also called deck boards. They undergo special treatment, so they are sufficiently strong, resistant to wear and moisture. But it should be noted that the paths made of composite boards belong to the category “laid and forgot”. That is, during a long time of use they will not need to process, repair, change, and so on. This will not work with wooden boards. Every year such decking will have to be treated with antiseptics, flame retardants, wax or other protective agent.

However, there are species of wood in the group of deck boards, which are quite good outdoors. Here are just three of these varieties:

- Larch. The antiseptic-treated larch doesn’t rot, doesn’t warp, and it tends to tan from water, becoming even stronger. Over time, this wood does not lose its color and texture, is inert to salts and alkalis, easily endures mechanical stress.

- Exotic species: Kempes, Iroquois, Membau. Beautiful structure, resists water well, doesn’t rot or warp with time.

- Today on the market there are traditional types of wood, of which terrace boards are made. This is ash, birch, walnut, cedar, which are subjected to temperature heating to 100-240C. Such material specialists call thermo-wood. After the passage of heating wood becomes durable, moisture-resistant and wear-resistant. Its color changes accordingly.

So, let’s move on to the question of how to make paths on the dacha from decking. To begin with, this material is laid only on the frame. That is why it should be built in the first place. The easiest way to do it:

- At the site of the construction of the path is drawn its shape and size (mainly it concerns the width). The optimal width of 80-100 cm.

- Every 2 meters along the length, on each side of the markings holes are dug to a depth of 20-30 cm. If the walkway has a curved shape, in the places of bending or turning holes are dug regardless of the pitch. Holes are dug in pairs, that is, in one place on each side of the path.

- The sand is poured in there and tamped down until it stops. The main task is to create a sand layer flush with the ground.

- In each prepared hole, filled with sand, one paving tile made of concrete mortar is laid. Tile sizes: 30x30x3 cm. Install the paired tiles at the same level and height.

- Now form the supporting beams, on which the decking will be installed. For this use a bar section of 100×100 mm, which is pre-treated with antiseptic composition.

- Note that the bars are jointed only on the concrete slabs. The connection is carried out by metal plates and screws. The width of the plates. 10 cm. The number of screws to be screwed in is two in each support beam.

So, the frame is assembled. It remains only to lay the wood-polymer composite coating. For example, the assembly will be carried out in the seam method. The first board is attached to the substrate on one side with two self-tapping screws into each carrier beam. Some manufacturers offer so-called starter fasteners, which are small claymores. On the other side of the boards with a self-drilling screw attach a double-sided claymaker. Put one end into the groove of the board, and then tighten it with a self-tapping screw, but not all the way through. Lay a second piece of coverage, put the second free end of the claymeter in the groove. And now the fastening screw is screwed all the way in. And this is how the entire path is assembled.

The last step is to close the ends of the laid boards of the wood-polymer composite. To do this, use a special finishing trim, which should buy, as an element of equipment. It is simply put on the ends of the flooring. There is no need to fix it.

The subtleties of assembling a decking

There are a few nuances, which affects the quality of the final result:

- Protrude wood-polymer boards beyond the base bars can only by a distance of no more than 2 cm.

- Screw self-tapping screws into them without pre-drilling the hole can not. In this case the hole is drilled with a drill, the diameter of which should be slightly larger than the diameter of the screw used, but smaller than the diameter of its head.

- Manufacturers offer ready-made beams made of wood-polymer composite, which are many times better than wooden beams. But they are light, so you have to think about how to attach them to the ground or paving slabs. Although for garden paths is optimal to install a wooden heavy bar, which will stand firmly in one place. The more connected boards.

- When the curves of the garden path boards are laid with a large gap is in places of great roundness, thereby creating a bend in the construction.

It is better to install the wood-polymer composite decking on the joists from the same wood-polymer composite Source com

Basic types

The technology of production of decking and its base can vary significantly. Manufacturers offer products with smooth surface, as well as having a texture in the form of a scarf and velvet. Products with a textured surface have a rectangular and beveled profile.

