How to cut a profile under the loops on the fence.

How to make a gate from a corrugated board with your own hands

The instinct of self.preservation embedded in each of us is manifested in the desire to protect our house from dangers. Fences, gates and gate are an obligatory element of protection. But a person is also not alien to the desire to surround himself with beautiful objects. Therefore, it is not surprising that the modern elements of the fence, in addition to direct purpose, also act as a decorative design of the site. The gate of corrugated board installed by yourself is one of the most acceptable options for creating a reliable and aesthetically attractive design that can decorate the front area of the site.

Before making a gate, we propose to figure out what are the advantages of a profiled sheet over other equally popular building materials for the manufacture of enclosing structures.

A number of main advantages of corrugated board include:

- Excellent quality characteristics. Profile sheets are the material that are covered by several layers of protection: anti.corrosion, and after from the outside a polymer, and with an internal. varnish.

- Simplicity and ease of installation. This material is ideal for arranging fences and gates. Designs of light and at the same time durable metal plates can be built in just two to three days, which in turn accelerates and reduces the cost of construction. Erected gates and fences from corrugated board look solid and thoroughly.

- Aesthetic attractiveness. Excited metal plates can have a completely different shades. The use of color polymer coating when staining sheets of corrugated board makes it possible to choose the product of the required color in order to make a gate that supplemented the ensemble will harmoniously combine with other building structures on the site.

- Long service life. The life of structures equipped with corrugated board can reach over 50 years.

Thanks to multi.stage processing, the material has high anti.corrosion resistance and the ability to maintain aesthetic attractiveness even under the influence of ultraviolet radiation and weather conditions

The main stages of manufacture and installation

Step #1. choice of optimal size

When planning to make a gate in the fence, it is important first of all to determine the dimensions of the structure. The optimal width of the gate is not more than 1 meter, the height is not more than 2 meters.

A competent calculation will prevent problems associated with premature wear of the loops and the structure of the structure, as well as the inconvenience during operation when opening a wide sheet of the canvas

Wanting to create a more overall design, one should take into account the moment that an increase in the mass of the sash can lead to accelerated wear of locks and hinges of the canvas.

In the manufacture of a gate with a height of more than two meters of the structure, it is advisable to supplement the upper insert with the crossbar. This will allow you to get a solid canvas in the finished form, which will not only close the space above the gate, but also reduce the load on the support column.

Step #2. Building of supporting racks

In order to make a strong gate from a profiled sheet, which will properly serve over the next few decades, it is necessary to properly equip racks for it. Metal pipes or pillars made of stone or brick can act as supporting racks. When installing racks, it is important to monitor the deviations from the vertical position, which may entail a skew and violation of the performance of the finished product.

The arrangement of the foundation will help to prevent subsidence of the support rack. The depth of its laying is 1-1.5 meters

In the dug pit under the foundation, racks are strictly vertically installed in level and poured with a solution of small crushed stone of sand and cement. Over the next 7-10 days, concrete “gets tired” and freezes.

Step #3. manufacturing the frame

The easiest way is to make the frame from a profiled metal pipe with a cross section of 60×30. In order to cut the blanks and cook the gate, you need a welding machine and a corner grinder. Before cutting the pipe on the workpieces, it is important to clean it of rust and ward using a metal brush mounted on an angular grinder. After that, the surface of the pipe must be degreased by the solvent to be primed with an anti.corrosion composition.

When installing, it should be taken into account that the distance between the door leaf and the cover of the path or the sidewalk should be at least 100mm

note! The working gap is necessary for the normal functioning of the structure even when the ice is accumulated in the winter.

Having decided on the size of the gate, you can proceed to the manufacture of its frame. To do this, on a profile pipe, it is necessary to note the size of the blanks and cut them with an angular grinder at an angle of 45 degrees. The creation of such a feature will improve the quality of the weld, while making it almost invisible.

To equip the gate, two longitudinal parts of 1.75-1.9 m and 2-3 transverse parts at 0.9-1 m will be required. Details are welded with each other 2-3 cm tacks around the entire perimeter every 20-30 cm. Longitudinal and transverse pipes, including the central transverse pipe, should be located strictly perpendicular relative to each other. The distance between all horizontal elements should also be the same. This will not only give additional stiffness of the structure, but also make its appearance more attractive.

To increase the strength of the structure, you can lay the diagonal elements from the upper corner of the narthex in the lower corner of the hung rack

To increase the strength of the gate, you can also make a smaller frame from the same pipes in size 20×40 mm inside the frame. It is possible to prevent distortion of the frame in the process of welding from overstrown by performing the tacks in a checkerboard pattern. After the frame for the gate is cooked, we proceed to the installation of additional elements. awnings, plates for fastening the lock and outer handle.

Triangular “scarves” from a steel sheet welded to interconnected details will increase the strength characteristics of the entire structure

A visual video sentence for beginners, how to properly cook the gate:

Step #4. installation of a gate

After the welding work is completed, it is necessary to clean the welds, priming damaged places and painting the frame.

The corrugated board is easily attached to the frame using self.tapping screws or rivets. The distance between the mounts depends on the preferences of the owner: you can attach each wave of the sheet, or you can also through one. Mandatory is only fixing the profiled sheet to the middle jumper of the frame.

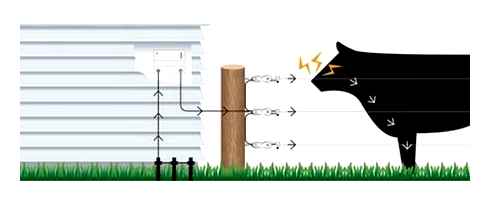

To install the gate, you can use both traditional metal loops and new.fangled polymer curtains. If metal pillars are used as racks, then the curtains are welded directly to them. The loops are attached to brick or stone racks by welding to a profile pipe fixed with anchors or dowels on the pillar. The finished gate can be hung on the support and check the work of the castle.

In order for the gate to not open on both sides, the limiter from the corner is welded to the opposite support. Mocking strips will also cover the gaps between the racks of the gate and the canvas.

Gate from the profiled sheet. pros and cons of

The most popular gate model is a metal swing design. presented in the photo that opens on both sides. At the same time, painted corrugated board is used to skin the frame, which can be decorated with forging elements. The floors of the fence system have a lightweight design with a gate placement in the neighborhood. This kind of gate has gained popularity in private sector houses.

Such popularity was achieved by a large operational resource of the product without the need for regular repairs, unlike wooden analogues. Modern models of a profiled sheet are often complemented by an automatic opening system, which is very convenient. At the same time, the profiled sheet used for the manufacture of fences has a number of the following advantages:

- relatively low cost of a profiled sheet;

- A simple process of manufacturing and installing the gate, both with the gate and without it;

- long.term operational resource and ease of care;

- multifunctionality of the material;

- attractive appearance of painted corrugated board.

If we consider the shortcomings of such material. I would like to highlight the following problems:

- To open the swing structure of the gate, you need a large free space around the protective structure;

- Due to the large area of the gates of the gate, an increased wind load operates on them, which must be taken into account depending on the region in which the fence is established.

But still, the advantages of the hinged design of the gate with the gate, the reduced shortcomings of such a product are crossed out in the photo. over, the problems are not so critical and they can be eliminated in the process of installation work with your own hands. And as it became known from practice, the gates from the profiled sheet are the most reliable among such structures.

Features of the design of the swing.type gates

Considering the drawing of standard gates from the profiled sheet, it can be understood that this fence is based on a frame from a square metal profile or a thick.walled pipe with a 30 mm diameter. At the same time, to strengthen the wings, horizontally located metal lines are used. Thanks to this strengthening, the geometry of the gate will be held.

The manufacture of a swing design of the gate from corrugated board is quite possible on their own, even in the absence of work skills with metal products. All that is needed is the minimum knowledge of the use of welding, drill, electric boiler, screwdriver and construction roulette.

The fastening of the swing fences is carried out using metal screws or electric welding directly to the pillar. Due to the comparative lightness of the profiled sheet, two durable metal loops of 20 mm diameter are sufficient to hold the gate floors. As bearing supports, metal pipes with a diameter of 60 to 100 mm are used.

Depending on the fence, which is surrounded by house building, the fastening of the gate sash can be performed to brick supports. But for this, it is still necessary to provide for the installation of mortgages in the seams between the bricks, to which the hinged supports of the gate will be welcomed at the stage of construction of the fence.

From practice, it became known that the optimal dimensions of the entrance gates used in private housing construction are width indicators of 3 m. Such parameters are enough for entering the courtyard, both a passenger car and a truck. Therefore, even with the aim of saving, it is not worth reducing the width of the width by more than 20 cm. If we consider the height of the fence, then according to drawings, standard designs are made no higher than 2 meters from the ground.

As a locking mechanism for the gate, pins in shape are used, resembling the letter “g”, which are located below on each sash. Clatters are installed in the surface of the earth or other coating of the yard. metal tubes with an internal diameter, slightly large thickness of the locking mechanisms. At the same time, no rigid requirements for the locking mechanism are not presented. A horizontal valve is installed as an addition to the stoppers at the place of accommodation.

The use of corrugated facilities as a finish for the frame of the swing gate will allow the protective design to harmoniously fit into the overall stylization of the fence. Typically, profiled sheets are attached to the frame of the gate sash at a distance of 50-70 mm from the ground. so that they do not stir on the surface during opening and closing.

Preparatory work

The theater begins with a hanger, and any design. with calculations and drawing. The width of the gate should provide a free passage of people with small.sized things. For these purposes, enough 1 meter. With large dimensions, sailing and weight of the structure increases, which will require installation of more than two loops, and it will also be necessary to put an additional constipation and install pipes of a larger diameter.