The latter variety is used as cladding material. With its help, internal and finishing works are carried out, complete or partial cladding of residential buildings, fences, pergolas. The side surfaces of the planken make beveled or rounded. This makes overlapping installation possible, and eliminates the formation of gaps between the elements.

Straight boards have special grooves that make installation work easier. Figuring out how to install the decking with your own hands, it is worth asking for help from professionals. They know exactly how to ensure the correct spatial position and securely fix each panel.

Used for the manufacture of panels allows you to divide the raw material into natural and composite. Each type has its own distinctive features, which should be taken into account when selecting the appropriate option.

Natural Board

Natural wood, primarily larch, is used for making wooden decking. It has these characteristics:

Tip! Given that for the manufacture of decking is used natural wood, some differences in texture and shade are allowed.

Larch is a light-colored wood. To obtain the desired color the material is tinted by applying special compositions to the formed surface.

For improvement of performance characteristics natural decking is exposed to thermal processing. To do so, the wood is hardened for a given period of time at temperatures close to 200 °C. Thermally exposed decking boards:

- Resist moisture better, making it possible to clad surfaces outside the building;

- have good insulating properties;

- have a distinct and organic texture, which improves the appearance and tactile sensation when touching the formed cladding

- do not rot within a long period of time;

- are biologically resistant.

composite boards

In the manufacture of wood-polymer composite use a composition that includes different materials. Prepared components are bonded together with a polymer binder. Most often for the formation of decking used grain starch. To it is added a certain amount of fiberglass, waste pulp industry and other components.

Color and texture of future slats determined at the production stage. For this purpose to the basic material is added a certain amount of dyes, mixed in a given proportion. The size and configuration of the finished panels affects how the plastic decking is fixed.

Preparation stage

To make the finished coating is of high quality and last long enough, should properly prepare the base and the decking to be laid. Preparation of the latter is to promptly deliver the required amount to the place of work. Here it is removed from the packaging and left for 1. 2 days. This time is enough for the material to adapt to local climatic conditions and “rest”.

Next, you need to prepare a rough substrate, pre-deciding how to lay the decking, depending on the type of substrate. Most often the installation is carried out on the joists that are installed on a concrete foundation or directly on the ground.

Installation on the ground begins with the preparation of the base. For this purpose:

- The site is tamped with the use of vibrating equipment;

- A 9-10 cm layer of middle size rubble is poured;

- A 4 to 5 cm layer of sand should be filled in;

- Lay the reinforcement mesh.

Stages of the decking installation

1 Substrate preparation

To do this completely remove the top layer of soil, and form a sand-gravel cushion. The best base is the surface of their concrete. Do not lay the board on the bare soil, grass or sand. Before you start assembling, it is worth making sure that no water is trapped on the base. Be sure to install the beams along the drain, otherwise there must be a gap between them to let the water run off freely.

The lags are placed on the base and fixed with dowels. The spacing between the beams should not exceed 35-45 cm. If the board has a thickness of 19-20 mm, the distance between the joists is 40 cm. If the material has a large thickness, you can allow a distance of 60 cm.

If the surface is uneven, you can install adjustable beams. When installing it is necessary to make a slope at a slight angle, it will allow the water to drain.

2 Assembly of the boards

In order to install the boards, stainless steel brackets are used. Also they are fixed with self-tapping screws. It makes it possible to form a gap of 5-7 mm.

If during the work the board had to be cut, then the open surface is treated with a special wax emulsion. In order to avoid cracking, all the holes are made in advance.

To fix the decking use open or closed method. The second option of mounting decking allows you to make the surface more attractive, and fasteners are strong and more reliable.

When installing it is very important to understand how to mount the decking correctly. If the boards are located where they will be exposed to moisture, during installation, it is worth to leave a gap between them. Take into account the increase and decrease in size as a result of temperature changes and leave a small space between the slats. Also a gap is needed under the decking. Free space will provide ventilation and prevent the formation of mold.