Scheme of the main elements of the sash of corrugated board for installation with your own hands

The gate for the fence from the corrugated board can be of any height. the choice is individual. But experience shows that a low design will not provide visual restrictions for curious faces and does not look very good. With a significant difference in the height of the fence and doors, the opening on top is closed with an insert from the profile of the same color that the main design.

Having determined the main sizes of the gate from the corrugated board, we make drawings or diagrams (sketches) of the structure. Since the design is simple, any person can cope with this task, but in this case the following must be taken into account:

Dota 1 на iCCup.com. Эффект Даннинга — Крюгера в вакууме.

- The design should be tough. The number of internal ribs is determined taking into account the height and width of the structure.

- Designing the main elements, determine their length. Pay special attention to the types of joints of the profile pipe and its size.

- With the proposed installation of a powerful mortise locking device or valve, additional elements of the intensification of the structure are provided.

- Determine the height of the supporting pillars taking into account their immersion in the ground to a depth of at least the level of freezing of the soil for the region, the location of the lock, as well as the location of the loops.

Scheme of structural parts of the door from corrugated board

After preparing the drawing, the total amount of the necessary material is calculated by categories and quantity. This information will help to exclude excess, therefore, will reduce expenses.

Production and installation

When assembling the design of a gate from corrugated board, step.by.step instructions will help with your own hands:

- marking the location of the pillars, earthwork;

- installation of pillars, their concreting;

- manufacturing of the frame;. locking devices;

- Installation of a profile sheet.

Scheme for the selection of profile pipes for the frame

The comfortable use of the gate depends on the quality of the work performed by the work of each stage without the need to make changes and finalizing the structure for a long time.

Do.it.yourself installation of pillars

Profile or ordinary pipes are used as pillars. It is recommended to use a square pipe with a side of at least 50 mm and wall thickness of 2 mm, and round. with a cross section of 1.5 inches.

The sequence of work is presented by step.by.step instructions:

- The pipes are cut to the required size of the angular grinding machine. Eliminate rust and primer.

- Ducking holes to the planned depth is carried out in any convenient way. The centers of the pits must correspond to the calculated distance between the pillars. The use of a construction drill will require a more accurate marking, since a hole dug up with a shovel allows you to adjust the position, the first possibility excludes this possibility.

- If the lower end of the pillar is not brewed, then to prevent moisture from getting into the bottom of the pit, the roofing material is laid and the layer of crushed stone is made.

- Part of the pillar immersed in the ground is covered with bitumen.

- Pillars are set in level and poured with a concrete solution prepared in proportions: 1 part of cement, 2 parts of sand, 3 parts of crushed stone.

The photo shows the gates of a private house with a door leaf.

An example of the equipment of the entrance group with a built.in door

The period of concrete drying depends on the external temperature environment. Refrained from concreting structures if there is less than 4 degrees of heat on the street or the prevailing hot weather is worth. In the latter case, regular watering is necessary for gradual hardening of concrete.

It is not superfluous to make a canopy over the gate, which in rainy weather will make it possible to open the lock and at the same time not get wet.

If the visor above the gate is supplemented by elements forged by the master, then visually the entrance to the site will seem solid and exquisite.

How to drill under the poles of the fence, you can find out by the link.

Making a metal profile gate with your own hands

A profile pipe is used for the frame. Its size depends on the width and height of the product. For a product of 1000×2000 mm, a square pipe 40x20x1.8 mm is sufficient.

Making a gate from corrugated board at home with their own hands is carried out in the following sequence:

- The external elements are cut off according to the calculated dimensions taking into account the option of the docking (at an angle of 45 ° or perpendicular).

- On a flat surface, the workpiece is laid out and withdrawn on both sides, excluding the thermal “departure” of the metal.

- Cut the blanks for stiffener ribs, installed on the places provided, grabbed with welding.

- Set the gate between the pillars taking into account the technological distance to install the canopies, using welding and remains of the pipes, temporary fixing of the structure is carried out.

- Install the canopies in regular places, carry out preliminary fastening on the gate sash and column welding. A fixer limiting the movement of the door in one direction is welded, constipation is attached.

- With the help of corner grinder, the frame is separated from the pipes, welding all seams is welded, avoiding overheating of the metal.

- A trial installation of the gate is carried out in the regular place, the opening of the opening and the accuracy of technological gaps are checked.

- The surface of the frame is cleaned from the consequences of the welding apparatus, rust, primer is.

- A forged design with a visor is installed, if necessary.

- After completely drying the primer, the pillars and the frame of the gate are painted in the color preferred by the owner.

- They are engaged separately. Cut to the desired sizes, using self.tapping screws with heads, the main color is mounted on the frame, the gate is installed.

The photo shows an interesting design of the fence in the country.

Option of designing the gate and front door

In order to avoid minor mechanical damage obtained during operation by an electric tool during the installation of locking devices (lock, constipation, latch), the profile sheet is fastened lastly.

How the gate is made from the profile pipe, you can find out by the link.

How to make a gate in the fence

Selecting the appropriate location of the arrangement of the design of the entrance door in the country, the basic principles are taken into account. For example, you need to think about how to organize a convenient approach to the garage or household buildings in a summer cottage. It should be taken into account if there are holes nearby. If the hollows are present near the front door, then water and dirt will certainly be collected here.

Do not believe that you can build only one gate in the country. You can install several. For example, one will be used as a front door, and the other will be the rear designed to reduce the distance to the required object.

There are various ways of arranging the front door, but, one way or another, it is obliged to correctly fit into the design of the fence and the personal territory. Therefore, it is necessary to pay great attention to the choice of building materials, door assembly and decorative elements.

Among the most popular, the following door designs can be distinguished, which differ in the material used, appearance, structure:

- Metal entrance doors. They consist of forged patterns, look quite beautiful, used in the structure of fences with the same decor.

- Eurostaken allows you to give the door leaf to the original design. Having complemented the design of the door with carved wooden pillars, it can be installed as an internal fence, which will separate the adjacent territory.

- Metal profile products are best suited for fences that have a similar design.

- The shield structure looks great with a fence from masonry.

Furniture will also require additionally. For any design of the doors, the following accessories may be needed:

- automatic or manual latch;

- the closer closer;

- bilateral loop;

- bolt;

- electric drive;

- patch loop;

- castle (mechanical or electromagnetic);

- Skokold with a ring;

- Switch constipation.

Designer version of the fence with the gate

Options for designs of wood input graters

During the manufacture of any design, the choice of lumber is of no small importance. It is advisable to choose deciduous or coniferous varieties. Larch. the most durable material. Therefore, if it is important for a long time of operation, purchase this particular variety.

over, the thickness of the board for assembling the door leaf should be the same.

Parteper products

Small in height or door.protected from the wind is best made of wood according to the frame scheme. For standard canvases, the input gate frame is made of boards in size 35×140 cm, the main strips. 20×80 cm. Support should be made of Z-shaped.

Wooden picket fence sketch

If the filling of the door leaf is unable to maintain increased loads, the frame must be made in the form of a shortbread watch (x-shaped supporting structure) or a “butterfly”. In the latter case, under the crate of the bars 15×25 mm, 2 crosses are installed horizontally from above and below, the framing of the X-shaped structure is carried out around the entire perimeter. For a door stretched in height, it is better to make an e-shaped frame.

Garden gate

As a rule, the canvases are made with an openwork pattern. To ensure good strength, it is better to make a frame gate. The elements on the compounds are cut into half.term and fixed with several diagonally installed self.tapping screws.

Beautiful frame products will be obtained from the wings of the interior structures of the entrance doors for fine glazing.

Shield gates

Thyroid structures of gates are the most durable. The gate frame is made from a bar with a cross section of 55×160, the elements of the frame at the corners are attached with a latch “Ship-Paz”.

To fill the door frame, you need a downted board 35×100 mm. The size of the frame is chosen so that the whole number of boards can meet in the flight, not taking into account the height of the spont. It is required to make a groove around the perimeter. Paves for the gate can be installed with shortened, so.called semi.amam. It is undesirable to install card loops for the front door.

Since high humidity quickly destroys wood, it is advisable to protect it with the help of a hinged visor from polycarbonate installed on top. So you can extend the service life. If desired, the visor can be installed not only on the door, but along the entire perimeter of the fence.

The design of the input gate “Strela”

In the personal territory, the design of the arrow gate looks very beautiful. For manufacturing, the following will be needed:

In total you need 12 details, six for each side. If it is a packaging plywood, before making arrows, wooden elements must be impregnated with a water-polymer composition. The “legs” of two medium elements are shortened by approximately 10 centimeters for installation on a spike.

The lancet gate is fixed to PVA and self.tapping screws. First, you need to collect four facial elements, including those made under the spike, after which they are assigned to them two back. Connect the elements of a “snake” with an interval of 90–160 mm.

Straight “legs” of the product can be made in short, taking into account the chosen design. At the upper endings of the vertical elements, the spike must be cut for the arrow attachment.

Standard drawing of creating the entrance group

Construction type “Pergola”

Pergola is the entrance that does not have a roof and walls. For example, the input structure of the pergola can be made in the form of a tunnel where curly plants are located.

The traditional input structure, colonnade with several rows, is simply crowned with intersection boards. It has become popular thanks to the inhabitants of ancient Greece, but they came up with this type of entrance gate in Persia. Such a portal was used for sanctuaries and palaces.