Place the first board at a distance of 15 mm from the edge or wall and fix it firmly. After that, install hidden fasteners and fasten them with self-tapping screws on the board and on the lag. After this, start laying the following boards. The distance between the boards should be at least 4-7 mm. It is controlled with different inserts. The last board is fixed in the same way as the first one.

Peculiarities of work with larch

Before installation, the material should be removed from the packaging to hold for a few days outdoors or under a roof so that it adapts to the humidity of the air. Before you start the work, you should carefully understand how to mount the larch terrace board.

For larch decking, beams of the same material are used. They are installed with the use of special supports, which can be adjusted. All end pieces are treated with special wax-based compounds and the surface is covered with antiseptic. Do not allow the wood to come into contact with the soil. The spacing between the beams must be uniform. All beams are aligned with a level, and ensure that they are parallel with each other. The closer the spacing between the beams, the higher the load bearing capacity of the surface.

4 Assembly of the stairs

A porch from a decking has a presentable appearance, does not need any special care and serves for a long time. For such designs it is best to use a composite board. They do not rub off quickly and are not slippery even when there is water on the floor. Balcony slats have a width of 30 cm and a height of 15 cm. This option is considered the most convenient and ergonomic. If necessary, you can make a construction with other dimensions.

Installing wood-polymer composite decking. what you need for installation?

The key to the success of the installation of the decking of the wood-polymer composite is competent preparation. Of supplies you will need wood-polymer composite decking, in the selection process, pay attention to the ratio of the components, this parameter depends on the performance properties. For use on the territory of our country, taking into account the peculiarities of the climate, it is recommended that the ratio of wood and polymer in the material is approximately 50% to 50%.

Always take extra planks to spare, because some of them can appear faulty and damaged during installation. You can quickly make repairs, and if necessary, to replace the element.

In the work can not do without the composite joists, they are used for the construction of purlins. They can be used for home installation, where the load on the decking is not planned the highest. These elements are evaluated as resistant to negative external factors, for private use they are strong enough.

Beams can be used from different material, but the construction of the decking will last much longer if it is constructed of similar elements. The reason for that are different indicators of temperature expansions in wood and composite.

Do not do without the fasteners, for this purpose are used klyamerov, and if necessary to ensure minimum clearance should use metal clips, they are made of stainless steel. If the size of the gap is not important to you, it is better to give preference to plastic fasteners, so you improve the underfloor ventilation of the terrace of the open type. Fixing the fasteners is carried out using stainless steel self-tapping screws. The elements that are used at the stage of decorative finishing, are end trims, finishing corners.

As for the working tool, then everyone will surely have the necessary tools for work. For example, for sawing boards longitudinally you will need an electric saw. Do not do without a drill, an electric screwdriver, a level, a tape measure, a joiner’s hammer with a rubber head. To make it convenient to use the tool, take care to have an extension cord.

Preparing for installation correctly

Experienced specialists recommend making sure that the surface on which the material is planned to be laid is even. The best option is the cross boards in contact with the elements of the decking along its entire length. It is not recommended to let the surface of the products in contact with construction debris. If you do not have the slightest experience in such work, it is better to trust professionals.

Especially important is the adaptation, preparation and checking of the decking. It needs to be allowed to adapt to the environment, which occurs within 1-2 days. For this purpose, the material is transported to the installation site in advance. Installation works are carried out by at least two people, the air temperature should not be below 0 degrees Celsius. Remember that terraced products can not be the only support, the basis for the balconies / staircases.

It must not be forgotten that

The installation of the decking from the wood-polymer composite must take place with the provision of full ventilation for the complete drying of the space under the flooring. In the products of all manufacturers there are slight differences in color elements. This is due to the presence of wood components.

To ensure that the finished flooring looks good, try to use boards from the same batch in the work. The natural process is to color change during the first few weeks. This occurs under the influence of moisture, ultraviolet light, with the passage of time changes disappear.

As you can see in the photo of laying the decking made of wood-polymer composite there are always striking expansion gaps, namely the longitudinal joints. They are made to quickly drain water from the surface, as well as to take care of it conveniently. The same can be said about slight thermal contraction/expansion in conditions of temperature fluctuations.