DIY production sketch

The structure of this type has a powerful psychological effect of dominance, which is also reflected in the owner. In the east, pergola was used to suppress the pride of visitors before they approach the royal throne. Therefore, to install pergola as an entrance to the house is undesirable.

If, taking into account the design, it is necessary to build a classic pergola, it will need to be made visually light, and it is advisable to form a fence and design with an openwork ornament and set in height below the level of pergola.

Openness minimizes the dominance of the structure.

Photo of a successful solution of finished designs of the entrance door for the cottage presented below.

Selection of material

The appearance of the input group determines the selection of building materials for supporting pillars and sewing of paintings. You can boil a gate from a round pipe, but it is inconvenient to fix the loops, and when connecting the angles of the frame there are difficulties. Square section allows you to avoid such difficulties.

Interior filling is made of mesh, art forging, such a structure looks openwork, reveals an overview of the internal space of the courtyard. Corrugated board is used more often due to a rich choice of color and pattern for stone, wood.

A cellular or monolithic polycarbonate is used for the canvas, a sandwich panel is placed. Sometimes combined forged elements with wooden filling.

Characteristics of the professional tube

All profile tube products have the following basic characteristics:

- affordable cost;

- reliability and strength in application;

- small weight;

- a significant degree of resistance to mechanical influences and corrosive processes.

Each home craftsman, if desired, is able to make a gate from a profile pipe without the help of a master, for which it is not required to have professional knowledge and skills. You just need to confidently use the drill, welding machine, corner grinding. It will also be necessary to draw a simple drawing.

For the designed design, high.quality building materials should be purchased. But before you go shopping, they develop a detailed drawing of a gate from a profile pipe with all sizes.

The price of the pipe depends on the size and thickness of the wall. Products are produced square and rectangular shape. Profile shelves 10–180 mm. Wall thickness 1-14 mm. For private construction, a profile pipe is used with a thickness of 1 to 4 mm, it is a strong, light, round analogue heavier than 20 %.

Varieties of professional pipe to create a frame

The most popular profile for the construction of a gate from a profile pipe at home:

- For pillars and a frame of 3D pounds, use a 60×30 and 60×40 mm pipe with a wall thickness of 2 mm. Approximate meter.

- For the manufacture of an open type of large size, a pipe 50x25x2 mm is used. The price depending on the region is an average of 110

- 40x20x2 mm profile is the most common for products of this type. It is used for corrugated products, as well as from a metal sheet. Pipe price for one meter. 78

- To facilitate the structure, a 40×20 mm profile is used with a wall thickness of 1.5 mm. The price of one meter. 75 jumper for stiffness is made from the profile 20x20x1.5 mm, the cost is 40 per linear meter.

The shape of the rectangle allows you to fix the facing material with great convenience

Due to the rectangular form, the pipe has natural stiffeners, due to this it is strong, withstands heavy loads, this is the advantage of profiles over a round analogue.

How to make a gate from a profile pipe. with your own hands

There are many owners of summer cottages when arranging the fence prefer to install a gate with a gate made of profile pipes. Such a metal structure can be made independently. In addition, a qualitatively made gate from a profile pipe can become a decoration of a summer residence.

Welding the frame of the gate

When preliminary calculations are made, and the material is purchased, you can proceed to the creation of a frame for a gate.

- Before boiling the gate from the profile pipe, prepare a place. A metal table with a flat surface is the best option for work. The table is set horizontally, all the irregularities are cleaned with a grinder. This is necessary so that the product is even in the horizontal plane.

- The material is cleaned of rust and garbage with a grinder with a cleaning circle. It is better to clean the workpieces in a separate form, since it is more difficult to do this in the finished product.

- The prepared material is cut in size. The blanks are cut off at an angle of 45 degrees. Such cooked seams look aesthetically pleasing, and moisture does not get inside.

- To get exactly cut off the workpiece, a stationary cutting angular grinder with a scale of degrees is used or drawn manually using a corner. When cutting, ensure that the workpiece lay exactly in the plane, and the corner grinder stands perpendicular to the surface.

- Before assembly, all metal parts are primed. The gate from the profile pipe must be processed from all sides so that when moisture gets, rust does not appear.

- Prepared blanks are put on the desktop, tightly joined, checked diagonals.

- Make neatly tacks in three places to fix the design, check the dimensions again.

- If the dimensions and diagonals are normal, the design is turned to the other side and weld the blanks. They do this so that the structure does not stray in a horizontal plane. Then they turn it over to its original position and finish to spark the joints. After the gate frame is ready, the welding places are polished, filled with decor elements or a metal sheet.

The finished product is primed and then painted.

Slothing the castle

The gate experiences temperature changes, the effects of humidity and atmosphere. A feature of the lock is a narrowed bar and a short gap from it to the axis of constipation.

Each entrance gate needs a lock. The choice of castles is large: from hinged to electronic. But most of the castles are flat, they are reliable, have many degrees of protection. In the manufacture of a frame, a 40×20 mm profile pipe is used, which is suitable for installing a crazy lock.

For convenience, the lock is cut when the frame is not yet cooked and easy to work with the blanks. On the 40 of the shelf, retreating from the bottom of 90 cm, make the marking of the opening under the castle from the inner and outer side.

For cutting, take a small corner grinder, a small diameter circle is installed, usually these are used circles. Marking is made from the center of the profile with a margin of 1 mm on each side.

First make longitudinal cuts in a profiled pipe. Then small cross cuts from two ends and in the middle are made in a small circle. Middle cut is made diagonally, it is easier to cut the bar. Then the plate is picked up in the middle. Clamping the edge with pliers and break two halves in turn. Cut out on both sides, inside and out. You can watch in detail on the video at the end of the article.

In the collected form, the design should look represented

Painting

Painting is an important part of the work. The paint protects the metal from corrosion, gives an attractive appearance. Particular attention is paid to preparing the product for painting. Metal is cleaned of rust. This is better to do at the preparatory stage of the assembly, then it is not necessary to manually clean the rust from hard.to.reach corners.

Coating of metal surfaces with paint

The blanks are wiped from dust, degreased with a rag dipped in the solvent so that the painted surface is without dust. To dilute the paint and primer, use a solvent 646 or 647. After dilution, proceed to the primer of the product.

This is the preliminary processing of the metal with an alkyd primer, which levels the surface, provides good adhesion with paint. Now they produce 2 in 1 in 1, which are used without primer.

Painting with a spray gun significantly reduces the consumption of the protective composition

It is better to paint the product with a spray gun, then the paint lies evenly with a thin layer. You need to paint twice. The first layer is applied for aligning the surface, and then partially overlap all uncompassed places. The second time is painted after the first layer is completely dried. Paint gives shine and stable color.

The appearance of the domestic primer GF-021

Note. Try to prevent paint leakage. Apply the first thin layer, and after drying the second. Suns and thick paint do not look attractive on the finished structure.

Installation of the gate

We proceed to final work. set the gate. Keep in mind that at the stage of welding, loops are fixed, which cover the paintwork. Before starting the installation of the frame and gate, it is necessary to install the support pillars. To do this, use a tube with a diameter of 60 x 60 mm. The element is buried in the ground up to 70. 100 cm, this is enough to ensure the stability and strength of the structure.

Which corrugated board to choose

First of all, it is necessary to decide on the choice of profiled sheet. Today they exist several types, and in particular:

- N. means the supporting. This type of material is considered the most durable and reliable. It is even used to overlap the roof. This sheet uses the thickest metal, there is a high corrugation that provides the rigidity of the corrugated board and the presence of an additional groove.

- Ns- designation implied by a wall-carrying corrugated board. It is universal in its kind as can be used for roofs, walls and all kinds of structures, including fences, gates.

- C. exclusively wall. The corrugated board has a small thickness, an attractive appearance. It is used exclusively for walls.

In addition to these designations, there are also numbers. For example, you can find sheets such as N-60. If everything is clear (bearing) with the letter, then what the figure means? The first digit indicates the height of the wave. There are also such designations-C20-0.80-850-1500. In this case, it is indicated on a wall sheet with a wave height of 20 mm, metal thickness 0.80 mm, sheet width 850 mm and a length of 1500 mm. As you can see, this cipher is very simply explained.

Choosing corrugated board for the manufacture of a gate, start from aesthetic reasons. For example, whether the gate with a too high wave will look beautiful and t.P. Among other things, it is worth paying attention to the choice of edging, which gives the product a complete look. Today there is a large selection of colors. Therefore, you should not make problems choose a sheet, edging and even hats of self.tone for one tone and color.

We determine the size of the gate

Having decided on the type of corrugated board for the gate, you should decide what sizes will be. You can make a gate from a corrugated board with your own hands, you can start from such standards:

- The optimal width of the gate 1000 mm. This width will allow you to bring furniture and other things of large sizes without any problems. Of course, if the sizes are non.standard, you will have to open the gate. If you increase the width of the gate, this can lead to rapid wear of awnings.

- The optimal height is 2000 mm and less. In this matter, you should push off from the height of the entire fence. It is important that everything looks beautiful visually.

An example of a gate from corrugated board is a photo of an option with installation on brick pillars

How to choose the size of the gate from corrugated board?

There are no strict mandatory norms and restrictions in terms of the size of the gates. However, when choosing them, you need to take into account the following:

- The optimal width of the corrugated board gate is 1.0 m. Such a width of the opening allows you to easily bring furniture or other overall things to the site. over, if it is larger, this can lead to the rapid wear of the loops or the skew of the gate canvas.