You can use one of two ways of installation, this seamless and seamless. To form seams we will need stainless steel clips/plastic clips. The closed method is relevant if the surface is decorated indoors. The appearance of the finished decking will be more attractive, avoiding clogging of the interior space.

Peculiarities of installation of the decking

Saw a decking or decking can be made with a regular hand saw. In these boards will need holes so you can screw in screws. You will need an angle grinder, level and tape measure.

Before you start, you need to prepare the tools and material. Board made of larch should get used to your climate, so after unpacking leave it in the air for a couple of days.

The choice of decking is now very large, you can choose it according to your taste, it should be noted that the price of decking from Holzdorf.com.ua/terrasnaya-doska/holzdorf/ is quite acceptable, with very good quality.

- Before laying, you need to understand, open or closed method will be installed. many details of the work will depend on it. If you choose the open method of installation, the fasteners will be visible.

- You will need screws that have an anti-corrosion coating. Before you start the work, make a marking and drill holes on it, then fasten the boards to the base with screws.

- If the closed method is chosen, the fasteners will be hidden under the flooring, special fasteners will be needed for this. clips. They are similar to metal plates and have an anti-corrosion coating, up to 20 clips per square meter are needed.

The board can be laid diagonally or using the deck method. When installing diagonally, the decking boards are laid parallel to each other and the walls. This way, you will have very few leftover pieces.

A solid base is very important for a successful installation. It can be metal beams, wooden joists or cement screed. The base must be treated and covered with a special material to prevent weeds from sprouting.

Before starting work, a water drainage system must be designed, so that the ground will not swell after the cold weather. It is better to have a slight slope at the base, in the direction where the water will go.

The slope should be up to one centimeter per meter, visually it will be noticeable. Do not allow water to accumulate either on the floor or under the flooring.

The base for installation can be joists made of wood-polymer composite. Lay the boards perpendicular to the joists, the distance between them should be up to 40 cm, and in passing places, they should be laid every 25 cm.

The timber can expand and shrink so leave a gap of a centimeter between the joists. Observe 2 cm from joists to kerbs, walls, fences, pipes and supports. Moisture can accumulate on the flooring, so make a drain for water in advance, it must be done when laying the frame.

Water will drain if you lay the beams parallel to the slope. If this is not possible, make a special water drainage system. Raise the beams slightly and place them on the plastic supports.

Supports can be placed at any angle, relative to the board, in any case, it will not cost you that much, perpendicular to the slope of the runoff leave a gap logs.

If the joists are placed on concrete, the distance between the beams should be up to 40 cm. If you are installing diagonally or have a heavy load on the boards, it should be up to 3.5 cm.

For better ventilation of the structure and flooring lay the beams on plastic or metal supports, so that the ends of the decking polymer boards lay on the frame, place one support beam at each end of the structure, do it very carefully. The framework should be as strong and secure as possible.

Wider joists can be placed at the joints of the boards, the material can be secured to the base in any way.

Do not lay the material if it is less than 5 degrees outside, unpack it a day before starting work, so it can get some air. Start laying from a fixed structure, such as a wall.

Fix the first board with self-tapping screws at a 45-degree angle to the support foot, and do the same with the last strip. Holes for screws must be made in advance.

On each leg place at least 2 boards, between the wall and the boards should be gaps. Now the boards must be attached to the joists, using galvanized or plastic clips.

They will help to make an even gap along the entire length of the board. In the camp for them there is a reinforcement, in which the self-tapping screws are fixed.

Boards must be consistently attached to all points of support, then yours will be secure. The gaps between the ends of the boards should be up to a centimeter, to make it easier to work, use wedges of this width, place fasteners at all joints of the ends.

Sometimes the laying is done in a way in a scattered manner, that is, all subsequent rows are shifted in comparison with the previous ones by half the length.

After laying, leave the ends of the boards, protruding beyond the edges of the structure, after fixing all the boards need to level them, to do this, use an ordinary disc board.

During the work, trim the open ends of the boards, using decorative strips of composite material. Make holes in the logs for screws and install the bars in them, the same holes should be in the end boards.