- The height of the gate should not exceed 2.0 meters. If the fence around the site has a greater height, then such a curtain from a profiled sheet will not look very good. In this case, in the opening between the supporting pillars above it, it is better to install additional crossbars with a metal profile insert. This will not weight the excess of the canvas of the gate itself.

Of these rules, of course, there are exceptions. For example, if your height or growth of someone from your family is above 2.0 meters, then making a high-altitude gate will be simply necessary. However, you should not forget about the use of special loops and strengthening the frame with additional crossbars.

Purpose and types of loops

There are many options for loops on the market that differ in price, quality and design. It is quite possible to install the gate with your own hands, but even then it becomes necessary to repair it. Opening gate also requires proper selection and installation of accessories.

In fact, this is a mechanism consisting of 2 or more parts and a hinge moving around the axis. There are several types of loops by design and fastening method. The caliper loops, like the garages designed for the gate, can open the door by 90 or 180 degrees in one or both sides.

An important factor is the performance of the sash and its functionality. The main selection criteria:

- reliability;

- compliance with the weight that they must withstand;

- opening angle;

- method of installation, fastening;

- material;

- Other features.

Subject to the rules of choice, you can buy a quality product that will last a long time and will function well. Hinges for gates and gate, in principle, have no differences. But the weight in the first case is less, unless the door is forged, with heavy decor. Requirements for the choice of acquisition in all cases are the same: opening without difficulties, resistance to hacking, aesthetics.

Features of loops

All varieties of loops for gates are divided into the following three groups:

- Classic type, looking like ordinary door, with the same mechanism. But some have an advantage associated with corrosion processing. And also differ in increased reliability, resistance to loads, which is provided by bearings with increased strength. There is a type of loops without ears that need to be welded independently. this is a universal type.

- Hidden have increased resistance to hacking. It is difficult to remove such a caliper structure, because the suspensions are mounted in a secret way.

- Decorative, performing the same function, but endowed with aesthetics. Models correspond to the exterior, can be selected in style. Sometimes they are made individually, to order.

Photo of a beautiful gate is presented below.

Each of these groups has advantages and cons, but functionality is inherent in all varieties that are quite a lot. GOST provides for classification by groups.

Given this in relation to your needs, it will be easier to make a choice.

Classification

In order to choose the right product when buying, consider popular species acceptable for various cases. Standards are reflected in the next list:

- Invoices. a popular classic version. They are distinguished by ease of installation and operation, affordable.

- Veverbated, suitable for a wooden gate with a light canvas. Resistant to hacking, look beautiful, but are not suitable for a heavy door.

- Through (through which the rod passes) correspond to the thin canvas. The simplest species includes 3 elements: the loops are right and left, a pin, but there are also up to 6 parts.

- Secret (hidden type) with increased safety, but affordable in cost. It is difficult to mount, which is the only minus. A special design hides the mechanism in the gate from the eyes when it is closed. Fastening is carried out to the ends of the supporting pillars and to the frame from the inside. Such loops cannot be cut or removed without special tools.

- Enhanced, used for a heavy canvas. For example, with a diameter of 34 mm for a load of 300 kg per 1 steam.

- Cylindrical, corresponding to classical models. There are also mechanisms with a support bearing and an enhanced design. The first are the most standard in appearance and form. This is a cylinder of 2 parts with a pin in one of them and the hole for its installation in the other. There is a modification. a ball of a bearing that does a smooth. In an enhanced model, the thicker rod and walls. This is a garage option used for the gate.

- Three.section types are also used for gate. They are similar to through, but are ranked to cylindrical types. In the middle there are 2 pins with the opposite orientation. From 2 sides, empty cylinders are worn on them. They are welded to the pillars (for example, this is a pipe). As a result, they cannot be removed without cutting.

Each type is characterized by distinctive features. But in everyday life, the gates are usually supplied with reinforced suspensions. And for gates, cylindrical simple ones are used, which in the form are the following species:

Configuration affects the method of fastening.

How to choose

You should keep in mind a whole list of factors to choose a suitable mechanism.

- The material from which the canvas is made is of weight. So, they produce loops for a gate of corrugated board, braids or plastic. through, cylindrical or secret type. And the canvas itself belongs to light in weight.

- Based on the conditions of use, distinguish areas with reduced safety, when hidden or enhanced modifications are applicable.

- Method of fastening. There are cases when the installation of classic loops cannot be carried out. The canvas usually has an optimal size that does not exceed a meter in width, and in a height of two. But if these dimensions are exceeded, reinforced devices with durable hinges are needed, resistant to wear.

Subtleties of installation

Installation of gates from corrugated board (metal profile) involves a width of no more than a meter, and a height not exceeding 2 m. Otherwise, the loops will quickly worn, and the canvas from the profiled sheet may be distorted. The lower edge should be higher than the soil by 10 cm. Supported pillars are made of brick or metal professional pipe.