The edges of the flooring can be closed with a skirting board, you can use corners made of composite material or aluminum. Fix decorative materials using fixed stoppers.

Even when installing you need to take care about the drainage of moisture, when you install the slats make holes in them 1.5 cm. After laying the decking, clean it of dust.

After a month. Two after installation, the material may change color. To learn more about installing decking boards you can visit our website, there you will find a lot of useful information.

Installation works

Below we will consider the option of fixing the decking on the joists made of wood-polymer composite. The essence of the technology is that the boards are laid perpendicular to the installed joists. Given that a large percentage of the composition in the decking is wood, this material tends to expand and contract. As a consequence a small spacing of at least 10 mm between two joists and at least 20 mm from walls or other structures is necessary.

It is important to make sure the whole floor is well ventilated. To do this, the wood-polymer composite boards are placed on the supports made of metal or plastic. Plus, make sure that each end of the wood-polymer board is lying on the camp, not hanging down.

Tip! It is recommended to mount the decking at a temperature of at least 5°C.

The first board should be fixed from a fixed side, such as a wall. The first board is fastened with screws at an angle of 45° to the supporting beams. The last board will be attached in the same way. Before you tighten the screw, be sure to drill a mounting hole of the appropriate diameter. Each subsequent board to the supporting joists will be fixed with a special galvanized fastener. Also these clips can be made of plastic. Using them allows you to create an equal gap along the entire length between the decking boards. For ease of installation there is a special groove in the board, where the clip is fixed with a screw. Start fastening the clip from one edge and on each pitch. But before this it is important to make sure that the board is in place.

Tip! If a larger area needs to be covered, the installation method can be implemented in a side-by-side manner. In this case, each successive board will be shifted in relation to the previous one by a certain distance.

In the process of installation you should not be distracted immediately and adjust each board to the size of the edges of the terrace. After all protruding ends can be cut in one cut with a circular saw. The result will be very beautiful.

finishing touches

After all the turnkey mounting of the decking is done, it is necessary to perform the final touch, which is to treat all the ends. One of the ways. use a special decorative strip. To install it in the leg or end part of the board must be drilled a hole for screws to fix the strip. You can also use aluminum corners or special corners made of wood-plastic composite. Each decorative element must be fixed in its place with fixed stops.

During the installation work errors are made that affect the performance. For example, in a hurry one forgets to make ventilation gaps between the joists along the entire length and between the walls. This can result in the deformation of the installed flooring. Also screws or self-tapping screws are too tight. In this matter requires a measure.

In addition, the wrong organization of the water drainage. Even worse is the fact that the planking itself and the joists are mounted strictly on the level. In this case, rainwater and other moisture will accumulate on the surface. Because of this decking can absorb moisture. While there are nowadays types of decking, which absolutely does not absorb moisture, but it has a rather high cost.

Violating these rules can lead to irreparable consequences. Therefore, given all the caveats, the following should not be allowed:

- Flooding the decking structure and logs with water for more than 4 days.

- When cleaning the surface is not allowed to use a metal scraper or spatula. They can damage the top layer of the decking. It is best to use brushes with soft pile.

Tools and materials required for installation of wood-polymer composite

To lay the decking, you will need:

- Construction materials for the formation of the base for paving: loose materials (sandy loam, gravel, crushed stone, sand), concrete for pouring the foundation, concrete blocks, paving slabs, adjustable supports and other means for the formation of the base for paving;

- Geotextile or roofing felt to prevent weed growth under the decking;

- Special pipes for drainage;

- Set of wood-polymer composite board, initial and finishing rails, fasteners, rubber “cushions” and other accessories;

- Drill;

- Circular saw or angle grinder;

- Hydro-level;

- Electric screwdriver or screwdriver;

- A tape measure and a pencil;

- Caulking.

Installation of the decking wood-polymer composite

The work does not begin with the leveling of the base. Experienced craftsmen recommend that you first carefully prepare for the work. And the first thing should be a plan-project.

Therefore, the process of laying the decking is as follows:

Creating a laying scheme

To calculate the exact amount of decking and accessories you need, and to choose the best solution, form a drawing. It is better, of course, to use special programs that are available at each dealer, but you can draw a scheme on paper on a scale. Because the installation does not have to be strictly perpendicular or parallel to the walls, other building envelopes. You can make a diagonal paving at an angle of 30 ° or more. An important point. in the calculations to consider the correct spacing between the joists:

The spacing of the joists also depends on the width of the board and its filling. If the planks are solid, you can make an interval of 50 cm. Hollow with such a gap will spring, sag, so the maximum distance between the support beam. up to 40 cm, for floorboards up to 22 mm wide. no more than 30 cm.

Important is the choice of mounting method :

Preparing the base

The base must be clean, solid, dry, flat and frostproof. You can not just put slats on the ground or asphalt. Under the planking there must be a gap for air circulation and the drainage of melted or rain water.

The basis for the decking can be diverse. Including:

- Concrete screed with a thickness of 8 cm or asphalt with a mandatory slope of 1 cm per linear meter (or 1. 1.5 °) from the static structures or constructions. Potholes, holes, loose areas are not allowed. If the base is already prepared, and there is no slope, you can cut 3 cm wide and up to 1.5 cm deep holes in the concrete at a slope.

- Sand and gravel or crushed stone-sand “cushion”, which is formed by vibrotrambovki soil, followed by filling and compaction of loose materials. The total layer of the base. 8-10 cm. Over the prepared base you can lay geotextile or Ruberoid to prevent weeds germination. Then with a gap of 40-60 cm support beams or slabs of concrete, metal profiles with corrosion-resistant coating, paving slabs of at least 20x20x3 cm in size are laid. On this very foundation the frame will be installed in the future.

The formation of surface drainage when installing decking on the ground. a prerequisite. For this purpose in the ground to dig a drainage channel-drainage from the site, line it with geotextile, lay special pipes with holes along its length, fill with crushed stone and sand, cover with soil.

Special adjustable rigid PVC feet, which have been developed for installation of flooring on asphalt, concrete and other rigid surfaces.

Forming the supporting frame

Two days before the start of work the wood-polymer composite should be brought to the site and folded horizontally. Recommended temperature for installation. from 5 to 30 ° C.

The framing of beams is laid with a minimum clearance of 10 mm from vertical barriers (walls, sidewalks, pillars, etc.) and the surrounding area.п.). Beams are placed on the surface at precalculated intervals, holes are drilled in each with a spacing of 50-100 cm, then the hardware is screwed. Some manufacturers recommend fixing the underlay with metal mounting foam or steel corners.

Boards laying

Keep in mind that decking is characterized by unidirectional. That is, when installing it is necessary to ensure that the lamellas lie in the same direction to avoid some “stripes” flooring. Some manufacturers draw arrows on the ends of the floorboards for this purpose.

Laying begins from a wall or other motionless structure. On the lag is fixed the starter element (clip, corner) with screws. The first board is inserted into it and slightly knocked down with a rubber mallet. The next installation component (staple or terminal) is fixed by the metalware on the other side of the initial board, then the second lamella is placed and hammered. Remember that the floorboards must be fixed to every support point on the joist.

The edge of the decking must not project beyond the frame by more than 5 cm. If necessary the ends are trimmed with a circular saw. And the recommended thermal compensatory intervals between the slats are shown in the scheme below.

If the decking is mounted in a heated premise, installation of lamellas back-to-back is supposed. Corner connection can be made in two ways: diagonally with trimming and the method of attachment.

After the last board is installed, it is mounted to the final profile or bracket, and the ends of the boards are decorated with plugs.

The final touch is to wash the flooring surface with water to remove dust and sawdust. Your terrace is ready for full exploitation.

Advice! If you need repairmen, there is a very handy service to find them. Just send in the form below a detailed description of the work that needs to be done and you will receive offers with from construction companies and teams. You can see reviews of each of them and photos with examples of work. It’s FREE and does not bind you to anything.