The finished gate is installed vertically using the level. On the column, places for attaching loops are marked. First make a temporary welding seam. And after checking the work, continuous welding is carried out. If everything is done correctly, spontaneous opening and closing is absent. To open in one direction, a limiter is welded.

Welding is carried out before fastening the facade

In addition to the fittings for welding, there are loops for gates on bolts. They are also applicable, but do not differ in reliability in relation to corrosion and other factors. This issue is solved by the use of a protective coating.

For example, durability is ensured by anti.corrosion galvanizing. Another option is a polymer protection that provides a persistent color, or nanocramic, which is applied to sections, rods and accessories.

Sometimes the manufacturer makes whole fence structures with fluids, pillars, lock and hinges that can be adjusted. So the anti.icing type of suspension, including bolts, can be adjusted in 4 directions.

That is, the wings can be forced to open left, right, as well as correct in height and depth. The part was made by hot galvanizing, equipped with protection against promotion.

Profile fence requires the installation method of a caliper sash that is different from the classic version. Strengthen the jumpers to which the loops are welded, and the profile is screwed on them. Otherwise, welding will spoil the appearance. With this method, it is better to take accessories for the garage.

For a longer service, the loops are tinted from time to time, which protects them from corrosion. Suitable for this case is a paint from the Leroy Merlin store chain, as well as other household items. The pristine quality and shape of the loops will help maintain lubrication produced once every 3 months.

This provides a smooth course of the gate, protects the metal from erasure, makes it reliable.

A step.by.step installation of a metal profile gate with your own hands

One of the most successful ways to assemble a gate for non.professionals is to install directly in the opening of the fence. So that the frame does not deform during the assembly process is boiled directly on the support pillars. After the gate is ready, it is simply cut out of the opening. Installation “in place” excludes the risk of not getting in size or make a mistake in measurements, since all proportions are clearly visible. The assembly process is carried out in the following order:

- The upper and lower parts of the frame are welded to the supporting pillars at the level. It is necessary to ensure that the plane of the pipes is not turned out. Between the lower part of the frame and the foundation/land, a gap of 10. 20 cm should remain;

A welded sidewall of a frame with a necessary gap

Installation of a second sidewall with a welded canopy

Marking corner for trim under 45 degrees

Welding the lower part of the upper canopy to the support column

The frame of the gate can be painted in tone to the corrugated board or choose any other color. It is advisable to carry out the staining procedure until the frame is sheathed with a corncase, but after the welding work.

Finishing and care

Due to the availability of polymer coating of the structure from corrugated board, they practically do not need supportive care and additional decoration. You can clean the fence seasonal before the summer or after winter to remove dirt and dust from the surface. Additional coloring is permissible, but does not carry any practical or decorative benefit.

The only thing to pay attention to is the processing of cracks, chips and other damage to the protective coating. The damaged place must be cleaned of corrosion, if any, degreased and painted over with corrosion.resistant paint to the color of corrugated board. It is advisable to carry out this procedure immediately after the appearance of the defect, preventing corrosion from spreading deep into the sheet.

Call for the gate from corrugated board

Inexpensive wireless call set

A mandatory element of any gate is a bell that allows guests not to knock on the door with heavy objects. The gate of corrugated board are at a considerable distance from the house and pulling the wires to power a traditional call will not be very convenient. The optimal solution is the use of wireless calls that do not depend on the city power grid. finger or batteries are used as autonomous power sources in them. advanced and expensive models can be additionally equipped with a motion sensor, video camera or intercom.

The wireless call consists of two parts: buttons and receiving block. The button is installed directly on the gate, and the receiving unit is entered into the house. An important parameter of a wireless call is the radius of receiving the signal. the maximum distance to which you can divide the button and the receiving unit. Depending on the model, the radius of receipt of the signal can be from 25 to 200 meters.

note! In this case, the distance is free from any obstacles that can jam the signal. A brick barrier reduces an effective reception range by 25. 40%, and reinforced concrete by 40. 85%.

Installation of wireless calls is as simple as possible. most buttons are available on a self.adhesive basis. There are also special recesses for fixing through self.tapping screws in the housing. The installation of the call is carried out in the following order:

How To Level Wooden Fence Posts

- The selected place is cleaned of dust and degreased with alcohol or acetone;

- The film is removed from the self.adhesive base. The button is tightly pressed to the surface of the gate/fence;

- Tight installation is carried out through special metal screws. The location of the future call is noted on the surface of the gate/fence;

- The holes of the corresponding diameter are drilled at the place of entering the screws. You can try to tighten the screws at once, but there is a great risk of making a dent on the surface of the canvas;

- A call is installed and screws are screwed;

- The junction of the self.tapping screws and corrugated board is treated with sealant to prevent corrosion.

Installation of the base part of the device is carried out inside the house, next to the outlet. As a rule, in the case there is a nest for a nail or self.tapping screw. the device is simply hung on any suitable fasteners.